Table of Contents

Market Insight: Enameled Copper Wires

Market Analysis: Industrial Demand for Enameled Copper Winding Wire in Transformers

Global transformer manufacturing represents a dominant and structurally growing application segment for high-performance enameled copper winding wire. This demand is fundamentally driven by continuous expansion and modernization of electrical infrastructure worldwide, coupled with the accelerating adoption of renewable energy integration systems, electric vehicle charging networks, and industrial automation. Transformers require winding conductors that deliver exceptional and consistent electrical conductivity, thermal stability, and mechanical integrity throughout decades of operational life under varying load and environmental conditions. Copper remains the conductor material of choice due to its superior conductivity compared to alternatives, making enameled copper wire the indispensable core component for efficient electromagnetic energy transfer within these critical power assets.

The stringent performance requirements of modern transformers elevate the significance of enameled wire quality beyond mere conductivity. Precise control over copper purity (minimum 99.99% Cu, low oxygen) is non-negotiable to achieve target resistivity and prevent embrittlement. The enamel insulation system must provide robust dielectric strength, thermal endurance matching the transformer’s designated class (e.g., Class 180, 200, 220 per IEC 60317), and exceptional adhesion to the copper substrate. Crucially, the wire must exhibit high elongation (>25%) and consistent tensile strength to withstand the significant mechanical stresses of high-speed winding processes without breakage or surface damage that could compromise insulation integrity. Dimensional tolerances on both conductor diameter and enamel thickness must be held within extremely tight specifications (±0.005mm typical) to ensure optimal fill factor within winding windows and predictable electrical performance.

Quality deviations in enameled copper wire directly translate to transformer reliability risks and lifecycle cost escalations. Substandard enamel adhesion leads to delamination under thermal cycling, creating partial discharge sites. Inadequate thermal class rating accelerates insulation degradation, shortening transformer lifespan and increasing the probability of catastrophic failure. Variations in copper purity or diameter increase resistive losses (I²R losses), reducing operational efficiency and generating excess heat. Pinholes or thin spots in the enamel, often undetectable visually, are primary initiators of interturn short circuits – a leading cause of in-service transformer failures. These failures result in costly unplanned downtime, expensive repairs or replacements, and significant collateral damage to connected equipment. The total cost of ownership for a transformer is heavily influenced by the initial quality of its winding materials; investing in premium enameled copper wire from suppliers with rigorous metallurgical process control and comprehensive quality assurance protocols is therefore a critical risk mitigation strategy, not merely a procurement cost. Luoyang Xinzhaohe Aluminum CO., Ltd leverages over 20 years of specialized expertise in conductor and insulation science to consistently deliver enameled copper wire meeting the most demanding global transformer specifications, ensuring reliability and performance for our industrial partners.

Technical Specs: Enameled Copper Wires

Technical Specifications for Enamel-Coated Copper Winding Wires

Enamel-coated copper wire, also known as magnet wire, is a critical component in the manufacturing of electromagnetic devices such as motors, transformers, relays, and inductors. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in precision wire production, we emphasize adherence to international standards and rigorous quality control to ensure optimal performance under demanding thermal and electrical conditions. The technical specifications of enameled copper wire directly influence its reliability, efficiency, and service life in end-use applications.

One of the most critical electrical parameters is the insulation breakdown voltage, which measures the dielectric strength of the enamel coating. This value indicates the maximum voltage the insulation can withstand before electrical failure occurs. For standard single-build enameled wires, breakdown voltage typically ranges from 1,500 to 3,500 Vrms depending on wire diameter and insulation thickness. Heavy build or dual-layer coatings can achieve breakdown voltages exceeding 5,000 Vrms, providing enhanced protection in high-voltage or high-stress environments. Testing is performed in accordance with IEC 60317 and ASTM D4566 standards using controlled immersion in a saline solution under increasing voltage stress.

Mechanical performance is equally vital, particularly elongation at break, which reflects the wire’s ductility and ability to withstand winding stresses without cracking the insulation. High elongation ensures the wire can be tightly wound around sharp corners or complex geometries without compromising insulation integrity. For soft-drawn electrolytic tough pitch (ETP) copper, elongation values typically range from 10% to 40%, depending on wire gauge and temper. Finer gauges exhibit lower elongation due to work hardening during drawing, while larger diameters maintain higher ductility. Proper annealing processes are employed to balance tensile strength and elongation, ensuring consistent spool-to-spool performance.

Thermal classification defines the maximum continuous operating temperature the wire can endure while maintaining electrical and mechanical integrity. Our enameled copper wires are available in thermal classes ranging from 130°C to 220°C, compliant with NEMA MW and IEC 60317 classifications. These ratings are determined through thermal endurance testing, including the modified rigid loop method, where insulation resistance is monitored after prolonged exposure to elevated temperatures. Higher thermal classes utilize advanced polymer coatings such as polyamide-imide (PAI), polyester-imide (PEI), or polyimide (PI), offering superior thermal stability, chemical resistance, and mechanical toughness.

The following table summarizes key technical parameters for standard enameled copper winding wires produced by Luoyang Xinzhaohe Aluminum Co., Ltd.:

| Parameter | Test Method | Typical Range / Value | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, ASTM D4566 | 1,500 – 5,000 Vrms | Increases with heavy build insulation |

| Elongation at Break | ASTM B3 | 10% – 40% | Depends on wire diameter and temper |

| Thermal Class | IEC 60317, NEMA MW | 130°C, 155°C, 180°C, 200°C, 220°C | Based on insulation system |

| Conductor Material | ASTM B3 | ETP Copper (Cu ≥ 99.95%) | High conductivity, low impurity |

| Diameter Tolerance | IEC 60122 | ±0.005 mm to ±0.020 mm | Tight tolerance for precision winding |

These specifications are validated through in-house testing laboratories equipped with thermal aging ovens, high-potential testers, tensile testers, and precision micrometers. Consistent compliance ensures that our enameled copper wires meet the stringent demands of industrial, automotive, and renewable energy sectors.

Factory Tour: Manufacturing

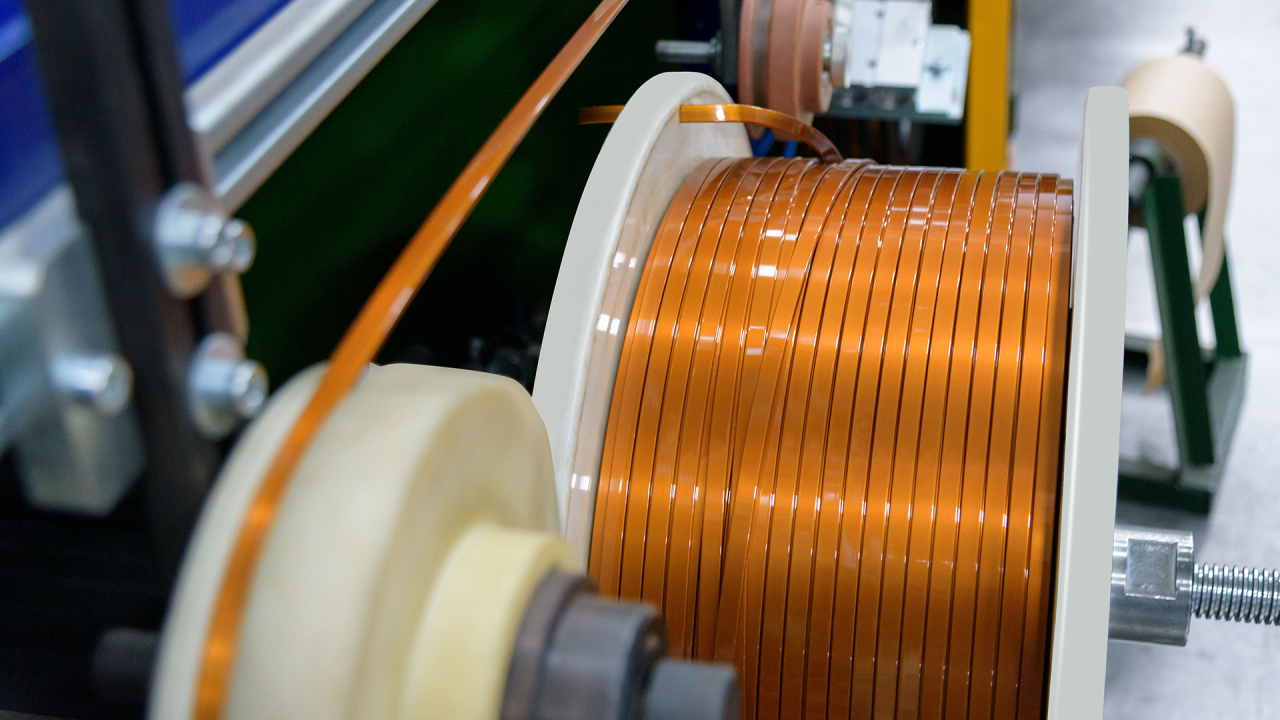

Manufacturing Process for High-Performance Enameled Copper Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of metallurgical and supply chain expertise to specify stringent production protocols for enameled copper winding wire, ensuring optimal performance in demanding electromagnetic applications. Our technical oversight emphasizes a rigorously controlled sequence: Rod Drawing, Annealing, Enameling, and Inline Testing, with integrated Quality Control (QC) at each critical juncture.

The process initiates with high-conductivity electrolytic tough pitch (ETP) copper rod, typically conforming to ASTM B3 or IEC 60468 standards. Rod Drawing reduces the diameter to the precise gauge required, utilizing multi-die block systems under strict tension control. Surface integrity is paramount; dies are meticulously maintained, and intermediate cleaning removes lubricants and oxides. In-process QC employs laser micrometers for continuous diameter monitoring, ensuring dimensional tolerance adherence (e.g., ±0.002 mm for 0.1 mm wire) and immediate detection of surface defects like scratches or pits. Statistical process control (SPC) charts track reduction ratios and mechanical properties.

Subsequent Annealing occurs in a continuous inert atmosphere furnace, typically nitrogen or nitrogen-hydrogen mix, to eliminate work hardening from drawing and restore optimal electrical conductivity (>100% IACS) and ductility. Precise temperature profiling (typically 450-600°C) and dwell time are critical; deviations cause grain growth inconsistency or oxidation. Real-time pyrometers and atmosphere analyzers verify conditions, while periodic QC checks measure hardness (e.g., via micro-Vickers) and conductivity per ASTM E8 and ASTM B193. Oxygen-free processing prevents hydrogen embrittlement risks.

The Enameling stage applies one or multiple polymer insulation layers (e.g., polyesterimide, polyamide-imide) via precision die coating. Solvent content, viscosity, and application speed govern film uniformity and adhesion. Curing occurs in multi-zone ovens with exact temperature ramping to volatilize solvents and fully imidize the resin. Critical QC parameters include dry film thickness (measured per IEC 60851-3, e.g., 0.03-0.15 mm tolerance), pinhole density (spark testing at 5-10 kV), and adhesion (mandrel bend test). Inline spectrophotometers may monitor color consistency for multi-layer systems.

Final Inline Testing validates electrical and mechanical integrity. Every meter undergoes high-potential (Hi-Pot) testing at specified voltages (e.g., 3x operating voltage + 1500V AC) to detect insulation weaknesses. Additional automated checks often include elongation measurement, thermal shock resistance (rapid cooling from 200°C), and solderability. A comprehensive final inspection per IEC 60317 standards verifies all parameters: dimensional accuracy, surface quality, electrical resistance, thermal class rating, and chemical resistance. Non-conforming lots are quarantined immediately, with root cause analysis driving corrective actions. This end-to-end controlled process, underpinned by Xinzhaohe’s metallurgical oversight, guarantees enameled wire reliability for motors, transformers, and inductors in global supply chains.

Packaging & Logistics

Export Packaging for Enamel-Coated Copper Winding Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and global distribution of high-performance winding wires, we recognize that export packaging is not merely a logistical necessity but a critical component in preserving product integrity during international transit. Enamel-coated copper wire, due to its sensitivity to mechanical damage, moisture, and environmental contamination, demands a packaging solution engineered for resilience, stability, and compliance with international shipping standards—particularly for sea freight, which remains the dominant mode of transport for bulk industrial materials.

Our standard export packaging system is built around robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the substantial weight of full spools—typically ranging from 250 kg to 1,000 kg—while maintaining structural integrity under dynamic loading conditions encountered during ocean transport. The use of interlocking joints and high-tensile fasteners ensures that the pallets resist deformation or collapse, even when subjected to stacking pressures in containerized shipments.

Each spool of enameled copper wire is meticulously wound and inspected prior to packaging. The spools are then sealed using multi-layer moisture-proof composite film, which acts as a primary barrier against humidity, salt spray, and condensation—common hazards in maritime environments. The film consists of aluminum-polyethylene laminates with a vapor transmission rate of less than 0.5 g/m²·24h, effectively minimizing moisture ingress. Sealing is performed under controlled conditions using heat-welded seams to ensure complete enclosure, preventing any exposure during extended voyages that may span multiple climatic zones.

Additional protective measures include the application of desiccant packs within the sealed film envelope and the use of edge protectors on pallet corners to prevent film punctures during handling. For orders requiring enhanced protection—such as those destined for tropical or high-humidity regions—we offer optional vacuum packaging or nitrogen-flushed enclosures to further mitigate oxidation risks.

All packaged units are clearly labeled with UV-resistant, tamper-evident tags containing traceability data, including batch number, wire specifications, production date, and handling instructions. This ensures full compliance with international logistics protocols and facilitates customs clearance. Pallet dimensions are optimized to maximize container utilization, supporting both 20-foot and 40-foot dry freight containers while adhering to weight distribution and center-of-gravity requirements.

Our packaging methodology has been validated through accelerated aging tests, real-world shipment monitoring, and feedback from long-term partners across Southeast Asia, Europe, and South America. By integrating material science with logistical engineering, Luoyang Xinzhaohe ensures that every coil arrives at its destination in the same condition as when it left our facility—ready for immediate integration into demanding applications such as motor windings, transformers, and electromagnetic devices.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Enamelled Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and manufacturing expertise to deliver enameled copper winding wire meeting the most stringent industrial demands. Our vertically integrated production facility, operational since 2003, is engineered for precision, consistency, and reliability in every meter produced. We transform high-purity electrolytic tough pitch (ETP) copper rod, verified to 99.99% Cu minimum, through a rigorously controlled sequence encompassing continuous drawing, annealing, enamel application, and curing. This end-to-end oversight ensures absolute traceability and adherence to international standards including IEC 60317, NEMA MW 1000, and GB/T 6109.

Our manufacturing strength resides in process control and material science application. State-of-the-art drawing lines maintain tolerances within ±0.001mm diameter variance, critical for high-speed automatic winding applications. Precise thermal management during annealing optimizes ductility without compromising conductivity, achieving consistent 100% IACS minimum. Enamel application utilizes multi-zone ovens with laser-guided thickness monitoring, guaranteeing uniform insulation build across thermal classes 130°C (Polyester) to 220°C (Polyester-imide, Polyamide-imide). Real-time spark testing at 3kV/mm and 100% continuity verification eliminate defects before shipment. This technical discipline directly translates to reduced machine downtime, minimized scrap rates, and enhanced end-product longevity for our clients’ motors, transformers, and inductors.

Quality assurance extends beyond production. Our ISO 9001-certified laboratory conducts comprehensive validation, including thermal endurance (155°C, 200°C), thermal shock (-65°C to 200°C), solderability, and dielectric breakdown testing. Batch-specific certificates of conformance detail key parameters:

| Parameter | Typical Capability | Test Standard |

|---|---|---|

| Diameter Tolerance | ±0.001mm (0.300mm wire) | IEC 60172 |

| Elongation | 35-40% | IEC 60468 |

| Dielectric Strength | >7kV (0.300mm wire) | IEC 60851-5 |

| Thermal Class | 130°C to 220°C | IEC 60317 series |

Supply chain resilience is engineered into our operations. Strategic raw material partnerships secure consistent high-purity copper supply, while our 12,000-ton annual production capacity accommodates large-volume contracts with flexible JIT delivery scheduling. Dedicated logistics management ensures on-time shipment globally, with packaging designed to prevent coil deformation during transit.

Partnering with Luoyang Xinzhaohe mitigates your winding wire supply risk through demonstrable metallurgical control, uncompromising quality systems, and scalable production. We resolve critical challenges in insulation integrity, dimensional stability, and supply continuity that impact your manufacturing efficiency and product performance. For immediate technical consultation or to specify requirements for your next transformer or motor production run, contact our Chief Technical Officer Cathy directly at cathy@transformerstrip.com. Provide your target thermal class, diameter range, and volume needs to receive a tailored production capability analysis within 24 hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enameled copper wires directly from China.