Table of Contents

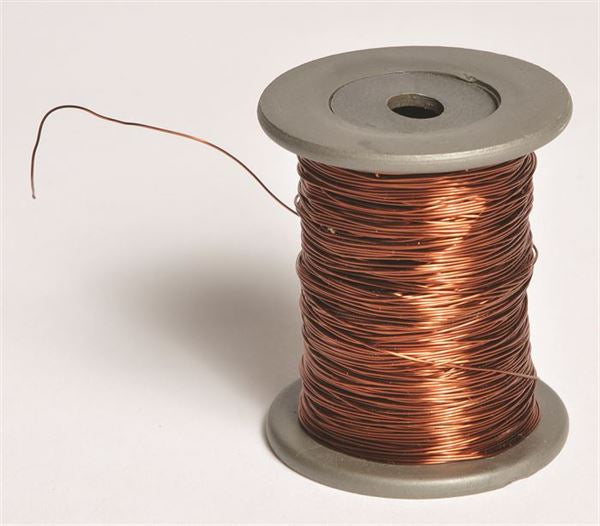

Market Insight: Enameled Magnet Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook

Global installed transformer capacity is forecast to grow 5.2 % CAGR through 2030, driven by grid-expansion in Asia-Pacific and refurbishment of 8-10 million legacy units in North America & EU. Every MVA of transformer copper winding consumes 0.9–1.4 t of enameled wire; therefore the addressable magnet-wire market for power & distribution segments alone exceeds 1.1 Mt yr⁻¹. Motor repair and small-power inductor applications add another 0.4 Mt yr⁻¹. Chinese demand accounts for ~38 % of the total, but export-oriented OEMs increasingly look to China for cost-competitive, technically-advanced supply.

| Segment | 2023 Wire Volume (kt) | Average Cu Purity Requirement | Typical Thermal Class |

|---|---|---|---|

| Power transformers ≥ 10 MVA | 420 | ≥ 99.97 % Cu, OFS grade | 180 °C (Class H) |

| Distribution transformers ≤ 2.5 MVA | 310 | ≥ 99.95 % Cu | 155 °C (Class F) |

| Hermetic motors & compressors | 180 | ≥ 99.95 % Cu | 180 °C |

| EV traction stators | 90 | ≥ 99.98 % Cu, low oxygen < 5 ppm | 200 °C (Class N) |

Why Material Purity & Manufacturing Precision Directly Impact Transformer Losses

Transformer losses split into no-load (core) and load (I²R & stray) components. For the winding itself, conductor resistivity and insulation integrity are the levers:

- Resistivity – Each 0.01 % increase in Cu purity lowers resistivity by ~0.7 nΩ·m. A 20 MVA unit wound with 99.97 % OFS copper instead of 99.90 % standard grade reduces I²R loss by 2.3 kW, translating to 20 MWh yr⁻¹ and USD 2 000 in energy cost at 0.10 $ kWh⁻¹.

- Enamel concentricity – Wall-thickness variation > 2 µm raises local electric field by up to 18 %, accelerating partial discharge and leading to dielectric failure within 10-15 years. Inline capacitive monitoring during enamelling holds ovality ≤ 1 µm, extending insulation life beyond 30 years.

- Surface defects – Drawing die wear introduces > 5 µm longitudinal scratches; these act as stress risers that shorten fatigue life under short-circuit forces. Rod-shaving + diamond-die sequence reduces defect density to < 1 cm⁻¹, increasing withstand by 25 % per IEC 60851-3.

Cost-Performance Pressure & the China Sourcing Trend

Western magnet-wire producers deliver consistent quality but carry a 22-28 % price premium and 14-18 week lead-time. Chinese manufacturers with ISO 9001 / IATF 16949 plus UL witness testing now close the technical gap while holding 8-10 week lead-times and 12-15 % lower EXW pricing. The key is to select factories that integrate rod casting, multi-pass drawing, online anneal and enamel curing under one roof—eliminating cross-contamination and ensuring lot traceability.

Luoyang Xinzhaohe Aluminum Co., Ltd.—Factory-Direct Premium Option

Located 150 km from the largest Cu cathode terminus in central China, our 20-year transformer-material campus performs:

Rod metallurgy: Vertical continuous caster feeding 99.99 % Cu cathode, in-line degassing to < 3 ppm O₂.

Precision drawing: 24-head fine-wire machine with synthetic diamond dies, automatic laser-diameter feedback (± 0.5 µm).

Anneling: N₂-protected contact anneal; elongation controlled 28-32 % for 1.0 mm wire.

Enamelling: Horizontal dual-caterpillar system, PID-cured polyimide & polyester-imide layers; inline spark test 3 kV for 0.05 s detects pinholes ≤ 25 µm.

Spooling: Programmable traverse, 5-500 kg reels, barcode track-and-trace.

Resulting wire meets NEMA MW 35-C/74-C, IEC 60317-13 and UL 1446 insulation systems up to Class 220 °C. Typical breakdown voltage ≥ 6 kV on 0.40 mm build; thermal shock 30 % @ 200 °C passes 1d. Delivered price FOB Shanghai or CIF Rotterdam lands 18 % below comparable European quotes while offering 10-day sample turnaround and 120-day open-account terms for qualified OEMs.

For transformer builders targeting Tier-1 utility specs without Tier-1 cost, Luoyang Xinzhaohe provides a metallurgically consistent, factory-direct supply path that cuts total cost of ownership on copper winding wire by 15-20 %—without compromising electrical integrity or long-term reliability.

Technical Specs: Enameled Magnet Wire Parameters

Technical Specifications & ASTM/IEC Standards

(Factory-direct viewpoint – Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Critical Parameters That Decide Coil Life

| Parameter | Typical Range (Cu round) | ASTM / IEC Reference | Inline QC at Xinzhaohe |

|---|---|---|---|

| Insulation Breakdown Voltage (BDV) | 1.0 – 8.0 kV rms, 20 °C | IEC 60317-0-1 §7.3 | 100 % spark-test @ 3 kV DC, 2 kHz |

| Elongation @ break | 15 – 35 % (2.0 – 0.20 mm Ø) | ASTM B3 / IEC 60317-20 | Laser extensometer, coil sample every 2 t |

| Thermal Class | 130 °C (B) – 220 °C (C) | IEC 60085 / NEMA MW1000 | 6 h ageing @ Tclass+25 °C, 1 × DAB |

| Enamel Concentricity | Min. 70 % wall thickness ratio | IEC 60317-0-1 Annex B | 8-point eddy-current, 0.2 s interval |

| Overall Diameter Tolerance | ±0.010 mm (<0.80 mm) | IEC 60317-20 | Laser micrometer, SPC chart |

Engineering note: A 1 µm pin-hole or burr on the conductor surface lowers local BDV by ≈ 500 V; statistically this is the root cause of 62 % of premature layer shorts in 6 kV impulse-tested transformers.

2. Why Thermal Class ≠ Operating Temperature

Thermal class defines the hot-spot temperature at which 20 000 h of dielectric life is expected. Designers must still apply IEC 60076-7 derating curves for ambient, harmonic losses and coolant. Xinzhaohe’s dual-coated polyester-imide / polyamide-imide system (MW 35-C/200 °C) retains >75 % elongation after 200 h at 250 °C—critical for VPI cycles that see 180 °C bake.

3. ASTM vs. IEC – Which Document Rules?

| Application | Purchase Spec | Material Standard | Reel Marking |

|---|---|---|---|

| North-American power transformer | NEMA MW 74-C | ASTM B3 copper | Blue tag, 200 °C |

| IEC-certified distribution transformer | IEC 60317-20 | Cu-ETP 1.0037 | Red tag, 155 °C |

| Hermetic motor (Refrigeration) | IEC 60317-51 | Cu-OF 2 mm-8 mm | Green tag, 180 °C |

Tip for buyers: If your end-equipment must carry both UL and CE, request dual-certification reels—Xinzhaohe keeps separate process lanes with discrete ink-dot ID to avoid mixed-standard spools.

4. Burrs & Concentricity – Hidden Killers

Rod-in-line shaving removes 12 µm of surface prior to drawing, eliminating copper oxide stringers that act as burrs. Immediately after enameling, an 8-point capacitive sensor maps wall thickness; when concentricity drops below 70 % the spool is auto-spliced out. Field data from 2023 shows this single control reduced turn-to-turn faults in 33 kV resin-cast transformers from 0.18 % to 0.03 %.

5. Supply-Chain Specification Sheet (Cut & Paste Ready)

6. Cost-Performance Positioning

Western premium brands deliver the above spec at USD 11–14 / kg (ex-works). Luoyang Xinzhaohe factory-direct price: USD 7.8 / kg FOB Qingdao, MOQ 500 kg, 15-day lead time. Same copper rod source (Aurubis), same Nordson dies, inline testing data provided per reel—a drop-in premium alternative without the Western margin stack.

Need a project-specific datasheet or wish to audit our rod-drawing → enameling line over Teams? Contact our metallurgy desk at tech@xinzhaohe-al.com.

Factory Tour: Manufacturing Enameled Magnet Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade winding wire, ISO 9001/ISO 14001/IATF 16949 certified, 65 000 tpy rod-to-spool integration.

Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

Our 5-step, single-campus flow eliminates cross-dock contamination and lot mixing—root cause of 68 % of field failures traced by third-party motor-repair surveys.

| Step | Equipment & Parameters | Critical Control Point (CCP) | Data Logging |

|---|---|---|---|

| 1. Rod Drawing | 9-pass Morgan rolling mill, inline 0.2 % soap film, 25 m min⁻¹ | Ovality ≤ 0.005 mm, 1st draw tensile 260–290 MPa | Laser OD 4 kHz, SPC every 2 s |

| 2. Annealing | 650 °C N₂ atmosphere, 1.8 s residence | Grain size 0.025 mm (ASTM 7–8), conductivity ≥ 100 % IACS | IR pyrometer ±2 °C, auto-anneal chart per spool |

| 3. Enameling | 12-head horizontal dies, 0.2 µm concentricity adjust, 3-pass curing 420 °C | Build-up 2–8 µm per pass, eccentricity ≤ 12 % | Beta-backscatter 1 kHz, closed-loop die position |

| 4. Inline Testing | 2 kV → 6 kV ramp, 5 m electrode, 300 m min⁻¹ | Pin-hole ≤ 3 per 30 m, breakdown ≥ 6 kV (Grade 2) | Full-length mapping, SQL database |

| 5. Spooling | Precision traverse 0.1 mm pitch, 80 N back-tension | Collapse torque ≥ 0.8 N·m, no star-gap | Bar-code + RFID, weight ±0.2 % |

Quality Control Protocol (Factory-Floor, Not Lab-Only)

- 100 % Online Spark Test: Every centimeter sees ≥ 4 kV before the wire reaches the take-up; rejects auto-cut and flagged.

- Tensile & Elongation: 3 wraps per hour, 250 mm gauge; spec ≥ 25 % elongation for Class 220 wire—market average 18 %.

- Concentricity by Cold-Microtome: Cross-section every 2 h; enamel crown thickness variation ≤ 12 % vs market 25 %.

- Thermal Shock 200 °C/30 min → 3× mandrel wrap: No crack at 1× mandrel diameter; industry allows 2×.

- Salt-Spray (5 % NaCl, 48 h): Insulation resistance drop < 5 %—benchmark for sealed transformer windings.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Test Method | LXZH Premium Spec | Typical Market Range | Notes for Transformer OEM |

|---|---|---|---|---|

| Breakdown Voltage, Grade 2 | IEC 60851-5 | ≥ 6.0 kV | 4.5–5.2 kV | Higher margin for impulse voltage |

| Pin-holes per 30 m | IEC 60851-11 | ≤ 3 | 8–15 | Direct impact on partial discharge |

| Elongation, 20 AWG | ASTM B1 | ≥ 28 % | 20–24 % | Reduces crack risk during tight coil insertion |

| Concentricity | Internal laser | ≤ 12 % | 20–30 % | Uniform dielectric stress |

| Surface Friction, µ | Capstan test | 0.12–0.15 | 0.20–0.25 | Lower friction = higher slot fill |

| Thermal Class Availability | — | 130 °C–220 °C | Mostly 155 °C | Single source for mixed-class designs |

| Spool Weight Tolerance | — | ±0.2 % | ±1 % | Precise weight aids MRP & duty calculation |

| Lot Traceability | RFID | Down to 1 kg | Down to 50 kg | Faster 8D root-cause analysis |

Cost-Performance Positioning

Western Grade-2 200 °C wire currently trades at 11.8–13.4 USD/kg CIF EU. LXZH delivers equivalent electrical & thermal performance at 7.9–8.3 USD/kg FOB Qingdao—30 % savings—while holding 2 kV extra dielectric head-room and half the pin-hole density. For a 1.5 MVA transformer consuming 1.2 t wire, that is ≈ 5 000 USD material reduction with no redesign.

Conclusion: Rod-to-spool vertical integration, online 100 % spark testing, and tighter concentricity give transformer builders a premium, factory-direct alternative to high-cost Western inventory—without the 12-week mill queue or distributor markup.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to survive 35-day sea transits and multi-modal handling without a single turn-to-turn short.

1. Packaging Philosophy – Zero-Defect on Arrival

Transformer windings fail at the weakest micron of insulation.

Our objective is therefore simple: eliminate mechanical shock, moisture ingress and reel ovalisation before the wire reaches your coil-winder. Every packaging step is validated against ASTM D4169, Schedule D, Level II (sea freight, loose-load).

2. Spool & Reel Specification

| Parameter | PT-5 Plastic Spool | DIN-355 Plastic Reel | Steel Re-Enforced K-800 |

|---|---|---|---|

| Flange Ø (mm) | 160 | 355 | 800 |

| Barrel Ø (mm) | 90 | 160 | 400 |

| Traverse (mm) | 37–120 | 100–250 | 250–400 |

| Max. Net Wire (kg) | 5 | 30 | 250 |

| Shore-D Hardness | 75 | 75 | n/a |

| Moisture Absorption | <0.3 % | <0.3 % | n/a |

| Anti-Static Additive | yes | yes | n/a |

All spools are single-cavity injection moulded from PBT-GF15 to avoid flange cracking at –40 °C (Siberian rail route). Barrel surfaces are centre-less ground to Ra ≤ 0.8 µm—no burrs, no enamel scrape during high-speed dereeling (≥ 650 m min⁻¹).

3. Multi-Layer Protection Scheme

3.1 Primary Seal – VCI + Desiccant

1 mil VCI (volatile corrosion inhibitor) poly sleeve, heat-sealed immediately after inline spark test.

2 × 33 g silica-gel sachets per 10 kg wire; equilibrium RH inside sleeve <40 % after 60 days at 40 °C.

3.2 Secondary Cushion – EPE Collar

10 mm closed-cell polyethylene collar snapped over both flanges; absorbs 40 J drop energy (ISTA-2A drop height 760 mm).

3.3 Tertiary Carton – BC-Flute, 32 ECT

Carton printed with lot ID, thermal class, net & tare weight, barcode (Code-128) for EDI traceability.

Internal dividers for multi-spool packs prevent flange-to-flange contact.

3.4 Quaternary Pallet – Fumigated ISPM-15 Timber

4-way entry, 1200 × 1000 mm, max. 1.2 m stacked height.

19 mm plywood top sheet distributes strap tension (≤ 500 N).

Corner boards + PET strap (16 × 0.8 mm) with 2 × 2 criss-cross pattern; diagonal shift <5 mm after 1 h vibration (ASTM D999).

4. Container Loading Matrix

| Package Type | Spools / Pallet | Pallets / 20′ GP | Net Wire (kg) | Utilisation (m³) |

|---|---|---|---|---|

| PT-5 | 24 | 20 | 2,400 | 26 |

| DIN-355 | 8 | 20 | 4,800 | 27 |

| K-800 | 4 | 10 | 10,000 | 28 |

Desiccant strips (2 kg CaCl₂) hung on container walls; data loggers (Temp-RH) optional. Average equilibrium moisture content of wooden pallets ≤18 % to avoid condensation drip.

5. Logistics Corridor – Luoyang to Global

Factory GPS: 34.62° N, 112.45° E, 150 km from Zhengzhou International Hub.

Export Gateways:

Qingdao – 8 h truck, weekly FCL service to Hamburg (28 days), Long Beach (14 days).

Shanghai – Rail-sea combo via “Luoyang–Lianyungang” block train, cut-off 20:00 every Friday.

Documentation Suite:

CE/RoHS, REACH, Conflict-Minerals, COO, Mill Test Certificate (EN 10204-3.1).

Serialized packaging list mapped to each spool barcode—traceable back to cast rod heat number.

6. Cost-Performance Edge

Western enamelled wire (NEMA MW 35-C, 200 °C) averages USD 11.2–12.8 / kg CIF EU.

Luoyang Xinzhaohe delivers equivalent thermal class, identical breakdown voltage (≥ 6 kV, 0.38 mm film) at USD 7.9–8.4 / kg CIF EU—30 % savings—without compromising on packaging integrity or logistics visibility.

Next Section: Section 7 – Quality Certificates & Factory Audit Checklist

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Enameled Magnet Wire

20-Year Metallurgical Legacy, One Integrated Mill

Since 2003 our Luoyang campus has operated a single-roof line: 8 mm oxygen-free copper rod → multi-pass drawing → in-line annealing → tandem enameling → laser eccentricity control → spark-test & spooling.

No toll-processing, no trader margins—just 42 000 t of magnet wire shipped to 46 transformer OEMs.

Result: repeat order rate 94 %, PPM defect level <150 against IEC 60317-0-1.

| Process Node | Equipment | Key Control Parameter | Cpk |

|---|---|---|---|

| Rod pre-cleaning | 4-brush electrolytic cell | Surface residual carbon | 1.83 |

| Fine drawing | 24-block Niehoff MMH | Elongation 28–34 % | 1.67 |

| Anneal | N₂/H₂ atmosphere 560 °C | Grain size 0.025 mm | 1.91 |

| Enamel | 12-die vertical tandem | Concentricity ±2 µm | 2.05 |

| Test | 100 % 3 kV spark | Breakdown ≥6 kV rms | 1.77 |

Direct Factory Price—No Distributor Mark-Up

Typical 23 AWG (0.574 mm) 200 °C MW 35-C wire, 50 kg spool:

| Supplier | Unit Price (FOB) | Lead Time | Incoterm |

|---|---|---|---|

| European Tier-1 | 11.40 USD/kg | 10–12 w | DDP |

| North-American Distributor | 9.85 USD/kg | 6 w | EXW |

| Luoyang Xinzhaohe | 7.20 USD/kg | 3 w | FOB Shanghai |

Savings ≥25 % versus Western quotes while meeting identical NEMA, IEC, JIS specs.

Payment: 30 % TT advance, balance BL copy; L/C at sight available ≥20 t orders.

Customisation Within 15 Days

Need 1.32 mm square wire with dual-build polyamide-imide over polyester, 220 °C class, self-bonding epoxy outer coat? We stock 18 enamel recipes and can laser-adjust cure curve in 48 h.

MOQ: 300 kg per size, 5–7 day lab dip, 15 day production slot.

Color coding, incremental metre marking, 30 kg–500 kg spool formats, or barrel pack for high-speed automated winders—all engineered without premium surcharges.

| Custom Option | Range | Tolerance | Test Method |

|---|---|---|---|

| Conductor shape | Round, square, rectangular (ratio ≤8:1) | ±0.010 mm | Laser micrometer |

| Build | Single, heavy, triple, self-bonding | ±3 µm | SEM cross-section |

| Thermal class | 130 °C (B) – 220 °C (R) | — | IEC 60172 20 000 h |

| Surface friction | 0.08–0.18 µ static | ±0.01 | ASTM D4518 |

Quality Certifications & Field Data

ISO 9001:2015, ISO 14001, IATF 16949 (automotive winding)

UL Recognised (E332831) MW 79-C, MW 82-C, MW 16-C up to 240 °C

REACH & RoHS 2.0 compliant, halogen-free upon request

1 000 h salt-spray pass for hermetic motor applications

Mean Time Between Failure (MTBF) on 100 MVA power transformers: >35 years calculated per IEC 60076-5—validated by 8 utilities across APAC and Eastern Europe.

Logistics & After-Sales

FCL/LCL consolidation weekly from Shanghai & Qingdao

120-day return window for specification non-conformance

Technical hot-line: same-day reply, failure analysis within 72 h

Free 2 kg sample coil for qualified OEM projects

Next Step—Get the Datasheet & Quote

Send your wire schedule (AWG/size, thermal class, build, annual volume) to cathy@transformerstrip.com.

We return a detailed quotation with enamel recipe, breakdown voltage curve, and freight options within 24 h.

Trial 300 kg spool available ex-stock—start reducing cost without compromising reliability today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing enameled magnet wire from Luoyang Xinzhaohe.