Table of Contents

Market Insight: Flat Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for flat copper strip in transformer manufacturing remains strategically significant despite aluminum’s dominance in distribution transformers. Copper strip is essential for high-efficiency power transformers, traction transformers in rail systems, and specialized industrial units where maximum electrical conductivity and thermal stability are non-negotiable. Stringent energy efficiency regulations (e.g., DOE 2016, EU Ecodesign) drive adoption in premium segments, as copper’s 100% IACS minimum conductivity reduces resistive losses by 30–40% compared to aluminum equivalents. This translates to lower lifecycle operating costs for utilities and industrial users, particularly in high-load or continuous-operation scenarios. Current market dynamics reflect rising demand from renewable energy integration projects and grid modernization initiatives, where copper’s reliability in high-voltage applications supports infrastructure resilience. However, copper faces persistent cost and weight pressures, limiting its use to applications where performance justifies the premium.

Quality parameters for flat copper strip are critical determinants of transformer performance and longevity. Substandard material directly compromises core efficiency and safety. Electrical conductivity must consistently meet or exceed 100% IACS (International Annealed Copper Standard), verified through rigorous batch testing per ASTM B193. Deviations as small as 0.5% IACS increase resistive losses exponentially, accelerating thermal aging of insulation systems. Surface integrity is equally vital; microscopic scratches or oxide inclusions disrupt enamel adhesion during winding, creating partial discharge sites that initiate insulation breakdown. Dimensional precision—particularly thickness tolerance (±0.02 mm) and edge straightness—ensures uniform magnetic flux distribution. Poorly controlled strip causes localized eddy current hotspots, reducing transformer lifespan by up to 25%. Metallurgical homogeneity, achieved through controlled annealing and grain structure management, prevents mechanical stress during coil winding and thermal cycling.

Supply chain risks further underscore quality imperatives. Impurities from recycled copper feedstocks (e.g., phosphorus, sulfur) can degrade conductivity if refining protocols are inadequate. Seasonal volatility in copper LME prices necessitates long-term supplier partnerships with transparent traceability from cathode to strip. As experienced suppliers understand, transformer manufacturers increasingly mandate full material test reports (MTRs) covering chemical composition, tensile strength, and bend-test results to mitigate field failure liabilities. A single batch rejection due to inconsistent temper can halt production lines, incurring costs exceeding $200,000 per incident. Consequently, sourcing decisions prioritize certified mills with ISO 9001 and IATF 16949 accreditation, robust QC infrastructure, and proven metallurgical expertise—not merely spot-market pricing. For mission-critical applications, the total cost of ownership model consistently validates investment in premium-grade copper strip, where quality deviations risk catastrophic failure in grid infrastructure.

| Critical Quality Parameter | Industry Standard | Consequence of Non-Compliance |

|---|---|---|

| Electrical Conductivity | ≥100% IACS (ASTM B193) | Increased no-load losses; reduced efficiency rating |

| Thickness Tolerance | ±0.02 mm | Flux imbalance; localized overheating |

| Surface Roughness (Ra) | ≤0.4 μm | Insulation delamination; partial discharge |

| Edge Camber | ≤0.5 mm/m | Winding misalignment; mechanical stress |

Technical Specs: Flat Copper Strip

Technical Specifications: Flat Copper Strip

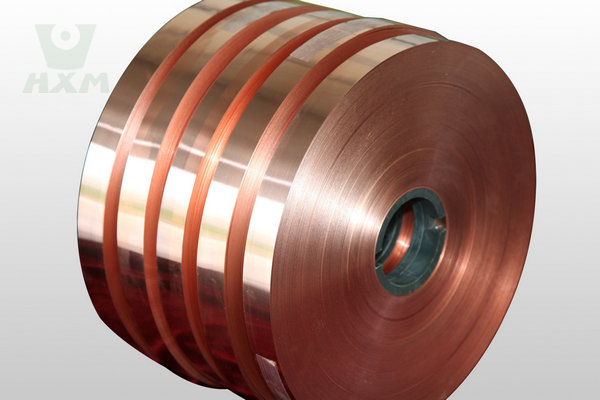

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures precision flat copper strip for high-performance applications in power transformers, electrical connectors, busbars, and industrial electronics. With over two decades of metallurgical expertise, our production processes are engineered to meet stringent international standards, ensuring dimensional accuracy, optimal electrical performance, and superior surface integrity. The following technical parameters define our flat copper strip product line, tailored for mission-critical electrical systems requiring reliability and consistency.

Flat copper strip supplied by Xinzhaohe is produced from high-purity electrolytic tough pitch (ETP) copper, meeting ASTM B187 and GB/T 5584 standards. The base material guarantees a minimum conductivity of 100% IACS (International Annealed Copper Standard), with typical batch averages ranging between 100.5% and 101% IACS. This ensures minimal resistive losses and high thermal efficiency in transformer windings and conductive components. The strip is fully annealed to achieve a soft temper (C11000-O), providing excellent formability and low mechanical stress during coiling and winding operations.

Precision slitting is a core competency in our manufacturing process. All flat copper strips are slit to customer-defined widths with a dimensional tolerance of ±0.002 mm, maintained across full coil lengths up to 1,500 meters. This tight tolerance is achieved through computer-controlled rotary shear slitting systems equipped with laser-based edge detection and real-time feedback loops. Consistent width control is critical for automated winding equipment and ensures uniform magnetic performance in transformer cores.

Edge quality is rigorously controlled to eliminate burrs, micro-tears, or edge翘边 (edge翘边 refers to edge翘曲 or edge lifting). Burr height is maintained below 2% of material thickness, verified through optical profilometry and cross-sectional metallography. Burr-free edges reduce the risk of dielectric breakdown in transformer windings and prevent damage to insulating films during layer stacking.

Surface finish is smooth and oxide-controlled, with a typical roughness average (Ra) of 0.4–0.8 µm. The strip is cleaned post-annealing using inline electrolytic cleaning and dried under inert atmosphere to minimize surface oxidation. Each coil is wound under constant tension with interlayer paper to prevent scratching and coil collapse.

| Parameter | Specification |

|---|---|

| Material Grade | C11000 (ETP Copper), ASTM B187 / GB/T 5584 |

| Temper | O (Annealed) |

| Thickness Range | 0.10 mm – 3.00 mm |

| Width Range | 5.00 mm – 100.00 mm |

| Width Tolerance | ±0.002 mm |

| Thickness Tolerance | ±0.005 mm (for 0.1–0.5 mm); ±0.01 mm (>0.5 mm) |

| Conductivity | ≥100% IACS (Typical: 100.5–101% IACS) |

| Edge Burr | <2% of thickness |

| Surface Roughness (Ra) | 0.4 – 0.8 µm |

| Coil Inner Diameter | 200 mm, 300 mm, 500 mm (customizable) |

| Max Coil Outer Diameter | 1,200 mm |

| Packaging | Vacuum-sealed with desiccant, wooden reel |

All flat copper strip shipments are accompanied by material test reports (MTRs) including conductivity verification, chemical composition (ICP-MS analyzed), and dimensional inspection data. Custom slit widths, special tempers, and oxygen-free copper (C10100) options are available upon request.

Factory Tour: Manufacturing

Manufacturing Process for Flat Copper Strip: Precision Engineering for Transformer Applications

Luoyang Xinzhaohe Aluminum CO.,LTD leverages two decades of metallurgical expertise to produce high-purity flat copper strip for critical transformer and electrical applications. Our integrated manufacturing process ensures dimensional precision, surface integrity, and mechanical consistency, adhering strictly to international standards including ASTM B117 and IEC 60137. The core sequence comprises cold rolling, precision slitting, and edge conditioning, each stage incorporating rigorous quality control protocols.

Cold rolling initiates the process, transforming annealed copper ingot strips into precise gauges. Input material undergoes thorough cleaning to eliminate surface contaminants prior to entry into our 4-high reversing cold mills. Controlled reduction ratios (typically 70–90% cumulative) are applied under precise tension management to prevent edge waviness or center buckling. Critical parameters include roll gap calibration (±2μm tolerance), interstand tension control (±0.5%), and emulsion cooling systems maintaining strip temperature below 40°C to avoid thermal distortion. This stage achieves target thicknesses ranging from 0.05mm to 3.0mm with flatness deviations under 5 I-Units. Surface roughness is meticulously monitored via non-contact profilometry, ensuring Ra values remain within 0.2–0.8μm to optimize winding performance and interlayer adhesion in transformer cores.

Precision slitting follows, converting master coils into customer-specified widths. Strips are processed through servo-driven slitting lines equipped with tungsten carbide rotary knives and automatic knife positioning systems. Width tolerances are maintained at ±0.05mm for strips below 50mm width and ±0.1mm for wider formats. Tension control throughout the line prevents coil telescoping, while edge guiding systems ensure straightness deviations stay below 0.3mm per meter. Critical to this phase is real-time monitoring via laser micrometers sampling dimensions at 1,000Hz, with automated feedback loops adjusting knife positions to counteract thermal drift.

Edge conditioning is executed to eliminate micro-burrs and stress concentrations that could compromise insulation integrity in transformer windings. Strips pass through precision edge rounding stations utilizing abrasive belts or wire brushes calibrated to achieve consistent edge radii of 10–50μm, verified through optical edge inspection systems. This step prevents dielectric breakdown during coil winding and operation, a non-negotiable requirement for high-voltage applications.

Quality control is embedded at every process stage. In-line systems include continuous surface defect detection (employing high-resolution cameras scanning at 20m/min), eddy current testing for subsurface flaws, and automated thickness mapping. Post-production, destructive testing validates mechanical properties: tensile strength (220–250 MPa), elongation (>4%), and electrical conductivity (>100% IACS per ASTM E8). Dimensional certification reports detail thickness profiles, edge radius measurements, and flatness data for each production lot. Final inspection includes ASTM B117 salt spray testing for corrosion resistance and microscopic edge analysis to confirm burr-free profiles. This closed-loop quality framework ensures every coil meets the exacting demands of transformer manufacturers, where material consistency directly impacts operational safety and efficiency.

Packaging & Logistics

Export Packaging Standards for Flat Copper Strip – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global supply of transformer-grade flat copper and aluminum strip, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity throughout international transit. Our export packaging protocols are engineered to meet the rigorous demands of sea freight, where prolonged exposure to humidity, temperature fluctuations, and mechanical stress can compromise product quality if not properly mitigated.

All flat copper strip shipments destined for overseas markets are systematically secured on high-load-bearing wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. This certification ensures that all wooden components have undergone heat treatment to eliminate biological contaminants, meeting international phytosanitary standards for cross-border transport. The structural design of the pallets supports uniform weight distribution and facilitates secure stacking, minimizing the risk of deformation during containerized shipping.

Each coil or stack of flat copper strip is meticulously arranged on the pallet with alignment that prevents edge damage and maintains dimensional stability. To counteract the high-humidity environments typical of maritime transport, we apply a multi-layer moisture-proof barrier system. This includes a primary wrap of industrial-grade polyethylene vapor barrier film, sealed with heat-welded seams to create an airtight enclosure. An additional outer layer of UV-resistant, puncture-proof wrapping film provides mechanical protection against abrasion and incidental impact during handling.

Between the copper material and the inner film, desiccant packs are strategically placed to absorb residual moisture and mitigate the potential for oxidation or surface tarnishing. The entire wrapped unit is then strapped to the pallet using high-tensile steel or composite polyester straps, tensioned to industry specifications to prevent shifting during vessel movement. All strapping points are reinforced with edge protectors to avoid damage to both the packaging and the metal product.

Our packaging methodology is validated through internal quality audits and real-world performance tracking across major global trade lanes, including trans-Pacific and trans-Indian Ocean routes. This data-driven approach allows us to continuously refine our procedures in alignment with evolving carrier requirements and environmental exposure profiles.

For B2B partners sourcing flat copper strip for use in transformers, electrical systems, and precision conductive applications, the assurance of receiving material in as-produced condition is paramount. Our export packaging system is designed not only to comply with international freight standards but to exceed them, ensuring that every shipment arrives with the surface finish, mechanical properties, and dimensional accuracy required for downstream processing. This commitment to packaging excellence reflects our broader philosophy: that quality extends beyond the mill to every phase of the supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Copper Strip Manufacturing for Critical Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and industrial engineering expertise to deliver flat copper strip meeting the stringent demands of modern transformer and electrical component manufacturing. Our vertically integrated production ecosystem, purpose-built for high-performance conductive materials, ensures consistent quality, technical reliability, and supply chain resilience for global B2B partners. We transcend standard metal supply by embedding deep process control within every production phase, from raw material selection to final shipment.

Our core strength resides in advanced metallurgical process engineering. We maintain rigorous control over copper alloy composition, microstructure development, and mechanical properties through proprietary melting, casting, and continuous rolling protocols. This enables precise tailoring of electrical conductivity (exceeding 98% IACS), tensile strength (200-350 MPa range), and elongation characteristics to match specific transformer design requirements. Critical to high-frequency applications, our cold rolling and annealing lines achieve exceptional dimensional stability with thickness tolerances held to ±0.005 mm across widths up to 600 mm. The table below summarizes key production capabilities relevant to transformer strip sourcing.

| Parameter | Capability Range | Precision Control |

|---|---|---|

| Thickness | 0.05 mm – 3.0 mm | ±0.005 mm (critical zones) |

| Width | 50 mm – 600 mm | ±0.1 mm |

| Conductivity | ≥ 98% IACS | Batch variation < 0.5% |

| Surface Roughness | Ra 0.1 µm – 0.8 µm | Optimized for lamination |

| Annual Capacity | 20,000 Metric Tons | Dedicated copper lines |

Quality assurance is non-negotiable. Every coil undergoes 100% inline eddy current testing for subsurface defects alongside rigorous laboratory validation of chemical composition, mechanical properties, and surface integrity per ASTM B117, GB/T 5584, and custom client specifications. Our ISO 9001 and IATF 16949 certified systems integrate statistical process control (SPC) at critical control points, ensuring batch-to-batch repeatability essential for automated transformer winding operations. Traceability from cathode to finished coil is maintained via our integrated MES platform, providing full material history for audit compliance.

Supply chain execution is engineered for predictability. Strategic partnerships with primary copper refiners guarantee access to high-purity feedstock (99.99% Cu min), mitigating raw material volatility. Our dual-production facility in Luoyang operates redundant rolling mills with dedicated copper processing lines, enabling flexible scheduling for urgent requirements while maintaining standard lead times of 15-25 days. We manage global logistics through certified freight forwarders, offering EXW, FOB, and DDP solutions with comprehensive export documentation support.

For transformer manufacturers requiring copper strip where dimensional precision, surface perfection, and material consistency directly impact core loss and efficiency metrics, Luoyang Xinzhaohe provides a technically validated partnership. We collaborate with engineering teams to resolve material-specific challenges in lamination, winding, and thermal management. Contact Cathy Zhang, Technical Sourcing Manager, directly at cathy@transformerstrip.com to discuss your project specifications, request certified test reports, or schedule a virtual factory audit. Initiate a supply chain solution engineered for transformer excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing flat copper strip directly from China.