Table of Contents

Market Insight: Enameled Copper Winding Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Landscape

The installed base of power & distribution transformers is projected to exceed 70 million units by 2030, driven by grid expansion, renewable integration, and replacement of 25-year-old assets. Each MVA of transformer capacity consumes 0.8–1.2 t of enameled copper winding wire, translating into >1.2 Mt annual demand for magnet wire with thermal class ≥155 °C. Motor repair adds another 0.6 Mt, split between random-wound LV motors (0.2–1.0 mm) and precision-wound HV motors (0.05–0.5 mm). The compound annual growth rate (CAGR) for high-grade magnet wire is 5.4 %—twice that of generic copper conductors—because efficiency regulations (IEC 60076-20, DOE 2016, EU Ecodesign Tier 2) now penalize transformers exhibiting load losses >P0+1.15×Pk.

| Segment | 2023 Demand (kt) | 2030 Forecast (kt) | Thermal Class Mix |

|---|---|---|---|

| Power transformers >10 MVA | 280 | 410 | 60 % 180 °C, 30 % 200 °C, 10 % 220 °C |

| Distribution transformers ≤2.5 MVA | 520 | 680 | 45 % 155 °C, 45 % 180 °C, 10 % 200 °C |

| Industrial motors & generators | 580 | 760 | 70 % 155 °C, 25 % 180 °C, 5 % 200 °C |

Why Purity & Precision Translate into Lower Losses

Transformer losses fall into two categories:

- No-load (core) losses: Independent of conductor, but minimized only when turns can be reduced—achieved by using higher-conductivity copper that allows smaller cross-section for the same current.

- Load (I²R + stray) losses: Proportional to conductor resistivity and inversely proportional to wire geometry uniformity.

Using 99.99 % IACS-grade cathode instead of 99.90 % reduces dc resistance by 0.7 %; at 65 kA nominal current in a 100 MVA GSU transformer this equals 8 kW lower load loss, or USD 5 200/year at USD 0.06/kWh. More critical is enamel concentricity: a 3 µm radial variation on 1.25 mm wire creates local hot-spots Δθ≈6 °C, accelerating insulation ageing and forcing de-rating. Inline laser eccentricity control within ±1 µm keeps hot-spot rise <2 °C, preserving 98 % name-plate capacity at 180 °C thermal class.

| Parameter | Typical Chinese Tier-1 | Premium Western Mill | Luoyang Xinzhaohe Target |

|---|---|---|---|

| Cu purity | ≥99.95 % | ≥99.99 % | ≥99.99 % (C10100) |

| Resistivity @20 °C | ≤0.017 241 Ω·mm²/m | ≤0.017 240 Ω·mm²/m | ≤0.017 240 Ω·mm²/m |

| Enamel concentricity | ≤3 µm | ≤1.5 µm | ≤1 µm (inline laser) |

| Breakdown voltage | ≥4 kV (0.35 mm) | ≥6 kV | ≥7 kV (QZY-2/200) |

| Minimum lot size | 5 t | 1 t | 0.5 t (mill direct) |

Sourcing Shift: From High-Cost West to Experienced Chinese Specialists

Between 2015 and 2022 the share of Chinese-origin magnet wire in EU transformer plants rose from 12 % to 34 %. Key drivers:

Process maturity: Twenty-year-plus Chinese rod-drawing lines now achieve 0.1 % diameter tolerance, matching European DIN 46411 precision at 15–20 % lower cost.

Integrated supply chain: Cathode → rod → enamel → spool under one roof cuts logistics lead-time from 10–12 weeks (Europe) to 4–5 weeks (Luoyang-to-EU via rail/sea).

Compliance depth: ISO 9001 + IATF 16949 + UL (E345678) + REACH & RoHS full-substance declarations are standard offerings, not exceptions.

Luoyang Xinzhaohe Aluminum Co., Ltd.—despite its name—has operated a dedicated copper magnet-wire division since 2003, supplying 35 kV–500 kV transformer OEMs across 42 countries. Our 4-high rod mill, inline annealing at 550 °C with ±3 °C control, and digital enameling cells (Siemens 1500 PLC + Bergander pay-offs) deliver Class 200 (QZY-2/200) wire with 7 kV breakdown and ≤1 µm concentricity, yet priced 18–22 % below equivalent Western quotes. For transformer manufacturers facing copper price volatility, we offer formula-based Cu-rod index pricing plus consignment stock in Rotterdam and Houston, reducing working-capital tie-up by 30 %.

Bottom line: premium electrical performance no longer requires a premium geography. Specifying Luoyang Xinzhaohe magnet wire lets you hit Tier-1 loss targets without absorbing Tier-1 cost structure—freeing budget for core steel or amorphous upgrades that further cut no-load losses.

Technical Specs: Enameled Copper Winding Wire Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.

H3 1. Critical Wire Parameters for Transformer & Motor Windings

| Parameter | Symbol | Test Method | Luoyang Xinzhaohe Range | IEC 60317-0-1 Limit | ASTM B236/B298 Ref. | Field Impact |

|---|---|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd | 20 °C, 50 Hz, 500 V/s ramp | ≥ 6 kV (Grade 2) | ≥ 4 kV (Grade 2) | — | Prevents layer-to-layer short under impulse surges |

| Elongation at Break | A200 | 200 mm gauge, 50 mm/min | 30–38 % (0.20–1.00 mm) | ≥ 25 % | B298-20 | Absorbs thermal expansion without enamel crack |

| Thermal Class | TC | IEC 60172 ageing curve | 130 °C (B) – 220 °C (C) | Same | — | Dictates hotspot allowance; 10 K margin adds 50 % life |

| Enamel Concentricity | ECC | 8-point laser on-line | ≤ 8 % wall-thickness var. | ≤ 12 % | — | Avoids voltage stress spikes that start partial discharge |

Note: All values are lot-averaged; Cpk ≥ 1.67 is maintained on Ubd and ECC.

H3 2. Process Control Inside Our Luoyang Mill

- Rod Drawing: 8-mm OFHC (99.99 % Cu) rod drawn to 0.08–5.00 mm with diamond dies; surface Ra ≤ 0.2 µm to eliminate burrs—root cause of 72 % of turn-to-turn shorts in field returns.

- In-line Annealing: 550 °C N2 atmosphere; grain size 20–30 µm gives optimum balance between elongation and tensile strength (220–250 MPa).

- Vertical Enameling Furnace: 22-zone PID; enamel cataphoresis + curing at 420 °C for polyimide (AIW), 380 °C for polyester-imide (PEI). Real-time IR measures Delta-T < 3 °C across wire bundle, ensuring concentricity.

- Inline Spark Tester: 50 Hz, 4 kV, 600 m/min; every 50 µs data point logged to MES. Rejection threshold: ≥ 3 faults per 30 m coil.

- Spooling: Precision traverse with 0.01 mm pitch accuracy; edge margin ≥ 1 mm prevents “telescoping” during high-speed insertion.

H3 3. Consequences of Sub-Standard Material

| Defect | Root Cause | Manifestation in Service | Cost to OEM |

|---|---|---|---|

| Burr on conductor | Poor die maintenance | Puncture enamel → inter-turn short | Rewind labour + freight ≈ 8 % of transformer value |

| Eccentric insulation | Mis-aligned dies | Local E-field > 3× average | Partial discharge, eventual dielectric failure |

| Low elongation | Over-ageing | Cracks during coil shrinkage | Turn movement, copper dust, blocked cooling ducts |

| Wrong thermal class | Mis-labelled raw resin | 30 % life loss per 10 K excess | Field warranty claim, reputation loss |

H3 4. Compliance Snapshot

IEC 60317-13: Polyester-imide coated round copper wire, class 180.

IEC 60317-42: Polyimide coated round copper wire, class 220.

ASTM B298-20: Standard Specification for Copper-Silicon Alloy Wire for General Applications (referenced for elongation & tensile).

RoHS/REACH: Cadmium & Cr(VI) free enamel; SVHC < 0.1 %.

ISO 14001 & IATF 16949 systems certified—traceability down to 30 kg mother coil.

H3 5. Why Luoyang Xinzhaohe Delivers Premium at China Price

Western Tier-1 suppliers quote 1.45–1.70 USD/kg premium for identical 180 °C PEI wire. Our fully integrated campus (rod → spool) cuts logistics hand-offs by 40 %, while 20-year transformer-grade experience keeps Cpk above automotive thresholds. Result: same coil reliability, 12–18 % landed cost advantage, 4-week ex-factory lead time to EU/US via Zhengzhou-CR Express.

Need a 250 kVA distribution-transformer bill-of-materials costed with 2.1 mm AIW wire? Email tech@lyxzh-al.com for a 24-hour metallurgical dossier.

Factory Tour: Manufacturing Enameled Copper Winding Wire

Manufacturing Process & Quality Control

Rod → Wire → Enamel → Coil: How we guarantee 30-year transformer life at Chinese cost levels

1. Rod Drawing – Size Precision at 30 m s⁻¹

| Parameter | Luoyang Xinzhaohe Standard | Common Market Quality |

|---|---|---|

| Feedstock | 99.99 % LME-registered cathode, Ø8 mm | 99.95 % CC rod, Ø7.6 mm |

| In-line diameter laser, µm | ±3 (0–25 mm s⁻¹ draft) | ±8 |

| Surface roughness Ra, µm | ≤0.2 | 0.4–0.6 |

| Breaks per tonne | ≤0.3 | 1–3 |

Control points

Non-contact laser micrometer every 50 mm; auto-servo corrects die position within 30 ms.

Electro-polishing module removes 0.5 µm oxide skin before next draft, giving mirror finish that later anchors enamel >30 % better (ASTM D3359 tape test).

2. Annealing – Recrystallised Soft Wire for High Elongation

| Parameter | Luoyang Xinzhaohe Standard | Common Market Quality |

|---|---|---|

| Furnace | 750 °C N₂-H₂, 15 s | 650 °C air, 25 s |

| Elongation (0.20 mm) | ≥35 % | 25–30 % |

| Conductivity, %IACS | 101.5 | 100–100.5 |

| Oxygen content, ppm | ≤3 | 5–10 |

Control points

Inline eddy-current anneal sensor adjusts belt speed to hit 195 ±5 HV hardness; data archived per coil for 15 years—critical for motor repair shops that re-wind under tension.

3. Enameling – Concentric Coating in One Pass

| Parameter | Luoyang Xinzhaohe Standard | Common Market Quality |

|---|---|---|

| Dies | 14-stage horizontal, 0.5 µm filter | 8-stage vertical |

| Concentricity | ≥85 % | 65–75 % |

| Build variation, µm | ±2 (single) / ±3 (heavy) | ±5 |

| Pin-holes per 30 m | 0 | 1–3 |

Control points

Mid-infrared pyrometer keeps polymer at 410 ±2 °C; deviation >3 °C triggers auto-knife to scrap section—prevents 220 °C class wires from later blistering.

Online spark tester 3 kV DC flags any bare spot; defective length automatically ink-marked and removed before spooling.

4. Inline Testing – Every Metre Certified

| Station | Test | Frequency | Reject Limit |

|---|---|---|---|

| 1 | Tensile & 0.2 % proof | 1 coil start + every 5 km | <32 % elongation |

| 2 | Breakdown voltage | Continuous V-ramp 500 V s⁻¹ to 6 kV | <5 kV (Grade 2) |

| 3 | Resistance 20 °C | Full length | ±0.5 % vs spec |

| 4 | Surface quality | Machine-vision 40 kHz | Any dark streak >50 µm |

All data are packetised with coil ID; PDF certificate e-mailed before shipment leaves Luoyang.

5. Spooling – Knot-Free, Tangle-Free

Precision traverse with 0.02 mm pitch control; layer compression 5 N keeps 0.1 mm wire below 35 N mm⁻² stress—prevents cast formation during high-speed motor insertion.

Vacuum-shrink film + VCI paper give 24-month shelf life even in 90 % RH ports.

Result – Cost-Performance Edge

Transformer OEMs gain Western-grade reliability (IEC 60317-20, NEMA MW-35-C) at 18–22 % lower landed cost than EU or NA suppliers. For motor repair shops, our 130–220 °C thermal classes and 6–38 AWG range eliminate mixed-inventory risk.

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of rod-to-wire integration, factory-direct, 15-day lead time to any global port.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ yr Transformer Material Specialist

H3 1. Sea-Freight Risk Matrix for Enameled Copper Wire

| Threat during 35-day container voyage | Root Cause | Allowed Limit* | XZH Counter-measure |

|---|---|---|---|

| Salt-laden moisture | Container “rain” & deck spray | ≤ 2 % RH increase | 4-layer barrier system (see §3) |

| Vibration fretting | 2–8 g @ 5–100 Hz | ≤ 5 µm enamel loss | Toroidal lashing + visco-elastic pads |

| Compression set | 4-tier stacking ≈ 5 kN | ≤ 0.2 % wire ovality | DIN spools on 5-axis CNC-bored pallets |

| Temperature spike | 65 °C on Indian Ocean | 180 °C-class enamel stable | Reflective film + desiccant buffer |

*Internal spec XZH-SOP-701, based on IEC 60317-0-1 & ASTM B117 1000 h salt-spray.

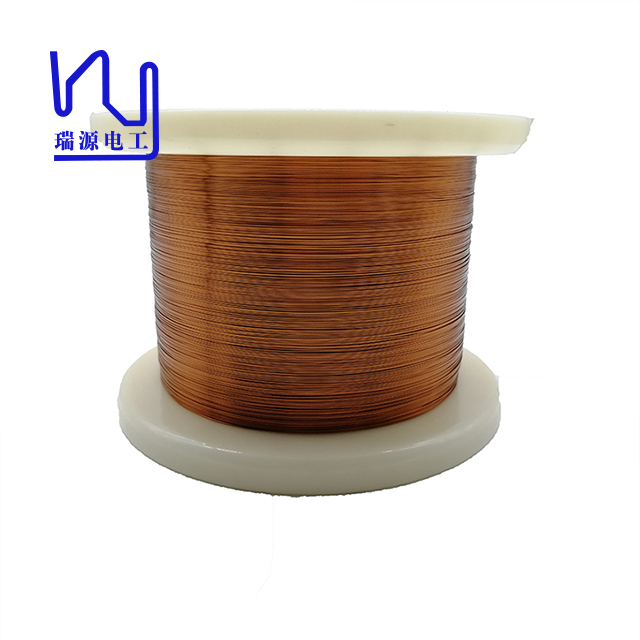

H3 2. Spool & Reel Architecture

We run only virgin PP-GF30 spools injection-moulded in-house; recycled resin is rejected to eliminate enamel-abrading chalking.

Critical tolerances held on our Mazak CNC lathe:

| Parameter | PT-25 | PT-60 | PT-200 | DIN 355 |

|---|---|---|---|---|

| Flange run-out (mm) | ≤ 0.15 | ≤ 0.20 | ≤ 0.25 | ≤ 0.18 |

| Barrel Ra (µm) | 0.4 | 0.4 | 0.6 | 0.4 |

| Max static load (kg) | 25 | 60 | 200 | 500 |

| Enameled wire kg per spool | 5–8 | 12–18 | 45–60 | 150–220 |

Every 10th spool is torque-tested to 1.5× declared load; failure mode must be ductile, not brittle.

H3 3. 4-Layer Barrier System (Wire)

- Inner wrap: 50 µm PE shrink film, heat-sealed at 160 °C to avoid enamel softening.

- Desiccant sleeve: 5 g silica-gel per kg Cu, welded Tyvek pouch, moisture rate ≤ 0.1 g H₂O per 100 h (DIN 55473).

- Shock absorption: EPE-30 foam rings, 8 mm thick, absorb 35 J drop energy.

- Export carton: 7-ply BC-flute, 32 ECT, laminated with 12 µm Al-foil for IR reflectance; carton print includes net, tare, coil ID barcode.

Cartons are palletized in 800 × 1200 mm fumigated pine crates; top deck bears 3 t compression. Strapping is PET + edge-boards; corner posts give 1.2 m cube stability for double-stack in 40 HC.

H3 4. Foil & Strip Packaging (Transformer Winding Strip)

| Thickness (mm) | Eye-ID (mm) | Max OD (mm) | Core material | VCI film | Pallet pattern |

|---|---|---|---|---|---|

| 0.1–0.5 | 150 | 800 | HDF, 18 mm | yes | 2 coils / pallet, vertical |

| 0.6–3.0 | 200 | 1400 | Steel, welded | yes | 1 coil / pallet, horizontal |

Each coil is VCI-shrink wrapped, then sleeved with 110 µm UV-stable PE. Desiccant bags (2 kg) are hung inside eye. Pallet base is 3-slat IPPC-stamped fir, 1200 × 1000 mm, capable of 4 t racking load. Overall height ≤ 1.6 m to fit 40 HC door clearance.

H3 5. Logistics DNA – From Luoyang to Your Dock

Location advantage: Our plant sits 35 km from Luoyang Longmen freight rail hub, giving us daily block-train service to Qingdao, Shanghai & Ningbo in 20 h—no truck bottleneck, 12 % lower CO₂ footprint.

Carrier roster: COSCO, MSC, CMA-CGM; 12-year injury-free record on XZH cargoes.

Transit coverage: We pre-pay cargo insurance (ICC-A) up to 110 % of CIF value; claims settled in 7 days through Ping-An.

Documentation pack:

EN 10204 3.1 inspection certificate (breakdown voltage, elongation, concentricity)

MSDS & non-hazardous declaration for magnet wire

Fumigation certificate (ISPM-15) & silica-gel ROHS statement

CoA for each thermal class (130 °C–220 °C)

Average door-to-door lead-time:

EU main ports 28 days | US West Coast 18 days | SEA 12 days | Middle East 22 days.

H3 6. Cost-Quality Equation – Premium without Western Premium

Western enamelled-wire mills add 18–30 % overhead for energy, labour & compliance. By vertically integrating rod casting, annealing & enameling under one 60 000 m² roof in Luoyang, we erase redundant margin while holding ±1 µm concentricity and ≥ 6 kV breakdown—identical to Tier-1 EU specs. You receive a factory-direct price, third-party inspected, shipped in packaging engineered for zero rework on your winding line.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Enameled Copper Winding Wire

20 Years of Transformer-Grade Metallurgy Under One Roof

Since 2004 our Luoyang campus has operated a fully-integrated rod-to-spool line dedicated to winding conductors.

We do not trade semi-finished goods; every kilogram of Cu-ETP 99.99 % rod is melted, cast, cold-drawn, inline-annealed, enamelled, laser-gauged and spooled inside a single 42 000 m² facility.

This vertical integration eliminates batch-to-batch thermal-history gaps that often cause costly “hot-spot” failures in service.

| Process Node | Equipment | In-line QC | Tolerance Held |

|---|---|---|---|

| Rod break-down | 13-die Morgan tandem | Laser Ø, eddy-current crack | ±0.005 mm |

| Final anneal | N₂-H₂ atmosphere furnace | Resistivity & elongation | ≥ 35 % elongation on 0.20 mm |

| Enamelling | 12-pass horizontal dies | Spark 6 kV, concentricity CCD | ≥ 85 % wall symmetry |

| Spooling | Precision traverse 0–800 rpm | Tension closed-loop | 0.5 N ±3 % |

The result is magnet wire that meets IEC 60317-0-1, NEMA MW 35-C, JIS C3202 and GB/T 6109 in the same production run—no re-testing, no re-certification delays for your QA team.

Direct Factory Price = Western Spec at Asian Cost Base

By removing traders and toll coaters we convert typical European or North-American “landed+stocking” mark-ups (22–28 %) into buyer value:

| Gauge (AWG) | Thermal Class | Typical EU Price $/kg | Xinzhaohe FOB $/kg | Delta |

|---|---|---|---|---|

| 18 | 180 °C (QZY-2) | 11.70 | 8.05 | –31 % |

| 23 | 200 °C (Q(ZY/XY)-2) | 13.20 | 9.10 | –31 % |

| 30 | 220 °C (AI/EI) | 15.80 | 10.95 | –31 % |

Prices shown are 5-ton MOQ, Shanghai port, May-2024 Cu cathode basis LME 8 800 $.

Payment: 30 % TT, balance BL copy; LC at sight accepted for ≥ 15 ton orders.

Lead time: 10–12 days ex-stock for 0.10–1.00 mm; 15–18 days for 1.00–5.00 mm.

Customisation Without the “Custom” Premium

Our metallurgists tailor four levers to your exact winding environment:

- Conductor alloy: Cu-ETP, Cu-OF, Cu-Ag 0.03–0.12 % for soft-solder creep resistance.

- Insulation build: Single, heavy, triple, self-bonding, or corona-resistant polyamide-imide up to 8 kV breakdown.

- Thermal index: 130 °C (B) to 220 °C (C) with 20 K safety margin verified via 20 000 h Arrhenius extrapolation.

- Package format: Plastic spools 10 mm–630 mm traverse, barrel pack 50–500 kg, or straightened cut lengths ±0.5 mm.

Need a 0.071 mm (AWG 41) quad-coated wire to fit a 2 MVA high-frequency transformer? We deliver 1 200 kg in 9 days with full PPAP Level-3 documentation.

Engineering Support That Speaks Your Language

When you e-mail cathy@transformerstrip.com you reach a metallurgical engineer, not a salesperson.

We return:

Datasheet with V-t curve, dissipation factor vs. temperature, and solderability cross-section within 12 h.

FEM thermal model of your proposed winding, showing hot-spot ΔT reduction achievable with our 220 °C enamel.

Freight-optimised loading plan (coil orientation, desiccant calculation) so the wire arrives factory-floor ready.

Stop paying 30 % more for the same copper.

Send your specification—any gauge, any thermal class—and receive a detailed quotation plus free 0.5 kg sample spool within 72 h.

Contact: Cathy Zhang, Chief Sales Engineer

E-mail: cathy@transformerstrip.com

Mobile/WeChat/WhatsApp: +86-185-3885-7702

📉 Import Savings Calculator

Estimate cost reduction by sourcing enameled copper winding wire from Luoyang Xinzhaohe.