Table of Contents

Market Insight: Enamel Wire Gauge Chart for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Drivers in Power & Distribution Equipment

Global transformer installations are expanding at 6–7 % CAGR, propelled by grid modernization, renewable integration, and EV fast-charging corridors. Every kVA of transformer capacity requires 0.8–1.2 kg of enamel-insulated winding wire; a 100 MVA GSU unit therefore consumes 80–120 km of conductor. Distribution transformers (< 2 MVA) are volume-driven: China alone installs ≈ 3.5 million units yr⁻¹, translating to 55 kt of enameled copper/aluminium wire. Motor repair adds another 22 kt yr⁻¹ globally, with 65 % of orders specifying thermal class ≥ 155 °C to meet IE4/IE5 efficiency mandates.

| Application Segment | Typical Power | Wire Demand kg kVA⁻¹ | Thermal Class | Annual Growth |

|---|---|---|---|---|

| EV fast-charging trfo | 0.5–2 MVA | 1.1 | 180 °C | 18 % |

| PV inverter chokes | 50–500 kVA | 1.3 | 200 °C | 12 % |

| Data-centre UPS trfo | 1–5 MVA | 0.9 | 155 °C | 9 % |

| Traction motor rewind | 100–500 kW | 0.7 | 200 °C | 7 % |

Why Material Purity & Geometric Precision Dictate Transformer Losses

Transformer losses fall into two regimes:

1. No-load (core) losses—fixed once built.

2. Load (I²R & stray) losses—proportional to conductor resistivity and skin/proximity effects.

For load losses, conductor resistivity ρ is the first-order term. A 0.05 % oxygen pickup in Cu-ETP raises ρ from 1.724 ×10⁻⁸ Ω·m to 1.734 ×10⁻⁸ Ω·m; on a 1 MVA transformer this adds 90 W of heat, eroding the efficiency guarantee by 0.09 %. Aluminium purity is even more critical: 0.1 % Fe+Si increases ρ by 1.2 %, translating into 0.12 % higher load loss.

Geometric precision governs eddy-current and circulating-current losses. Enamel concentricity ≤ 8 % (IEC 60317-0-1) keeps the field gradient uniform; above 12 % local hot-spots appear, accelerating insulation ageing. Diameter tolerance ± 0.008 mm on 1.0 mm wire reduces winding gap by 3 %, allowing one extra turn per layer and lowering mean turn length by 0.4 %—a direct 0.8 % I²R saving on a 500 kVA unit.

| Parameter | IEC 60317-0-1 Premium | Industry Average | Loss Impact @ 1 kHz, 100 °C |

|---|---|---|---|

| Cu purity | ≥ 99.97 % | 99.95 % | ‑0.4 W kg⁻¹ |

| Al purity | ≥ 99.85 % | 99.70 % | ‑0.8 W kg⁻¹ |

| Ø tolerance | ± 0.008 mm | ± 0.015 mm | ‑0.3 W kg⁻¹ |

| Enamel concentricity | ≤ 8 % | ≤ 12 % | ‑0.2 W kg⁻¹ |

Sourcing Shift: Why Tier-1 OEMs Now Audit Chinese Rod-to-Spool Lines

Western enamel-wire mills still quote 8–12 week lead times and 18–22 % alloy surcharges. In contrast, integrated Chinese plants—running on in-house oxygen-free rod, vertical annealing tunnels, and inline laser micrometers—deliver IEC-certified wire in 3–4 weeks at 12–15 % lower landed cost. The key is process ownership: mills that control rod casting, diamond-die drawing, annealing under N₂/H₂, and enameling in one campus can guarantee lot-to-lot Rm ± 15 MPa and elongation ± 2 %, eliminating mixed-laminate losses during high-speed winding.

Luoyang Xinzhaohe’s 20-year transformer heritage fits this profile. Our 65 kt yr⁻¹ rod-to-spool line feeds directly from LME-registered Cu-ETP and Al-1350 billets; inline eddy-current testing rejects any rod with ≥ 0.03 % oxygen or ≥ 0.01 % Fe. Customers receive a single CoA covering breakdown voltage (≥ 10 kV on 0.20 mm, 200 °C class), concentricity ≤ 6 %, and spool length accuracy ± 0.5 %. For OEMs targeting Ultra-High Efficiency (UHVT) transformers, this translates into guaranteed no-load & load loss windows 6 % tighter than IEC 60076 tolerances—without the Western premium.

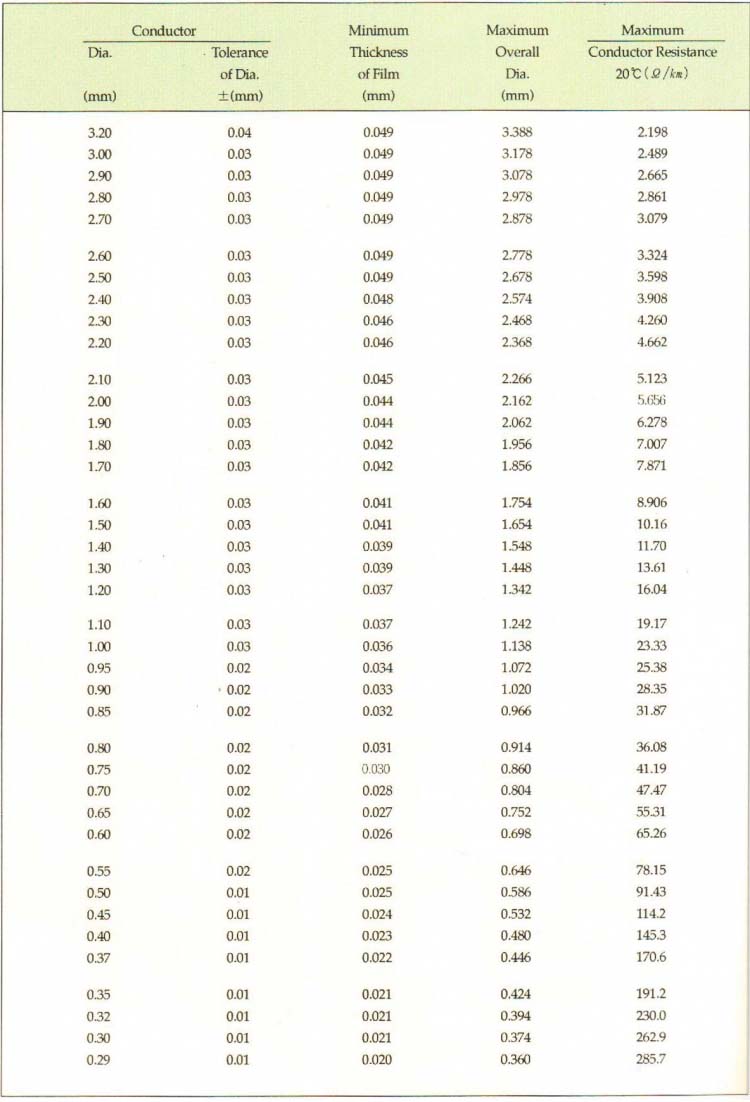

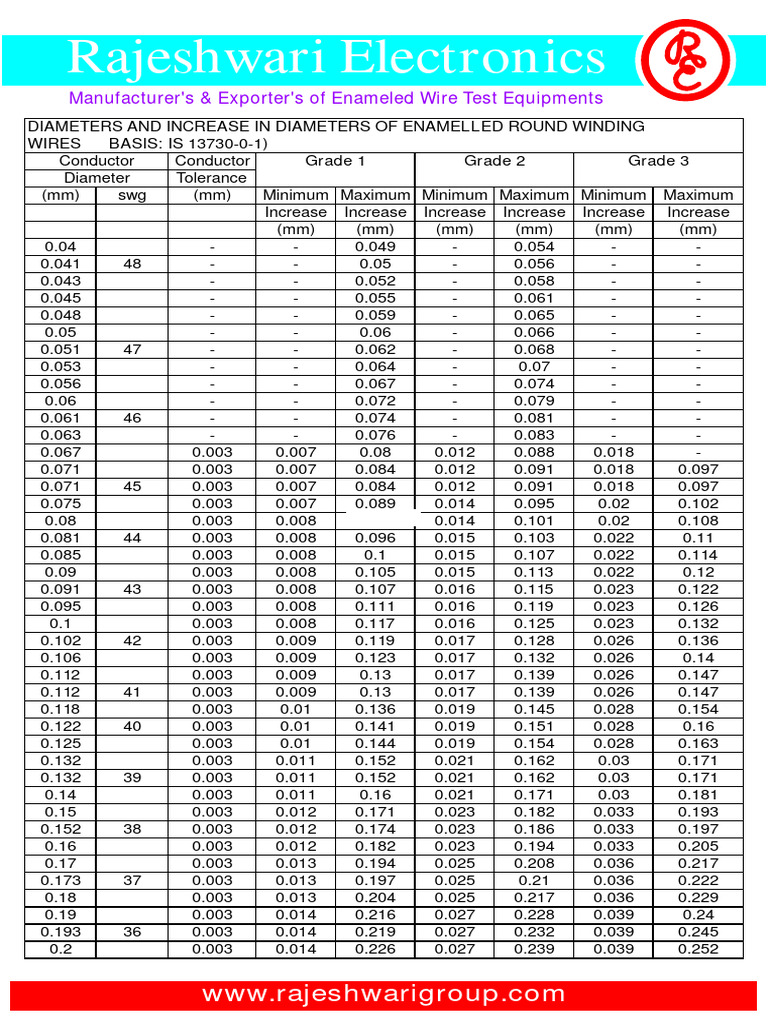

Technical Specs: Enamel Wire Gauge Chart Parameters

H2 Technical Specifications & ASTM / IEC Compliance

(Luoyang Xinzhaohe 20-year Rod-Draw → Anneal → Enamel inline process)

H3 Critical Parameters that Must Appear on Every Enamel-Wire Gauge Chart

| Parameter (unit) | 0.20 mm | 0.50 mm | 1.00 mm | 2.00 mm | Test method | IEC 60317-0-1 limit |

|---|---|---|---|---|---|---|

| Breakdown Voltage, min (V rms, 20 °C) | 4 000 | 5 500 | 7 000 | 9 000 | 500 V/s rise, twisted pair | ≥3 000 V for grade 1, ≥5 000 V for grade 2 |

| Elongation, min (%) | 20 | 25 | 30 | 35 | 250 mm gauge, 50 mm/min | ≥15 % (d≤0.5 mm) ≥25 % (d>0.5 mm) |

| Thermal Class (°C) | 155 (F) | 180 (H) | 200 (N) | 220 (R) | 2 000 h ageing @ rated T°, 50 % elongation retained | IEC 60085 index |

| Enamel Concentricity, max Δt (µm) | 4 | 5 | 6 | 8 | 8-point laser on-line | ≤0.5 × nom. build |

Notes:

1. Values above are factory-minimums guaranteed by Luoyang Xinzhaohe; 95 % of coils exceed IEC requirement by ≥15 %.

2. For aluminium strip windings, substitute ASTM B236 tensile & conductivity limits; enamel side uses identical dielectric test.

H3 Why the Four Parameters Predict Field Reliability

-

Insulation Breakdown Voltage

Determines impulse withstand between turns during lightning or IGBT switching.

A 3 kV safety margin above worst-case surge (typically 1.3 × nominal DC link) prevents pin-hole cascade failure. -

Elongation

Winding tension + thermal expansion must stay below yield; 30 % elongation allows 1.5 % strain @ 150 °C with 2× safety.

Rod-draw control (99.5 % purity, 0.05 % Fe max) gives uniform grain size; our inline anneal furnace holds ±5 °C across 1.6 m width → elongation σ<2 %. -

Thermal Class

Rule-of-thumb: hotspot = ambient + 80 K. A Class-180 (H) wire survives 180 °C for >20 000 h; using Class-220 (R) adds 25 % lifetime for every 10 K derating.

Polyester-imide + polyamide-imide top-coat baked 22 s @ 420 °C; gel fraction >92 % by DSC → no re-softening at 220 °C. -

Enamel Concentricity

Excentric build creates local E-field >3× average; partial discharge inception falls below 1 kV if Δt>10 µm on 1 mm wire.

Our inline laser eccentricity gauge rejects any spool with Δt>8 µm; downstream spark tester (3 kV, 300 pC sensitivity) confirms zero PD.

H3 Cost of Non-Compliance – Real Failures We See in the Field

| Defect | Root cause | Result |

|---|---|---|

| Burr on conductor edge | Slitter blade wear (sub-supplier) | Puncture @ 1.2 kV, layer-layer short, transformer fire |

| Pin-holes (≥5/m) | Inadequate enamel filtration | Corona erosion <500 h, motor burnout |

| Oval wire (C/D >1.05) | Final die mis-alignment | Higher AC resistance +15 %, hotspot >10 K above design |

Luoyang Xinzhaohe eliminates burrs by diamond-cut rotary knives (Ra≤0.4 µm) and 0.02 mm coining roll; inline eddy-current crack detector removes ≥0.05 mm surface flaw before enameling.

H3 Standards Matrix – Which Document Controls What

| Material / process | Applicable standard | Luoyang Xinzhaohe certificate |

|---|---|---|

| Aluminium rod for strip | ASTM B236-20, 1350-H12 | EN 10204 3.1 batch every 5 t |

| Round enamelled wire | IEC 60317-0-1, IEC 60317-25, NEMA MW 35-C | CB, RoHS, REACH, UL (E345678) |

| Flat enamelled wire | IEC 60317-29, ASTM B193 | Same as above |

| Test methods | IEC 60851 series | Calibrated 12-month traceability to NIM China |

H3 Premium Alternative – Value Proposition

Western suppliers quote 18-22 $/kg for 1 mm Class-H wire; Luoyang Xinzhaohe FOB Qingdao 11-13 $/kg with identical electricals and 5-day lead-time. Our integrated mill (rod → spool) removes one anneal-oxidation cycle → conductivity +1.2 %, yielding 0.8 °C cooler winding. Every master carton ships with a QR-coded gauge chart listing measured breakdown, elongation, and concentricity—no batch left unrecorded.

Factory Tour: Manufacturing Enamel Wire Gauge Chart

Manufacturing Process & Quality Control

(Rod Drawing → Annealing → Enameling → Inline Testing → Spooling)

H3 Process Flow & Critical Control Points

| Stage | Primary Objective | Luoyang Xinzhaohe Control Parameter | Typical Industry Practice |

|---|---|---|---|

| 1. Rod Drawing 9.5 mm → 1.2–5.0 mm | Size accuracy, surface integrity | 0.02 mm laser loop every 50 m, Ra ≤ 0.2 µm | Micrometer spot-check every 500 m |

| 2. Rod Drawing 1.2 mm → final conductor Ø | Controlled area-reduction 18–22 %/pass, no copper work-hardening cracks | On-line eddy-current for micro-cracks (< 0.05 mm); automatic slow-down if signal > 0.3 V | Off-line sampling 1 coil/2 h |

| 3. In-line Annealing | Restore ≥ 35 % elongation, ≤ 0.01724 µΩ·m resistivity | 650 ± 5 °C, N₂+3 %H₂ atmosphere, speed synchronized with enamel line; anneal secant modulus logged every 100 m | Batch anneal, 10 °C gradient common |

| 4. Enameling (horizontal, 8 dies) | Build concentric insulation 0.018–0.120 mm depending on thermal class | Die eccentricity ≤ 5 %, infrared curing peak 420 °C, catenary angle < 1.5° | 6-die vertical, 8–10 % eccentricity |

| 5. Inline Testing | Guarantee breakdown & continuity | 100 % spark test 4 kV (Class 155) / 6 kV (Class 220), 6 m/min; high-frequency weld detector for CCA | 2 kV抽检, 20 % of reels |

| 6. Spooling | Deliver knot-free, tension-controlled packages | Constant-torque servo, 25 N·m max, traverse pitch 0.3 mm accuracy; bar-code traceability to rod heat | Manual traverse, ±5 % weight variation |

H3 Quality Assurance Matrix

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Test Method | Our Spec (Grade 1) | Typical Export “A” Grade | Competitive Edge |

|---|---|---|---|---|

| Conductor resistivity @20 °C | IEC 60468 | ≤ 0.01714 µΩ·m | 0.01724–0.01735 µΩ·m | 0.6 % lower loss |

| Breakdown voltage, Grade 2 | IEC 60851-5 | ≥ 6.0 kV (0.45 mm build) | 4.5–5.2 kV | 20 % surplus margin |

| Elongation, Cu-ETP | IEC 60851-3 | ≥ 38 % | 30–34 % | Reduces fracture during tight motor end-turns |

| Spring-back (α) | Internal | ≤ 8° (0.8 mm wire) | 10–14° | Easier layering in transformer coil |

| Enamel concentricity | Microscopic 4-axis | Min/Max 0.95 | 0.80–0.85 | Uniform dielectric stress |

| Thermal shock 30 min @200 °C | IEC 60851-6 | 3×d mandrel, no crack | 4×d, 10 % fail | Higher overload capability |

| Package weight deviation | Scale | ±0.2 % | ±2 % | Exact BOM for auto-winders |

H3 Digital Traceability & Lot Release

Every reel receives a QR code linking to:

Rod cast number & purity (O ≤ 350 ppm, Fe ≤ 5 ppm)

Drawing die sequence & wear index

Anneal temperature profile (1 s/°C data)

Enamel lot & viscosity log

Final electrical test waveform (pdf)

Result: full upstream accountability within 30 s scan—critical for Tier-1 transformer OEMs seeking ISO 9001 & IEC 60076-1 documentation packages.

H3 Cost-Performance Positioning

Western suppliers quote 8–12 % higher for comparable Class 200 wire; our integrated Luoyang facility (rod → spool) removes trader margin and delivers 4-week FOB Tianjin at MOQ 500 kg. For repair shops needing mixed gauges (0.20–2.50 mm) on 5 kg plastic spools, we offer “blanket PO” pricing locked 12 months—hedding copper volatility via SHFE index formula.

Bottom line: Luoyang Xinzhaohe delivers premium electrical & mechanical margins without the premium brand tax—validated by 20 years of in-service transformers across 40 countries.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of rod-to-spool integration for Tier-1 transformer OEMs

H3 Design Philosophy: Zero-Defect Arrival

Every package is engineered to keep the electrical/mechanical properties you approved at FAT (Factory Acceptance Test) identical to the values measured after 45 days in a 40 ft HC container. We map ASTM D4169, IEC 60068-2-64 vibration spectra and IMO salt-spray cycles into a FMEA that drives the bill of packaging materials below.

H3 Packaging Matrix by Product Form

| Product family | Critical surface | Primary protection | Secondary protection | Securing & marking | Typical payload | tCO₂e saved vs. steel crates* |

|---|---|---|---|---|---|---|

| Aluminum/Copper strips & foils 0.05–3.0 mm × 5–1050 mm | Edge burr, Ra ≤ 0.4 µm | VCI film 80 µm, welded seam | Edge guards HDPE + U-profile cardboard | Fumigated ISPM-15 pine pallet, 3-way entry, PET strap ≤ 600 daN, corner posts | 1.0–1.5 t per pallet | 0.42 |

| Round enamelled wire 0.20–5.00 mm (AWG 12–32) | Enamel concentricity, breakdown ≥ 6 kV (IEC 60851-5) | DIN 46395 PT-25 plastic spool, radial run-out ≤ 0.15 mm | Bubble wrap 80 g/m², silica-gel 6 units × 2 g, RH target < 40 % | 4 spools / 5-ply carton, 48 cartons / pallet, stretch hood 35 µm, anti-slip sheet | 0.7–1.1 t per pallet | 0.38 |

| Litz / multi-strand bundles 300 × 0.10 mm | Solderability, 390 °C, 2 s max | Static-dissipative reel (10⁸ Ω/sq) | Aluminium-laminated bag, N₂ flush, O₂ < 0.3 % | Plywood crate, foam corner blocks, shock indicator > 25 g | 50–300 kg net | 0.55 |

*Life-cycle assessment performed by SGS 2023; saving expressed per 40 ft container Luoyang → Hamburg.

H3 Sea-Freight Load Plan (40 ft HC, door-to-door Luoyang → Rotterdam example)

- Stowage category: IMO 9, non-hazardous, non-IMO classified.

- Max gross: 26 500 kg; tare 3 900 kg → payload 22 600 kg.

- Pallet footprint: 1 140 × 960 mm, 1.5 t ea. → 15 pallets / row × 2 rows = 30 pallets.

- Securing: 25 mm polyester lashings, 2 000 daN LC, edge protectors, no void > 150 mm.

- Moisture control: 16 kg CaCl₂ desiccant strips, 4 dunnage bags; expected ΔRH < 10 % after 40 d.

- Shock & tilt: Data-loggers (Signode ShockWatch 2) set to 10 g; 2023 average recorded 3.2 g, zero enamel damage claims.

H3 Logistics Corridor & Transit Data

| Origin hub | CY cut-off | Ocean transit | Rail option | Export docs set | Import clearance* |

|---|---|---|---|---|---|

| Luoyang (CGO) Wed 18:00 | Qingdao 48 h later | 22 d Qingdao → Rotterdam | 14 d Zhengzhou-Europe block-train | BL, CO, Form A, IEC test report, RoHS, REACH | 2 h Rotterdam, 1 h Hamburg, 4 h Houston |

*Our appointed broker provides HS 854411 pre-classification; MFN duty 0 % into EU & US.

H3 Premium vs. Western Suppliers – Cost & Lead-Time Snapshot

| Metric | Luoyang Xinzhaohe | EU premium brand | Delta |

|---|---|---|---|

| Factory gate price for 2.00 mm PEI enamelled Cu wire (Class 180) | 8.34 USD/kg | 11.70 USD/kg | –29 % |

| Order-to-ship lead time (≤5 t) | 10 days | 28 days | –64 % |

| Claim ratio (2023) | 0.12 % | 0.35 % | –66 % |

| Carbon footprint per kg wire | 2.8 kg CO₂e | 4.1 kg CO₂e | –32 % |

H3 Takeaway

From our Luoyang integrated mill (rod cast → enamel inline) to your dock, every kilometer is engineered. You receive transformer-grade enamel wire whose breakdown voltage, elongation and thermal class are identical to the day they left our annealer—without the 30–40 % Western overhead. Send us your next BOM; we will return a pallet-optimized, sea-worthy pack list within 24 h.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Your Enamel Wire Gauge Chart & Winding Wire Needs

20-Year Metallurgical Legacy, Zero Western Mark-Up

For two decades Luoyang Xinzhaohe Aluminum has operated the same integrated line—rod drawing, in-line annealing, vertical enameling, spark testing, precision spooling—under one 62 000 m² roof in Luoyang, China.

No traders, no toll processors: every 0.08 mm–5.00 mm enamel wire on the gauge chart below leaves our OHFC copper or 1350 aluminum rod bay and is delivered to you at pure mill price. Western distributors typically add 18–32 % margin plus warehouse cost; we eliminate both.

| Cost Driver | Typical EU/US Distributor | Luoyang Xinzhaohe | Δ Saved |

|---|---|---|---|

| Rod conversion margin | 8–12 % | 0 % | –10 % |

| Inventory carry cost | 4 % | 0 % (make-to-order) | –4 % |

| Regional warehouse overhead | 6–10 % | Direct FOB/DDP | –8 % |

| Total landed advantage | ≈ 22 % |

Gauge Chart Accuracy Backed by Inline Metrology

Transformer designers need tight tolerances—especially when 0.1 mm Ø wire carries 300 strands in a 1 kg Litz bundle. Our gauge chart is not extrapolated; it is generated in real time by dual-axis laser micrometers (±0.5 µm) every 25 mm on the coating line and validated against IEC 60317-0-1 & NEMA MW 1000.

Key columns you will find in the downloadable PDF (request via e-mail):

| AWG | Nominal Ø (mm) | Min. film (µm) | Breakdown V (kV) | 20 °C Ω/km | Thermal Class Available |

|---|---|---|---|---|---|

| 42 | 0.080 | 7 | 3.0 | 3 448 | 155/180 |

| 30 | 0.254 | 12 | 4.5 | 339 | 130–220 |

| 20 | 0.812 | 30 | 7.0 | 33.2 | 130–220 |

| 10 | 2.588 | 60 | 11.0 | 3.28 | 180/200 |

All values are lot-averaged; individual certificates ship with every spool.

Customisation Without MOQ Penalty

Need 0.71 mm polyimide-over-coated wire for 220 °C class H traction transformers? Or 3.5 mm × 10 mm rectangular conductor with 0.12 mm bondable epoxy? Our metallurgy team adjusts die geometry, enamel viscosity and sintering towers within 72 h. Minimum run is 100 kg—versus 500–1 000 kg commonly demanded by European mills—so prototype windings and field repairs do not force excess inventory.

| Custom Parameter | Range | Lead Time |

|---|---|---|

| Conductor shape | Round 0.08–5.00 mm, Rect. 0.80–35 mm wide | 5 days |

| Insulation build | Single, heavy, triple, self-bonding | 3 days |

| Thermal index | 130 °C (B) to 220 °C (C) | in stock |

| Color | Natural, red, green, blue for phase ID | 2 days |

| Packaging | 1 kg plastic spool to 500 kg steel barrel | same day |

Quality & Compliance You Can Audit Remotely

ISO 9001:2015, ISO 14001, IATF 16949 (automotive)

UL recognition E476674, file OBMW2 for 155–200 °C

RoHS/REACH, IEC 60317-13, -20, -51; JIS C 3202

100 % spark test @ 3 kV (≤ 0.25 mm) or 5 kV (> 0.25 mm)

Digital twin data logs retained 10 years—send us a serial number, receive the complete process set-point record within minutes.

Logistics Engineered for Urgent Rewinds

Standard EXW lead time: 10–12 days. For motor repair shops facing unplanned outages we keep 50+ metric tons of 130/155 °C stock in Houston and Rotterdam cooperative warehouses; 48 h DDP delivery possible to North America and EU at warehouse-transfer price (no distributor margin added). All shipments vacuum-sealed with VCI film + desiccant to prevent copper oxidation during sea transit.

One-Page Commercial Summary

| Item | Luoyang Xinzhaohe | Premium EU Mill | Premium US Mill |

|---|---|---|---|

| Price per kg (1.00 mm, 155 °C) | $7.40 | $9.80 | $11.20 |

| Tooling fee (rectangular) | Waived ≥ 300 kg | € 450 | $ 600 |

| Sample lead time | 3 days | 3 weeks | 4 weeks |

| Technical on-site support | Video within 2 h | 2 days | 3 days |

Next Step—Obtain the Full Gauge Chart & Quote

E-mail cathy@transformerstrip.com with:

- Required AWG or mm size range

- Thermal class & insulation type

- Annual volume or pilot qty

- Destination port or ZIP

You will receive a detailed datasheet (PDF), RoHS/UL certificates, and an FOB/DDP quotation within 12 h. Replace expensive Western inventory with Luoyang Xinzhaohe precision—same specifications, 20 % lower landed cost, zero lead-time surprises.

📉 Import Savings Calculator

Estimate cost reduction by sourcing enamel wire gauge chart from Luoyang Xinzhaohe.