Table of Contents

Market Insight: Enameling Wire

Market Analysis: Winding Wire – Enameling Wire Demand in Transformer Applications

The global demand for enameling wire, particularly in transformer manufacturing, continues to expand in response to increasing requirements for efficient power transmission, renewable energy integration, and industrial electrification. Enameling wire—commonly referred to as magnet wire—is a copper or aluminum conductor coated with a thin, electrically insulating polymer film. In transformers, it serves as the primary winding material responsible for enabling electromagnetic induction, making its performance critical to the operational reliability and efficiency of the equipment.

Transformers, whether distribution, power, or specialty units, rely on precise winding configurations to manage voltage transformation with minimal energy loss. The selection of high-quality enameling wire directly influences key performance parameters such as thermal endurance, dielectric strength, mechanical robustness, and resistance to thermal aging. As transformer designs evolve to meet higher efficiency standards (e.g., DOE 2016, IEC 60076), the electrical and thermal stresses on the winding system intensify, demanding superior insulation integrity and conductor consistency.

Industrial demand is further driven by the global shift toward compact, high-capacity transformers used in renewable energy systems, electric vehicle charging infrastructure, and smart grid technologies. These applications require enameling wire capable of withstanding variable loads, frequent thermal cycling, and harsh environmental conditions. In such contexts, substandard wire—characterized by inconsistent enamel thickness, micro-voids, or poor thermal class ratings—can lead to premature insulation breakdown, short circuits, and catastrophic transformer failure.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in winding wire production, we recognize that quality is not a final inspection criterion but an integrated outcome of precise process control. Our aluminum-based enameling wire is engineered to meet or exceed international standards including IEC 60317 and GB/T 23312. We utilize high-purity aluminum conductors (≥99.99%) and advanced enamel coating technologies to ensure uniform dielectric properties, excellent flexibility, and adhesion. Each batch undergoes rigorous testing for breakdown voltage, thermal shock resistance, and softening, pinhole, and abrasion performance.

Quality assurance extends beyond material specifications. Consistent dimensional tolerances, surface smoothness, and elongation properties are essential for automated winding processes prevalent in modern transformer manufacturing. Variability in these parameters can result in winding defects, increased scrap rates, and reduced throughput. Furthermore, long-term reliability in field operation depends on the wire’s ability to resist thermal degradation over thousands of hours at elevated temperatures—typically classified under thermal classes such as 130°C (Class B), 155°C (Class F), or 180°C (Class H).

As the transformer industry advances toward higher efficiency, smaller footprints, and longer service life, the role of high-performance enameling wire becomes increasingly strategic. Sourcing from a technically capable and quality-focused supplier is not merely a cost consideration but a critical factor in ensuring product reliability, compliance, and competitive advantage in the industrial supply chain.

Technical Specs: Enameling Wire

Technical Specifications for Aluminum Enameling Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise in aluminum conductor production to deliver enameling wire meeting stringent global industrial standards. Our technical specifications prioritize dielectric integrity, mechanical resilience, and thermal stability for demanding motor, transformer, and inductor applications. Critical parameters are rigorously controlled through in-line process monitoring and final product validation per IEC 60317 and equivalent standards.

Insulation breakdown voltage defines the dielectric strength of the polymer coating under electrical stress. This parameter is diameter-dependent and tested per IEC 60851-5 using AC (50 Hz) or DC voltage ramp methods. Minimum breakdown thresholds must exceed operational voltages by a safety margin to prevent arcing during transient surges. For aluminum enameling wire, film uniformity and adhesion to the conductor are paramount due to aluminum’s oxide layer dynamics. Our standard enamel systems achieve breakdown voltages starting at 1,200 V for 0.35 mm diameter wire, scaling proportionally with increased conductor size and insulation thickness.

Elongation at break, measured per IEC 60851-3, quantifies the wire’s ductility during winding operations. Aluminum inherently exhibits lower elongation than copper, necessitating precise annealing control. Values below 15% risk conductor fracture during tight-radius coiling, while excessive elongation (>30%) may indicate insufficient temper for mechanical stability. Our process optimizes annealing to deliver 18–25% elongation at 20°C, ensuring compatibility with high-speed automatic winders. Critical note: elongation degrades above 100°C; thermal class validation includes elevated-temperature elongation testing.

Thermal Class (IEC 60085) is the core indicator of insulation system longevity under thermal stress. Classes range from 130°C (B) to 220°C (C), denoting the maximum continuous operating temperature where the insulation retains ≥50% of its initial mechanical/electrical properties after 20,000 hours. Aluminum’s lower melting point (660°C vs. 1,085°C for copper) demands specialized enamel formulations to manage interfacial reactions at elevated temperatures. Our Class 180 (F) and 200 (H) wires utilize modified polyester-imide and polyamide-imide resins, validated through thermal endurance testing per IEC 60216. Continuous operation beyond the rated class accelerates thermal degradation kinetics, reducing service life exponentially per the Arrhenius model.

Key Parameter Specifications

| Parameter | Test Standard | Typical Range (Aluminum Wire) | Critical Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60851-5 | 1,200–5,000 V (AC/DC) | Diameter-dependent; min. 1.5x operating voltage |

| Elongation at Break | IEC 60851-3 | 18–25% (20°C) | Must maintain >12% at 150°C for Class 180 |

| Thermal Class | IEC 60085 | 130 (B) to 220 (C) | Validated via thermal aging at 20,000 hours |

| Conductor Resistivity | IEC 60889 | ≤0.028264 Ω·mm²/m (20°C) | Annealed grade; ±1.5% tolerance |

| Film Thickness | IEC 60317 | 30–120 μm (per class/diameter) | Uniformity critical for voltage endurance |

All parameters are interdependent; thermal class directly influences allowable elongation at operating temperature, while film thickness affects both breakdown voltage and flexibility. Luoyang Xinzhaohe’s quality system integrates these variables through statistical process control, ensuring batch-to-batch consistency for OEM production lines. Technical datasheets provide diameter-specific values and application engineering support for critical deployments.

Factory Tour: Manufacturing

Manufacturing Process of Enameling Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance enameling wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure consistent electrical, mechanical, and thermal properties. With over two decades of specialization in winding wire technologies, our process integrates advanced equipment, real-time monitoring, and rigorous quality control to meet international standards including IEC 60317 and GB/T 2367.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher) are fed into a multi-die drawing machine. The rod undergoes incremental diameter reduction through a series of tungsten carbide or diamond dies, transforming it from a standard 9.5 mm diameter down to the target wire gauge, which can range from 0.08 mm to 4.0 mm. Lubrication with water-soluble drawing oil ensures surface integrity and minimizes work hardening. The drawn wire is spooled onto precision take-up bobbins under constant tension control to prevent deformation.

Following drawing, the wire enters the annealing stage, a critical step to restore ductility lost during cold working. Our continuous annealing system employs resistance heating in a controlled nitrogen atmosphere to prevent oxidation. The temperature profile is precisely regulated between 300°C and 500°C depending on alloy and diameter, ensuring uniform recrystallization and optimal elongation (typically 18–25%). The annealed wire is immediately cooled using deionized water quenching to stabilize the microstructure.

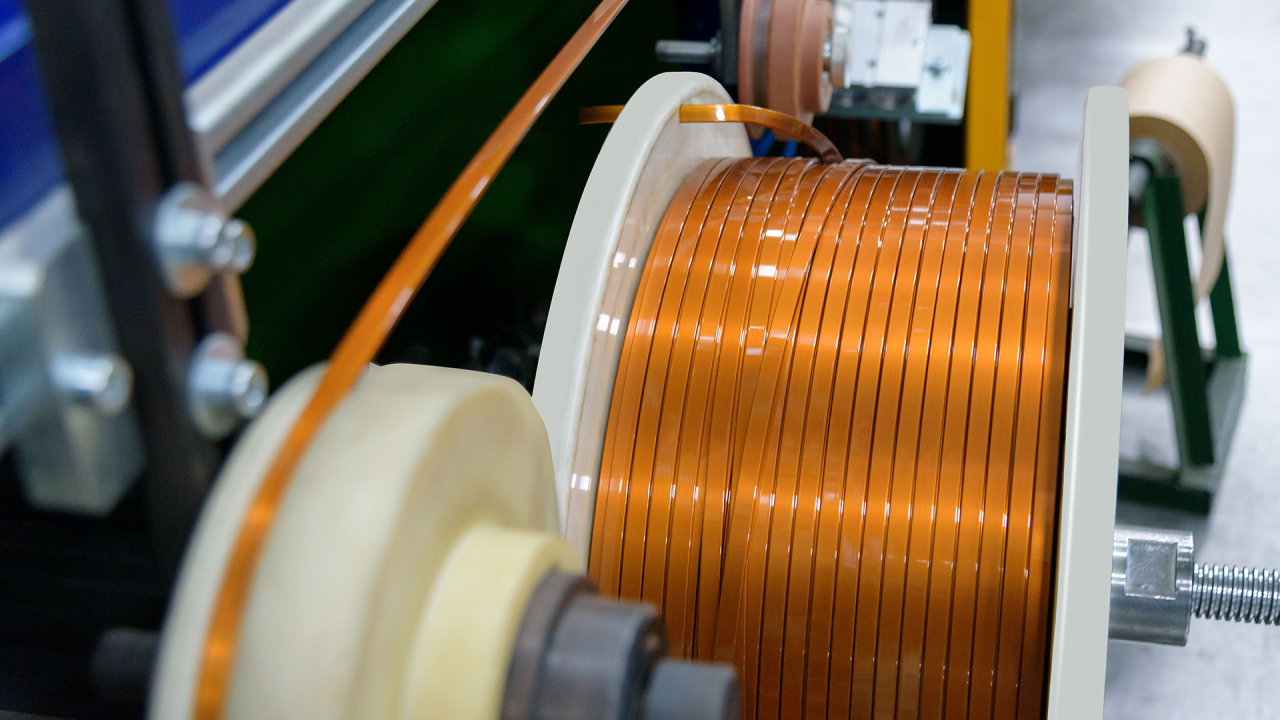

The enameling process involves applying multiple layers of thermosetting polymer insulation—commonly polyurethane (PU), polyester (PE), or polyamide-imide (PAI)—via a series of dip-and-cure stations. The wire passes through a coating die where enamel is applied, followed by pyrolysis ovens at 350–500°C to cure each layer. Depending on insulation class (e.g., Class 130, 155, 180, or 200), up to three layers may be applied to achieve dielectric strength ratings of 3,000–8,000 V. Film thickness is maintained within ±5% tolerance using laser micrometers and closed-loop feedback systems.

Throughout production, inline testing ensures compliance with electrical and mechanical specifications. Key tests include breakdown voltage measurement, conductor resistance verification, thermal shock resistance (per GB/T 23312.4), and scrape endurance. A high-voltage spark tester continuously monitors insulation integrity at 2–5 kV, rejecting any wire with pinholes or thin spots. Dimensional accuracy is verified using non-contact laser gauges sampling at 100 Hz.

Final quality control includes batch sampling for elongation, springability, and thermal aging performance. All test data are logged and traceable to production lot numbers. This integrated approach—combining precision engineering with systematic quality assurance—ensures that every coil of enameling wire from Luoyang Xinzhaohe meets the demanding requirements of motors, transformers, and electromechanical devices in industrial and automotive applications.

Packaging & Logistics

Export Packaging Specifications for Enameling Wire: Ensuring Integrity in Global Logistics

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing in precision winding wire, we recognize that export packaging is not merely a container but a critical component of product integrity assurance. Enameling wire, particularly aluminum-based variants, exhibits high sensitivity to moisture ingress and mechanical stress during extended maritime transit. Our engineered packaging system directly addresses the unique hazards of sea freight, including prolonged high humidity, salt-laden atmospheres, temperature fluctuations, and multi-modal handling stresses, thereby preventing hygroscopic degradation of the enamel insulation and core wire deformation.

All export shipments utilize robust, ISPM 15 compliant wooden pallets as the foundational structural element. These pallets are fabricated from kiln-dried, heat-treated softwood meeting stringent international phytosanitary standards, eliminating pest risks and minimizing residual moisture content. Pallet dimensions and load-bearing capacity are rigorously selected based on coil weight and external diameter, ensuring stability under ISO container stacking loads exceeding 5 tons. Critical reinforcement includes edge protectors on all four sides and base blocking to prevent coil shifting during vessel motion or crane handling. This structural integrity is non-negotiable for maintaining coil geometry and preventing wire buckling or edge damage during the typical 30-45 day sea voyage.

The primary moisture barrier employs a multi-layer, high-performance moisture-proof film system. A minimum 0.1mm thick aluminum composite film, featuring low water vapor transmission rate (WVTR < 0.5 g/m²/day per ASTM F1249), forms the essential shield. This film is meticulously sealed using heat-welded seams around the entire palletized load, creating a hermetic enclosure. Internal desiccant packs, calculated at 50g per cubic meter of enclosed volume, actively absorb any residual atmospheric moisture. This dual-layer defense—barrier film plus desiccant—is validated through controlled humidity chamber testing simulating tropical maritime environments (95% RH, 35°C for 72 hours), confirming zero moisture penetration to the wire surface. Standard packaging configurations are detailed below.

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Pallet Type | ISPM 15 Heat-Treated Softwood | ISPM 15, EN 12195-1 |

| Film Thickness | ≥ 0.10 mm Aluminum Composite | ASTM F1249 (WVTR) |

| Seal Integrity | Continuous Heat-Welded Seams | Internal Procedure XP-7 |

| Desiccant Loading | 50g / m³ Enclosed Volume | MIL-D-3464E |

| Stack Test Load | ≥ 5,000 kg (Static, 48hrs) | ISO 10531 |

This integrated packaging protocol, refined through 20+ years of global shipments to demanding markets including Southeast Asia, Europe, and the Americas, directly mitigates the leading causes of in-transit damage: corrosion under insulation and coil deformation. We document a 99.7% intact delivery rate for properly packaged enameling wire consignments, underscoring the system’s efficacy. Partnering with certified freight forwarders experienced in hazardous material handling (enameling wire often requires Class 9 labeling due to flammability of insulation solvents) further ensures seamless customs clearance and optimal stowage below deck, away from container walls prone to condensation. For critical high-value orders, optional vacuum sealing or nitrogen purging within the film enclosure is available, providing an additional layer of atmospheric control for ultra-sensitive applications. Our packaging is engineered not just to contain, but to actively preserve the metallurgical and electrical properties of your wire from factory gate to production line.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Enameling Wire

With over two decades of specialized experience in the production of winding wire, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global enameling wire supply chain. Our core focus on aluminum-based enameled wire solutions has enabled us to develop deep technical expertise, advanced manufacturing capabilities, and a robust quality assurance framework tailored to the demanding requirements of electric motors, transformers, and other electromagnetic applications.

Our manufacturing facility spans over 30,000 square meters and is equipped with fully automated drawing, annealing, and enamel coating lines. We operate under strict ISO 9001:2015 and IATF 16949 quality management systems, ensuring consistency and traceability across every production batch. Our process begins with high-purity electrolytic aluminum rod (Al ≥ 99.7%), which undergoes precision cold drawing to achieve tight dimensional tolerances—down to ±0.005 mm for fine gauges. The drawn wire is then coated with multiple layers of thermosetting polymer insulation, including PEI, PAI, and polyester-imide systems, providing thermal classes up to 220°C (Class R). Each spool undergoes 100% spark testing at 3 kV and rigorous post-coating inspection for dielectric strength, flexibility, and thermal shock resistance.

We specialize in aluminum enameled round wire ranging from 0.08 mm to 4.0 mm in diameter, with custom configurations available upon request. Our product line supports international standards, including IEC 60317, GB/T 23312, and NEMA MW-74-C, and is widely adopted in energy-efficient motor manufacturing, household appliances, and industrial automation systems. In addition to standard products, we offer technical collaboration for application-specific formulations, such as high-frequency compatibility, enhanced moisture resistance, and lead-free solderability.

Vertical integration is a cornerstone of our operational strategy. By controlling the entire production cycle—from raw material sourcing to final packaging—we ensure supply chain stability, cost efficiency, and rapid response to customer specifications. Our in-house R&D team, composed of metallurgists and polymer chemists, continuously advances coating adhesion, thermal endurance, and mechanical durability. This technical depth allows us to support clients during prototyping, qualification, and volume production phases.

With an annual production capacity exceeding 15,000 metric tons and export experience in over 30 countries, Luoyang Xinzhaohe delivers reliable, scalable supply with on-time delivery rates above 98%. We maintain strategic stock inventory for fast-turnaround orders and offer OEM packaging with custom labeling.

For engineers, procurement managers, and technical buyers seeking a long-term partner in enameling wire, Luoyang Xinzhaohe Aluminum Co., Ltd combines industrial precision with responsive service. Contact us today to discuss your technical requirements.

Contact: Cathy Zhang

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enameling wire directly from China.