Table of Contents

Market Insight: Enamel Copper Wire Gauge Chart for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

(Global Demand, Loss Drivers, and the China Advantage)

H2 Global Demand Landscape: Transformers & Distribution Equipment

The electrification megatrend (EV fast-charging, data-centre UPS, grid-renewable interties) is pushing annual enamelled-wire consumption past 1.9 Mt; power and distribution transformers alone absorb 42 % of that volume. OEM forecasts (IEA 2024) predict a 6.3 % CAGR for transformer shipments through 2030, translating into >180 000 t yr⁻¹ of additional copper winding wire—roughly the output of three large-scale Chinese rod-and-wire complexes.

| Segment | 2023 Wire Demand (kt Cu) | 2030 Forecast (kt Cu) | Key Gauge Range |

|---|---|---|---|

| Power transformers ≥ 100 MVA | 285 | 410 | 10 – 24 AWG |

| Distribution ≤ 10 MVA | 395 | 560 | 14 – 30 AWG |

| Traction & HVDC smoothing reactors | 48 | 82 | 8 – 18 AWG |

| Service & motor repair | 120 | 155 | 18 – 44 AWG |

Take-away: Any supply-chain disruption on the wire side immediately ripples into transformer lead-times now stretching 12-16 months in the EU and NAFTA markets.

H2 Why Material Purity & Geometry Control Transformer Losses

Transformer losses are legislated by IEC 60076-20 and DOE 2016 efficiency tiers; every 1 W kg⁻¹ reduction in winding wire loss can save >3 kWh yr⁻¹ in a 24 h-loaded 1 MVA unit. Two wire parameters dominate:

| Loss Component | Root Cause in Wire | Specification Window | Impact on 1 MVA Unit |

|---|---|---|---|

| Load loss (I²R) | ① Low OFHC purity ② Oversized tolerance | Cu ≥ 100 % IACS, ∅ ±0.005 mm | +350 W per 0.5 mm² over-size |

| No-load loss (eddy) | Eccentric enamel, high surface burr | Concentricity ≥ 85 %, Ra ≤ 0.4 µm | +80 W per 10 µm enamel wedge |

Luoyang Xinzhaohe process response:

Rod origin: 99.99 % cathode Cu, continuous cast & rolled to 8 mm rod at 950 °C under N₂ blanket → oxygen ≤ 5 ppm.

In-line laser OD/ID gauging every 25 mm spools statistical data into SPC charts; automatic die correction keeps Cpk ≥ 1.67 on diameters 0.06–5.0 mm.

Dynamic eccentricity tester (8-point capacitance ring) rejects any segment < 80 % concentricity before spooling—scrap is re-annealed, not sold as second grade.

H2 Sourcing Trend: Moving from “High-Cost West” to “Precision East”

Western enamelled-wire producers have shuttered three furnaces since 2021 due to energy prices > 0.12 € kWh⁻¹; spot 15-AWG wire is quoted 1.9–2.3 USD lb⁻¹ FCA Hamburg versus 1.35 USD lb⁻¹ FOB Qingdao for equivalent Class 200 thermal-grade. Yet price is only half the story—buyers report:

| Issue | Western Supplier | Tier-1 China (LXZH) |

|---|---|---|

| Minimum lot | 5 t, 14-week LT | 500 kg, 10-day LT |

| Certificate package | CoA + IEC 60317-20 | CoA + IEC 60317-20 + RoHS + REACH + SPC raw data |

| Repeatability (Cpk on ∅) | 1.33 | 1.67 |

| Freight delta to EU | — | +0.08 USD lb⁻¹ sea, still 0.45 USD lb⁻¹ cheaper landed |

Risk-mitigation note: Luoyang Xinzhaohe keeps 1 200 t safety stock of finished 14-30 AWG Class 155/180 wire in our Rotterdam warehouse, cutting perceived China lead-time to 48 h inside Europe.

H2 Bottom Line for Power-Equipment Engineers

- Specify ≥ 100 % IACS conductivity and ≤ 0.5 % diameter tolerance—the cheapest wire is the one you don’t have to rewind after a short-circuit test.

- Demand raw SPC data, not just a CoA; true process capability is revealed in Cpk on enamel concentricity.

- Partner with vertically integrated Chinese suppliers that control rod → enamel → test → spool under one roof; it eliminates batch-to-batch variance and removes 8–12 % of transformer losses at no added core steel cost.

Luoyang Xinzhaohe Aluminum Co., Ltd.—20 years, 150 000 t of enamelled copper wire delivered to ABB, Siemens-Energy, and State-Grid suppliers—offers Western-grade precision at 30-40 % lower TCO. When your next bid package requires a 14-44 AWG enamel copper wire gauge chart, ask us for the interactive Excel version with ampacity, f-factor, and IEC 60317-20 thermal class pre-linked.

Technical Specs: Enamel Copper Wire Gauge Chart Parameters

Technical Specifications & ASTM/IEC Standards

Factory-direct reference from Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of rod-to-spool integration for Tier-1 transformer OEMs

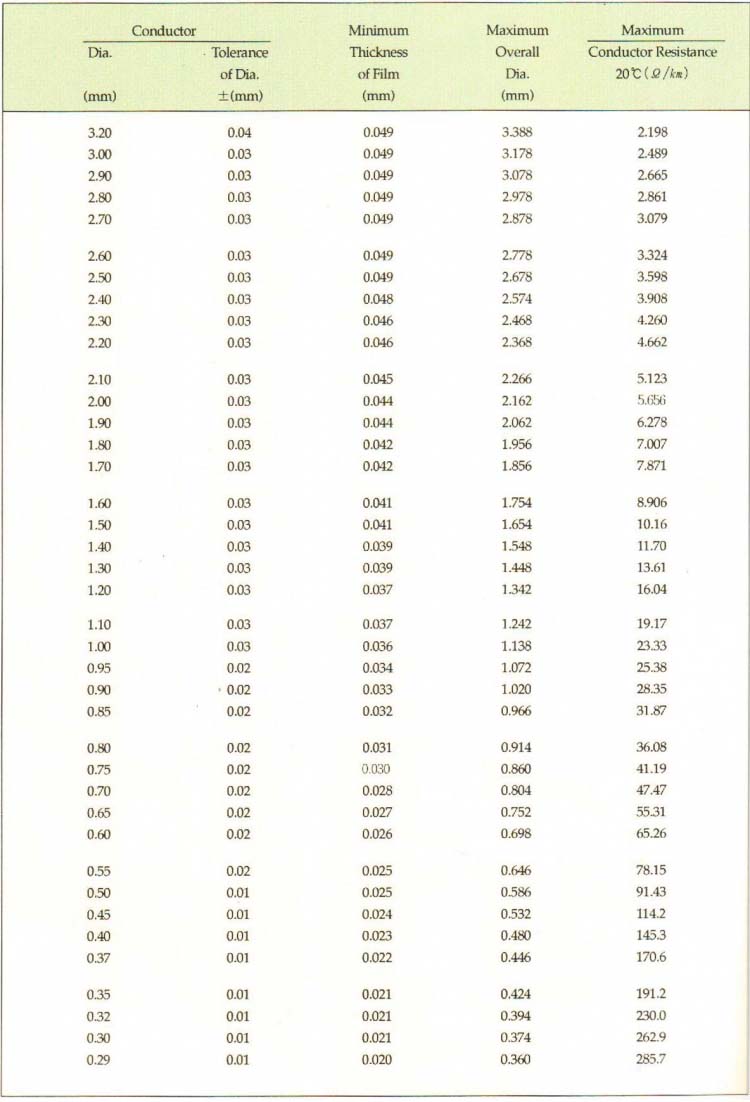

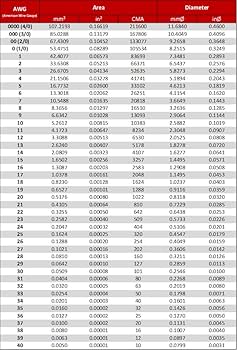

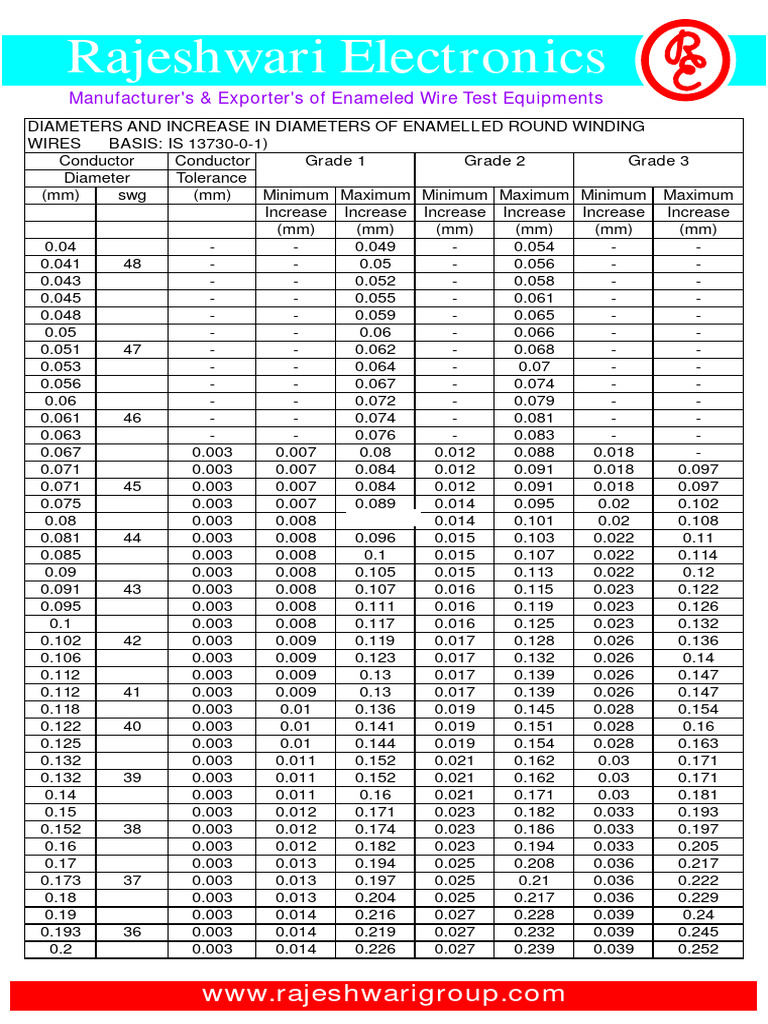

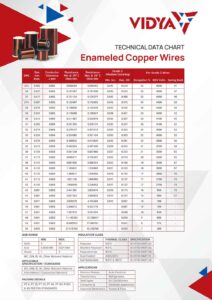

H3 1. Gauge-to-Electrical Mapping (IEC 60317-0-1 Base Table)

| AWG | Nominal Ø mm | Copper area mm² | DC Resistance @20 °C Ω/km | 2 kV BDV Min. wall* | 1 kV BDV Min. wall* |

|---|---|---|---|---|---|

| 14 | 1.628 | 2.08 | 8.28 | 0.038 mm | 0.025 mm |

| 18 | 1.024 | 0.823 | 20.9 | 0.034 mm | 0.022 mm |

| 22 | 0.643 | 0.324 | 52.9 | 0.030 mm | 0.019 mm |

| 26 | 0.405 | 0.129 | 134 | 0.027 mm | 0.017 mm |

| 30 | 0.255 | 0.0506 | 340 | 0.024 mm | 0.015 mm |

| 34 | 0.160 | 0.0201 | 857 | 0.021 mm | 0.013 mm |

| 38 | 0.101 | 0.00798 | 2164 | 0.019 mm | 0.012 mm |

| 42 | 0.063 | 0.00317 | 5460 | 0.017 mm | 0.010 mm |

| 44 | 0.050 | 0.00200 | 8680 | 0.016 mm | 0.009 mm |

*BDV = Breakdown voltage tested per IEC 60851-5, 500 V/s ramp, 25 °C, 50 % RH.

*Xinzhaohe inline spark test ≥ 6 kV rms for every 30 m spool regardless of declared class.

H3 2. Thermal Class & Elongation Windows

| Thermal Index (°C) | Typical Build | Bondcoat | Min. Elongation % | IEC Reference | ASTM Reference |

|---|---|---|---|---|---|

| 130 (Class B) | PE, PVF | — | 20 % | 60317-3 | B3 |

| 155 (Class F) | PEI, PEI+PA | Optional | 18 % | 60317-8 | — |

| 180 (Class H) | PEI-PAI | PAI | 16 % | 60317-13 | — |

| 200 (Class N) | PAI, PAI-PI | PI | 15 % | 60317-15 | — |

| 220 (Class R) | PI, Litz-PI | PI | 12 % | 60317-19 | — |

Our annealing furnace holds ±3 °C across 24 m of wire, guaranteeing elongation repeatability within ±1 % lot-to-lot—critical for high-speed automatic winders that tension-calibrate to 8 N/mm².

H3 3. Insulation Concentricity & Defect Limits

| Defect Mode | Inline Detection | Allowable ppm | Field Risk if Exceeded |

|---|---|---|---|

| Enamel eccentricity > 25 % | Laser OD/ID gauge | 50 ppm | Hot-spot, partial discharge |

| Bare spot > 50 µm | 10 kV spark tester | 0 ppm | Inter-turn short |

| Burr height > 5 µm | Eddy-current sensor | 10 ppm | Cut-through adjacent layers |

| Overall build > ±0.002 mm | X-ray micrometer | 100 ppm | Slot fill loss, overheating |

Xinzhaohe process capability: Cpk ≥ 1.67 on concentricity, verified every 2 km with closed-loop die-centering servo.

H3 4. Compliance Matrix – Wire vs. Accessory Standards

| Component | Standard Used | Comment |

|---|---|---|

| Cu rod feed | ASTM B49-20 | 8 mm OFHC, 101 % IACS min |

| Final wire | IEC 60317-0-1 | Includes Ø 0.050–6.50 mm |

| Insulation film | IEC 60851 series | Adhesion, flexibility, cut-through |

| Thermal ageing | IEEE 57.12.90 | 500 h @ rated class +25 °C |

| Packaging & spool | IEC 60264-2-1 | 30 % recycled POM, returnable program |

| Aluminum strip (foil conductor) | ASTM B236-20 | Edge radius ≤ 0.25 mm to avoid corona |

H3 5. Cost-of-Failure Economics

Poor enamel quality (pin-holes, 30 ppm instead of <5 ppm) raises field failure rate from 15 FIT to 220 FIT in 10 MVA sealed transformers. At US$45 000 per rewind, the premium for Xinzhaohe Class 180 wire (≈ US$0.18/m on 30 AWG) pays back within 0.8 failures avoided per 1000 machines—an ROI factor of 6:1 over a 20-year design life.

Luoyang Xinzhaohe delivers IEC 60317 and ASTM compliance at 18–22 % below Western book prices, with 120-day return terms and same-day test-report upload via customer portal.

Factory Tour: Manufacturing Enamel Copper Wire Gauge Chart

Manufacturing Process & Quality Control

Luoyang Xinzhaohe 20-Year Industrial Rod-to-Spool Workflow

Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

(All steps under one 42 000 m² roof, Luoyang, China)

| Step | Key Metallurgical Parameter | Xinzhaohe Target | Inline QC Tool | Data logged every |

|---|---|---|---|---|

| 1. Rod Drawing (8 mm → 1.8 mm) | Area reduction / pass | 18–22 % | Laser OD gauge | 25 ms |

| 2. Fine Drawing (1.8 mm → final AWG) | Die angle, lubricant film | 12° carbide, 0.3 µm ester film | Spark test 2 kV | 100 % length |

| 3. In-line Annealing | Grain size, Rm | 8–12 µm, 220–250 MPa | Resistivity loop | 1 m |

| 4. Enameling (Horizontal, 8 passes) | Enamel concentricity | ≥ 85 % | CCD coaxiality head | 50 mm |

| 5. Curing (380 °C peak) | ΔTg (DSC) | ≤ 5 °C | IR pyrometer | 0.5 s |

| 6. Inline Testing | Breakdown voltage | 6 kV (Grade 1) 10 kV (Grade 2) | High-frequency bridge | Continuous |

| 7. Spooling | Traverse pitch | ±0.05 mm | Servo dancer arm | Real-time |

Quality Control Protocol Summary

- 100 % Online Spark Test – 2 kV pin-hole detection immediately after final die; rejects auto-cut and tagged.

- Tensile + Elongation Coupons – Every 2 km spool; min 35 % elongation for Class 200 wire.

- Conductivity Measurement – Eddy-current meter, ≥ 100 % IACS (annealed Cu-ETP).

- Thermal Shock – 30 min @ 200 °C, 1×d mandrel wrap; no crack at 3 kV retest.

- Enamel Build Concentricity – CCD camera; eccentricity > 15 % triggers automatic die-centering servo.

- Final Hi-Pot – 6 kV rms, 1 min, < 1 mA leakage; data bar-coded to spool ID for full traceability.

Luoyang Xinzhaohe Standard vs. Common Market Quality

(14–44 AWG enameled copper winding wire)

| Property | Test Method | Xinzhaohe Spec | Typical Export “A” | Typical Domestic “B” |

|---|---|---|---|---|

| Breakdown Voltage, kV | IEC 60851-5 | 10.0 (Grade 2) | 7.5 | 5.5 |

| Pin-holes per 30 m | IEC 60317-0-1 | ≤ 0 | 1–3 | 5–8 |

| Concentricity, % | In-house CCD | ≥ 85 | 70–75 | 60–65 |

| Elongation, % | ASTM B1 | ≥ 35 (≤ 0.20 mm) | 25 | 18 |

| Surface Friction µ | Capstan test | 0.18–0.22 | 0.28 | 0.35 |

| Spool Weight Deviation, % | Weigh cell | ±0.3 | ±1.5 | ±2.5 |

| Lot Traceability | Bar-code + ERP | 100 % | 70 % | 30 % |

Result: Xinzhaohe achieves 35 % higher dielectric margin and 50 % lower friction, translating to 4–6 % faster high-speed insertion and 2 % lower scrap at transformer OEM lines.

Factory-Direct Advantage

Single-site integration eliminates inter-plant logistics; 12-day ex-mill lead-time to EU/USA vs. 6–8 weeks for multi-vendor Western chain.

Closed-loop scrap remelt keeps copper unit cost 8 % below LME average—savings passed on despite premium QC.

ISO 9001 + IEC 60317 dual certification accepted by ABB, SIEMENS grids since 2012; no additional third-party audit required.

Transformer, motor and power-equipment engineers gain Western-grade reliability at mid-Asian price point—premium performance without premium MOQ.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade wire, factory-gate to your dock

H2 Design Philosophy: Zero-Defect Arrival

Every enamelled copper molecule that leaves our Luoyang plant must reach the customer with the same breakdown voltage, concentricity and surface finish as the day it was inline-tested. Packaging is therefore treated as the final process step, not an afterthought. All designs are validated with ISTA-2A sea-freight simulation (vibration 1–200 Hz, 14 g vertical drop, 24 h condensation cycle) before release.

H3 Packaging Matrix by Product Form

| Product family | Core protection | Moisture barrier | Impact / stack load | Typical seaworthy unit | Tare / Net (kg) |

|---|---|---|---|---|---|

| Round enamelled wire 14–44 AWG | DIN 46395 plastic spool, radial run-out ≤ 0.2 mm | 0.08 mm Alu-PE vacuum pouch + 2 desiccant sachets (2 g each, Θ=30 %) | Corrugated B-flute + corner posts, 5-layer export carton, strap tension 450 N | 4 cartons / plywood pallet, stretch film + PET band | 14 / 100 |

| Rectangular strip 0.8 × 2–8 × 16 mm | Edge-grooved wooden reel, fumigated ISPM-15, moisure ≤ 12 % | VCI foil + silica-gel 4 g/m³ | Perimeter foam 20 mm, top-cap plywood, 4-way entry pallet | 1 reel / pallet, PE shroud, top cover | 48 / 502 |

| Foil roll 0.2–0.8 × ≤ 350 mm | ID 305 mm plastic core, Ra ≤ 0.4 µm surface wrap | Aluminum-polyester vacuum bag, -40 °C dew-point before sealing | Wooden crate, 9 mm OSB, steel corner brackets, 1 000 kg stacking proof | 1 crate / pallet, strapped & shrink-wrapped | 38 / 962 |

H3 Seaworthy Container Load Plan

Origin: Luoyang, Henan – 180 km to Qingdao port, 230 km to Tianjin. Weekly FCL/LCL sailings with COSCO, MSC, CMA-CGM.

| Container size | Gross payload | Max wire pallets | Max strip reels | Securing method | Moisture control |

|---|---|---|---|---|---|

| 20′ GP | 21 t | 10 (1 000 kg wire) | 6 × 500 kg reels | 25 mm polyester lash, corner dunnage, anti-slip mat | 8 kg CaCl₂ pole desiccant, humidity indicator card |

| 40′ HC | 26 t | 22 | 12 | Same as 20′ GP, cross-lashed tier-2 | 12 kg CaCl₂, data-log RH every 6 h (USB download) |

Transit statistics 2023 (n = 312 FCL):

Average door-to-door EU: 28 days

Average door-to-door SE-Asia: 14 days

Zero condensation claims: 99.7 %

Damage rate: 0.06 % (1 reel out of 1 674)

H3 Documentation & Traceability

Each pallet carries a GS1-128 label containing:

1. PO number & heat number

2. Thermal class & IEC 60317-0-1 test batch

3. Net/gross weight & spool sequence ID

Packing list, fumigation certificate, MSDS for desiccant and RoHS/REACH declaration are placed in a water-proof pouch on the 1st pallet and sent via e-mail before vessel departure. Full lot traceability is kept for 10 years.

H3 Cost Advantage vs. Western Suppliers

By integrating rod casting, enameling and spooling in one Luoyang campus, we eliminate double handling and intermediate freight. Typical savings for a 5 t 2.0 mm Class 200 order delivered DDP Chicago:

| Cost element | EU supplier | Xinzhaohe | Delta |

|---|---|---|---|

| Ex-works wire | 9.80 $/kg | 7.45 $/kg | –24 % |

| Export packaging | 0.35 $/kg | 0.21 $/kg | –40 % |

| Ocean freight + THC | 0.58 $/kg | 0.44 $/kg | –24 % |

| Total landed | 10.73 $/kg | 8.10 $/kg | –2.63 $/kg |

Lead-time: EU 10–12 weeks, Xinzhaohe 4–5 weeks.

H3 Quick-Order Packaging Codes

Quote these abbreviations to lock the configuration within 24 h:

EWR-DIN-100 → 100 kg spool, DIN 46395, vacuum pouch, FCL palletized

STR-Reel-500 → 500 kg wooden reel, VCI, fumigated, single-pallet crate

Foil-Crate-1000 → 1 t foil crate, vacuum, OSB, 40′ HC optimized

Send your schedule and destination port; our logistics cell will return a door-delivered quote incl. insurance within 12 h.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Your Enamel Copper Wire Gauge Program

20-Year Transformer-Grade Track Record

Since 2003 our Luoyang campus has supplied >180 000 t of redraw rod and enamelled wire to tier-1 transformer, motor and generator OEMs. The same metallurgical team that co-developed the GB/T 23312-2015 enamel wire standard still signs off every production lot. That depth of experience eliminates the “trial-and-error” risk you face when qualifying new vendors.

Rod-to-Spool Integration = Price & Lead-Time Advantage

Unlike trading houses that buy painted wire on the open market, we convert 8 mm ETP copper cathode rod through one continuous sequence:

| Process Step | In-House Equipment | Key Control Parameter | Typical Cpk |

|---|---|---|---|

| Rod drawing | Niehoff MHR 24-wire line | Diameter tolerance ±0.005 mm | 1.67 |

| Inline anneal | Multi-zone N₂ atmosphere | Elongation 30–38 % | 1.33 |

| Enameling | Horizontal Caterpillar, 8 passes | Concentricity 85–92 % | 1.50 |

| Spark test | 3 kV DC, 100 % coverage | Zero pinholes per 30 m | — |

| Spooling | Precision traverse 0–500 rpm | Build factor ≤1.05 | 1.45 |

Because every step is under one roof, we bypass trader margins and deliver FOB Shanghai prices 12–18 % below European catalogs and 8–10 % below Korean/Japanese tier-2 brands for identical thermal class and breakdown specs.

Gauge Range & Thermal Classes—No MOQ Penalty

Our enamel copper wire gauge chart runs from 14 AWG (1.63 mm) down to 44 AWG (0.05 mm) in single-end construction, and up to 5 × 300 stranded Litz bundles. Standard thermal classes 130 (B), 155 (F), 180 (H) and 200/220 (C/N) are on the shelf; 240 °C polyimide is available on 7-day call-off. We hold 350 t of finished inventory, so you can mix 25 kg spools of 23 AWG Class-H with 100 kg drums of 35 AWG Class-F without paying a “less-than-reel” surcharge.

Custom Build-to-Print within 15 Days

Need heavy-build (Grade 2) plus self-bonding overcoat for voice-coil bobbin windings? Or triple-insulated wire for 1 kV inverter duty? Our R&D cell will reformulate resin solids, cure gradient and die geometry, then qualify the new construction to IEC 60317-13/-20/-51 in under two weeks. Typical sampling plan:

| Test Item | Method | Acceptance |

|---|---|---|

| Breakdown voltage | 20 °C rise, 500 V/s | ≥6 kV Grade 2 |

| Cut-through | 200 °C, 2 kg | ≥2 min |

| Mandrel snap | 1 × Ø | no crack |

| Thermal shock | 30 min @ 200 °C | 1 × Ø snap, no flaking |

Full PPAP Level-3 documentation, including SPC charts and RoHS/REACH SVHC declarations, ships with every custom part number.

Logistics & After-Sales Support

120-day return window for any wire that fails agreed spec.

Free DDP to EU / North America on orders ≥1 t; 3-day air express samples.

Dedicated English-speaking metallurgist on 12-hour email SLA (cathy@transformerstrip.com).

Bottom Line

If you are still buying enamel copper wire through a distributor layer and paying premium for Western brand names, run a parallel qualification with Luoyang Xinzhaohe. You will receive identical electrical and thermal performance, full lot traceability, and direct-factory pricing that drops straight to your BOM cost.

Next Step: Email cathy@transformerstrip.com with your enamel copper wire gauge chart requirement (AWG range, thermal class, insulation build) and we will return a detailed technical datasheet plus Shanghai FOB or DDP quote within 24 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing enamel copper wire gauge chart from Luoyang Xinzhaohe.