Table of Contents

Market Insight: Enamelled Copper Wire

Market Analysis: Winding Wire for Transformer Applications

Global demand for high-performance enamelled copper wire in power and distribution transformers continues robust expansion, driven by critical infrastructure modernization and renewable energy integration. The International Energy Agency projects a 6.5% annual growth in global transformer capacity through 2030, primarily fueled by grid reinforcement for solar/wind interconnection, electric vehicle charging networks, and industrial electrification. This necessitates transformers operating at higher efficiencies (IE4/IE5 standards) and elevated thermal loads, placing stringent demands on winding wire integrity.

Quality in enamelled copper wire is non-negotiable for transformer reliability and lifecycle cost. Substandard wire introduces latent failure points through three primary mechanisms: thermal degradation, dielectric breakdown, and mechanical instability. Copper purity (minimum 99.99% OFE per ASTM B152) ensures optimal conductivity and minimizes resistive losses. Inefficient annealing or impurity ingress elevates DC resistance, directly increasing I²R losses—accounting for up to 60% of total transformer losses in distribution units. Enamel composition and application uniformity are equally critical. Variations in film thickness exceeding ±5µm create localized hotspots under load, accelerating thermal aging. Industry data indicates a 10°C rise above rated temperature halves insulation lifespan per the Montsinger rule.

Transformer failures stemming from wire defects incur catastrophic costs far exceeding material savings. A single grid-scale transformer outage can exceed $10 million in replacement and downtime costs. Key quality parameters must be rigorously validated:

| Critical Parameter | Standard Requirement | Failure Consequence |

|---|---|---|

| Copper Resistivity | ≤1.7241 µΩ·cm at 20°C | Increased load losses, overheating |

| Enamel Thermal Class | Minimum 180°C (Class H) | Premature insulation degradation |

| Pinhole Density | ≤1 per 50m (IEC 60317-0-5) | Partial discharge inception |

| Elongation after Wind | ≥12% (IEC 60317-1) | Cracking during coil processing |

Partial discharge (PD) is a critical failure precursor directly linked to enamel defects. PD inception voltage must exceed 1.5x operating voltage under thermal stress per IEEE C57.12.00. Inverters and harmonic-rich grids subject modern transformers to high-frequency voltage transients, where enamel voids or thin spots initiate PD, eroding insulation until catastrophic ground fault occurs. Luoyang Xinzhaohe Aluminum Co., Ltd applies metallurgical process control across 20+ years of production: continuous casting for oxygen-free copper, multi-layer enamel extrusion with in-line capacitance monitoring, and thermal shock testing to 220°C. Our supply chain integrates certified raw material traceability and batch-specific thermal aging reports, ensuring wire meets the dielectric integrity demands of 150kVA to 500MVA transformers operating in harsh environments.

Procurement decisions must prioritize verified technical compliance over nominal cost. Inferior wire incurs hidden lifecycle penalties through reduced efficiency, unplanned outages, and shortened asset life. Rigorous supplier qualification—auditing metallurgical processes, enamel adhesion testing (IEC 60851-5), and accelerated life validation—is essential for grid resilience.

Technical Specs: Enamelled Copper Wire

Enamelled Copper Wire Technical Specifications

Enamelled copper wire, also known as magnet wire, is a critical component in the manufacturing of electromagnetic devices such as motors, transformers, inductors, and generators. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in winding wire production, we emphasize precision in material properties and insulation performance to ensure reliability under demanding operational conditions. The technical specifications of enamelled copper wire are governed by international standards including IEC 60317, GB/T 23312, and NEMA MW 1000, which define key electrical, mechanical, and thermal parameters.

A primary performance indicator for enamelled copper wire is the insulation breakdown voltage, which reflects the dielectric strength of the polymer coating. This parameter ensures the wire can withstand high-voltage stresses without electrical failure. Breakdown voltage is tested under standardized conditions, typically using a step-voltage method, and values are measured in alternating current (AC) and direct current (DC). The insulation system must provide consistent performance across wire diameters and operating temperatures. Higher thermal classes generally require enhanced dielectric stability to maintain integrity under prolonged thermal exposure.

Elongation is another critical mechanical property, indicating the ductility of the copper conductor and the flexibility of the insulation system. It is measured as the percentage increase in length before fracture during a tensile test. Adequate elongation ensures the wire can endure winding processes without cracking or insulation damage, especially in tight-coil applications. Minimum elongation values vary depending on wire diameter and grade, with finer wires typically exhibiting lower elongation percentages.

Thermal class defines the maximum continuous operating temperature the insulation can withstand while maintaining electrical and mechanical performance. Thermal classes range from 130°C to 220°C, with higher classes utilizing advanced polymer coatings such as polyimide, polyamide-imide, or polyester-imide. These materials offer superior thermal stability, chemical resistance, and mechanical toughness. Operating above the rated thermal class accelerates insulation degradation, leading to reduced service life and potential system failure.

The following table outlines the typical technical parameters for enamelled copper wire across various thermal classes:

| Parameter | Test Method | Thermal Class 130 (°C) | Thermal Class 155 (°C) | Thermal Class 180 (°C) | Thermal Class 200 (°C) | Thermal Class 220 (°C) |

|---|---|---|---|---|---|---|

| Minimum Breakdown Voltage (V) | IEC 60317 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Elongation (%) | GB/T 23312 | ≥15 | ≥15 | ≥12 | ≥10 | ≥8 |

| Thermal Shock (mm) | IEC 60317 | 4D | 4D | 3D | 2D | 2D |

| Heat Bonding (°C) | NEMA MW 1000 | — | — | 180–200 | 200–220 | 220–240 |

| Resistance to Refrigerants | IEC 60317 | Standard | Standard | Enhanced | Enhanced | High |

These specifications are validated through rigorous in-house testing and third-party certification. Consistent quality control ensures compliance with global industry requirements, supporting long-term reliability in industrial and automotive applications.

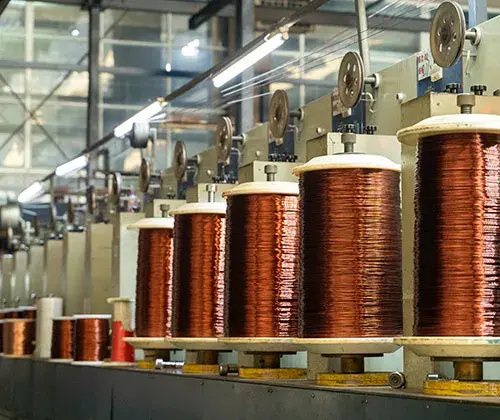

Factory Tour: Manufacturing

Enamelled Copper Wire Manufacturing Process: Technical Overview

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and process engineering expertise in winding wire production. While our corporate name reflects historical aluminum specialization, our current enamelled copper wire division applies rigorous copper metallurgy principles and precision manufacturing protocols. This section details the critical stages from raw material to finished coil, emphasizing integrated quality control essential for high-reliability electromagnetic applications.

The process commences with high-purity Electrolytic Tough Pitch (ETP) copper rod, typically 8mm diameter, meeting IACS conductivity standards of ≥100%. Rod drawing reduces diameter to the precise gauge required, utilizing multi-die block machines with diamond or tungsten carbide dies under controlled tension. Critical parameters include die geometry, lubricant viscosity, and capstan speed synchronization to ensure dimensional accuracy (±0.002mm) and a defect-free surface. In-process inspection employs laser micrometers for real-time diameter verification and surface flaw detection systems; rods exceeding ovality tolerance or exhibiting scratches are automatically rejected before annealing.

Continuous annealing follows drawing, passing the wire through an oxygen-free nitrogen-purged furnace at 450-550°C. This recrystallization step restores ductility lost during cold working, crucial for subsequent winding without fracture. Precise temperature profiling and residence time control prevent grain coarsening or surface oxidation. Post-anneal, a mandatory conductivity test (minimum 98% IACS) and tensile strength verification (typically 150-250 MPa) occur; deviations trigger immediate line stoppage for root cause analysis.

Enameling applies the insulating polymer layer via precision die coating. Single or multi-layer systems (e.g., polyurethane basecoat with polyester-imide topcoat for Class 180/200 thermal rating) are applied with strict viscosity and solids content control. Each coat undergoes staged thermal curing in vertical ovens, with zone temperatures calibrated to the specific resin’s cross-linking kinetics. Film build is monitored via beta-gauge thickness sensors, maintaining tolerances within ±0.002mm per IEC 60317 standards. Adhesion testing per ASTM D2303 is performed hourly on production samples.

Inline electrical testing occurs continuously at line speeds up to 1200 m/min. Key checks include:

| Test Parameter | Standard Requirement | Frequency |

|———————–|———————-|—————–|

| Dielectric Breakdown | ≥3 kV (dry), ≥1.8 kV (wet) | 100% in-line |

| Pinhole Detection | Zero defects | 100% in-line |

| Elongation at Break | ≥10% minimum | Per batch |

Final quality validation includes thermal endurance testing (20,000-hour extrapolation per IEC 60172), solderability checks, and chemical resistance verification. All critical process data—tension, temperature profiles, coating thickness—is logged for full traceability. This integrated approach, combining metallurgical science with statistical process control, ensures consistent production of enamelled copper wire meeting stringent automotive, industrial motor, and renewable energy sector demands. Non-conforming batches undergo metallurgical failure analysis before disposition.

Packaging & Logistics

Export Packaging for Enamelled Copper Winding Wire: Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and global supply of high-performance winding wires, we recognize that packaging is not merely a logistical necessity but a critical component in preserving product integrity during international transit. For enamelled copper wire, which is highly sensitive to mechanical damage, moisture, and contamination, proper export packaging is essential to ensure that the material arrives at its destination in optimal condition, ready for immediate use in precision applications such as motors, transformers, and electrical appliances.

Our standard export packaging system is engineered to meet the rigorous demands of sea freight, the predominant mode of transport for bulk industrial shipments. Each coil of enamelled copper wire is securely mounted on a robust wooden pallet, constructed from high-grade, kiln-dried hardwood that complies with ISPM 15 international phytosanitary standards. These pallets are designed to withstand the dynamic stresses of containerized shipping, including stacking loads, vibration, and abrupt handling during port operations. The structural integrity of the pallet ensures that wire coils remain stable and aligned, minimizing the risk of deformation or edge damage that could compromise winding performance.

Prior to palletization, each coil is individually wrapped in multi-layer moisture-proof film, a critical barrier against humidity and salt-laden air encountered during maritime transport. This film is heat-sealed to form a hermetic enclosure, effectively isolating the copper conductor from atmospheric moisture that could lead to oxidation or degradation of the enamel insulation. The film’s low water vapor transmission rate (WVTR) ensures long-term protection even on extended voyages crossing tropical or high-humidity zones.

Additional protective measures include the use of edge protectors on coil rims to prevent mechanical abrasion and the inclusion of desiccant packs within the sealed packaging to absorb any residual moisture. Each packaged unit is clearly labeled with product specifications, batch numbers, and handling instructions, facilitating traceability and proper storage upon arrival.

All packaging configurations are validated through internal drop, vibration, and humidity exposure testing to simulate real-world shipping conditions. This proactive quality assurance approach aligns with our commitment to zero-defect delivery and customer satisfaction.

By integrating durable wooden pallets with advanced moisture-resistant wrapping, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that our enamelled copper winding wire maintains its electrical, mechanical, and surface properties throughout the export supply chain. This packaging strategy not only safeguards material quality but also reduces the risk of costly delays, rejections, or field failures, providing our global partners with confidence in every shipment.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Technical Excellence in Enamelled Copper Wire Production

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and precision manufacturing expertise to deliver industry-leading enamelled copper winding wire. Our vertically integrated production ecosystem, anchored in rigorous material science protocols, ensures unwavering consistency for demanding applications in transformers, motors, and EV power systems. We prioritize technical specifications over generic assurances, focusing on measurable performance parameters critical to your operational reliability.

Our 50,000-ton annual production capacity operates under ISO 9001 and IATF 16949 certified processes, with dedicated lines for diameters spanning 0.02 mm to 5.0 mm. Advanced annealing furnaces maintain oxygen-free copper purity (99.99% Cu min), while proprietary enamel polymerization systems guarantee uniform insulation thickness within ±3% tolerance. Every production batch undergoes 100% spark testing at 3x operating voltage and mandrel winding verification per IEC 60317 standards. Key insulation classes and thermal endurance metrics are summarized below:

| Insulation Class | Thermal Index (°C) | Voltage Withstand (kV/mm) | Elongation at Break (%) |

|---|---|---|---|

| Class 155 (PEI) | 155 | ≥18.0 | ≥12 |

| Class 180 (PAI) | 180 | ≥20.0 | ≥10 |

| Class 200 (PFAE) | 200 | ≥22.0 | ≥8 |

Metallurgical process control defines our competitive edge. In-house copper rod casting eliminates third-party variability, with real-time spectrometry ensuring trace element compliance (Ag ≤5 ppm, P ≤3 ppm). Our dual-stage drawing benches achieve surface roughness ≤0.4 µm Ra, critical for minimizing partial discharge in high-voltage windings. Statistical process control (SPC) monitors 28 critical parameters per production hour, including tensile strength (200-250 MPa), elongation (8-12%), and dimensional stability under thermal cycling.

Supply chain resilience is engineered into our operations. A 15,000-ton strategic copper inventory buffer mitigates LME volatility, while our JIT logistics network guarantees 99.2% on-time delivery across 32 global ports. Dedicated quality assurance teams conduct pre-shipment audits per ASTM B354, providing full traceability from cathode to coil via blockchain-enabled batch records. This integration of metallurgical precision and supply chain agility reduces your total cost of ownership by minimizing line stoppages and rework.

Partnering with Luoyang Xinzhaohe means accessing a technical collaborator, not merely a supplier. Our engineering team co-develops solutions for niche requirements, such as ultra-thin insulation for high-density windings or halogen-free formulations for aerospace compliance. We validate all recommendations through in-house testing facilities accredited to ISO/IEC 17025, including thermal endurance ovens, dielectric strength testers, and adhesion peel testers.

Initiate a technical discussion to optimize your enamelled wire specifications. Contact Cathy Zhang, Supply Chain Director, at cathy@transformerstrip.com to request material test reports, capacity calendars, or a factory audit schedule. Specify your required wire grade, volume, and application for a tailored capability assessment within 48 hours. Luoyang Xinzhaohe commits to engineering partnerships that advance your product performance and supply security.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamelled copper wire directly from China.