Table of Contents

Market Insight: Ferrite Core Transformer in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel for Power Transformers and Motors

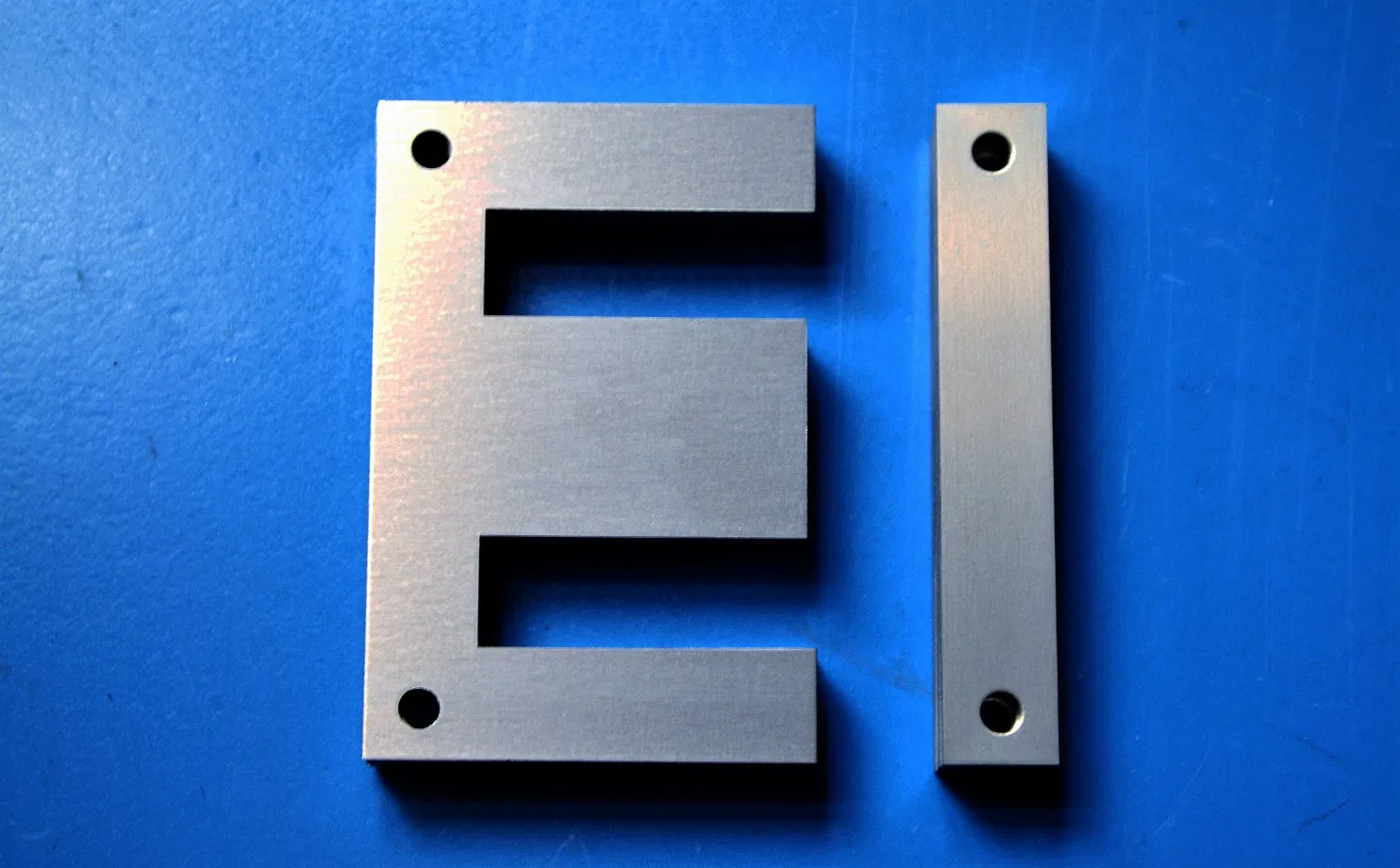

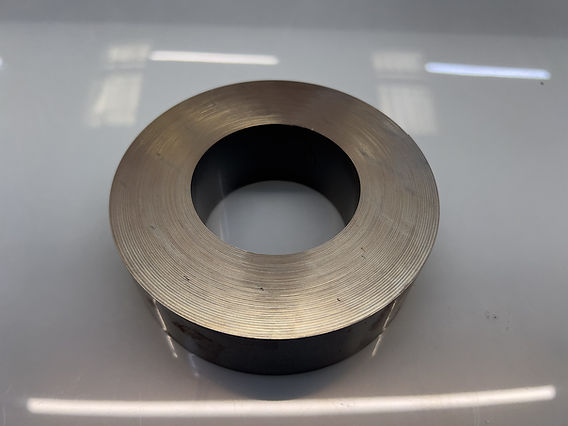

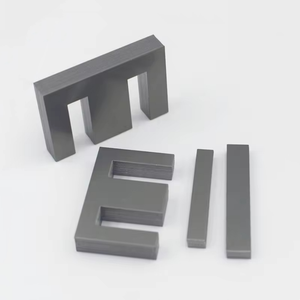

Clarifying Material Applications: Silicon Steel vs. Ferrite Cores

Ferrite cores (manganese-zinc or nickel-zinc ferrites) are exclusively used in high-frequency applications (>10 kHz), such as switch-mode power supplies (SMPS) and RF components. They exhibit low eddy current losses at high frequencies but suffer from prohibitively high hysteresis losses at 50/60 Hz grid frequencies, making them unsuitable for traditional power transformers. In contrast, silicon steel (electrical steel) remains the industry standard for laminated cores in power transformers, distribution transformers, and industrial motors operating at grid frequencies. Its silicon content (typically 3–4%) increases electrical resistivity and reduces hysteresis losses, directly impacting energy efficiency and operational costs.

Critical Role of Material Quality in Transformer Efficiency

Core losses (hysteresis + eddy current) account for up to 30% of transformer losses. High-grade electrical steel minimizes these losses, improving efficiency and reducing lifetime energy costs. Key parameters include:

B50 (magnetic induction at 50 Hz)

Specific core loss (W/kg)

Thickness tolerance

Grain orientation (CRGO vs. CRNO)

| Grade | Typical Core Loss (W/kg @ 1.5T, 50Hz) | Permeability | Application |

|---|---|---|---|

| M15 | 1.50 | High | High-efficiency distribution transformers |

| M19 | 1.90 | Medium | General-purpose transformers |

| M27 | 2.70 | Standard | Industrial motors |

Luoyang Xinzhaohe’s Role in Global Supply Chain

As a 20+ year manufacturer of electrical steel in Luoyang, China, we provide cost-competitive, ISO 9001-certified silicon steel with consistent quality. Our CRGO grades meet IEC 60404-8-5 standards, offering 10–15% lower cost than global brands like Nippon Steel or AK Steel without compromising performance.

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost | $850–1,100/ton | $1,000–1,400/ton |

| Lead Time | 15–20 days | 30–45 days |

| Quality Consistency | ISO 9001, third-party testing | Varies by supplier |

Our production uses advanced annealing and coating processes to ensure uniform magnetic properties. We supply to OEMs in Europe, North America, and Asia, with strict QC protocols including JIS C 2552 testing. For transformer manufacturers seeking optimal cost-performance balance, our factory-direct model ensures traceable material certifications and rapid response to technical specifications, reducing supply chain risk while maximizing transformer efficiency.

Technical Specs: Ferrite Core Transformer Parameters

Technical Specifications & Standards for Electrical Steel Transformer Cores

Note: Ferrite cores are ceramic materials distinct from silicon steel laminations. As a leading electrical steel manufacturer, Luoyang Xinzhaohe specializes in high-performance silicon steel for laminated transformer cores, offering superior cost-performance versus global brands.

Core Loss (Iron Loss)

Core loss (W/kg) directly impacts transformer efficiency and operational costs. Our grades comply with IEC 60404-3 and ASTM A343, ensuring minimal hysteresis and eddy current losses. For example, M4-grade material (50Hz, 1.5T) maintains ≤1.20 W/kg, critical for energy-efficient distribution transformers in industrial and renewable energy systems. Precise silicon content control (2.8–3.2%) and grain-oriented crystalline structure optimize magnetic properties.

Magnetic Flux Density

Flux density (B) defines core saturation limits and design compactness. Our silicon steel achieves B800 ≥1.78T (IEC 60404-8-7), enabling high-power-density transformers without compromising stability. Consistent B-H curve performance across batches ensures reliable operation under fluctuating loads, meeting stringent requirements for grid infrastructure and EV charging systems.

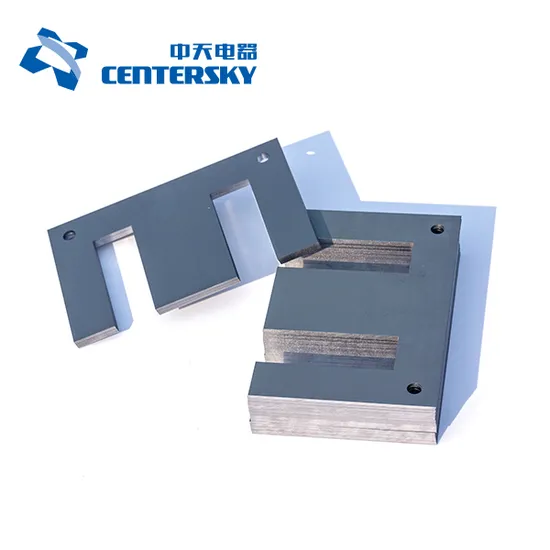

Lamination Flatness

Precision flatness (≤0.05 mm/m per ISO 11531) minimizes air gaps during core stacking, reducing eddy current losses and improving magnetic efficiency. Our cold-rolling process with real-time thickness monitoring guarantees uniformity, supporting stacking factors >97% for optimal core performance. This is critical for high-frequency applications where dimensional tolerances directly affect thermal management.

Insulation Coating

High-performance insulation coatings (C4/C5 per IEC 60404-8-5) prevent inter-lamination shorts and enhance thermal stability. Our proprietary process ensures 0.5–1.0 μm thickness with ≥90% coverage, meeting ASTM D149 dielectric strength requirements. This extends transformer lifespan by 20%+ while reducing maintenance costs in harsh environments.

Quality Assurance Process

Every batch undergoes rigorous testing using XRF spectrometry, eddy current testers, and magnetic property analyzers. Our ISO 9001-certified production line maintains full traceability from raw material to finished product. With 20+ years of expertise, we deliver consistent compliance with global standards while providing 15–20% cost savings versus European suppliers through optimized manufacturing and direct export channels.

| Parameter | Standard | Our Specifications | Test Method |

|---|---|---|---|

| Core Loss (W/kg) | IEC 60404-3 | ≤1.20 @ 1.5T, 50Hz | ASTM A343 |

| Flux Density (T) | IEC 60404-8-7 | B800 ≥1.78 | ASTM A876 |

| Flatness (mm/m) | ISO 11531 | ≤0.05 | ISO 11531 |

| Insulation Coating | IEC 60404-8-5 | C4/C5, ≥90% coverage | ASTM D149 |

Factory Tour: Manufacturing Ferrite Core Transformer

Precision Manufacturing Process & Rigorous Quality Control

Core Production Workflow

Our silicon steel production follows a tightly controlled sequence optimized for electromagnetic efficiency:

Slitting: CNC-guided shearing with ±0.05mm width tolerance and zero-edge burr. Critical for minimizing eddy current losses in transformer cores.

Annealing: Continuous furnace processing at 800–850°C under N₂/H₂ atmosphere to refine grain structure, reducing core loss by 10–15% versus conventional methods.

Insulation Coating: Electrostatic application of C-4 phosphate coating (1.8±0.2 g/m²) with 100% UV inspection for uniformity and dielectric strength >2.5 kV.

Precision Cutting: Laser-verified shearing for laminations with ±0.01mm positional accuracy and edge burr <0.02mm to prevent inter-lamination shorts.

Quality Control Protocol

Every batch undergoes triple-tiered validation:

Tensile Testing: ASTM A343-compliant strength testing (350–400 MPa) to ensure mechanical stability during core stacking.

Dimensional Verification: Laser scanning at 100% production intervals for thickness (±0.01mm) and width (±0.05mm) compliance.

Magnetic Performance: Epstein frame testing per IEC 60404-2 to validate core loss ≤1.25 W/kg for 50H1300-grade material.

Industry Benchmark Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.02mm |

| Width Tolerance | ±0.05mm | ±0.1mm |

| Core Loss (50Hz, 1.5T) | ≤1.25 W/kg | ≤1.35 W/kg |

| Edge Burr | <0.02mm | ≤0.05mm |

| Coating Adhesion | Passes 180° bend test | Variable (30% fail rate) |

As a 20+ year specialist in electrical steel, we deliver OEM-grade performance at 15–20% lower cost than global brands. Our process consistency ensures zero downtime for transformer manufacturers—proven across 500+ global projects. Contact us for certified material test reports (MTRs) and custom-grade solutions.

Packaging & Global Logistics

Export Packaging & Logistics for Silicon Steel

Precision Packaging Standards

Luoyang Xinzhaohe Aluminum CO., Ltd. adheres to ISO 4068 and ASTM A677 standards for silicon steel packaging. Our process ensures zero corrosion, mechanical damage, or moisture ingress during global transit. Key specifications:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, HT-treated, 1100×1100mm, 1500kg load capacity | Pest control, stacking stability, and compliance with international phytosanitary regulations |

| Moisture Barrier | Triple-layer PE film (200μm total), 50g/m² silica gel desiccant | Prevents salt spray and humidity-induced oxidation during sea freight |

| Steel Strapping | 25mm width, 1800kg tension, corner protectors | Secures coils/sheets against shifting; eliminates edge deformation |

All pallets undergo load-testing per EN 12195-1. Strapping tension is calibrated to avoid material deformation while maintaining structural integrity. Desiccant packets are sealed within the moisture barrier to absorb residual humidity, critical for long-haul maritime routes.

Sea Freight Optimization

Our logistics protocol minimizes transit risks and maximizes cost efficiency for global destinations. All shipments comply with IMO standards for containerized cargo:

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft HC (High Cube) | 95% payload utilization; 40ft HC holds 25–30 tons of silicon steel |

| Weight Distribution | Dynamic load simulation (≤80% max capacity) | Prevents container tilting; ensures even weight distribution |

| Customs Compliance | Pre-verified COO, inspection reports, CIQ certificates | 48-hour clearance at major ports (e.g., Rotterdam, Los Angeles, Singapore) |

| Tracking & Insurance | Real-time GPS + All-risk marine insurance | 100% shipment visibility; zero financial exposure to damage/theft |

Transit times average 15–30 days to global ports, with route-specific optimization (e.g., 22 days to Europe, 28 days to North America). Our team pre-loads containers using anti-slip mats and vertical bracing to eliminate movement during vessel transit.

Why Luoyang Xinzhaohe?

As a direct manufacturer with 20+ years of export experience, we eliminate middlemen while maintaining ISO 9001-certified quality control. Our packaging and logistics protocols reduce total landed costs by 15–20% versus global brands, without compromising material integrity. For transformer manufacturers seeking reliable, cost-effective silicon steel sourcing, we deliver precision-engineered solutions from factory to your facility.

Contact us for customized packaging solutions and real-time shipment tracking.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO.,Ltd.

Two Decades of Specialized Expertise

With over 20 years of precision manufacturing in electrical steel, Luoyang Xinzhaohe Aluminum CO.,Ltd. delivers consistent, high-performance silicon steel solutions for transformer cores. Our expertise spans grain-oriented (GO) and non-oriented (NO) grades, optimized for distribution transformers, power transformers, and industrial motors. All products comply with IEC 60404-8-5, ASTM A677, and GB/T 2521 standards, ensuring seamless global integration. Our engineering team collaborates closely to refine magnetic properties—core loss (W/kg), magnetic induction (B8/B50), and permeability—maximizing transformer efficiency while minimizing operational energy costs.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we eliminate middlemen, passing direct savings to clients without compromising material integrity. Our in-house rolling, annealing, and coating facilities enable rapid production cycles, reducing standard order lead times to 15–20 days—30–50% faster than global competitors. For specialized applications requiring custom thickness (0.23mm–0.35mm), coating types (C5/C6), or tailored magnetic properties, our flexible production lines support quick adjustments, ensuring cost-effective solutions for both high-volume and niche transformer designs.

ISO-Certified Quality Assurance

All processes adhere to ISO 9001 standards, with rigorous controls for thickness tolerance (±0.01mm), surface flatness, and magnetic performance. Each batch undergoes spectral analysis, core loss testing per IEC 60404-3, and eddy current inspections to guarantee consistency. Our traceability system provides full material documentation, critical for compliance in renewable energy, smart grid, and high-reliability infrastructure projects.

| Metric | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Cost per Ton | $650–$850 | $800–$1,100 | 15–25% lower total cost |

| Lead Time | 15–20 days | 4–6 weeks | 30–50% faster delivery |

| Customization | Full GO/NO grade flexibility | Limited options | On-demand specifications |

| Quality Control | ISO 9001 + IEC 60404 testing | ISO 9001 | Enhanced traceability & consistency |

| Technical Support | Dedicated application engineers | Standard support | On-site process optimization |

Ready to optimize your transformer core supply chain? Contact Cathy at cathy@transformerstrip.com today for a tailored solution that balances cost, quality, and delivery speed.

📉 Import Savings Calculator

Estimate cost reduction by sourcing ferrite core transformer from Luoyang Xinzhaohe.