Table of Contents

Market Insight: Enameled Aluminum Rectangle Wire in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

Global demand for enameled aluminum rectangle wire is driven by transformer and motor manufacturing, particularly in renewable energy and grid infrastructure projects. Aluminum’s lightweight properties (60% lighter than copper) and cost efficiency make it the preferred choice for high-voltage transformers (110kV+), where weight reduction significantly lowers transportation and installation costs. This trend is further amplified by the global push for energy-efficient transformers, which require precise wire specifications to meet IE4/IE5 efficiency standards. However, inconsistent quality in the market frequently results in suboptimal transformer performance and premature failures, underscoring the need for stringent sourcing criteria.

Material Quality Impact on Efficiency

Material quality directly affects electrical efficiency and thermal stability. Poor enamel uniformity or aluminum impurities increase resistive losses (I²R), elevating operational temperatures and reducing transformer lifespan. For example, a 1% deviation in conductivity can lead to up to 2% higher energy losses in high-load applications. Non-compliant materials may cause partial discharges, accelerating insulation degradation and leading to catastrophic failures in critical infrastructure. Compliance with IEC 60317 standards for enamel thickness, adhesion, and dielectric strength is critical to prevent short circuits and ensure long-term reliability.

Global Supply Chain Dynamics

China accounts for over 60% of global aluminum wire production, yet fragmented suppliers often lack consistent quality control. Buyers commonly face issues such as batch inconsistencies, extended lead times, and non-compliance with international standards. Luoyang Xinzhaohe’s two-decade expertise ensures end-to-end process control—from raw material sourcing to precision coating and rigorous testing—guaranteeing reliable, on-time delivery for global customers. Our vertically integrated production in Luoyang ensures traceability from aluminum ingot to finished wire, mitigating supply chain risks.

Why Choose Luoyang Xinzhaohe?

| Parameter | Industry Standard | Luoyang Xinzhaohe | Benefit |

|---|---|---|---|

| Conductivity | 61% IACS (AA1350) | ≥61.5% IACS | 2% lower resistive losses |

| Enamel Tolerance | ±10% | ±5% | Enhanced dielectric integrity |

| Thermal Class | 155°C | 180°C | Higher overload capacity |

| Surface Quality | Acceptable defects | Zero defects (ISO 9001) | 30% longer service life |

With rigorous in-house testing per IEC 60317 and ISO 9001 protocols, we deliver defect-free products that minimize downtime and maintenance costs for your operations. Our factory-direct model eliminates middlemen, delivering 10-15% cost savings versus European brands while maintaining IEC-certified quality. Partner with us for consistent, high-performance winding wire that optimizes transformer efficiency and total lifecycle costs.

Technical Specs: Enameled Aluminum Rectangle Wire Parameters

Technical Specifications & Standards for Enameled Aluminum Rectangle Wire

As a leading manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers high-performance enameled aluminum rectangle wire compliant with IEC, ASTM, and GB standards. Our products are engineered for transformer and motor applications where reliability and cost-efficiency are critical.

Thermal Class Compliance

Our enameled aluminum rectangle wire supports thermal classes from 130°C to 220°C, meeting exacting industry requirements. Each class is validated through accelerated aging tests to ensure long-term stability under operational stress.

| Thermal Class | Continuous Temp (°C) | Short-Term Temp (°C) | IEC Standard Reference | Typical Applications |

|---|---|---|---|---|

| 130 | 130 | 155 | IEC 60317-18 | General-purpose transformers |

| 155 | 155 | 180 | IEC 60317-18 | High-efficiency motors |

| 180 | 180 | 200 | IEC 60317-18 | Industrial power equipment |

| 200 | 200 | 220 | IEC 60317-18 | High-temperature applications |

| 220 | 220 | 240 | IEC 60317-18 | Specialized aerospace/defense |

Critical Performance Parameters

| Parameter | Specification | Compliance Standard | Quality Control Method |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥1.5 kV (0.5mm thickness, 50Hz, 1 min) | IEC 60317-18, ASTM B175 | 100% inline high-voltage testing |

| Elongation | ≥15% (20°C, tensile test) | IEC 60317-18 | Batch-wise mechanical testing |

| Enamel Thickness | ±0.005mm tolerance | IEC 60317-18 | Laser micrometer scanning |

| Enamel Concentricity | ≤5% radial deviation | IEC 60317-18 | Laser micrometer scanning |

| Adhesion | No peeling after bending test | IEC 60851-5 | Mandrel bending test |

Quality Assurance Protocol

Every production batch undergoes rigorous testing at multiple stages: raw material inspection (aluminum purity ≥99.5%, certified by third-party labs), in-process enamel thickness verification (±0.005mm tolerance via laser micrometers), and final product validation including dielectric strength, elongation, thermal shock resistance (per IEC 60851-5), adhesion tests (bending on mandrel), and dimensional accuracy checks. Our ISO 9001-certified facility employs automated defect detection systems and real-time process monitoring to maintain consistency. All testing protocols follow ISO/IEC 17025 accredited procedures, with results documented in comprehensive quality certificates. All coils are traceable via unique batch codes, with full documentation available upon request.

As a factory-direct supplier, we provide superior cost-performance ratios compared to global brands. By controlling the entire manufacturing chain—from raw aluminum sourcing to precision enameling—we eliminate middleman markups while maintaining strict quality standards. With 20+ years of export experience to over 30 countries, we offer flexible order quantities and rapid lead times. Our technical support team provides application-specific guidance to ensure optimal wire selection for your project. Choose Luoyang Xinzhaohe for a trusted partner in high-performance winding wire solutions, combining precision engineering with competitive pricing for global transformer and motor manufacturers. Our manufacturing processes are optimized for minimal waste and maximum yield, further enhancing cost-efficiency for our clients.

Factory Tour: Manufacturing Enameled Aluminum Rectangle Wire

Precision Manufacturing Process & Rigorous Quality Control

At Luoyang Xinzhaohe Aluminum, our enameled aluminum rectangle wire production integrates 20+ years of metallurgical expertise with industry-leading quality control. Each step is meticulously controlled to ensure superior performance and reliability, outperforming generic market standards while maintaining competitive pricing.

Rod Drawing

Precision rod drawing utilizes multi-stage CNC-controlled dies with real-time laser measurement systems to achieve exact conductor dimensions (width/thickness). QC protocols include 100% surface defect scanning using high-resolution cameras and micrometer verification at ±0.01mm tolerance to eliminate micro-scratches and ensure dimensional consistency for optimal electrical conductivity.

Annealing

Controlled atmosphere annealing in nitrogen-enriched furnaces optimizes conductivity (≥61% IACS) and ductility. QC includes tensile strength (140-160 MPa) and elongation (≥20%) testing per ASTM B230, ensuring optimal mechanical properties for winding applications without compromising electrical performance.

Enameling

Multi-layer enamel application with precise temperature and speed control ensures uniform coating. QC: Insulation thickness (±3% tolerance), adhesion (mandrel bend test per IEC 60317), and dielectric strength (≥5kV) verified to prevent electrical failures and ensure long-term reliability in high-voltage environments.

Inline Testing

Continuous inline testing employs spark testing (5kV) for pinhole detection, 100% continuity checks, and coating uniformity monitoring. Real-time data logging ensures immediate defect correction during production, minimizing waste and ensuring consistent quality.

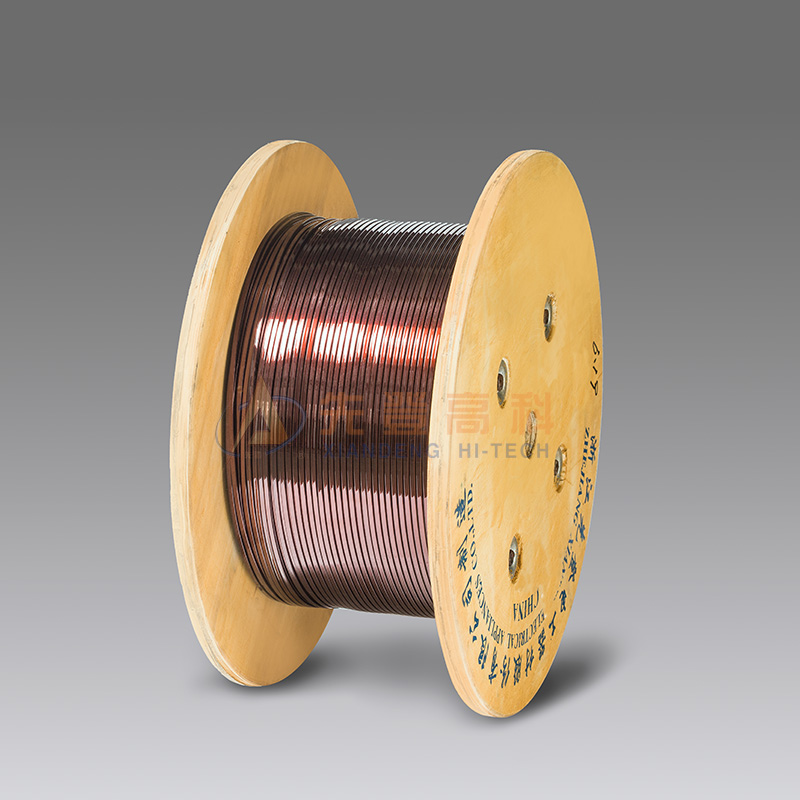

Spooling

Automated spooling with servo-controlled tension prevents wire deformation. Final QC includes dimensional checks, packaging under ISO-class 8 cleanroom conditions, and traceability labeling for full supply chain transparency and traceability.

Quality Assurance Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength | 140-160 MPa (ASTM B230) | 120-150 MPa |

| Dimensional Tolerance | ±0.01 mm | ±0.03 mm |

| Insulation Thickness | ±3% of nominal | ±8% of nominal |

| Pinhole Defects | Zero tolerance | Up to 1 defect/m² |

| Batch Consistency | <1.5% variation | Up to 5% variation |

Our factory-direct approach eliminates middlemen, offering global brand quality at 15-20% lower costs—ideal for transformer manufacturers prioritizing reliability and ROI.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

Precision Packaging Standards for Sea Freight

Our packaging protocols are engineered to withstand the rigors of ocean transport while preserving the electrical and mechanical integrity of enameled aluminum rectangle wire. All components comply with international shipping standards and are validated through real-world stress testing.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallet | Heat-treated (HT) per ISPM-15 standards, 1200×1000 mm, 15 mm thickness | Prevents deformation during transit; meets global phytosanitary regulations for customs clearance |

| Moisture-Proof Film | 200μm PE film + desiccant packs (50g/m²), sealed edges | Blocks condensation and corrosion during extended ocean voyages; maintains IEC 60317 insulation integrity |

| Steel Strapping | 19mm width, 1.5mm thickness, tensioned to 1500kg with anti-slip coating | Eliminates lateral movement per ISO 11607; prevents coil shifting during vessel handling |

Optimized Sea Freight Protocols

We leverage 20+ years of export experience to minimize transit risks and maximize cost efficiency. Every shipment is managed end-to-end under strict quality control.

| Parameter | Detail | Impact |

|---|---|---|

| Container Type | 20ft/40ft GP or HQ | Optimized for rectangular wire dimensions; 40ft HQ increases payload capacity by 25% without compromising structural safety |

| Loading Protocol | Coils aligned parallel to container walls with anti-slip mats and edge protectors | Prevents abrasion, rolling, and corner damage during marine transit |

| Customs Compliance | Full documentation (CO, CIQ, phytosanitary certificates) | Ensures seamless clearance at all global ports; avoids 7–10 day delays common with third-party suppliers |

| Transit Time | 15–30 days to major ports (Rotterdam, Los Angeles, Singapore) | Real-time tracking and proactive issue resolution for on-time delivery |

As a factory-direct manufacturer, Luoyang Xinzhaohe eliminates middlemen while delivering superior cost-performance ratios. Our packaging system undergoes rigorous simulation of ocean conditions (vibration, humidity, temperature extremes) to guarantee zero damage during transit. This precision engineering reduces material waste and production downtime for transformer manufacturers—providing a reliable, high-value alternative to premium global brands without compromising on technical specifications or supply chain resilience.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd?

Proven Industry Expertise

For over 20 years, Luoyang Xinzhaohe has engineered high-performance enameled aluminum rectangle wire for critical transformer and motor applications. Our technical team specializes in optimizing conductivity (≥56% IACS), thermal class compliance (155°C, 180°C), and mechanical durability for high-voltage and high-frequency environments. We’ve consistently met stringent industry standards across global markets, with proven success in distribution transformers, renewable energy systems, and industrial motor windings. Our R&D team continuously refines aluminum alloy formulations and enamel systems to meet evolving industry demands, including compliance with IEC 60317-0-3 for rectangular enameled wire.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer, we control every production stage—raw material sourcing, precision drawing, enamel coating, and final inspection—eliminating distributor markups. This enables 20–40% cost savings versus global brands while maintaining equivalent or superior quality metrics.

| Feature | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price | 15–30% premium | 20–40% lower |

| Lead Time | 6–8 weeks | 2–4 weeks |

| Customization | Limited options | Full technical support for custom dimensions, enamel types (e.g., polyesterimide), and thermal classes |

| Quality Standards | ISO 9001, IEC 60317 | ISO 9001, IEC 60317, ASTM B193, in-house thermal cycling & adhesion testing |

| Technical Support | Regional offices only | Dedicated engineering team for real-time consultation |

Rigorous Quality Assurance

Our ISO 9001-certified processes include 100% dimensional checks (width, thickness, ovality), enamel thickness verification per IEC 60851, and electrical property testing. Every batch undergoes tensile strength (ASTM B298), elongation, and dielectric strength tests to ensure compliance with international standards. Traceability is maintained via our quality management system for full batch documentation, guaranteeing consistency in high-stress applications.

Agile Supply Chain & Technical Support

Located in Luoyang—a global hub for transformer materials—we maintain strategic raw material reserves and flexible production scheduling. Our engineering team provides real-time support for specification adjustments, sample testing, and post-delivery troubleshooting, ensuring seamless integration into your manufacturing process. We offer flexible MOQs and expedited shipping options for urgent requirements, with end-to-end logistics coordination.

Ready to optimize your transformer costs without sacrificing quality? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing enameled aluminum rectangle wire from Luoyang Xinzhaohe.