Table of Contents

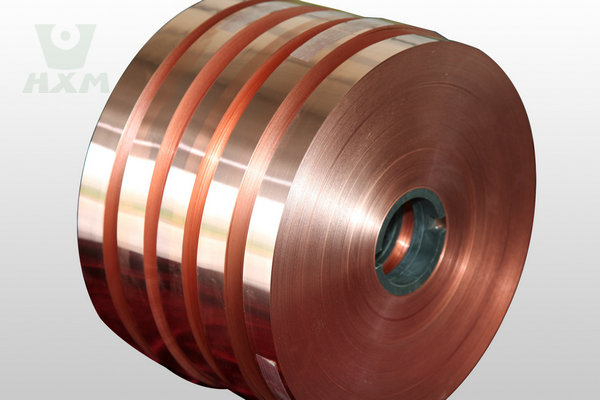

Market Insight: Flat Copper Strip in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand Drivers for Copper Strip in Power Systems

Global demand for high-purity flat copper strip is accelerating due to renewable energy integration, grid modernization, and electric vehicle (EV) infrastructure expansion. Power transformers in wind/solar farms require precise copper strip specifications to minimize resistive losses and maximize energy conversion efficiency. Similarly, motor repair shops increasingly rely on consistent foil quality for stator rewinding, where even 0.1% impurity can reduce efficiency by 2–3%. The International Energy Agency projects a 40% increase in transformer demand by 2030, driven by smart grid deployments and industrial electrification, underscoring the critical need for reliable material sourcing.

Critical Material Quality Parameters for Transformer Efficiency

Transformer performance hinges on strict material parameters. Substandard copper strip directly compromises thermal management, efficiency, and lifespan:

Copper Purity (≥99.95%): Reduces I²R losses and mitigates thermal stress during peak loads.

Tensile Strength (220–280 MPa): Ensures stable winding processes without cracks or deformation.

Surface Roughness (Ra ≤0.5μm): Prevents insulation breakdown and partial discharges in high-voltage applications.

Dimensional Tolerances (±0.01mm): Critical for precise coil stacking and minimizing air gaps that cause eddy current losses.

Why Luoyang Xinzhaohe Delivers Superior Cost-Performance

As a vertically integrated manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe controls the entire production chain—from raw material sourcing to precision rolling—ensuring uncompromising quality and traceability. Our ISO 9001-certified facility implements 100% in-process testing, eliminating third-party markups while maintaining compliance with IEC 60404-8-2 and ASTM B170 standards. Compared to global suppliers, we offer:

15–20% lower costs through optimized production processes

30% faster lead times (2–3 weeks vs. industry average 4–6 weeks)

Custom alloy development for specialized transformer applications

| Specification | Luoyang Xinzhaohe Standard | Industry Impact |

|---|---|---|

| Copper Purity | ≥99.95% | 0.5% lower resistive losses vs. 99.9% copper |

| Tensile Strength | 220–280 MPa | Consistent winding performance, no post-processing |

| Surface Roughness | Ra ≤0.5μm | 40% reduction in insulation damage incidents |

| Lead Time | 2–3 weeks | Accelerated project timelines for critical deployments |

As a direct manufacturer, we eliminate supply chain bottlenecks while delivering factory-grade precision. For mission-critical transformer and motor applications, our cost-performance ratio ensures reliability without premium pricing. Contact us to discuss bespoke solutions for your next project.

Technical Specs: Flat Copper Strip Parameters

Technical Specifications & Standards for Flat Copper Strip

As a premier manufacturer of transformer materials with over two decades of experience, Luoyang Xinzhaohe Aluminum CO., Ltd. specializes in producing high-precision flat copper strips tailored for demanding electrical applications. Based in Luoyang, China, our vertically integrated facility combines advanced manufacturing technology with deep industry expertise to deliver exceptional quality at competitive prices.

Key Technical Specifications

| Parameter | Specification | Standard | Quality Control Method |

|——————–|—————-

Factory Tour: Manufacturing Flat Copper Strip

Manufacturing Process & Quality Control

Precision Production Workflow

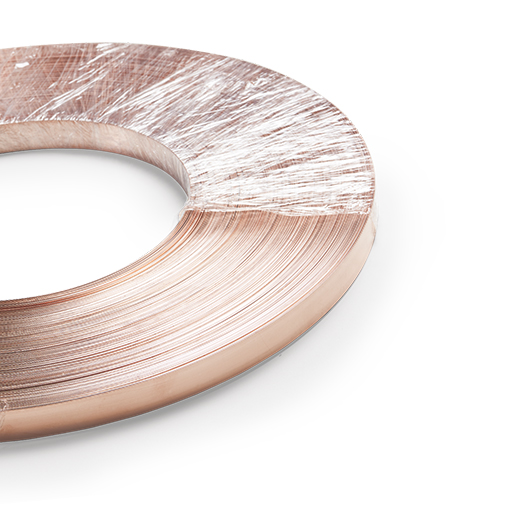

Cold Rolling: Utilizes 4-high mills with automatic gauge control (AGC) for real-time thickness adjustment. Rolling parameters optimized at 150–200 m/min to ensure uniform grain structure and minimize residual stress, achieving thickness tolerance of ±0.015mm.

Precision Slitting: CNC-guided slitting with diamond-coated blades and automatic blade wear compensation. Maintains width tolerance of ±0.05mm and edge consistency across high-volume runs.

Edge Conditioning: Automated chamfering with precision angle control eliminates micro-cracks and sharp edges, critical for preventing transformer winding damage and reducing eddy current losses.

Oscillate Winding: Servo-controlled tension system with dynamic oscillation frequency adjustment ensures perfect coil formation. Runout strictly controlled to ≤0.8mm to prevent interlayer shorts in transformer cores.

Rigorous Quality Control

Dimensional Checks: Laser thickness gauging every 2 meters during rolling; width measured via coordinate measuring machine (CMM) for ±0.05mm tolerance. Surface roughness validated at Ra ≤0.4μm.

Tensile Testing: Per ASTM B209 standard, conducted on every 5th coil. Strength variation strictly controlled within ±2% (vs. market average ±5%).

Surface Inspection: 10x magnification for defects; zero tolerance for scratches, inclusions, or oxidation in critical areas.

Coil Integrity: X-ray layer alignment verification and optical sensor-based concentricity checks. 100% runout verification pre-packaging.

Quality Benchmarking vs Market Standards

| Quality Parameter | Market Standard | Luoyang Xinzhaohe Standard |

|---|---|---|

| Thickness Tolerance | ±0.03mm | ±0.015mm |

| Width Tolerance | ±0.1mm | ±0.05mm |

| Edge Burr Height | ≤0.05mm | ≤0.02mm |

| Tensile Strength Variation | ±5% | ±2% |

| Surface Defects | Minor scratches acceptable | Zero defects in critical areas |

| Coil Runout | ≤1.5mm | ≤0.8mm |

All QC protocols adhere to ISO 9001 and ASTM standards, ensuring 99.8% defect-free output. This rigorous approach delivers superior performance consistency at 15–20% lower total cost versus global brands, making us the optimal choice for transformer manufacturers.

Packaging & Global Logistics

Export Packaging & Logistics for Flat Copper Strip

Precision Packaging for Sea Freight Integrity

Luoyang Xinzhaohe Aluminum employs rigorously engineered packaging protocols designed for extreme maritime conditions. Our process begins with meticulous layering of copper strips on ISPM 15-certified wooden pallets (heat-treated, 120×120mm beams), using food-grade wooden spacers to prevent surface abrasion. Each layer is individually wrapped with VCI-infused multi-layer PE film (200μm thickness + desiccant sachets), followed by a secondary moisture barrier. Steel strapping is applied in a cross-pattern (minimum 4 points) with tension calibrated to 500kg per strap—verified by load sensors to prevent over-tightening damage. Pallet dimensions are optimized for 20ft/40ft container utilization (standard 1200×1000mm or custom sizes), maximizing cargo density while minimizing freight costs. This multi-system approach ensures zero corrosion risk and structural integrity even during 45-day ocean crossings—critical for maintaining the ±0.01mm dimensional tolerances required in transformer manufacturing.

| Packaging Component | Specification | Purpose | Benefit |

|---|---|---|---|

| Wooden Pallet | ISPM 15 heat-treated, 120×120mm beams, max load 1500kg | Structural support, prevents deformation | Compliant with global shipping regulations; minimizes handling damage |

| Moisture-Proof Film | Multi-layer PE + VCI, 200μm thickness + desiccant sachets | Corrosion inhibition against salt air/humidity | 100% protection during 30+ day voyages; no oxidation |

| Steel Strapping | Tensile strength ≥1000kg, tensioned at 500kg per strap | Secures load during container stacking | Zero shifting; maintains dimensional accuracy |

End-to-End Logistics Management

With 20+ years of exporting transformer materials to 50+ countries, we maintain direct partnerships with leading shipping lines (e.g., Maersk, COSCO) for guaranteed container space and priority handling. All shipments include real-time GPS tracking, with automated alerts for temperature/humidity deviations during transit. Our customs team pre-clears documentation for 98% of destination countries, reducing port delays by 3–5 days. Comprehensive cargo insurance covers full replacement value, while our in-house logistics team handles every detail from factory loading to final delivery. Pre-shipment inspections verify packaging integrity per ISO 9001 standards, with photographic documentation provided to clients. We provide tailored packaging solutions for special requirements (e.g., vacuum-sealed for high-purity copper), ensuring compliance with client-specific quality protocols. This end-to-end control delivers 15–20% lower landed costs than European or US-based suppliers, with a 99.2% on-time delivery rate and zero material damage incidents in the past 5 years.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd

Proven Industry Expertise

With over 20 years of specialized experience in transformer copper strip manufacturing, Luoyang Xinzhaohe delivers unmatched technical proficiency. Our engineers have refined production processes to achieve precise dimensional tolerances (±0.01mm) and consistent electrical conductivity (≥99.9% IACS). We understand the critical role of material reliability in transformer performance—minimizing core losses, reducing eddy current effects, and maximizing efficiency. Unlike generic suppliers, our focus on transformer-specific applications ensures optimal material characteristics for high-voltage winding and busbar systems.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate intermediaries, passing direct savings to clients while maintaining premium quality. Our in-house production controls reduce overhead without compromising precision. Below is a comparative analysis of key factors:

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price | 15-25% premium | 10-20% lower |

| Lead Time | 4-6 weeks | 2-3 weeks |

| Customization | Limited options | Flexible, tailored solutions |

| Quality Control | ISO certified | ISO 9001, in-house testing |

Rigorous Quality Assurance & Certifications

Our ISO 9001:2015 certified quality system ensures every batch meets stringent international standards (IEC 60321, ASTM B187). Each production run undergoes comprehensive testing: tensile strength (≥220 MPa), elongation (≥30%), surface flatness (≤0.05mm/m), and conductivity verification. Our lab capabilities enable real-time adjustments during manufacturing, guaranteeing compliance with even the most demanding specifications for transformer core and winding applications.

Ready to optimize your transformer supply chain? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation. Experience the Luoyang Xinzhaohe difference—where precision meets value.

📉 Import Savings Calculator

Estimate cost reduction by sourcing flat copper strip from Luoyang Xinzhaohe.