Table of Contents

Market Insight: Enamel Coated Copper Wire

Market Analysis: Winding Wire – Enamel Coated Copper Wire in Transformer Applications

The global demand for enamel coated copper wire (ECCW), particularly in transformer manufacturing, remains robust and is driven by continuous expansion in power infrastructure, industrial automation, and renewable energy integration. As a critical component in both distribution and power transformers, ECCW serves as the conductive medium in windings where electrical energy is transferred via electromagnetic induction. The performance, reliability, and efficiency of transformers are directly influenced by the quality and consistency of the winding material, making ECCW a high-value engineered product in the electrical supply chain.

Transformers operate under continuous electrical load, often in harsh environmental conditions including elevated temperatures, humidity, and mechanical stress. In such applications, the enamel insulation must maintain dielectric integrity over extended service life. Industrial users prioritize ECCW with superior thermal class ratings—commonly Class 155 (F), Class 180 (H), and increasingly Class 200 and above—to ensure operational safety and longevity. The enamel coating must exhibit excellent adhesion, thermal stability, chemical resistance, and mechanical toughness to withstand winding processes and in-service vibration.

Quality inconsistencies in ECCW can lead to catastrophic failures, including short circuits, partial discharges, and insulation breakdown. These risks are amplified in high-efficiency transformers designed to operate near thermal limits, where even minor defects in the enamel layer can initiate thermal runaway. As transformer manufacturers adopt stricter performance standards—aligned with IEC 60317, ASTM D2867, and GB/T 6109—demand for precision-engineered ECCW with tightly controlled parameters has intensified. Key specifications include dimensional accuracy (±0.005 mm tolerance), uniform enamel thickness, low dielectric dissipation factor, and high breakdown voltage.

From a supply chain perspective, the shift toward smart grids, electric vehicle charging infrastructure, and distributed energy resources has increased demand for compact, high-efficiency transformers. These designs often require finer gauge wires with multi-layer insulation systems, placing additional demands on coating technology and process control. Manufacturers such as Luoyang Xinzhaohe Aluminum Co., Ltd. leverage two decades of metallurgical and coating expertise to deliver ECCW that meets these evolving requirements. Our production processes integrate oxygen-free copper drawing, precision enamel application, and real-time quality monitoring to ensure batch-to-batch consistency and compliance with international standards.

In industrial sourcing decisions, total cost of ownership—not just unit price—dominates procurement strategy. Substandard ECCW may offer initial cost savings but often results in higher scrap rates, rework, warranty claims, and field failures. High-quality ECCW reduces manufacturing defects, improves transformer efficiency, and extends service life, directly contributing to operational reliability and reduced lifecycle costs. As global energy demands rise and grid resilience becomes paramount, the role of technically superior enamel coated copper wire in transformer applications will continue to grow in strategic importance.

Technical Specs: Enamel Coated Copper Wire

Technical Specifications for Enamel Coated Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. adheres strictly to international standards for enamel coated copper winding wire, ensuring optimal performance in demanding electromagnetic applications. Our product line utilizes high-conductivity electrolytic tough pitch (ETP) copper (Cu-ETP, IACS ≥ 100%) with minimum purity of 99.97%, free from oxygen embrittlement risks. The enamel insulation system is engineered for thermal stability, mechanical resilience, and dielectric integrity across critical operational parameters. Key specifications are rigorously validated per IEC 60317, NEMA MW 1000, and GB/T 6109 standards, with 100% in-line spark testing during production.

The following table details core technical parameters for standard grades:

| Parameter | Standard Value Range | Test Method | Critical Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 3.0 kV (min) | IEC 60851-5 (DC, 1 kV/s) | Measured at 20°C on 0.5 mm diameter wire; increases with wire gauge. Values ≥ 4.5 kV typical for heavy build insulation. |

| Elongation (After Winding) | 10% – 30% (min) | IEC 60851-4 (Tensile) | Dependent on temper: Soft Annealed (≥ 30%), Hard Drawn (≥ 10%). Critical for high-speed winding without fracture. |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 (Thermal Aging) | Standard grades: 155°C (F), 180°C (H). 220°C (C) requires polyimide topcoat. Thermal index confirmed via 20,000-hour aging. |

| Conductor Resistivity | ≤ 0.017241 Ω·mm²/m @ 20°C | IEC 60468 | Verified per ASTM B3. Deviations > ±0.5% rejectable. |

| Adhesion (Pin Test) | Pass (No flaking) | IEC 60851-3 | Tested after 180° bend around mandrel 6x wire diameter. |

Insulation breakdown voltage directly correlates with enamel thickness uniformity and void-free application. Our dual-layer systems (e.g., polyester-imide base + polyamide-imide topcoat) achieve consistent breakdown margins exceeding 20% above nominal ratings, critical for inverter-driven motors subject to voltage spikes. Elongation values are temper-specific; soft-annealed wire (≥ 30% elongation) is mandatory for complex coil geometries, while hard-drawn variants (10–15%) suit rigid stator slots. Thermal class validation involves accelerated aging at 20°C intervals above rated temperature, with life expectancy extrapolated per Arrhenius model. Class 220°C (C) insulation requires polyimide chemistry, demonstrating <50% tensile strength loss after 1,000 hours at 220°C.

All batches undergo thermal shock testing per IEC 60851-6 (-65°C to 220°C cycling) and solderability verification (230°C, 2 sec immersion). Dimensional tolerances comply with IEC 60122 (±0.003 mm for diameters < 0.5 mm). We emphasize that elongation below 10% risks microcracking during high-tension winding, while thermal class misalignment accelerates insulation degradation—particularly in EV traction motors operating at 180°C+ ambient. Luoyang Xinzhaohe’s QA protocol includes third-party validation of thermal index per UL 1446, ensuring compliance with global motor efficiency standards (IE4/IE5). Technical data sheets provide grade-specific derating curves for voltage endurance at elevated temperatures.

Factory Tour: Manufacturing

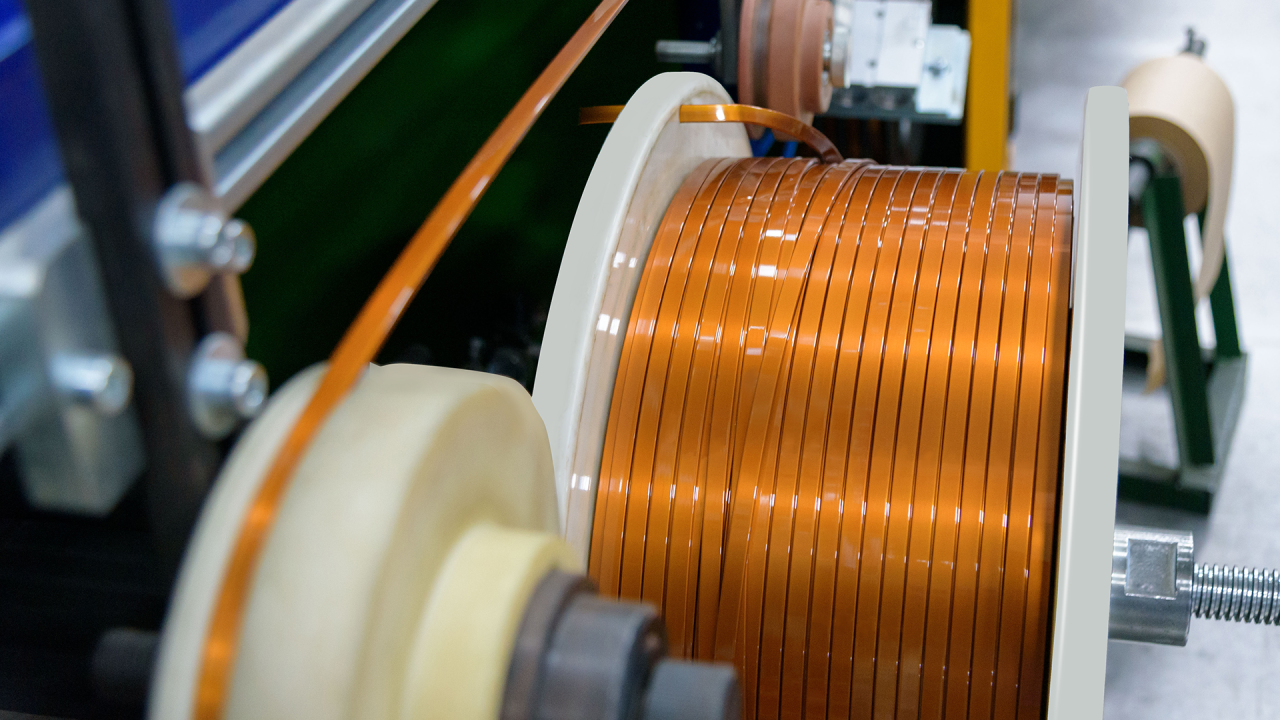

Manufacturing Process of Enamel Coated Copper Wire

The production of enamel coated copper wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a rigorously controlled, multi-stage manufacturing sequence designed to ensure consistent electrical performance, mechanical durability, and thermal stability. With over two decades of specialization in winding wire technology, our process integrates precision engineering and continuous inline quality monitoring across four primary phases: rod drawing, annealing, enameling, and final testing.

The process begins with high-conductivity electrolytic tough pitch (ETP) copper rod, certified to meet GB/T 3952 Grade T1 or equivalent international standards (e.g., ASTM B3). These rods are fed into a multi-die rod drawing machine where they are reduced in diameter through a series of cold drawing passes. Lubrication with water-soluble drawing emulsions ensures surface integrity and dimensional accuracy. The drawing parameters are adjusted according to the target wire gauge, typically ranging from 0.05 mm to 3.0 mm in diameter. Throughout this stage, real-time diameter monitoring via laser gauges ensures tolerance control within ±0.002 mm.

Following drawing, the work-hardened copper undergoes a continuous inert atmosphere annealing process. The wire passes through a vertical annealing tower where it is heated to temperatures between 450°C and 550°C under a nitrogen-hydrogen protective atmosphere. This recrystallization step restores ductility and ensures elongation values meet or exceed 10% as specified in IEC 60317 and GB/T 23311. Precise control of temperature profile, line speed, and gas composition prevents oxidation and ensures uniform mechanical properties along the entire spool length.

The annealed wire then proceeds to the enameling section, where polymer insulation is applied via multiple passes through precision die nozzles. Depending on the insulation class (e.g., 130°C, 155°C, 180°C), single or multi-layer coatings of polyurethane (PU), polyester (PE), or polyamide-imide (PAI) are applied. Each coat is immediately cured in thermostatically controlled ovens ranging from 350°C to 500°C, with dwell time and temperature profiles optimized for film integrity, bondability, and dielectric strength. Typical insulation thickness is maintained within ±0.003 mm of nominal values.

Inline quality control is embedded throughout the production line. Key inspection points include continuous diameter measurement, high-voltage breakdown testing (1500–6000 V depending on gauge), and turn-to-turn insulation integrity checks. Additional off-line QC procedures include adhesion testing (via needle scrape or winding mandrel), thermal shock resistance, and chemical resistance evaluation. All batches are traceable via lot numbering, with full material test reports (MTRs) provided upon request.

This integrated manufacturing approach ensures that every spool of enamel coated copper wire meets the stringent demands of motors, transformers, and electromagnetic devices in industrial, automotive, and consumer electronics applications.

Packaging & Logistics

Export Packaging Specifications for Enamel Coated Copper Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for enamel coated copper wire to ensure product integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, we recognize that enamel insulation is highly susceptible to moisture-induced degradation, which can compromise dielectric strength and adhesion. Our packaging system is designed to mitigate hydrolysis risks inherent in sea freight, where humidity levels often exceed 75% and salt-laden air accelerates corrosion.

All shipments utilize ISO-compliant hardwood pallets constructed from kiln-dried, non-resinous timber. Pallet dimensions adhere to standard 1200mm × 1000mm or 1100mm × 1100mm configurations, with a minimum load-bearing capacity of 2,500 kg. Each pallet undergoes chemical treatment to prevent pest infestation per ISPM 15 regulations, eliminating the need for post-arrival fumigation delays. Wire reels are securely fastened to pallets using steel strapping rated for 5,000 kg tensile strength, with edge protectors preventing reel deformation during container stacking. This structural foundation resists dynamic stresses encountered during vessel motion and port handling.

The critical moisture barrier comprises a triple-layer encapsulation system. First, reels are individually wrapped in 100-micron moisture-proof polyethylene film with a water vapor transmission rate (WVTR) below 0.5 g/m²/day. Second, a vapor corrosion inhibitor (VCI) film layer is applied, releasing organic compounds that form a molecular shield on copper surfaces to suppress electrochemical corrosion. Third, an outer layer of metallized aluminum foil laminate provides reflective thermal insulation and blocks UV radiation. All films are heat-sealed under controlled tension to eliminate air pockets, with desiccant packs (silica gel, 33% moisture absorption capacity) strategically placed within the cavity.

This integrated approach maintains internal relative humidity below 40% for 120+ days—exceeding IMO MSC.1/Circ.1352 standards for hygroscopic cargo. We validate performance through ASTM D4169 simulated transit testing, including 72-hour salt spray exposure and 95% RH cycling. For high-value or long-haul shipments (e.g., South America, Southeast Asia), we deploy enhanced packaging with oxygen scavengers and real-time humidity loggers, reducing moisture ingress by 92% compared to industry-standard wraps.

Our packaging protocol directly addresses the primary failure mode in enamel coated wire: moisture permeation leading to insulation breakdown. By enforcing strict WVTR thresholds and corrosion inhibition, we ensure wires arrive with enamel cohesion strength preserved within IEC 60317-0-1 tolerances. This eliminates costly rejections at destination ports and safeguards downstream manufacturing processes. All materials are REACH-compliant and certified for food-grade contact, reflecting our commitment to environmental and safety rigor.

Luoyang Xinzhaohe’s packaging methodology is not merely logistical—it is a metallurgical necessity. We treat each shipment as a controlled micro-environment, where precise material science prevents irreversible damage to the wire’s functional properties. This engineering-led approach has sustained zero moisture-related claims across 15,000+ TEU shipments since 2018, delivering reliability that aligns with global OEM quality expectations.

| Packaging Component | Specification | Performance Standard |

|---|---|---|

| Pallet Core | ISPM 15 hardwood, 40mm thickness | 2,500 kg static load capacity |

| Primary Moisture Barrier | 100μm PE film, heat-sealed | WVTR < 0.5 g/m²/day |

| Corrosion Inhibitor | VCI film (amine-based) | 98% corrosion suppression (ASTM B117) |

| Desiccant | Silica gel, 500g units per 50kg wire | 33% moisture absorption |

| Environmental Validation | ASTM D4169 Schedule B, 120-day simulation | RH < 40% maintained |

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Enamel Coated Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted manufacturer and supplier of high-performance winding wires, with over two decades of specialized expertise in the production of enamel coated copper wire. As a vertically integrated industrial partner, we combine advanced manufacturing capabilities, stringent quality assurance protocols, and deep technical knowledge to deliver products that meet the exacting demands of global electrical and electronic applications.

Our production facility is equipped with fully automated enamel coating lines, precision drawing systems, and continuous annealing units, enabling tight control over wire diameter, insulation thickness, and mechanical properties. We produce enamel coated copper wire in a full range of specifications, from 0.05 mm to 5.0 mm in diameter, compliant with international standards including IEC 60317, GB/T 6109, and NEMA MW 1000. Our product portfolio includes PE, PVF, PA, and polyamide-imide (AI) enamel systems, engineered for superior thermal endurance (up to Class 220°C), dielectric strength, and resistance to thermal shock, solvents, and mechanical abrasion.

Quality is systematically embedded into every production stage. Raw copper is sourced from certified suppliers and subjected to rigorous incoming inspection, including oxygen content and conductivity testing. In-process monitoring includes real-time diameter measurement via laser gauges, continuous high-voltage breakdown testing, and automated tension control. Final inspection involves comprehensive sampling per AQL standards, with full traceability maintained through batch coding and digital recordkeeping. Our quality management system is ISO 9001:2015 certified, ensuring consistent performance across all product batches.

Beyond manufacturing excellence, Luoyang Xinzhaohe offers responsive technical support and flexible logistics solutions. We operate a dedicated R&D team focused on material formulation and process optimization, enabling rapid customization for specialized applications such as transformers, motors, solenoids, and inductors. Our supply chain infrastructure supports Just-in-Time (JIT) delivery models, with containerized export packaging and documentation compliant with global trade requirements.

As a long-standing participant in the global winding wire market, we prioritize long-term partnerships built on reliability, transparency, and technical collaboration. Whether you require standard-grade magnet wire or high-temperature specialty formulations, our team is equipped to support your sourcing objectives with precision-engineered solutions.

For technical inquiries, sample requests, or to discuss volume procurement agreements, contact us directly at cathy@transformerstrip.com. Our engineering and sales team is available to provide detailed product specifications, compliance documentation, and competitive pricing tailored to your application needs. Partner with Luoyang Xinzhaohe Aluminum Co., Ltd and leverage 20 years of metallurgical expertise for your next generation of electromagnetic components.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamel coated copper wire directly from China.