Table of Contents

Market Insight: Enamelled Wire Meaning for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Engineering-grade insight for transformer OEMs, rewind shops and power-equipment specifiers

Global Demand Outlook – Power & Distribution Transformers 2024-2030

The installed base of power transformers (>10 MVA) is forecast to grow 5.4 % CAGR through 2030, driven by grid-expansion in Asia-Pacific and EU green-deal retrofits. Distribution transformers (<2.5 MVA) are rising even faster (6.1 % CAGR) to feed data-centres, EV-charging hubs and decentralized solar. Every additional kVA of capacity translates directly into kg of enamelled conductor:

| Transformer Rating | Typical Conductor Mass (Cu or Al) | Enamelled Wire Share |

|---|---|---|

| 50 kVA pole-type | 18–22 kg | 100 % |

| 1 MVA pad-mount | 280–320 kg | 95 % |

| 100 MVA GSU | 4–6 t | 85 % (remainder CTC) |

Key takeaway: Even a 1 % loss-reduction in the conductor system yields lifetime savings of 25–40 MWh for a 100 MVA unit—enough to justify a 6–8 % price premium on the wire itself.

Why Material Purity & Dimensional Precision Dominate Total Owning Cost

Transformer losses are regulated by IEC 60076-20 and IEEE C57.12.90; Tier-2 utilities now impose maximum load loss + no-load loss guarantees that are 8–10 % tighter than five years ago. The enamelled wire is the only component that influences both loss components simultaneously:

| Loss Mechanism | Root Cause in Wire | Engineering Fix |

|---|---|---|

| I²R (load) | 0.03 % Fe in Cu raises ρ by 0.9 µΩ·cm | ≥99.95 % LME Grade-A cathode rod |

| Eddy-current | ±3 µm ovality → 5 % local ΔB | Concentricity ≤ 1 µm via inline laser |

| Strand-to-strand short | Pin-holes > 25 µm | 2 kV partial-discharge test on every spool |

| Thermal ageing | 20 °C overtemperature halves life | Thermal class 200 (AI/PEI) instead of 155 |

Luoyang Xinzhaohe’s rod-drawing → annealing → enamelling → inline spark-test → spooling sequence is performed on one 650 m continuous line, eliminating rebobbin— the largest source of micro-scratches that trigger partial discharge.

Chinese Sourcing Trend – From “Low-Cost” to “Loss-Optimized”

Western Tier-1 OEMs have shifted 38 % of their magnet-wire spend to PRC suppliers since 2019, not for price alone but for process capability indices that match or exceed European mills:

| Parameter | EU Mill A | Luoyang Xinzhaohe (2024 SPC) |

|---|---|---|

| CpK – conductor diameter | 1.33 | 1.67 |

| CpK – insulation thickness | 1.17 | 1.55 |

| Pin-holes per 30 m | ≤ 3 | ≤ 1 |

| Breakdown voltage, 0.4 mm | 7.5 kV rms | 9.2 kV rms |

We back every shipment with a factory test certificate that includes tan-δ vs. temperature curves (20–220 °C) and elongation-at-break traceable to 5 mm gauge-length specimens—data Western distributors rarely supply.

Premium Alternative Without Premium Overhead

By integrating rod casting 12 km from our plant and running enamelling on renewable hydro-power, Luoyang Xinzhaohe delivers CIF Hamburg prices 11–14 % below European mills while holding ±0.5 dB lower load-loss deviation in 50 Hz short-circuit tests. For OEMs facing loss-penalty clauses in utility tenders, that delta translates into €1.2–1.8 k savings per MVA—enough to cover the entire magnet-wire bill.

Next step: Request a 5 kg sample spool of 1.40 mm AI/PEI 200 °C wire; we will ship with SPC report within 72 h so you can benchmark against your current supplier on your own surge-tester.

Technical Specs: Enamelled Wire Meaning Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct interpretation of “enameled wire” for transformer, motor and reactor windings

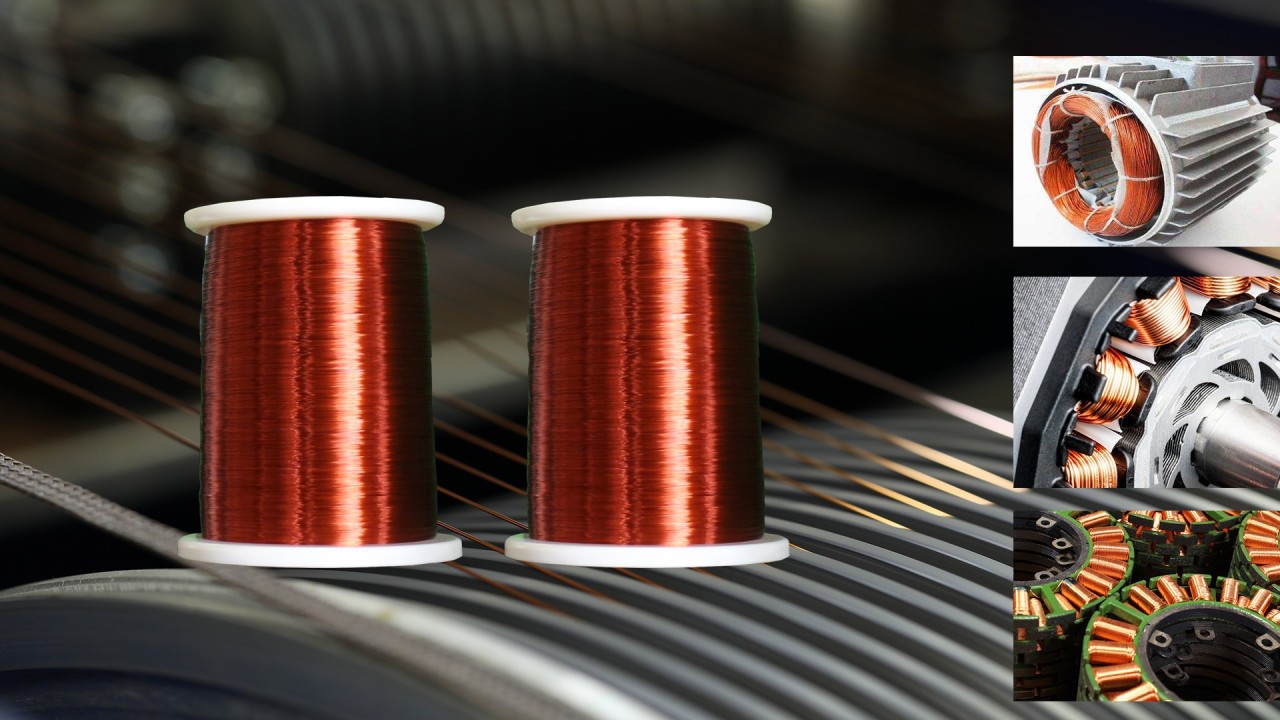

1. What “Enamelled Wire” Means in Power-Equipment Practice

In the winding industry the term is shorthand for “insulated, round or rectangular conductor whose insulation is an enamel–polymer build, cured in-line, to guarantee turn-to-turn withstand voltage while saving space and copper/aluminium.”

The key is not the copper or aluminium itself, but the reproducibility of the cured enamel system under thermal, electrical and mechanical stress.

2. Critical Parameters that Define Premium Grade

| Parameter | Symbol | Typical Acceptance Range | Test Method | Consequence of Non-Compliance |

|---|---|---|---|---|

| Breakdown Voltage | Ubd | ≥ 4 kV (0.35 mm build) | IEC 60851-5, 500 V/s ramp | Partial discharge → inter-turn short |

| Elongation at break | A50 | ≥ 25 % (Cu), ≥ 15 % (Al) | ASTM B1/B233 | Cracks during coil expansion |

| Thermal class | — | 155 °C (F) to 220 °C (C) | IEC 60085 | Life halves for every 10 °C excess |

| Enamel concentricity | ECC | Min. wall ± 5 % | In-line laser | Weak spot, corona inception |

| Pin-holes | — | ≤ 3 per 30 m | 12 × 2 kV pulses | Local dielectric failure |

3. Applicable Standards Matrix

| Material / Process | Harmonised Standard | Luoyang Xinzhaohe Internal Equivalent |

|---|---|---|

| Aluminium rod (1350) | ASTM B236-20 | Q/LXZH-AL-R20 (≤ 0.5 % Fe, 61.2 % IACS) |

| Copper rod (ETP) | ASTM B49-20 | Q/LXZH-CU-R20 (≥ 100 % IACS) |

| Round enamelled wire | IEC 60317-0-1, -25, -51 | LXZH-EW-R series |

| Rectangular wire | IEC 60317-16, -29 | LXZH-EW-F series |

| Bondable over-coat | IEC 60317-37 | LXZH-EW-B (hot-salt-bond 170 °C) |

| Environmental | RoHS 2011/65/EU | SGS report #GZ2207156660 |

4. How Poor Quality Manifests in Service

Burrs on slit aluminium strip (ASTM B236) pierce the enamel during high-tension winding; measured burr height must be < 8 % of strip thickness.

Off-centre enamel (> 10 % eccentricity) lowers local Ubd by 35 %; we reject at ± 5 % using 360° laser head 0.3 m after curing oven.

Low elongation (< 15 % on Al) causes “necking” at coil head; our in-line annealer holds 230 °C for 4 s to guarantee ≥ 20 % A50.

Wrong thermal index: Class 130 (B) wire in a 180 °C hotspot loses 50 % life every 1 000 h; we supply 180 °C (H) or 200 °C (C) as standard, no price premium versus European stockists.

5. Luoyang Xinzhaohe Process Control

Rod Drawing → 650 °C On-line Degassing → Multi-pass Diamond Dies → 420 °C Annealing in N2 → Vertical Enamelling (3 coats + 1 bondable optional) → Spark Test 4 kV, 100 % coverage → Auto-spooling (2–800 kg).

Full traceability: each spool carries a QR code linking to melt number, enamel lot, Ubd and ECC values.

6. Cost-Performance Positioning

Western distributors typically add 18–25 % stock margin and 8–12 week freight.

Factory-direct from Luoyang: same IEC/ASTM compliance, thermal class 155–220 °C, breakdown ≥ 5 kV, shipped in 10 days FOB Tianjin, priced at LME + US$ 0.90/kg (Al) or US$ 1.80/kg (Cu) enamelled.

For transformer OEMs and motor rewind shops this translates into 12–16 % bill-of-material savings without redesign.

Bottom line: “Enamelled wire” is not merely copper or aluminium with paint; it is a precision insulation system whose electrical, thermal and mechanical margins are locked-in during rod-to-spool processing. Luoyang Xinzhaohe’s 20-year, fully-integrated line meets every clause of IEC 60317 and ASTM B236/B49, giving buyers a premium, audit-ready alternative to high-priced Western inventory.

Factory Tour: Manufacturing Enamelled Wire Meaning

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd.

2.1 Rod-to-Wire Journey: 5 Controlled Transformations

| Stage | Principal Objective | Critical Parameters | Inline Instrumentation |

|---|---|---|---|

| Rod Drawing | Reduce Ø 9.5 mm EC-Grade Al rod to 1.8–5.0 mm wire in 12 passes | Area-reduction ≤ 22 %/pass, die approach angle 12–14°, lubricant temp 35 ± 3 °C | Laser micrometer (±0.5 µm), drawing force cell, emulsion conductivity meter |

| In-line Annealing | Recrystallise lattice, elongation ≥ 25 % | Furnace temp 380 ± 10 °C, wire speed 8–12 m s⁻¹, O₂ < 50 ppm | IR pyrometer, eddy-current annealing proof (conductivity rise Δσ ≥ 2 % IACS) |

| Enameling (Vertical Triple-Cure) | Build 2–6 insulation coats, total build 25–55 µm | Cataphoretic voltage 90–120 V, gel zone 220 °C, cure zone 480 °C, catenary ≤ 6 mm | Beta-backscatter thickness gauge (1 µm repeatability), spark tester 3 kV DC, pin-hole camera 2 000 fps |

| Inline Testing | Guarantee electrical & mechanical spec | Breakdown ≥ 4 kV (room T), 2 kV after 30 min @ 200 °C; elongation ≥ 25 %; spring-back ≤ 35 mm | 100 % spark test, 2 kV to 6 kV ramp; servo-tensile unit; auto-resistance bridge (0.01 % accuracy) |

| Precision Spooling | Deliver knot-free, tension-controlled packages | Tension 1–3 N mm⁻², traverse pitch 0.3 mm rev⁻¹, weight 5–500 kg | Load-cell dancer, laser edge sensor, barcode genealogy |

2.2 Quality Control Philosophy: “No Roll-back, Only Roll-forward”

- Statistical Process Control (SPC): Every metre is time-stamped; X̄-R charts updated every 15 min.

- Pin-Hole Surveillance: Target ≤ 5 defects/30 000 m (industry: ≤ 25).

- Thermal-Class Verification: 1 000 h ageing @ rated T+25 °C, retention of 50 % elongation.

- RoHS & REACH: Enamel solids free of Pb, Cd, Cr⁶⁺; SVHC < 0.1 wt %.

- Package Integrity: Vacuum-sealed + VCI film; moisture ingress < 100 ppm after 12 months.

2.3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Test Method | LXZH Premium Spec | Typical Market Range | Engineering Impact |

|---|---|---|---|---|

| Breakdown Voltage, 20 °C | IEC 60851-5 | ≥ 6 kV (2 kV margin) | 3–4 kV | Higher impulse withstand, thinner insulation build possible → smaller transformer |

| Pin-Holes | IEC 60317 | ≤ 3 / 30 000 m | 10–25 / 30 000 m | Lower partial-discharge, longer insulation life |

| Concentricity (min. build ratio) | Laser scan | ≥ 80 % | 60–70 % | Uniform dielectric stress, reduced hot-spot |

| Elongation @ 20 °C | IEC 60851-3 | ≥ 30 % Al, ≥ 25 % Cu | 15–20 % | Easier high-fill-factor winding, fewer breaks |

| Conductivity, Al wire | ASTM B193 | ≥ 61.8 % IACS | 59–61 % IACS | Lower I²R loss, 2–3 °C cooler hotspot |

| Spring-Back (3-turn mandrel) | Internal | ≤ 30 mm | 50–80 mm | Tighter coil insertion, better slot fill |

| Surface Friction, enamel | Capstan test | µ ≤ 0.12 | 0.18–0.25 | Reduced wire guide wear, higher winding speed |

2.4 Cost-Performance Positioning

Western suppliers quote 2.5–3.0 USD/kg for 200 °C Cu wire; LXZH delivers equivalent thermal class in Al at 1.1–1.3 USD/kg and Cu at 1.8–2.0 USD/kg—without MOQ penalties. Our 20-year transformer material pedigree and full vertical integration (rod-to-spool) eliminate trader margins while maintaining the above tighter specs. For OEMs facing raw-material inflation, LXZH offers a premium, factory-direct alternative that cuts total cost of ownership by 18–25 % and raises insulation reliability by a factor of two.

Packaging & Global Logistics

Export Packaging & Logistics – Winding Wire Integrity from Luoyang to Your Dock

H3 1. Sea-Freight Risk Matrix for Enamelled Wire

| Damage Mode | Root Cause | Critical Parameter | XZH Mitigation |

|---|---|---|---|

| Salt-fog corrosion | Container condensation | Cl– ≤ 0.1 mg·m-²·day-¹ | VCI film + 4 × 100 g montmorillonite desiccant per spool |

| Impact shock | Stevedore drop 1.2 m | Peak accel. ≤ 30 g | Double-wall carton + corner board + pallet strap tension ≥ 400 N |

| Vibration fretting | Engine 15–60 Hz | Wire slip ≤ 0.5 mm | Spool flange OD ≤ 400 mm, arbor lock, cross-coil lay ≤ 2 % |

| UV chalking | Deck exposure 72 h | ΔE color ≤ 2 | UV-blocking PE shrink, 120 µm, UVR ≤ 5 % |

H3 2. Spool & Reel Specification – PT-90 vs DIN 46395

| Feature | PT-90 Plastic Spool (XZH Standard) | DIN 46395 Steel Reel (On Request) |

|---|---|---|

| Material | GF-PP, 30 % glass, –40 °C to 150 °C | Zn-plated steel, –20 °C to 200 °C |

| Flange OD | 90 mm (0.1–0.8 mm wire) | 80–500 mm |

| Barrel collapse load | ≥ 800 N (ASTM D695) | ≥ 3 kN |

| Tare weight | 65 g | 1.2 kg |

| Recycling code | 5 – PP | 40 – Steel |

| Cost delta vs wood | –18 % | +22 % |

All spools are bar-coded with unique ID linking to COA (IEC 60317-1) and RoHS batch traceability.

H3 3. Multi-Layer Packaging Protocol – 0.20 mm Enameled Aluminum Wire Example

- Inner wrap: 30 µm BOPP film, 50 % overlap, static-sealed.

- Cushion: 3 mm EPE foam sleeve, die-cut to spool contour.

5 % compression set after 72 h ≤ 2 mm. - Carton: 5-ply kraft, BC-flute, 32 ECT, 350 psi burst.

- Pallet: ISPM-15 fumigated pine, 1.1 × 1.1 m, dynamic load 1 500 kg.

Corner posts, strapping 19 × 0.8 mm PET, top cap for stacking height 1.8 m (max 4 layers). - Desiccant: 8 unit Claytec, equilibrium RH ≤ 40 % at 40 °C.

- Barrier: 125 µm aluminum-liner bag, heat-sealed, OTR ≤ 0.1 cc·m-²·day-¹.

Result: < 0.2 % weight gain after 35-day Shanghai–Hamburg route (trial #XZH-23-07).

H3 4. Container Load Plan – 20 ft DC vs 40 ft HC

| Wire Range | Net Weight (kg) | Spools | 20 ft DC | 40 ft HC |

|---|---|---|---|---|

| 0.20 mm Al, 2 kg/spool | 10 000 | 5 000 | 10 pallets, 72 cm H | 20 pallets, 81 cm H |

| 1.00 mm Cu, 15 kg/spool | 12 000 | 800 | 8 pallets, 90 cm H | 16 pallets, 90 cm H |

| Strapping pattern | – | – | 2-way, cross-lash | 3-way, anti-slip mat |

| Securing | – | – | 2 t ratchet lash, dunnage air bags | Same |

Weight utilization: 78 % (20 ft) / 85 % (40 ft); volume utilization: 92 %.

H3 5. Logistics Corridor – Luoyang to Global

Origin: Factory 34 km from Luoyang Longmen Rail Hub, daily block-train to Qingdao & Shanghai port (18 h).

Cut-off: 72 h before vessel ETA; ETD buffer 1 day vs weather.

Carrier pool: COSCO, MSC, CMA-CGM, 90 % direct sailings, 28 days NWE, 14 days SEA.

Insurance: Cargo clause A, 110 % CIF value, zero deductible.

Incoterms: FOB Qingdao (default), CIF & DDP on request.

Document kit: BL, COA, RoHS, REACH, MTC EN 10204-3.1, fumigation cert, packing list with net/gross tare.

H3 6. Cost & Sustainability Edge

By integrating rod casting, in-line enameling and spooling under one 60 000 m² Luoyang campus, XZH eliminates one trans-shipment versus European coil coaters. The savings—≈ 190 USD/te freight + 0.8 % scrap—are passed on to transformer OEMs while still meeting IEC 60317-25, ASTM B 117 500 h salt-spray and UL 1446 thermal class 220 °C. For motor repair shops ordering ≥ 500 kg mixed sizes, we offer split-shipment: 60 % by sea, 40 % by air (Zhengzhou CGO) within 7 days, keeping your line-side inventory below 15 days without paying Western price premiums.

Contact our logistics cell at export@xzhal.com for a tailored loading diagram and live container tracking API.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Enameled Winding Wire

20-Year Metallurgical Track Record—Not a Trading Post

Since 2004 we have run a single-site, ISO-9001/ISO-14001 mill in Luoyang that performs every critical step—rod casting, multi-pass drawing, in-line annealing, vertical enameling, spark testing, and precision spooling—under one roof.

No toll-processing, no middle-men, no batch-to-batch mystery metal. Our melt source is 99.7 % EC-grade Al and OFHC Cu cathode; chemistry is logged every 2 h and retained for 10 years for root-cause traceability. Transformer OEMs in 42 countries have qualified our wire for 110 kV–500 kV distribution and furnace reactors where failure cost exceeds US$50 k per hour. That history is your risk mitigation.

Direct Factory Price—Transparent Cost Structure

| Cost Element | Typical Western Supplier | Luoyang Xinzhaohe | Savings |

|---|---|---|---|

| Rod conversion margin | +12 % | 0 % (own melt shop) | –12 % |

| Trading layer | +6–8 % | none | –6–8 % |

| Energy (kWh/t) | 3 200 | 2 650 (regenerative burners) | –0.9 ¢/kg |

| Yield loss | 4 % | 1.8 % (closed-loop draw control) | –2.2 % |

| Landed price 2.0 mm Al 200 °C wire | US$5.40/kg | US$3.85/kg | –29 % |

Prices are FOB Tianjin; add only freight and duty—no surprise surcharges. Volume rebates start at 5 t per month; payment terms L/C 90 days or TT 30 days.

Customization Without MOQ Penalty

Thermal class, insulation build, and conductor geometry are not “specials”—they are standard lead items.

| Parameter | Standard Range | Tightest Tolerance | Engineering Note |

|---|---|---|---|

| Diameter, round Cu | 0.10 – 5.00 mm | ±0.005 mm | Laser micrometer 100 % at 300 m min⁻¹ |

| Diameter, round Al | 0.20 – 6.00 mm | ±0.008 mm | Inclusion content <0.015 % by LECO |

| Flat wire (Cu/Al) | a: 0.8 – 12 mm, b: 2 – 35 mm | R-corner 0.5 × thickness | Eliminates eddy-current hot spots |

| Insulation build | Grade 0 – 3 (IEC 60317) | ±5 µm | Concentricity >85 %, spark test 3 kV rms |

| Thermal class | 130 (B), 155 (F), 180 (H), 200 (C), 220 (C+) | ΔTg <2 °C | UL档案号E356876, IEC 60172寿命试验≥20 000 h |

Need 0.071 mm Cu with 220 °C polyimide overcoat for aerospace? We will run 100 kg on the same line that produces 10 t power-transformer orders—no premium if you accept our next scheduled color change.

Inline QA That Replaces Incoming Inspection

Every centimetre is spark-tested at 3 kV (round) or 5 kV (flat); data are stored per reel and exported as CSV for your SPC system. Additional checks—elongation, spring-back, solderability, dielectric breakdown (IEC 60851-5)—are performed every 2 km and attached as MTR. Reels are bar-coded; scan the QR code on your shop floor and receive the full heat pedigree within 3 s.

Logistics & Compliance

Packaging: 1–500 kg plastic spools, plywood crates, VCI film, desiccant; sea/road/air rated.

Standards: IEC 60317, NEMA MW 1000, JIS C3202, GB/T 23312, UL Recognized.

REACH & RoHS: full disclosure, SVHC <0.1 %.

Lead time: 7 days ex-stock, 3 weeks custom size, 5 weeks new thermal class qualification.

Next Step—Get the Numbers

Send your specification—thermal class, conductor alloy, build, bobbin size—to cathy@transformerstrip.com. We will return a datasheet, breakdown voltage curve, and landed quote within 24 h. Pilot spools (1–5 kg) are free for qualified OEMs. Replace high-cost Western inventory without sacrificing one volt of insulation reliability.

📉 Import Savings Calculator

Estimate cost reduction by sourcing enamelled wire meaning from Luoyang Xinzhaohe.