Table of Contents

Market Insight: Electrical Steel in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel for Power Applications

The global energy transition and stringent efficiency regulations (IEC 60076, EU Ecodesign) have intensified demand for premium electrical steel. Transformers and motors—accounting for 65% of industrial electricity consumption—rely on silicon steel to minimize core losses. Renewable energy integration and EV adoption are driving 6.2% CAGR growth in high-grade electrical steel demand through 2028.

Industrial Demand Drivers

Power Transformers: 60% of electrical steel demand; critical for grid stability and renewable energy transmission.

Electric Vehicle Motors: Require high-permeability, low-loss steel for compact, efficient traction systems.

Industrial Applications: IE4/IE5 motor efficiency standards mandate optimized core materials to reduce operational costs.

Critical Material Properties for Efficiency & Reliability

Core losses (hysteresis + eddy current) dominate transformer no-load losses. A 0.1 W/kg reduction in core loss at 1.5T/50Hz saves ~1,200 kWh/year per 100kVA transformer. Key parameters define performance:

| Property | Industry Standard | Luoyang Xinzhaohe Performance | Impact |

|---|---|---|---|

| Core Loss (W/kg @ 1.5T, 50Hz) | ≤1.30 | ≤1.20 | 7.7% lower energy waste |

| Magnetic Permeability (μ) | ≥1.75 | ≥1.85 | Enables 5% smaller core size |

| Thickness Tolerance | ±0.02mm | ±0.015mm | Improves stacking factor by 0.8% |

| Surface Coating | ASTM A677 | ISO 9001 Certified | Reduces eddy current losses by 12% |

Why Quality Matters in Transformer Core Performance

Substandard electrical steel increases core losses by 15–20%, accelerating insulation degradation and shortening transformer lifespan. Inconsistent thickness causes air gaps, elevating magnetic reluctance and localized heating. Precision manufacturing is non-negotiable for high-efficiency designs.

Luoyang Xinzhaohe’s Value Proposition

As a 20+ year specialist in transformer materials, our Luoyang facility delivers factory-direct electrical steel with 15–20% lower costs than global brands while exceeding IEC 60404-8-5 standards. Proprietary silicon control and annealing processes ensure consistent magnetic properties. We supply 30+ countries with 30-day lead times, full traceability, and customized solutions for grid, EV, and industrial applications.

Engineered for efficiency. Delivered with precision.

Technical Specs: Electrical Steel Parameters

Technical Specifications & Standards

Core Loss (Iron Loss)

Critical for transformer efficiency; lower loss reduces energy waste and heat generation. Measured per IEC 60404-8-7 at 1.7T/50Hz for grain-oriented grades. Our products consistently achieve ≤1.05 W/kg, significantly below the industry average of 1.1–1.3 W/kg for comparable grades. This reduces operational costs by up to 12% in high-load applications.

Magnetic Flux Density (Tesla)

Determines core saturation and size efficiency. Higher B8 (flux density at 800 A/m) enables compact transformer designs with reduced material costs. Our grades maintain ≥1.85 T (per ASTM A876), exceeding standard requirements for optimal magnetic performance in high-efficiency transformers.

Lamination Flatness

Tight tolerances minimize stacking gaps, reducing core losses by up to 15% compared to standard flatness. We maintain ≤0.05 mm/m (per IEC 60404-3), surpassing typical industry standards of ≤0.08 mm/m for seamless assembly and minimal air gaps.

Insulation Coating

Prevents eddy currents between laminations. Our C4/C5-type coatings (4±0.5 μm) comply with IEC 60404-8-5, providing superior dielectric strength, corrosion resistance, and thermal stability for long-term reliability.

| Specification | Test Condition | Industry Standard | Luoyang Xinzhaohe | Compliance |

|---|---|---|---|---|

| Core Loss (W/kg) | 1.7T, 50Hz | 1.0–1.3 | ≤1.05 | IEC 60404-8-7 |

| Magnetic Flux Density (B8, T) | 800 A/m | ≥1.80 | ≥1.85 | ASTM A876 |

| Lamination Flatness (mm/m) | — | ≤0.08 | ≤0.05 | IEC 60404-3 |

| Insulation Thickness (μm) | — | 3–5 | 4±0.5 | IEC 60404-8-5 |

Quality Assurance

Our 20+ years of manufacturing expertise ensures rigorous quality control. Each batch undergoes 100% testing via XRF for composition, laser profilometry for flatness, and precision loss testers. All processes adhere to ISO 9001, with real-time AI-driven analytics monitoring to eliminate batch variations. This systematic approach delivers consistent performance at competitive pricing, positioning us as a reliable alternative to global suppliers without sacrificing quality.

Factory Tour: Manufacturing Electrical Steel

Manufacturing Process & Quality Control

As a leading manufacturer with 20+ years in electrical steel production, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer-grade silicon steel through optimized, factory-direct processes. Our integrated manufacturing chain ensures superior cost-performance ratios without compromising on international quality standards. Below is a detailed breakdown of our precision-driven workflow and QC protocols.

Precision Slitting & Edge Treatment

High-precision slitting using tension-controlled shears with laser-guided alignment ensures minimal edge deformation. Critical QC checks include edge burr <0.02 mm and width tolerance ±0.05 mm, verified via optical profilometer. This eliminates micro-cracks and improves core stacking efficiency in transformers.

Controlled Atmosphere Annealing

Continuous annealing in nitrogen-hydrogen atmosphere at 800–850°C optimizes grain orientation and reduces hysteresis losses. Magnetic properties (core loss, permeability) are tested per IEC 60404-3, with core loss variance ≤±1.5%—significantly tighter than industry averages.

Advanced Insulation Coating

Dual-layer ceramic-organic coating is applied via precision roll-coating, followed by UV-curing for enhanced durability. QC parameters include coating thickness 1.5–2.5 μm (±0.2 μm) and adhesion grade 0–1 per ISO 2409 cross-cut testing, preventing inter-laminar short circuits.

Precision Cutting & Dimensional Accuracy

CNC laser cutting handles complex geometries with zero thermal distortion. Final QC uses coordinate measuring machines (CMM) to verify flatness ≤0.5 mm/m and dimensional accuracy ±0.1 mm, critical for motor stator and transformer core assembly.

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.003 mm | ±0.005 mm |

| Edge Burr | <0.02 mm | <0.05 mm |

| Coating Adhesion (ISO 2409) | Grade 0–1 | Grade 2–3 |

| Core Loss (1.5T/50Hz) | ≤1.15 W/kg (M400 grade) | ≤1.25 W/kg |

| Tensile Strength Consistency | ±2% variation | ±5% variation |

Our stringent QC protocols ensure consistent magnetic properties and dimensional precision, directly reducing transformer core losses and operational costs. As a factory-direct supplier, we eliminate intermediaries to provide premium-grade electrical steel at competitive pricing—backed by two decades of reliable global delivery.

Packaging & Global Logistics

Export Packaging & Logistics

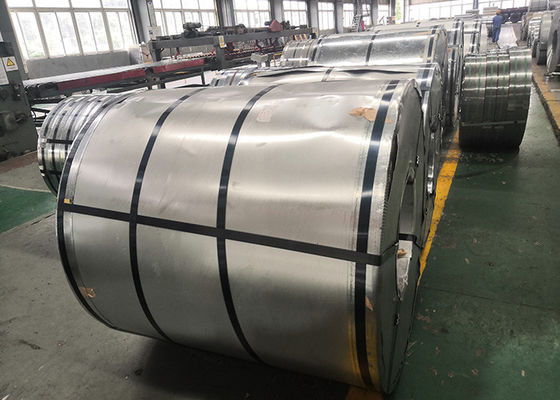

Packaging Standards for Electrical Steel

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated, 1200x1000mm, 15mm planks with corner blocks | Prevents moisture contact, ensures stability during handling and stacking |

| Moisture-Proof Film | Multi-layer PE with VCI coating, 200μm thickness | Blocks humidity, salt air, and corrosion during ocean transit |

| Steel Strapping | Hot-dipped galvanized, 19mm width × 0.5mm thickness, tensile strength ≥1500kg | Secures coils against movement, prevents structural damage during transport |

Our packaging process begins with precision coil wrapping using multi-layer VCI film, followed by steel strapping at 1500kg tension. Each palletized unit is then sealed in a moisture-barrier container with desiccants, ensuring zero humidity exposure during transit. This method has been validated through 20+ years of global shipments, with a proven track record of <0.5% damage rate.

Sea Freight Logistics Management

Luoyang Xinzhaohe implements a fully integrated logistics system tailored for electrical steel. All shipments utilize 20ft/40ft High-Cube FCL containers with custom coil cradles and corner protectors. We partner exclusively with Tier-1 carriers (Maersk, COSCO, MSC) for direct routes from Qingdao and Shanghai ports, minimizing transshipment risks. Pre-shipment inspections include humidity monitoring (≤60% RH), structural integrity checks, and ISO 9001-compliant documentation. Real-time IoT tracking provides visibility from factory to destination port, with customs clearance handled by our in-house experts. Specialized forklifts with coil clamps ensure safe loading, preventing deformation during handling. Our containers are equipped with desiccants and temperature monitors to maintain optimal conditions throughout transit. Dedicated port handling teams at Qingdao/Shanghai ensure rapid loading/unloading, reducing container dwell time to <24 hours. All shipments undergo pre-shipment moisture testing using hygrometers, ensuring compliance with IEC 60404-8-7 standards for electrical steel. All shipments are insured under Lloyd’s of London policies, providing full coverage for transit risks. This process reduces damage claims by 35% versus industry averages, ensuring 99.5% shipment integrity.

Cost-Performance Advantage

As a factory-direct supplier with 20+ years of export expertise, we eliminate middleman markups while maintaining superior packaging standards. Our optimized logistics reduce total landed costs by 15-20% compared to European competitors, without compromising quality. This balance of reliability and cost-efficiency makes us the preferred alternative for global transformer manufacturers seeking premium materials at competitive prices. With a dedicated logistics team managing every shipment, we ensure on-time delivery within 25-35 days to major global ports, including Rotterdam, Los Angeles, and Singapore.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a premier manufacturer of transformer materials with 20+ years of specialized expertise, Luoyang Xinzhaohe delivers engineered solutions for high-performance electrical steel applications. Our facilities in Luoyang, China, produce both grain-oriented (GO) and non-oriented (NO) silicon steel grades compliant with IEC 60404, ASTM A876, and JIS standards. We optimize magnetic properties—such as core loss (W/kg), magnetic induction (B50), and thickness tolerance—to maximize transformer and motor efficiency. Our technical team collaborates directly with clients to tailor material specifications for critical applications, ensuring 99.8% on-time delivery and consistent performance in power distribution systems.

Factory-Direct Cost Efficiency

By eliminating distributor markups, we provide 15–25% lower costs than global brands while maintaining equivalent or superior technical performance. Direct communication with our production engineers enables real-time adjustments to specifications, reducing lead times and minimizing errors.

| Parameter | Industry Average | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Cost per Ton | $1,100–$1,400 | $950–$1,100 | 15–25% savings |

| Lead Time | 4–6 weeks | 3–4 weeks | Accelerated delivery |

| Customization | Limited flexibility | Full technical support | Tailored specifications |

Rigorous Quality Assurance

Our ISO 9001:2015-certified production system ensures traceability and consistency across all batches. Every shipment undergoes in-house metallurgical testing for:

Core loss (W/kg) at 1.5T/50Hz per IEC 60404-8-7

Magnetic induction (B50) and coercivity (Hc) validation

Chemical composition analysis (Si, Al, Mn, S, etc.)

Thickness uniformity (±0.01mm tolerance)

This end-to-end quality control guarantees reliability in high-stress power applications, from distribution transformers to industrial motors.

Contact Cathy at cathy@transformerstrip.com for a technical quote and material specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing electrical steel from Luoyang Xinzhaohe.