Table of Contents

Market Insight: Enamelled Aluminum Wire

Market Analysis: Enamelled Aluminum Wire Demand in Transformer Applications

The global transformer industry exhibits accelerating adoption of enamelled aluminum winding wire, driven by strategic material substitution imperatives. While copper remains dominant in high-efficiency power transformers, aluminum wire has become the standard material for distribution transformers (typically ≤ 2500 kVA) and specific industrial transformer segments. This shift is fundamentally economic: aluminum offers a 60-70% lower base material cost versus copper and a critical 55% density advantage, significantly reducing core and structural material requirements in transformer design. Consequently, aluminum-based transformers achieve substantial weight reduction (up to 30%) and lower total landed costs, particularly vital in cost-sensitive markets and large-scale grid deployment projects across Asia, Africa, and South America. Current market analysis indicates aluminum wire now constitutes over 85% of the global distribution transformer winding wire volume, with sustained annual growth of 4-6% projected through 2030, primarily fueled by rural electrification and grid modernization initiatives.

Quality precision in enamelled aluminum wire is non-negotiable for transformer reliability and longevity. Aluminum’s inherent lower electrical conductivity (approximately 61% IACS versus copper’s 100% IACS) necessitates meticulous control over metallurgical properties to ensure optimal performance within designed parameters. Substandard wire introduces critical failure vectors. Inconsistent resistivity directly impacts load losses and thermal management, potentially causing thermal runaway under sustained operation. Poor metallurgical homogeneity or excessive residual stress leads to inadequate elongation (< 1.5%), resulting in micro-cracking during the tight winding processes essential for modern high-density transformer cores. This compromises the integrity of the enamel insulation, creating pathways for electrical breakdown. Furthermore, inadequate surface cleanliness or oxide layer control severely degrades enamel adhesion, accelerating insulation degradation during thermal cycling and moisture exposure. The enamel system itself must exhibit exceptional thermal aging performance (meeting IEC 60264 Class 155, 180, or 200 requirements) and chemical resistance to common transformer varnishes and insulating oils over decades of service.

The consequences of quality deviations are severe and quantifiable. Field data correlates substandard aluminum wire with premature transformer failures, including inter-turn shorts from enamel delamination, increased no-load and load losses exceeding design specifications, and catastrophic ground faults. These failures incur substantial costs: transformer replacement, grid downtime, warranty claims, and reputational damage. Rigorous adherence to international standards (IEC 60264, ASTM B354) for both the aluminum conductor (AA-1350 or AA-8076 alloys) and the enamel coating system is therefore a baseline requirement, not an option. Transformer manufacturers demand certified material traceability, consistent dimensional tolerances, and validated thermal endurance data from suppliers.

Critical Enamelled Aluminum Wire Quality Parameters for Transformers

| Parameter | Critical Threshold | Primary Failure Risk if Exceeded |

|---|---|---|

| Electrical Resistivity | ≤ 0.0295 Ω·mm²/m (20°C) | Increased load losses, thermal instability |

| Elongation (min) | ≥ 1.5% | Micro-cracking during winding, insulation breach |

| Ovality (max) | ≤ 0.01 mm | Uneven enamel coating, hot spots, reduced dielectric strength |

| Thermal Class | IEC 60264 Class 155/180/200 | Accelerated insulation aging, reduced transformer lifespan |

| Adhesion (post-bake) | Pass IEC 60851-5 Test 4 | Enamel delamination, inter-turn shorts |

Supplier capability in maintaining these parameters through advanced process control—from high-purity molten metal treatment and precision rod casting to multi-layer enamel application and curing—is paramount. Luoyang Xinzhaohe Aluminum leverages two decades of specialized production expertise and integrated quality management systems to deliver wire meeting the most stringent transformer OEM specifications, ensuring operational reliability and compliance with evolving global energy efficiency standards.

Technical Specs: Enamelled Aluminum Wire

Technical Specifications for Enamelled Aluminum Winding Wire

Enamelled aluminum wire is a critical component in electrical and electronic applications, particularly in motors, transformers, and inductors where lightweight, cost-effective conductors with reliable dielectric performance are required. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience, our enamelled aluminum winding wires are engineered to meet stringent international standards, ensuring consistent performance across demanding operational environments. The following technical parameters define the core performance characteristics of our product line, focusing on insulation breakdown voltage, elongation, and thermal classification.

Insulation breakdown voltage is a primary indicator of the dielectric strength of the enamel coating. This parameter determines the wire’s ability to withstand high voltage stress without electrical failure. Our standard enamelled aluminum wires are tested under controlled conditions, with breakdown voltage measured using the step-up method per IEC 60317 and GB/T 4074 standards. The insulation system is designed to exceed minimum industry thresholds, providing robust protection against short circuits and dielectric degradation under operational loads. The breakdown voltage increases proportionally with enamel thickness and is validated across multiple wire diameters.

Elongation, measured as a percentage during tensile testing, reflects the ductility and mechanical resilience of the aluminum conductor. High elongation values are essential for successful winding processes, especially in automated coil winding systems where mechanical stress is significant. Our aluminum base material, typically 1350-O or equivalent soft temper, ensures elongation values remain within the optimal range, minimizing the risk of conductor fracture during fabrication. Consistent elongation performance supports tight bend radii and complex winding geometries without compromising structural integrity.

Thermal class defines the maximum continuous operating temperature the insulation system can endure while maintaining electrical and mechanical properties. Our product range spans thermal classes from 130°C to 220°C, achieved through advanced polymer coatings such as polyesterimide, polyamide-imide, and silicone-based formulations. Higher thermal classes enable operation in elevated temperature environments, enhancing reliability in applications such as hermetic compressors, traction motors, and industrial automation equipment. Each thermal class is verified through thermal endurance testing and thermal index determination per IEC 60216.

The table below summarizes key technical parameters across standard product variants:

| Parameter | Test Standard | Value Range (Typical) | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, GB/T 4074 | 2.5 kV – 8.0 kV (AC, 1 min) | Increases with wire diameter and insulation build |

| Elongation (Aluminum Core) | ASTM B317, GB/T 4909 | ≥25% – 40% (depending on diameter) | Measured at 25 mm gauge length |

| Thermal Class | IEC 60172, GB/T 11021 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on thermal index and aging tests |

| Conductor Material | ASTM B317, GB/T 3954 | 1350-O (Soft Annealed Aluminum) | High purity (≥99.5%) |

| Insulation Material | IEC 60317 | Polyesterimide, Polyamide-imide, Silicone | Multi-layer options available |

These specifications are maintained through rigorous in-process quality controls, including continuous monitoring of coating thickness, spark testing for insulation defects, and batch-level mechanical and thermal validation. Custom configurations are available to meet specific OEM requirements.

Factory Tour: Manufacturing

Manufacturing Process for High-Performance Enamelled Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to produce enamelled aluminum winding wire meeting stringent global standards. Our integrated production sequence ensures optimal electrical, thermal, and mechanical properties for demanding applications like motors, transformers, and inductors. The process begins with high-purity aluminum rod (99.7% min) sourced from certified suppliers, verified for resistivity ≤0.028264 Ω·mm²/m at 20°C.

Rod Drawing

The rod undergoes precision cold drawing through tungsten carbide dies in a multi-pass system, reducing diameter to the target specification (typically 0.08–3.00 mm). Critical parameters include controlled reduction ratios per pass (≤15%) and continuous lubrication with synthetic emulsions to prevent surface defects. In-line diameter monitoring via laser micrometers maintains tolerances within ±0.005 mm. Post-drawing, the wire is cleaned in alkaline solutions to remove residual lubricants and oxides, ensuring optimal surface adhesion for subsequent enameling.

Annealing

Continuous annealing in a nitrogen-purged furnace (oxygen content <10 ppm) eliminates work hardening from drawing. Temperature profiles are calibrated to aluminum’s recrystallization kinetics (typically 300–450°C), with precise dwell time control to achieve target tensile strength (60–100 MPa) and elongation (≥15%). Atmosphere dew point is maintained below -40°C to prevent oxide formation, which compromises conductivity. Real-time conductivity verification (≥61% IACS) occurs via eddy current testing before enameling.

Enameling

The wire enters a multi-zone enameling system where liquid polymer resin (typically polyurethane, polyesterimide, or polyamide-imide) is applied via precision capillary or dip-coating. Critical process controls include:

Resin viscosity (measured hourly at 25°C)

Oven temperature gradients (250–450°C across 6–12 zones)

Curing speed (5–50 m/min, adjusted for film thickness)

Solvent recovery efficiency (>95%) for environmental compliance

Multiple coats build the insulation layer to exact thickness tolerances (±5% of nominal), with intermediate cooling between layers to prevent blistering.

Inline Testing and Quality Control

Every meter undergoes non-destructive verification:

| Test Parameter | Standard | Frequency |

|—————————|———————–|———————|

| Spark Test Voltage | 3.0 kV (min) | 100% continuous |

| Elongation at Break | ≥15% | Every 2 hours |

| Film Thickness | Per IEC 60317 | Every 30 minutes |

| Thermal Shock (200°C) | Zero cracks | Per batch |

| Adhesion (Mandrel Bend) | No flaking | Per batch |

Final QC includes batch-level verification of thermal class (up to 220°C), solderability (280°C/3s), and chemical resistance. All data is logged in our traceability system, linking each reel to raw material certificates, process parameters, and test results. This closed-loop approach ensures zero-defect delivery while meeting IEC 60216, ASTM B354, and customer-specific requirements. Our facility’s ISO 9001 and IATF 16949 certifications underscore systematic adherence to these protocols, minimizing field failure risks for end-users.

Packaging & Logistics

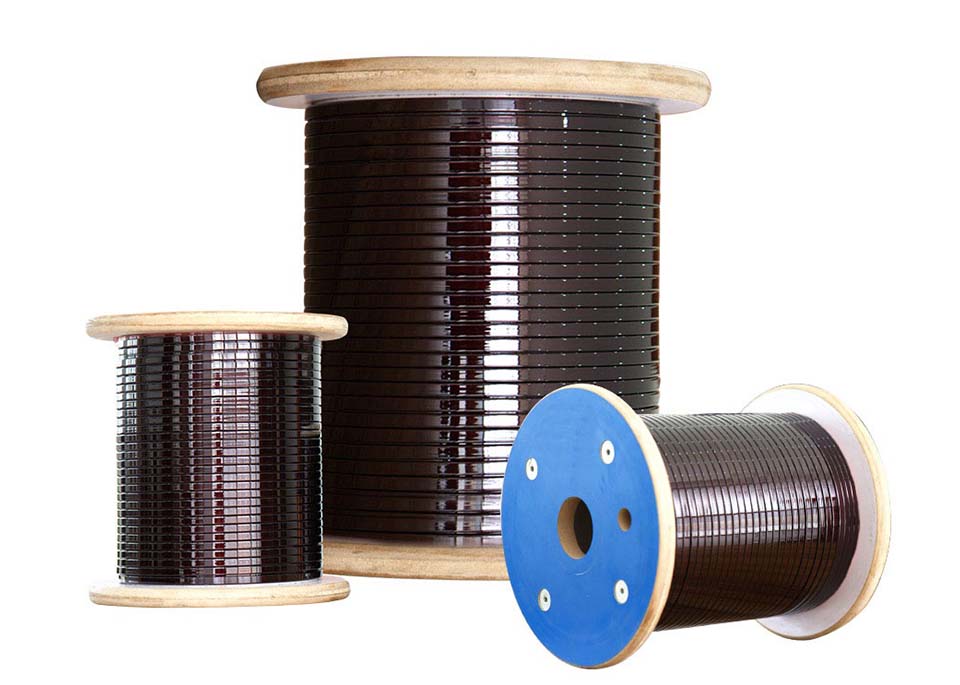

Export Packaging for Enamelled Aluminum Winding Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in enameled aluminum winding wire, we maintain rigorous standards in export packaging to ensure product integrity during international transit. Given the hygroscopic nature of enamel insulation and the susceptibility of aluminum conductors to oxidation and mechanical damage, our packaging methodology is engineered to mitigate risks associated with long-duration sea freight, variable climatic conditions, and multi-modal handling.

All export shipments of enameled aluminum wire are wound onto high-strength cardboard or composite spools, which are then secured onto robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to withstand stacking loads typical in containerized shipping and provide structural stability during crane lifts and forklift handling. The use of ISPM 15-certified wood ensures compliance with international phytosanitary regulations, eliminating the risk of customs delays due to non-compliant dunnage materials.

Each spool, once mounted on the pallet, is hermetically sealed using multilayer moisture-proof film consisting of aluminum foil laminate with low water vapor transmission rate (WVTR < 0.5 g/m²/day). This vapor barrier film is heat-shrunk to eliminate air pockets and prevent internal condensation, a critical safeguard during transoceanic voyages where temperature fluctuations between tropical and temperate zones can induce dew point conditions within containers. The sealed assembly is further protected by a secondary outer wrap of UV-resistant polyethylene, offering abrasion resistance and additional defense against salt-laden atmospheres encountered in maritime environments.

Palletized units are labeled with standardized industrial markings, including batch number, wire specification (AWG/mm², enamel class, temper), net weight, and handling indicators such as “Do Not Invert” and “Protect from Moisture.” These labels are printed on weather-resistant synthetic paper to maintain legibility throughout the logistics chain.

For container loading, pallets are arranged in interlocking patterns to minimize lateral movement, with dunnage and edge protectors used to prevent chafing. We recommend shipment via dry van containers with humidity control desiccants for consignments bound for high-humidity destinations or extended storage scenarios.

This comprehensive packaging protocol ensures that enameled aluminum winding wire arrives at its destination with preserved dielectric strength, surface finish, and tensile properties—critical parameters for downstream processing in motor, transformer, and inductor manufacturing. As a trusted supplier with extensive export experience across Southeast Asia, Europe, and the Americas, Luoyang Xinzhaohe Aluminum Co., Ltd. integrates material science expertise with logistical precision to deliver reliability from factory to end-user.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Engineering Precision in Enamelled Aluminum Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and manufacturing expertise to deliver industry-leading enamelled aluminum winding wire. Our vertically integrated production facility in Luoyang, China, is engineered for consistent quality and technical performance, directly addressing the stringent demands of transformer, motor, and inductor manufacturers globally. We transcend basic supplier status by embedding metallurgical science into every production phase, ensuring our wire meets the exacting electrical and mechanical requirements critical for modern electromagnetic components.

Our core strength originates in advanced aluminum metallurgy and precision drawing. We utilize high-purity primary aluminum ingots (99.99% min) with proprietary alloying and grain structure refinement protocols. This foundational control, combined with computerized tension management and optimized die geometry throughout the multi-pass drawing process, achieves exceptional dimensional stability and surface integrity across diameters from 0.08mm to 3.00mm. Crucially, our proprietary annealing profiles precisely balance conductivity (exceeding 61% IACS minimum) with the necessary elongation and tensile strength for reliable high-speed winding operations, minimizing breakage and enhancing coil fill factors.

Production capacity is robust and flexible, supporting annual outputs exceeding 15,000 metric tons. We operate fully automated enamelling lines equipped with precision metering systems for polyurethane (PU), polyester (PE), and polyesterimide (PEI) coatings. Each line features real-time viscosity and temperature control, ensuring uniform insulation thickness (±5% tolerance), excellent dielectric strength (>2000V), and superior thermal class performance (up to 220°C). Our process guarantees consistent enamel adhesion, flexibility, and chemical resistance, directly contributing to the longevity and reliability of the end-product windings. Key technical capabilities are summarized below.

| Parameter | Capability Range | Standard Compliance |

|---|---|---|

| Wire Diameter | 0.08mm – 3.00mm | IEC 60317, GB/T 23312 |

| Conductivity | ≥ 61% IACS (Typical 61.5-62.5% IACS) | ASTM B230 / B630 |

| Enamel Types | PU, PE, PEI, Dual Layers | IEC 60851, NEMA MW |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 |

| Annual Capacity | > 15,000 MT |

Rigorous quality assurance is non-negotiable. Our ISO 9001-certified laboratory implements 100% in-line testing for diameter, ovality, and electrical continuity, supplemented by comprehensive batch testing for conductivity, elongation, thermal shock, scrape resistance, and solderability. Advanced statistical process control (SPC) systems monitor critical parameters in real-time, enabling immediate corrective action and ensuring lot-to-lot consistency essential for automated manufacturing environments. Full material traceability from ingot to finished coil is standard practice.

Supply chain reliability is engineered into our operations. We maintain strategic raw material reserves and utilize lean manufacturing principles to ensure dependable lead times, typically 15-25 days for standard orders. Our global logistics network, with experience shipping to North America, Europe, and Asia, guarantees secure, on-time delivery via FCL/LCL or air freight, adhering strictly to Incoterms 2020. Partnering with Xinzhaohe means securing a stable source of technically superior enamelled aluminum wire backed by metallurgical insight and responsive engineering support.

Collaborate with our technical team to optimize your winding wire specifications and supply chain resilience. Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to discuss your project requirements and receive a detailed technical proposal and competitive quotation. Let Luoyang Xinzhaohe Aluminum be your engineered solution for high-performance enamelled aluminum conductor.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamelled aluminum wire directly from China.