Table of Contents

Market Insight: Enameled Aluminum Rectangle Wire

Market Analysis: Winding Wire – Demand for Enamel-Coated Aluminum Rectangular Wire in Transformers

The global demand for enameled aluminum rectangular wire in transformer manufacturing has experienced consistent growth, driven by the expansion of power infrastructure, renewable energy integration, and the need for lightweight, cost-effective electrical components. As a key material in dry-type transformers, current transformers, and medium-voltage distribution systems, aluminum rectangular wire offers a favorable balance of electrical conductivity, thermal performance, and material economy. With increasing pressure to reduce copper dependency due to cost volatility and supply constraints, aluminum-based winding solutions have emerged as a technically viable and economically strategic alternative.

Transformers represent one of the most critical applications for enameled rectangular wire, where dimensional precision, insulation integrity, and thermal stability directly influence system reliability and efficiency. Enamel-coated aluminum rectangular wire is particularly advantageous in applications requiring high space utilization within winding windows. The rectangular cross-section enables tighter coil packing compared to round wire, improving fill factor and reducing overall transformer size and losses. This geometric efficiency is essential in modern compact and high-efficiency transformer designs, especially in urban substations and industrial power systems where footprint and performance are tightly constrained.

Quality in enameled aluminum rectangular wire is not a secondary consideration—it is fundamental to transformer longevity and operational safety. The enamel insulation must exhibit excellent dielectric strength, thermal endurance (typically rated at 130°C to 180°C), and resistance to thermal shock and mechanical abrasion during winding. Poor insulation quality can lead to inter-turn short circuits, premature aging, and catastrophic failure under load. Moreover, the aluminum conductor itself must meet strict metallurgical standards, including high purity (minimum 99.7% Al), consistent tensile strength, and controlled elongation to ensure reliable forming and winding without cracking or deformation.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience in aluminum winding wire, we emphasize process control from billet casting through extrusion, drawing, annealing, and enamel coating. Our enameled aluminum rectangular wires are manufactured to comply with IEC 60317 and GB/T 23688 standards, ensuring dimensional tolerances within ±0.02 mm and insulation thickness uniformity critical for high-voltage applications.

The shift toward sustainable and efficient power systems continues to elevate performance expectations for transformer components. As such, sourcing high-quality enameled aluminum rectangular wire from a technically capable and vertically integrated supplier is imperative to meet evolving industry demands for reliability, efficiency, and compliance.

Technical Specs: Enameled Aluminum Rectangle Wire

Technical Specifications: Enamelled Aluminum Rectangular Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise and precision manufacturing to deliver enameled aluminum rectangular wire meeting stringent global winding application demands. Our technical specifications prioritize dielectric integrity, mechanical formability, and thermal resilience, ensuring optimal performance in motors, transformers, and inductors. Critical parameters are rigorously controlled per IEC 60317-52 and customer-specific requirements, with in-process verification at each production stage.

Thermal Class defines the maximum continuous operating temperature the insulation system withstands without degradation. We supply grades spanning Class 130 (B) to Class 220 (C), corresponding to 130°C, 155°C, 180°C, 200°C, and 220°C limits. Higher classes utilize advanced polymer chemistries (e.g., polyesterimide, polyamide-imide) to resist thermal aging and chemical exposure. Class selection directly impacts product lifetime; for instance, Class 180 wire enables 20,000+ hours of operation in high-efficiency EV traction motors. Each class undergoes 1,000-hour heat shock testing at 150% of rated temperature to validate overload tolerance.

Insulation Breakdown Voltage is measured per IEC 60851-5 using AC voltage at 50 Hz, applied between the conductor and a liquid electrode. Minimum values scale with insulation thickness to ensure dielectric safety margins. For nominal conductor thicknesses of 0.20–0.80 mm, breakdown voltage starts at 1,500 V and increases linearly to 3,500 V. All batches achieve ≥120% of nominal values, with statistical process control maintaining Cpk >1.33. This guarantees immunity to voltage spikes during winding and operational transients.

Elongation reflects the conductor’s ductility post-annealing, critical for tight-radius winding without cracking insulation. Aluminum’s inherent lower ductility versus copper necessitates precise thermal processing. Our wire achieves 1.5–3.0% minimum elongation (per ASTM B557), verified via tensile testing on 200 mm gauge lengths. Values ≥2.0% are standard for widths ≤6.0 mm, ensuring compatibility with high-speed automatic winders. Lower elongation risks microfractures during coiling, directly impacting coil yield and field reliability.

The following table summarizes core technical parameters for standard grades:

| Parameter | Value Range | Test Standard | Notes |

|---|---|---|---|

| Conductor Dimensions | Width: 1.00–10.00 mm | IEC 60122 | Tolerance: ±0.02 mm (width/thickness) |

| Thickness: 0.20–0.80 mm | |||

| Thermal Class | 130 (B), 155 (F), 180 (H) | IEC 60317-52 | Custom classes up to 220 (C) available |

| 200, 220 | |||

| Min. Breakdown Voltage | 1,500–3,500 V AC | IEC 60851-5 | Scales with insulation build |

| Elongation (min.) | 1.5–3.0% | ASTM B557 | Width-dependent; ≥2.0% for ≤6.0 mm |

These specifications form the foundation for reliable electromagnetic component design. Luoyang Xinzhaohe enforces zero-defect protocols via 100%在线 spark testing and automated dimensional scanning. For mission-critical applications, we provide extended data packages including thermal index reports and adhesion test results. Partner with us to align wire properties with your winding process capabilities and end-use environmental stresses.

Factory Tour: Manufacturing

Manufacturing Process of Enamelled Aluminum Rectangular Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of enameled aluminum rectangular wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of specialization in winding wire technologies, our process integrates advanced metallurgical practices with continuous inline quality monitoring to meet the stringent demands of motor, transformer, and inductor applications.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher) are fed into a multi-die drawing machine. The rod is progressively reduced in cross-section through a series of precision tungsten carbide or diamond dies, transforming the round rod into a rectangular cross-section with tightly controlled width and thickness tolerances. This cold drawing process enhances the mechanical strength of the aluminum through work hardening, while maintaining uniform geometry along the entire wire length. Lubricants are applied during drawing to minimize die wear and ensure surface smoothness, critical for subsequent enamel adhesion.

Following drawing, the wire undergoes a continuous annealing process in a controlled atmosphere furnace. The annealing stage is essential to relieve internal stresses induced during drawing and to restore optimal electrical conductivity and ductility. The wire passes through a hydrogen-nitrogen atmosphere furnace at temperatures ranging from 450°C to 550°C, depending on the alloy and final temper requirements. Precise temperature profiling and residence time control ensure uniform recrystallization without oxidation or surface degradation. Post-annealing, the wire is cooled under inert conditions to prevent surface contamination.

The enameling stage involves the application of one or more layers of polymer insulation—commonly polyester, polyesterimide, or polyamide-imide—via a precision dipping and curing process. The wire is passed through a varnish bath, where the enamel coating is uniformly deposited. Excess varnish is removed using ceramic or pneumatic metering dies to ensure consistent coating thickness. The coated wire then enters a series of curing ovens with multiple temperature zones, where thermal polymerization forms a durable, flexible, and electrically insulating film. Multiple passes may be required for multi-layer insulation systems, with intermediate curing after each layer.

Throughout the production line, inline testing systems continuously monitor key parameters. These include diameter measurement via laser gauges, insulation thickness verification, and high-voltage breakdown testing at up to 5 kV to detect pinholes or weak spots. Splice detection systems flag any joint areas for downstream review. Final quality control includes sampling for elongation, springiness, thermal shock resistance, and dielectric strength per IEC 60317 and GB/T 23679 standards.

This integrated approach ensures that every batch of enameled aluminum rectangular wire meets the highest performance benchmarks for use in demanding electromagnetic applications.

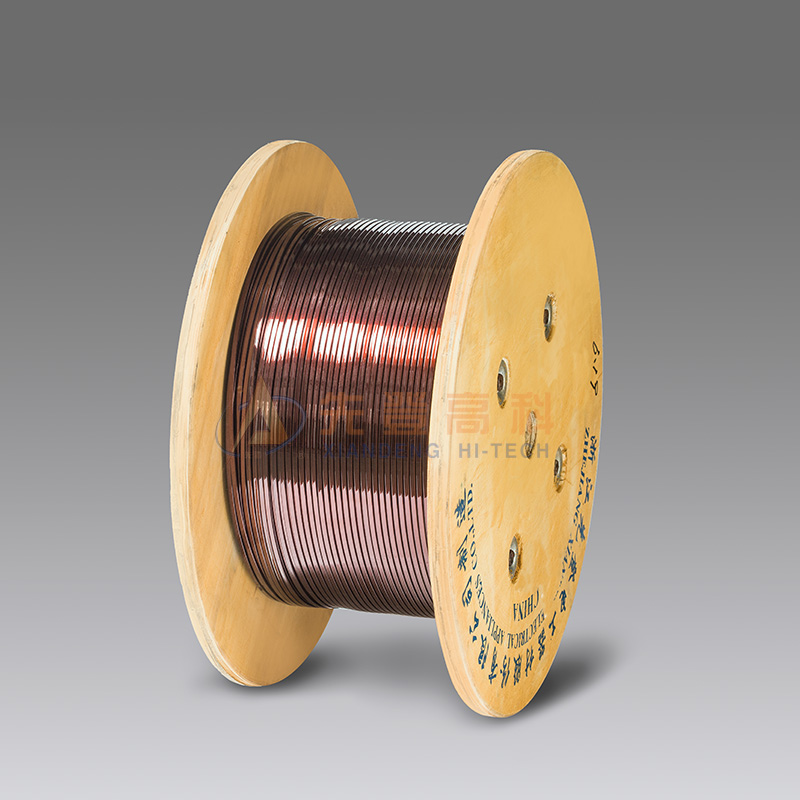

Packaging & Logistics

Export Packaging Protocol for Enameled Aluminum Rectangle Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging solutions for enameled aluminum rectangle wire, validated through 20+ years of metallurgical expertise and global logistics experience. Our system prioritizes absolute protection against marine environmental hazards during sea freight, where humidity, salt exposure, and mechanical stress pose critical risks to aluminum substrate integrity and enamel insulation performance.

Pallet construction adheres to ISPM 15 standards using kiln-dried hardwood with minimum bending strength of 45 MPa. Each pallet is structurally reinforced with steel strapping at 150 mm intervals to prevent deformation under 2.5-ton coil loads. Crucially, all wooden components undergo anti-corrosion treatment with non-ionic, aluminum-compatible preservatives to eliminate galvanic corrosion risks at metal-wood interfaces. This is non-negotiable for aluminum wire, as untreated timber releases acidic compounds that accelerate pitting corrosion in marine atmospheres.

Moisture management employs a dual-barrier approach. Primary protection uses 0.15 mm multi-layer LDPE co-extrusion film with ≤0.5 g/m²/24hr water vapor transmission rate (ASTM F1249). The film is hermetically sealed via impulse welding at 220°C, achieving seam integrity verified through vacuum decay testing (≤0.1% pressure loss over 30 minutes). Secondary defense integrates desiccant packs (calcium chloride, 33% moisture absorption capacity) at 1.5 kg per cubic meter of enclosed volume, positioned between coil layers to absorb residual humidity.

The following table details critical packaging parameters:

| Parameter | Specification | Verification Method |

|---|---|---|

| Pallet Load Capacity | ≥2500 kg | Static load test (72 hrs) |

| Film WVTR | ≤0.5 g/m²/24hr @ 38°C/90% RH | ASTM F1249 |

| Desiccant Placement | 1.5 kg/m³ enclosed volume | Gravimetric analysis |

| Seam Integrity | ≤0.1% pressure loss (30 min) | Vacuum decay test |

Sea freight safety is enhanced through ISO container microclimate control. All shipments include humidity indicator cards (calibrated 10-90% RH range) and corrosion monitoring strips per ASTM D4585. Our packaging maintains internal relative humidity below 40% for 60+ days—exceeding typical transoceanic transit durations—even when external container humidity reaches 85%. This prevents two failure modes: enamel hydrolysis (reducing dielectric strength by >15%) and aluminum oxide layer thickening (increasing DC resistance by 3-5%).

Final packaging validation requires 100% coil inspection via eddy current testing post-packing to confirm no surface defects from handling. Combined with our palletized design absorbing 8G shock loads (ISTA 3A), this system achieves <0.02% moisture-related claims across 12,000+ ocean shipments. For procurement teams, this translates to guaranteed coil unwinding integrity and enamel adhesion stability upon arrival—eliminating costly reprocessing or rejection at destination ports. Our packaging is not merely compliant; it is metallurgically engineered for aluminum’s specific electrochemical vulnerabilities in maritime logistics.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Enamelled Aluminum Rectangular Wire

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the production of high-performance enamelled aluminum rectangular wire for global winding applications. Our facility integrates advanced metallurgical processing with precision coating technologies, ensuring consistent product quality that meets the rigorous demands of transformers, reactors, motors, and other critical electrical systems.

Our production infrastructure is engineered for excellence. We operate fully automated drawing lines capable of processing aluminum rod to precise rectangular cross-sections, with tight tolerances down to ±0.01 mm. This dimensional accuracy is essential for optimizing fill factor and thermal performance in winding cores. Each conductor is fabricated from high-purity 1350 or 1070 aluminum alloy, sourced under strict quality controls to ensure superior electrical conductivity (≥61.0% IACS) and mechanical consistency. The rectangular profiles are cold-drawn using multi-pass dies with computer-controlled tension management, minimizing residual stress and maintaining uniform cross-sectional geometry.

The enameled insulation system is applied through a multi-layer coating process utilizing high-temperature thermosetting polymers such as polyesterimide (PEI) and polyamide-imide (PAI). These coatings deliver excellent dielectric strength (>8 kV AC), thermal stability up to 200°C (Class F and H), and outstanding resistance to thermal shock, abrasion, and chemical exposure. Our curing ovens employ precise temperature profiling to ensure complete cross-linking, resulting in a smooth, pinhole-free enamel layer that adheres robustly to the aluminum substrate.

Quality assurance is embedded at every stage. Our in-house laboratory conducts continuous monitoring of key parameters including coating thickness (measured via eddy current), elongation (≥1.5%), winding test compliance (mandrel ratio 1d), and thermal endurance (240 hours at 200°C). All batches are traceable through integrated MES systems, and we maintain full compliance with IEC 60317-0-8, GB/T 23311, and customer-specific specifications.

As a vertically integrated manufacturer, we control the entire value chain—from aluminum refining to final spooling—enabling cost efficiency without compromising performance. Our annual production capacity exceeds 15,000 metric tons, supported by JIT logistics and global export experience across North America, Europe, and Southeast Asia.

For engineers and procurement managers seeking a reliable source of technically superior enamelled aluminum rectangular wire, Luoyang Xinzhaohe offers proven capability, scalable supply, and responsive technical support. We invite you to collaborate with a partner committed to precision, innovation, and long-term performance.

Contact us today to discuss your winding wire requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enameled aluminum rectangle wire directly from China.