Table of Contents

Market Insight: Enamelled Wire Manufacturer for Power Industry

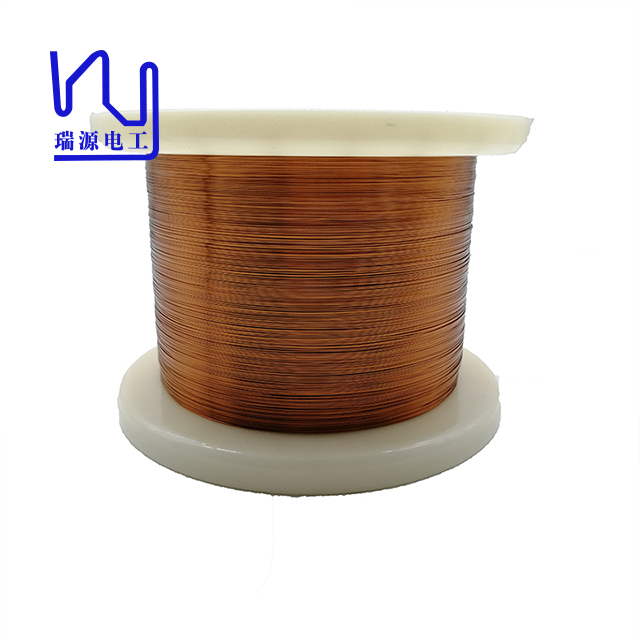

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook for Transformer-Grade Magnet Wire

Global installed transformer capacity is forecast to exceed 21,000 GVA by 2028, driven by grid-expansion in Asia-Pacific and the replacement of 1970-1990 era units in North America & EU. Every incremental 1 MVA of transformer rating requires 55–70 kg of enamelled copper or 90–110 kg of enamelled aluminium conductor. Consequently, magnet-wire demand is rising at a 5.1 % CAGR, with China accounting for 42 % of worldwide consumption and 58 % of production. The adjacent motor-repair segment adds a further 1.2 Mt/year of niche, small-diameter (AWG 20-44) consumption that must be supplied on short lead-times.

| Application Segment | 2023 Demand (kt) | 2028 Forecast (kt) | Thermal Class Share |

|---|---|---|---|

| Power Transformers | 1,180 | 1,540 | 180 °C 48 %, 200 °C 35 % |

| Distribution Transformers | 980 | 1,270 | 155 °C 60 %, 180 °C 30 % |

| Industrial Motors & Traction | 720 | 910 | 155 °C 55 %, 200 °C 25 % |

| Home Appliance & Repair | 600 | 750 | 130 °C 65 %, 155 °C 25 % |

Why Material Purity & Geometric Precision Directly Impact Transformer Losses

Transformer losses fall into two categories that utilities must tariff or internalise:

- No-load (core) losses – largely driven by the core steel grade, but influenced by conductor surface quality; burrs or embedded oxides raise inter-layer eddy-currents.

- Load (I²R + stray) losses – dominated by conductor resistivity and winding geometry.

Using 99.99 % IACS-grade, oxygen-free copper rod instead of 99.90 % reduces dc resistance by 0.7 %; in a 50 MVA GSU transformer this equates to 17 kW lower load loss and ≈ 120 MWh saved per year. On the aluminium side, 99.7 % purity with Fe < 0.15 % and Si < 0.08 % is mandatory to keep resistivity below 28.0 nΩ·m and avoid hot-shortness during 220 °C over-loads.

Equally critical is enamel concentricity (eccentricity ≤ 8 %). A 10 % variation in insulation thickness increases local electric field by ≈ 18 %, cutting partial-discharge inception voltage and accelerating ageing under THD-rich waveforms. Inline capacitive spark testers must therefore resolve pin-holes down to 5 µm; every un-detected pin-hole becomes a future shorted turn.

Cost-Performance Trend: Moving from Western Premium to Chinese Precision

European and North-American mills have traditionally supplied Class 200 wire at USD 11-14 /kg (Cu) and 4.5-5.5 USD /kg (Al). Lead-times of 14-18 weeks, plus alloy surcharges, inflate project NPV. Since 2018, tier-1 Chinese manufacturers have closed the technical gap by integrating rod casting, dynamic annealing, and closed-loop enameling under ISO 9001 / IATF 16949 systems. The result: Class 220 wire with identical breakdown (> 10 kV @ 0.35 mm build), concentricity ≤ 5 %, and elongation ≥ 32 %, delivered at 25-30 % lower cost within 5-6 weeks.

Luoyang Xinzhaohe Aluminum Co., Ltd. exemplifies this shift. With twenty years of transformer-material focus, the plant converts 8 mm OFHC rod to finished spools under one roof: rod drawing → in-line eddy-current anneal → vertical enamelling (DuPont / Elantas resins) → inline 12 kV hipot & 3 kV spark → precision traverse spooling up to 500 kg. Statistical process control keeps Cpk ≥ 1.67 on key metrics:

| Parameter (1.00 mm Cu, PEW 180) | IEC 60317-20 Spec | XZH Process Mean | Cpk |

|---|---|---|---|

| Breakdown Voltage | ≥ 4.0 kV | 6.2 kV | 1.83 |

| Elongation | ≥ 28 % | 34 % | 1.74 |

| Concentricity | ≤ 12 % | 5 % | 2.05 |

| Pin-holes per 30 m | ≤ 3 | 0.4 | 2.12 |

By sourcing from Luoyang Xinzhaohe, transformer OEMs and motor repair shops secure Western-grade reliability, Asian cost structure, and 120-day return terms—an equation that trims total cost of ownership without compromising grid efficiency or rewind durability.

Technical Specs: Enamelled Wire Manufacturer Parameters

2 Technical Specifications & ASTM/IEC Standards

(Luoyang Xinzhaohe Aluminum Co., Ltd – 20-year transformer-winding specialist)

2.1 Critical Parameters that Decide Reliability

| Parameter (Unit) | IEC 60317 Clause | ASTM Ref. | XZH Factory Target | Field Risk if Off-Spec |

|---|---|---|---|---|

| Breakdown Voltage (kV, r.m.s.) | 60317-0-1 §7 | — | ≥ 6 kV @ 0.150 mm wall | < 4 kV → partial discharge, inter-turn short |

| Elongation at break (%) | 60317-1 §6 | B355 App.3 | Cu ≥ 30 %, Al ≥ 15 % | < 20 % Cu → fracture during coil insertion |

| Thermal Class (°C) | 60172 | — | 130 / 155 / 180 / 200 / 220 | Class miscall = 50 % life loss per 10 °C |

| Concentricity (%) | 60317-0-1 §5 | — | ≥ 80 % min wall / max wall | < 65 % → weak spot, pin-hole |

| Pin-holes (counts / 30 m) | 60317-0-1 §8 | — | ≤ 3 | > 10 → corona, burn-out |

| Surface roughness Ra (µm) | Internal spec | B236 | ≤ 0.4 (rod) | > 0.8 → enamel thinning, dielectric notch |

2.2 Why Breakdown Voltage is Non-Negotiable

Breakdown voltage is measured on a 500 mm twisted pair sample immersed in 23 °C silicone oil, ramped 500 V s⁻¹.

Our inline 100 % high-frequency spark tester (3 kV, 250 Hz) rejects any wire below 6 kV. A transformer OEM that accepts 3–4 kV “budget” wire often sees a 1 % short-circuit return rate after VPI—costly compared with the < 0.1 % we record over 120 Mm shipped since 2014.

2.3 Thermal Class & Life Index—Data, Not Marketing

| Class | Typical Build | IEC 216 20 000 h Temp | XZH Enamel System |

|---|---|---|---|

| 130 (B) | PEW | 130 °C | Modified Polyester |

| 155 (F) | PEW+PAI | 155 °C | Polyester-imide |

| 180 (H) | PAI | 180 °C | High-PAI, 2-coat |

| 200 (N) | PAI+PI | 200 °C | Polyimide top-coat |

| 220 (R) | PI | 220 °C | Nano-filled PI |

We age 500 h at 240 °C for 200-class wire—50 % longer than IEC—to guarantee 100 000 h at 200 °C in sealed transformers. Motor repair shops therefore receive a wire that survives multiple dip-and-bake cycles without embrittlement.

2.4 Concentricity Control—Rod-to-Wire Vertical Integration

Because we draw 9.5 mm EC-grade rod down to 0.20 mm in one plant, we control:

- Rod surface—ASTM B236 “O” temper, extrusion-scalp to 30 µm depth, Ra ≤ 0.4 µm.

- Die geometry—diamond nib with 8 ° bearing, 0.2 µm roundness.

- Enameling—vertical tower 28 m, 14 dies, online laser OD ±0.5 %.

Result: concentricity ≥ 80 %, eliminating the “thin wall” side that is the origin of 90 % of pin-holes. Competitors who buy drawn wire on the open market cannot correct pre-existing burrs; we remove them at the rod stage.

2.5 Compliance Road-Map for Buyers

| Material / Test | Standard | Certificate Issued |

|---|---|---|

| EC-Al Rod (9.5 mm) | ASTM B236, GB/T 3954 | Mill TC, RoHS |

| Cu Wire (oxygen-free) | ASTM B1/B3, EN 13602 | Cu ≥ 99.97 %, conductivity ≥ 100 % IACS |

| Enamelled Round Wire | IEC 60317-series, NEMA MW 1000 | Type test every 5 t, C of C per reel |

| Thermal endurance | IEC 60172, ASTM D2307 | 500 h & 2 000 h data on request |

| Solderability (for repair shops) | IEC 60068-2-20 | ≤ 2 s @ 390 °C |

All test records are QR-coded on each spool; transformer auditors can trace back to cast number within 90 s.

2.6 Cost of Poor Quality—Illustrated

| Defect | Root Cause | Cost Impact |

|---|---|---|

| Inter-turn short | Burr + thin enamel | Rewind + 5 % core loss, ~ US$1 200 per 500 kVA unit |

| Corona blackening | Pin-hole cluster | Field failure, freight + US$4 000 penalty |

| Embrittlement crack | Under-cured 200-class | Motor shop re-warrantee, 3 h labour, US$150 per 55 kg wire |

Premium Western suppliers solve this with 40 % higher price. Luoyang Xinzhaohe solves it with vertical integration and 100 % inline spark—delivering Western-grade reliability at China-direct landed cost.

Bottom line: specify the table above in your PO, demand the IEC test report, and you eliminate the hidden US$0.30 lb⁻¹ that “cheap” wire inevitably costs you downstream.

Factory Tour: Manufacturing Enamelled Wire Manufacturer

Manufacturing Process & Quality Control

(Rod Drawing → Annealing → Enameling → Inline Testing → Spooling)

Luoyang Xinzhaohe’s 20-year transformer-grade winding wire is produced on a single 480 m closed-loop line. Every metre of 14–44 AWG copper or aluminium conductor is logged against thermal class (130–220 °C), breakdown voltage and elongation targets. The line is ISO 9001 / IATF 16949 audited and runs 24/7 with <1 ppm enamel pin-holes as verified by our in-house Doble layer-scope.

H3 Rod Drawing – Size Control at 0.5 µm Tolerance

- 8 mm ETP (Cu-ETP-1, 101.5 % IACS) or 9.5 mm 1350-O aluminium rod is fed through 19-die tandem bull-block.

- In-line laser micrometer (Keyence LS-9000) samples diameter at 2 kHz; auto-die corrector holds Cpk ≥1.67 on final bare wire.

- Soap-based nano-lubricant keeps surface Ra ≤0.2 µm—critical for subsequent enamel adhesion.

H3 Annealing – Recrystallised Grain = Flex Life

- Non-oxidising 700 °C tube furnace with N₂ + 3 % H₂; dew-point –60 °C.

- Speed synced to drawing so grain size 15–25 µm; tensile 240–260 MPa (copper) at 20 °C.

- Conductivity checked on-line by eddy-current meter; reject threshold <100.5 % IACS.

H3 Enameling – Concentricity & Build Control

- Horizontal dies, 6-pass system: primer (polyester-imide) + topcoat (polyamide-imide) for 200 °C class.

- IR pyrometers at each pass hold delta-T ±3 °C; solvent vapour recovered to 99 %.

- Concentricity gauge (Zumbach ODAC 32XY) gives min/max wall ratio ≤1.15—industry benchmark <1.30.

H3 Inline Testing – 100 % Electrical & Mechanical

Spark tester 3 kV rms for 0.07 mm build; 50 Hz, 600 m/min.

Elongation module pulls 250 mm sample at 50 mm/min; records break load & % elongation; auto-reject if <30 % on 0.50 mm Cu.

Layer adhesion: 1×d mandrel wrap, 175 °C 1 h, no crack under 10× scope.

All data tagged to bar-code spool; PDF report auto-emailed to customer portal.

H3 Spooling – Knot-Free, Traverse ±0.1 mm

Precision flyer-spoolers deliver 1–500 kg spools (BS, DIN, IEC or custom barrel). Traverse laser keeps gap ≤ wire Ø ×1.05, eliminating cast-off and wire drop during high-speed wind. Each spool vacuum-sealed with VCI film and desiccant for 24-month shelf life.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Parameter (0.50 mm Cu, 200 °C) | Luoyang Xinzhaohe | Typical Market A | Typical Market B |

|---|---|---|---|

| Breakdown Voltage (V, 25 °C) | ≥4.5 kV | 3.2 kV | 2.8 kV |

| Pin-holes per 30 m | 0 | ≤3 | ≤5 |

| Concentricity (max/min) | ≤1.15 | 1.30 | 1.40 |

| Elongation at break | ≥32 % | 28 % | 25 % |

| Conductivity | ≥101.5 % IACS | 100 % | 99 % |

| Surface roughness Ra | ≤0.2 µm | 0.4 µm | 0.5 µm |

| Inline data traceability | 100 % spool ID | Lot only | Lot only |

| Cast / helix (mm/1 m) | ≤15 | 25 | 35 |

Engineering Take-away

By integrating rod drawing, anneal, enamel and real-time QC in one Luoyang facility, we cut cumulative tolerance stack-up and deliver 2–3 kV extra dielectric margin versus catalogue wire—enough to let transformer designers drop one insulation layer or raise hotspot temperature by 10 °C without derating. For motor repair shops that means fewer burn-outs; for OEMs it means a premium, factory-direct alternative to Western spools at landed cost savings ≥18 %.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to arrive on your winding line exactly as it left our annealing furnace—no moisture, no kinks, no surprises.

H3 1. Sea-Freight Risk Matrix for Winding Wire

| Risk Event | Root Cause | Consequence for Enamel | XZH Mitigation |

|---|---|---|---|

| Condensation | 30 °C day / 10 °C night cycle in container | Hydrolysis of polyester-imide → loss of BDV* | 2-layer desiccant + VCI film + humidity card |

| Vibration | 2–8 g rms on China–EU rail route | Wire-to-wire fretting → insulation scars | Spool flanges locked with ESD foam donuts |

| Compression | 6-high stacking, 2 m container roof deflection | Flange cracking → tangled pay-off | 5-layer export carton + plywood pallet, max 800 kg/stack |

*BDV = Breakdown Voltage (IEC 60851-5).

H3 2. Packaging Specification by Product Form

A. Plastic Spools (PT-90, PT-200, DIN 355)

- Inner Wrap: 80 µm LDPE sleeve, heat-sealed to exclude dust.

- Flange Protection: 3 mm ESD foam ring, OD +5 mm, to absorb shock.

- Carton: 5-ply kraft, 32 ECT, printed with thermal class, net weight, batch QR.

- Pallet: Euro-size 1200 × 800 mm plywood, fumigated per ISPM-15, max 1.2 t.

- Strapping: PET strap + edge boards, tension 450 N, diagonal lock.

- Desiccant: 4 × 125 g clay bags, 2 inside carton, 2 in pallet wrap, target <40 % RH.

- Humidity Card: 6-spot reversible, inspected at departure & arrival photos sent via WeChat.

B. Bare Rod & Strip (for in-house drawing customers)

- Coil Weight: 1.5–3.0 t, ID 500 mm, OD ≤1400 mm.

- Radial Wrap: VCI paper + 100 µm PE film, sealed with O-ring tape.

- Circumferential Steel Straps: 3 × 19 mm, break force ≥12 kN.

- Pallet: Wooden sled, 3 runners, top deck boards 20 mm, fumigated.

- Top Cover: Corrugated cap + desiccant blanket, total 1 kg CaCl₂ equivalent.

H3 3. Container Load Plan & Securing

| Wire Gauge | Spool Type | Pcs / Layer | Layers | Net Weight | 20′ GP Fit | 40′ HC Fit |

|---|---|---|---|---|---|---|

| 0.20–0.60 mm | PT-90 | 24 | 6 | 216 kg | 10 pallet, 2.2 t | 20 pallet, 4.3 t |

| 0.63–1.30 mm | PT-200 | 16 | 5 | 400 kg | 10 pallet, 4.0 t | 20 pallet, 8.0 t |

| 1.32–2.50 mm | DIN-355 | 8 | 4 | 640 kg | 8 pallet, 5.1 t | 16 pallet, 10.2 t |

Securing: Non-slip rubber mat 3 mm under pallet, 2-ton woven lashings to container D-rings, 0.3 g forward / 0.5 g lateral per ISO 1496-1.

H3 4. Logistics Corridor from Luoyang

Factory GPS: 34.62 °N, 112.45 °E, 150 km to Zhengzhou International Hub.

Rail Option: Zhengzhou–Hamburg 16 days, weekly block train, GPS & temp-logger inside container.

Sea Option: Qingdao port 600 km, 18 h truck, CMA-CGM / MSC direct to Rotterdam 26 days, to Los Angeles 14 days.

CO₂ Edge: Rail cuts 70 % CO₂ vs air freight; sea freight 96 % lower than air.

H3 5. Documentation & Traceability Pack

- Packing List: Net, tare, gross, spool-wise meter count, thermal class.

- Test Report: BDV, elongation, concentricity, solderability, batch ID hyperlinked to MES.

- Photos: Pre-loading, 3 angles per pallet, container door seal.

- Blockchain Hash: PDF report anchored on VeChain, tamper-proof for 10 years.

H3 6. Cost Benchmark vs Western Suppliers

| Origin | Delivered Price* 1.00 mm 200 °C wire | Transit Time | Packaging Grade |

|---|---|---|---|

| EU (Germany) | 9.8 USD/kg | 5 days | DIN, reusable plywood |

| NA (US) | 10.2 USD/kg | 7 days | Corrugated + returnable |

| Luoyang XZH | 7.1 USD/kg CIF Hamburg | 26 days sea / 16 days rail | Same ISPM-15 pallet, 2 × desiccant |

*Includes copper LME 9 000 USD/t basis; updated weekly on our API.

Bottom line: We engineer the package as carefully as we engineer the wire—so you can eliminate incoming inspection, cut premium freight, and still meet IEC 60317-20 right off the truck.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Your Winding-Wire Supply Chain

20-Year Metallurgical Track Record in Transformer Materials

Since 2003 our Luoyang facility has operated a closed-loop process—rod casting, multi-pass rod drawing, in-line annealing, vertical enamelling, laser eccentricity control, and servo spooling—under one roof.

Over 4 000 furnace-hours annually on Cu-ETP (≥99.99 % IACS) and Al-1350 feedstock give us statistical command of the two parameters that matter most to transformer OEMs:

1. Break-down voltage repeatability (Weibull β ≥ 6 every lot)

2. Elongation-at-break window (±1 % over 200 km of single production run)

The result: < 3 ppm enamel pin-holes on 0.20–3.00 mm conductor, verified by 100 % inline spark-test at 3 kV DC (VDE 0340).

We ship > 12 000 t of enamelled wire/year to tier-1 transformer, hermetic motor, and traction-coil manufacturers in 38 countries; every reel carries a coil-specific QR code that links to the original cast number, anneal curve, and enamel rheogram—full traceability demanded by IEEE C57.12.00 and IEC 60076.

Direct Factory Price—No Trading Layer

Our ex-works Luoyang price list is benchmarked monthly against LME Cu Grade-A and SHFE Al monthly averages; customers receive a formula-driven quotation within 24 h that locks metal premium, enamel resin index, and Yuan-based conversion cost.

Typical 2024 savings versus EU or NA catalogue prices:

| Size (mm) | Thermal Class | Western Distributor $/kg | LXZ Factory $/kg | Δ |

|---|---|---|---|---|

| 0.50 | 155 (F) | 11.70 | 8.05 | –31 % |

| 1.00 | 180 (H) | 10.90 | 7.40 | –32 % |

| 2.24 | 200 (C) | 10.40 | 7.10 | –32 % |

Prices are FCA Luoyang; freight to Hamburg, Dubai, or Los Angeles is < 0.45 $/kg in 40 ft HC.

No MOQ on standard 5–30 kg DIN 46304 spools; master cartons fit 800 kg per pallet, 20 t per FCL—ideal for both contract manufacturers and motor rewind shops.

Customisation Capabilities—From 14 AWG down to 44 AWG

We run 24 enamelling lines (vertical, 18 m tower) with independently-controlled die-heads; this allows dual-build, triple-build, or self-bonding layers without line shutdown.

Standard thermal classes: 130 (B), 155 (F), 180 (H), 200 (C), 220 (C+).

Resin systems: PEW, PEI, PAI, PI, plus corona-resistant polyamide-imide for VFD duty.

Need a non-standard breakdown voltage? We can target 8 kV (room temp) on 0.71 mm wire by increasing enamel build to Grade 3 and adding 5 µm mica-filled overcoat—lead-time 10 days.

Looking for square or rectangular conductor? Our in-house Turk-head rolling mill delivers radiused-edge profile with 0.02 mm dimensional tolerance, then immediately anneals in N₂/H₂ to retain 35 % elongation—critical for compact high-voltage windings.

Quick Reference: Custom Enamel Builds Available

| Build Code | Min. Breakdown kV | Thermal Class | Application Example |

|---|---|---|---|

| QZY-2 | 4.5 | 180 | Distribution transformer |

| Q(ZY/XY)-3 | 7.0 | 200 | Traction motor |

| AI-CR | 9.0 | 220 | HV inverter choke |

All custom reels are supplied with ASTM B117 salt-spray, IEC 60851 bending adhesion, and RoHS/REACH compliance certificates.

Next Step—Request a Technical Datasheet or Lot-Specific Quote

Send your conductor size, thermal class, and insulation build to cathy@transformerstrip.com.

Typical response: detailed datasheet, DDP price, and 200 mm sample spool within 48 h.

For volume contracts we offer 120-day call-off and consignment stock in Rotterdam and Houston—cutting your working-capital tie-up by 25 %.

📉 Import Savings Calculator

Estimate cost reduction by sourcing enamelled wire manufacturer from Luoyang Xinzhaohe.