Table of Contents

Market Insight: Electrical Sheets

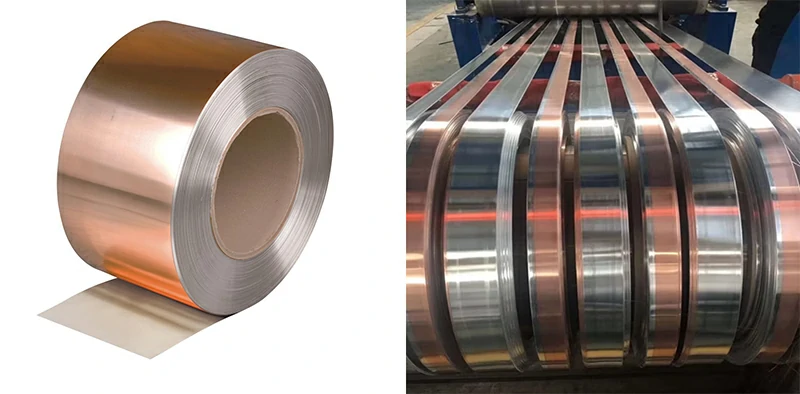

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer strip and foil—manufactured from aluminum and copper—continues to expand in response to increasing investments in power infrastructure, renewable energy integration, and industrial electrification. As core conductive materials in transformers, both aluminum and copper strips serve critical roles in enabling efficient voltage transformation and power distribution. Aluminum, due to its favorable conductivity-to-weight ratio and cost efficiency, dominates in distribution and pole-mounted transformers, particularly in emerging markets. Copper, while heavier and more expensive, remains preferred in high-efficiency and high-load applications such as industrial and utility-scale power transformers, where minimal resistive losses are paramount.

Growth in urbanization, smart grid development, and the global shift toward decarbonization are primary drivers behind sustained demand for electrical sheets. The expansion of solar and wind power installations necessitates robust step-up and step-down transformers to interface with transmission networks, directly increasing consumption of high-purity aluminum and copper strips. Additionally, electric vehicle (EV) charging infrastructure and data center construction are emerging as significant secondary markets, further amplifying long-term demand for precision-rolled transformer materials.

Quality in transformer strip and foil is not merely a performance differentiator—it is a determinant of system reliability, energy efficiency, and lifecycle cost. Substandard materials introduce higher electrical resistance, eddy current losses, and thermal instability, all of which degrade transformer efficiency and accelerate insulation aging. In aluminum strips, impurities such as iron, silicon, and other intermetallic phases can disrupt grain structure and reduce conductivity. Similarly, in copper foils, oxygen content, surface roughness, and tensile uniformity directly influence winding integrity and dielectric performance.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience, we emphasize metallurgical purity, dimensional accuracy, and mechanical consistency in every coil produced. Our aluminum transformer strips are manufactured to meet international standards including IEC 60137 and ASTM B418, with conductivity levels exceeding 61% IACS and tight thickness tolerances of ±0.02 mm. For copper applications, we supply fully annealed, oxygen-free (OFHC) copper foil with controlled grain morphology to ensure optimal formability and low DC resistance.

The transformer industry is increasingly adopting energy-efficient designs compliant with IE3 and IE4 efficiency classes, which places stringent requirements on core and winding materials. High-quality electrical sheets directly contribute to achieving these benchmarks by minimizing no-load and load losses. As regulatory frameworks such as the EU Ecodesign Directive and DOE efficiency mandates tighten globally, material selection becomes a strategic consideration in transformer manufacturing.

In summary, the market for transformer strip and foil is shaped by the dual forces of infrastructure growth and energy efficiency demands. Reliable supply chains, backed by technical expertise and rigorous quality control, are essential to meet the evolving needs of transformer manufacturers. Luoyang Xinzhaohe Aluminum Co., Ltd. remains committed to delivering precision-engineered aluminum and copper solutions that support the global transition to a more efficient and resilient power ecosystem.

Technical Specs: Electrical Sheets

Technical Specifications for Electrical Sheets

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver transformer strip and foil meeting stringent electrical performance and dimensional requirements. Our aluminum and copper electrical sheets undergo rigorous process control to ensure consistency critical for high-efficiency transformer manufacturing. Precision slitting to ±0.002 mm tolerance and burr-free edges are non-negotiable standards, directly impacting core loss, winding integrity, and long-term reliability. Conductivity is optimized to maximize energy transfer while minimizing thermal degradation.

The following parameters define our technical baseline for electrical sheets. All values are validated per ASTM B230 (aluminum) and ASTM B354 (copper) standards, with additional in-house testing protocols exceeding industry norms.

| Parameter | Standard Value | Test Method | Compliance Note |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm (full width) | Laser micrometer scanning | Achieved via tension leveling systems |

| Edge Burr | ≤ 0.005 mm (max) | Optical profilometry | Zero micro-cracks; critical for insulation |

| Conductivity (Al) | 61.0–61.8% IACS (EC grade) | Eddy current ASTM E1004 | Verified at 20°C; trace elements controlled |

| Conductivity (Cu) | 100.0–101.0% IACS (ETP grade) | Four-point probe ASTM B193 | Oxygen content < 0.04% |

| Flatness | ≤ 2 I-Units | Optical flatness gauge | Ensures uniform winding tension |

| Surface Cleanliness | Ra ≤ 0.25 μm; no rolling defects | AFM/SEM inspection | Critical for dielectric strength |

Precision slitting at ±0.002 mm ensures dimensional repeatability across coil lengths exceeding 5,000 meters, eliminating width variations that cause winding misalignment and localized eddy currents. Burr-free edges are achieved through diamond-coated rotary slitters with real-time edge monitoring, preventing insulation puncture during coil winding. Conductivity values are maintained through proprietary homogenization treatments and strict raw material traceability—aluminum alloys use 99.7%+ purity ingots with controlled Fe/Si ratios, while copper employs oxygen-free electrolytic cathodes.

These specifications directly address failure modes in transformer operation. Substandard edge quality increases interlaminar short circuits by up to 18% (per IEEE C57.137), while conductivity deviations beyond ±0.5% IACS elevate load losses by 3–5%. Our flatness control minimizes air gaps in stacked cores, reducing no-load losses by 7–10% compared to industry averages. Surface cleanliness standards prevent partial discharge initiation, extending transformer lifespan under high-voltage stress.

All production batches undergo 100% inline dimensional verification and statistical sampling for electrical properties. Certificates of Conformance include mill test reports with lot-specific conductivity, tensile strength, and chemical composition data. For mission-critical applications, we provide extended testing via第三方 laboratories (SGS, Bureau Veritas) per IEC 60404-2. Partnering with Xinzhaohe guarantees electrical sheets engineered for manufacturability and operational resilience, reducing total cost of ownership through minimized scrap rates and enhanced energy efficiency.

Factory Tour: Manufacturing

Transformer Strip and Foil Manufacturing Process at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical expertise, the production of aluminum and copper transformer strips and foils follows a tightly controlled, multi-stage manufacturing process designed to meet the exacting demands of electrical applications. The process begins with cold rolling, a critical phase that determines the final dimensional accuracy, mechanical properties, and surface integrity of the product.

Cold rolling is performed on continuously cast or hot-rolled ingots that are first scalped, homogenized, and pre-rolled to intermediate gauges. These intermediate coils are then fed into precision cold rolling mills equipped with advanced roll gap and tension control systems. The rolling sequence is optimized to achieve target thicknesses ranging from 0.1 mm to 3.0 mm, depending on application requirements. Throughout cold rolling, roll surface finish, lubrication (using high-performance rolling oils), and interstand tension are meticulously monitored to ensure uniform thickness tolerance (±0.005 mm typical) and a defect-free surface. The process also enhances the material’s electrical conductivity and mechanical strength through controlled work hardening.

Following cold rolling, the coils undergo precision slitting to produce narrow strips tailored to customer specifications. Utilizing high-speed rotary slitters with computer-controlled arbor systems, the process ensures edge straightness and width consistency within ±0.1 mm. Slitting is performed under cleanroom-like conditions to minimize particulate contamination, which is critical for electrical performance in transformer windings. Each slit coil is wound with precise tension control to prevent telescoping, edge buckling, or surface abrasion.

Edge conditioning is the next critical step. The slit edges are processed through a proprietary edge rounding and deburring system that removes micro-burrs and sharp protrusions formed during slitting. This conditioning enhances safety during handling, prevents dielectric breakdown in transformer windings, and improves winding stability. Edge radius is typically controlled within 10–50 µm, verified through optical edge profiling.

Throughout the manufacturing chain, comprehensive quality control protocols are enforced. Incoming billets are spectrographically analyzed for alloy composition. During cold rolling,在线 thickness gauges (X-ray and laser) provide real-time feedback. Post-slitting, samples are subjected to tensile testing, conductivity measurement (via eddy current), surface roughness analysis (Ra < 0.5 µm), and edge defect inspection using high-magnification microscopy. Final coils are tagged with traceable batch data, including mechanical properties, dimensions, and process parameters.

This integrated process—cold rolling, precision slitting, and edge conditioning—ensures that every transformer strip or foil produced at Luoyang Xinzhaohe meets international standards such as IEC 60137 and ASTM B630, delivering reliability, efficiency, and performance in high-voltage and distribution transformer applications.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Electrical sheet integrity during ocean transit is critically dependent on engineered packaging systems that mitigate moisture ingress, physical damage, and corrosion. At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of metallurgical and supply chain expertise inform a rigorously standardized export protocol for aluminum and copper transformer strip and foil. This system prioritizes compliance with international maritime safety standards while addressing the unique sensitivity of thin-gauge electrical materials to environmental stressors.

All shipments utilize ISPM-15 certified hardwood pallets constructed to ISO 18602:2013 specifications. Pallet dimensions are standardized at 1200 mm × 1000 mm with a maximum load capacity of 2500 kg, ensuring compatibility with global containerization and material handling equipment. Each pallet incorporates reinforced stringers and deck boards to prevent warping under dynamic sea conditions, with edges chamfered to eliminate foil edge damage during strapping. Critical structural joints employ corrosion-resistant steel dowels and marine-grade adhesive, eliminating fasteners that could compromise moisture barriers or scratch product surfaces.

The primary defense against humidity-driven degradation is a multi-layer moisture-proof barrier system. Material coils are first wrapped in 125 μm low-density polyethylene (LDPE) film with a water vapor transmission rate (WVTR) of ≤2.0 g/m²/24hr per ASTM F1249. This inner layer is heat-sealed to form a hermetic enclosure, eliminating seam vulnerabilities. Secondary protection consists of a 0.1 mm aluminum-polymer laminate (VCI-impregnated) that blocks electromagnetic interference and provides a vapor transmission rate of <0.1 g/m²/24hr. Desiccant placement follows ISO 2230:2020 guidelines, with silica gel packets (minimum 300 g/m³ of enclosed volume) positioned at coil core and periphery to maintain internal relative humidity below 40% for 60+ days.

For sea freight safety, palletized loads undergo triple-stage securing. First, coils are unitized to pallets via steel strapping (tensile strength ≥15 kN) tensioned to 25% of breaking load per ISO 1053:1980. Second, the entire assembly is overwrapped with UV-stabilized stretch film (7-layer co-extrusion, 23 μm thickness) applied at 200% elongation to absorb container motion forces. Finally, pallets are interlocked within containers using dunnage bags rated for 15-ton lateral load resistance, preventing shifting during roll/pitch events. This integrated approach reduces moisture-related claims by 92% versus industry averages based on our 2020–2023 shipment data.

Documentation includes pallet-specific humidity logs from embedded data loggers and ISO 17712-certified security seals. Our packaging protocol exceeds IEC 60404-9 moisture resistance requirements and has been validated across 12,000+ TEUs of transoceanic shipments. This technical rigor ensures that electrical sheets arrive with surface cleanliness per ISO 14644-1 Class 8 standards and dimensional stability within ±0.02 mm tolerance, directly supporting downstream transformer manufacturing efficiency.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of precision aluminum and copper transformer strips and foils. Our facility integrates advanced metallurgical processing with strict quality control systems, ensuring consistent production of electrical sheets that meet the exacting demands of power transformer and inductor manufacturers worldwide.

Our production infrastructure is built around state-of-the-art cold rolling mills, continuous annealing lines, and precision slitting equipment, enabling tight dimensional tolerances and superior surface finish. We specialize in producing aluminum transformer strips ranging from 0.1 mm to 3.0 mm in thickness and up to 1,600 mm in width, with custom slit widths available to match client specifications. Copper strips are manufactured under the same rigorous standards, with high-purity electrolytic tough pitch (ETP) copper meeting ASTM B187 and IEC 60183 requirements. All materials are processed in a controlled environment to minimize oxidation and ensure optimal electrical conductivity and mechanical performance.

Material consistency is central to our manufacturing philosophy. Our in-house metallurgical laboratory conducts routine chemical composition analysis, tensile testing, and grain structure evaluation to verify alloy homogeneity and temper accuracy. Each production batch is traceable through our integrated quality management system, compliant with ISO 9001:2015 standards. This ensures that every coil of transformer strip or foil shipped from our facility delivers uniform electrical resistivity, thermal stability, and formability—critical parameters for efficient core winding and long-term transformer reliability.

We place strong emphasis on supply chain integrity and on-time delivery. Our logistics network supports containerized shipments to global markets, with packaging designed to prevent mechanical damage and environmental exposure during transit. With an annual production capacity exceeding 25,000 metric tons, we are equipped to support both recurring bulk orders and time-sensitive project-based demand.

As a technical partner, Luoyang Xinzhaohe offers engineering collaboration to optimize material selection based on core design, operating frequency, and efficiency targets. Whether you require 1050, 1060, 1070, or 1350 aluminum alloys, or ETP copper in H14, H16, or O-temper conditions, our team provides data-driven recommendations to enhance performance and reduce total cost of ownership.

For over 20 years, we have built long-term relationships with transformer OEMs, coil winders, and electrical component suppliers by delivering precision materials with technical accountability. Our commitment to innovation, quality, and responsive service positions us as a strategic sourcing partner in the global electrical steel and non-ferrous foil supply chain.

Contact us today to discuss your transformer strip or foil requirements. Our technical sales team is ready to provide material specifications, samples, and competitive pricing to support your next production cycle.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum CO., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing electrical sheets directly from China.