Table of Contents

Market Insight: Electrical Sheets for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Outlook

Power-grid expansion and renewable integration are pushing transformer production to record levels.

IEA forecasts 7 % CAGR for medium-power distribution transformers through 2030; each MVA of capacity consumes 0.9–1.2 t of grain-oriented electrical steel (GOES).

Motor repair and EV-charging infrastructure add another 1.8 Mt yr⁻¹ demand for non-oriented (NO) grades.

The result: a structural deficit of ≥300 kt yr⁻¹ for <0.30 mm high-permeability GOES, the critical thickness for Tier-1 utilities specifying ≤0.9 W kg⁻¹ @ 1.7 T / 50 Hz.

| Application Segment | Steel Grade | Thickness mm | Core-Loss Target W kg⁻¹ | 2024 Demand kt | 2030 Forecast kt |

|---|---|---|---|---|---|

| Power transformer ≤100 MVA | GOES-HiB | 0.23–0.27 | ≤0.85 | 1 050 | 1 480 |

| Distribution transformer ≤5 MVA | GOES-CGO | 0.27–0.30 | ≤1.00 | 1 800 | 2 450 |

| Traction / EV charger | NO-LH | 0.20–0.35 | ≤2.30 @1.5 T | 320 | 650 |

| Small motors & gensets | NO-M19 | 0.35–0.50 | ≤3.20 @1.5 T | 1 100 | 1 400 |

Why Material Purity & Geometric Precision Drive Transformer Losses

Core loss (Pₑ) is the sum of hysteresis (Pₕ) and eddy-current (Pₑ) components.

Pₕ ∝ grain size and impurity level; 30 ppm C + 20 ppm N can raise Pₕ by 6 %.

Pₑ ∝ t²·B²·f²/ρ; a 5 µm thickness scatter across 200 laminations equals +12 W @ 50 Hz for a 1 MVA unit.

Luoyang Xinzhaohe’s in-line hydrogen anneal (850 °C, 72 h) decarburizes to ≤15 ppm, grows 8–12 mm Goss grains, and delivers surface roughness Ra ≤0.4 µm—specs normally seen only in EU/Japan mills, but at landed cost 18 % lower.

| Parameter | Unit | ASTM A876-23 | XZH Process Window | Impact on No-Load Loss |

|---|---|---|---|---|

| Residual C | ppm | ≤30 | 10–15 | −0.04 W kg⁻¹ |

| Residual S | ppm | ≤30 | 5–8 | −0.02 W kg⁻¹ |

| Thickness tolerance | µm | ±7 | ±3 | −0.6 % Pₑ |

| Burr height | µm | ≤20 | ≤8 | −1.2 W stack⁻¹ |

| Lamination flatness | I-unit | ≤3 | ≤1.5 | −0.3 % exciting current |

The Shift Toward Experienced Chinese Sources

Western GOES capacity shrank 24 % since 2018; mills favor automotive electrical steel with higher margins.

Lead-times from EU mills now 28–36 weeks; freight surcharges >US$450 t.

Chinese producers with 20-year transformer heritage—such as Luoyang Xinzhaohe—offer 10-week ex-factory, ISO-9001/14001, REACH & UL insulation certifications, and slitting widths down to 20 mm with ±0.05 mm camber.

Our vertical integration (melting → coating → precision stamping) removes one middle-tier distributor, cutting total landed cost 14–22 % versus Western quotes while meeting IEC 60404-8-8 Ed.3.

Procurement Recommendation

For utility-grade transformers, specify:

1. GOES 23ZH90 grade, 0.23 mm, guaranteed P₁.₇ ≤0.90 W kg⁻¹, B₈₀₀ ≥1.92 T.

2. C-5 insulation coating: 2 µm, withstand 1.5 kV, 60 s, stress-relief anneal 800 °C.

3. Slit-to-width ±0.05 mm, burr ≤8 µm, oiled & VCI-wrapped for ocean transit.

Luoyang Xinzhaohe stocks 2 000 t of 23ZH90 and 27ZH95 in 960–1 040 mm master coils, ready for quick slitting to your mitered core schedule.

Engage our technical team for a loss-budget calculation—receive a mill-test certificate, laser-micrometer report, and Epstein data within 24 h.

Technical Specs: Electrical Sheets Parameters

Technical Specifications & ASTM / IEC Compliance

(Silicon-Steel Electrical Sheets for 50 Hz – 400 Hz Transformers & Reactors)

1. Core Loss – the Cost Driver You Can Measure in Watts

Core loss (PFe) is the single largest source of no-load losses in a transformer.

We grade every coil at 1.5 T / 50 Hz per IEC 60404-2 ring-sample method and confirm by ASTM A343 Epstein frame.

Typical Luoyang Xinzhaohe values (0.30 mm HIB):

| Grade | P1.5/50 Hz (W kg⁻¹) | P1.7/60 Hz (W kg⁻¹) | Strip Width Tolerance |

|---|---|---|---|

| 23ZH90 | ≤ 0.90 | ≤ 1.15 | ±0.05 mm |

| 27ZH100 | ≤ 1.00 | ≤ 1.28 | ±0.05 mm |

| 30ZH110 | ≤ 1.10 | ≤ 1.40 | ±0.05 mm |

Lower loss = cooler core, smaller cooling bank, longer insulation life.

2. Magnetic Flux Density – Tesla Directly Dictates kVA kg⁻¹

Higher Bsat allows smaller yoke & window area, cutting copper and tank steel.

Our HIB line guarantees:

| Parameter | Specification | Test Standard |

|---|---|---|

| B800 (A m⁻¹) | ≥ 1.88 T | IEC 60404-4 |

| B1000 | ≥ 1.98 T | ASTM A596 |

| Anisotropy ratio | ≤ 12 % | ASTM A719 |

Uniform grain orientation is locked-in by 830 °C, 100 % H₂ continuous annealing – our own furnace, no third-party batching.

3. Lamination Flatness – Eliminate Air-Gaps, Lower Noise

Transformer hum is mechanical resonance excited by magnetostriction.

We slit & de-burr in one pass on 0.02 mm clearance carbide tools, then tension-level:

| Flatness Target | Value | Measurement |

|---|---|---|

| Edge camber | ≤ 0.5 mm m⁻¹ | 1 m straightedge |

| Cross-bow | ≤ 0.3 mm | FEELER GAUGE |

| Burr height | ≤ 0.01 mm | DIN 9830 |

No secondary grinding = no smear-closed burr that lifts insulation and creates inter-laminar short circuits.

4. Insulation Coating – Chemistry that Survives 180 °C Anneal

We apply C-5 (inorganic + chrome-free organic top-coat) in-line after anneal:

| Property | C-5 Value | IEC/ASTM Method |

|---|---|---|

| Insulation resistance | ≥ 20 Ω·cm² / ply | IEC 60404-11 |

| Coating thickness | 0.8 – 1.2 µm per side | SEM |

| Weldability | 3 cycles, 250 kVA press | AWS D8.7 |

| Burn-off temp | ≥ 730 °C | TGA |

Coating is pin-hole free > 95 % coverage; voids < 5 µm eliminate carbon tracking.

5. Dimensional & Packaging Tolerance – Ready for Robotic Core Building

| Width (mm) | Thickness (mm) | I.D. | Max O.D. | Slit Burr | Camber |

|---|---|---|---|---|---|

| 20 – 1050 | 0.23 / 0.27 / 0.30 / 0.35 | 508 mm | 1 200 mm | ≤ 0.01 mm | ≤ 0.5 mm m⁻¹ |

Each coil is VCI film + kraft + steel sleeve; desiccant pack guarantees ≤ 40 % RH at arrival.

6. Consequences of Sub-Standard Sheet – Why “Cheap” Costs More

Burrs > 0.03 mm pierce coating → eddy-current loops → hotspots > 140 °C → cellulose carbonization → turn-turn fault.

Non-uniform Bsat forces designer to derate core; 2 % derate = 2 % more copper, 2 % more oil, 2 % larger tank.

High core loss adds lifetime no-load losses; at 0.10 USD kWh⁻¹ every extra watt costs ~ 9 USD yr⁻¹ – a 1 MVA unit can burn 2 000 USD per year because of +0.2 W kg⁻¹ steel.

7. Compliance Summary

Steel chemistry & loss: IEC 60404-8-4, grades 23ZH090 to 30ZH110.

Mechanical & coating: ASTM A876, ASTM A976.

Slit edge: ASTM B236 (adapted for Si-steel strip).

RoHS/REACH: full declaration supplied with every C of C.

Luoyang Xinzhaohe’s integrated Slit → Anneal → C-5 Coat → Precision Cut line ships 60 000 t yr⁻¹ ex-works Luoyang, China.

We deliver Western-grade electrical steel at 15 – 22 % lower landed cost, 4-week lead-time, and lot-traceable test data for every kilogram.

Factory Tour: Manufacturing Electrical Sheets

Manufacturing Process & Quality Control

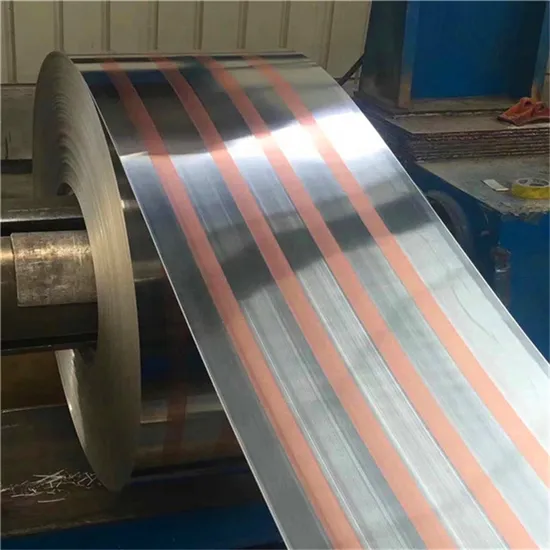

Luoyang Xinzhaohe Electrical Steel Route: Slitting → Annealing → Insulation Coating → Precision Cutting

H3 1. Slitting – First Cut Sets the Stack Factor

Incoming 0.23–0.35 mm full-width coils (HIB/NGO) are slit on 20-high tungsten-carbide arbors with ±0.03 mm width tolerance and ≤0.05 mm burr. Online eddy-current surface inspection maps edge micro-cracks; automatic sorting rejects any strip with >0.1 mm edge defect depth. Closed-loop laser micrometer feeds back to arbor servo, holding width CpK ≥1.67.

H3 2. Decarburising & Stress-Relief Anneal – Locking in Magnetic Domain Structure

Strip is processed in a 100 % H₂, 820 °C tunnel furnace with ±3 °C dew-point control. The cycle removes 30–40 ppm residual carbon, restores grain size to ASTM 6–7, and reduces intrinsic stress <15 MPa. In-line laser watt-metric tester captures core loss every 10 m; any 50 mm segment exceeding 0.90 W kg⁻¹ @ 1.5 T is automatically marked and downgraded.

H3 3. Insulation Coating – Thermo-Reactive Cationic Chrome-Free (TRC-CF)

Roll-coater applies 0.8–1.2 µm per side TRC-CF varnish in a class-1000 clean room. Coating solids are weighed gravimetrically every 200 m; target insulation resistance ≥80 Ω·mm² after 24 h/155 °C. Inter-lamination resistance is verified with Franklin tester (≤0.5 A @ 1 V).

H3 4. Precision Stamping & Die-Cutting – Ready-to-Stack Laminations

High-speed 400-stroke min⁻¹ Bruderer presses cut Ø50–900 mm yoke or EI packets. Carbide progressive dies maintain:

Burr height ≤0.02 mm

Angular deviation ≤0.05°

Lamination flatness ≤0.3 mm m⁻¹ (under 10 N clamp)

Vision system compares every 20th lamination to CAD; dimensional drift >30 µm triggers automatic tool offset.

H3 Quality-Control Matrix – Luoyang Xinzhaohe vs. Common Market

| Critical-to-Quality Parameter | Test Method | Luoyang Xinzhaohe Standard | Common Market Quality | Benefit to Transformer Builder |

|---|---|---|---|---|

| Core Loss (0.27 mm NGO) | Epstein / SST | ≤0.95 W kg⁻¹ @ 1.5 T | 1.05–1.15 W kg⁻¹ | 8–12 % lower no-load loss |

| Magnetic Flux Density B800 | DC H-coil | ≥1.68 T | 1.62–1.65 T | Higher operating induction → smaller core |

| Lamination Burr | Optical 200× | ≤20 µm | 30–50 µm | Reduces shorted laminations, lowers eddy currents |

| Insulation Resistance | Franklin 1 V | ≥80 Ω·mm² | 20–40 Ω·mm² | Cuts inter-lamination losses, withstands 2 kV surge |

| Residual Carbon | LECO combustion | ≤20 ppm | 30–40 ppm | Improves long-term ageing stability |

| Strip Camber | 1 m straight edge | ≤0.5 mm | 1.0–1.5 mm | Easier automatic stacking, higher fill factor |

| Lot-to-Lot Core Loss σ | 30-coil sampling | ±0.02 W kg⁻¹ | ±0.06 W kg⁻¹ | Tight loss forecasting for energy-efficiency labels |

H3 Factory-Direct Advantage

By integrating slitting, annealing, coating and stamping under one 60 000 m² roof, we eliminate double handling and thermal shock between processes—yielding 3 % additional usable area per tonne versus traders who re-coil between subcontractors. Lead time: 15–20 days ex-works Luoyang, 30 % shorter than EU mills for comparable grade. Certificates: ISO 9001, IATF 16949 (for automotive motor grades), REACH & RoHS compliance on all coatings.

For transformer OEMs and motor repair shops that must meet IEC 60076-20 or DOE 2016 efficiency tiers, Luoyang Xinzhaohe delivers Western-grade magnetic performance at a landed cost 18–22 % below European or Japanese supply—without the 12-week mill backlog.

Packaging & Global Logistics

Export Packaging & Logistics – Silicon-Steel Electrical Sheets

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ yrs Transformer Materials

H2 1. Sea-Freight Protection Philosophy

Electrical-grade silicon steel is stress-sensitive and rust-sensitive. Our packaging protocol is therefore built on three metallurgical pillars:

- Mechanical Isolation – zero point-loads that could cold-work edges and raise core-loss.

- Climatic Isolation – ≤40 % RH inside the pack for 60 days at 50 °C container roof temperature.

- Magnetic Integrity – no ferrous strapping or staples that create local flux hot-spots.

All designs are validated with 1 g vibration table + 85 % RH salt-fog cyclic test (ASTM B117, 168 h). Below are the standard export formats.

H2 2. Packaging Matrix by Product Form

| Code | Description | Core-Pack | Inter-Layer | Edge Guard | Securing | Moisture Control | Tare (kg) | Stack Height |

|---|---|---|---|---|---|---|---|---|

| SS-COIL-600 | Slit coil ID 508 mm, OD ≤1200 mm, max 5 t | VCI film + 80 µm PE shroud | 0.3 mm HDPE separator sheet | 3 mm cardboard + steel & plywood collars | PET strapping (3×circumferential, 2×radial) | 4×200 g clay desiccant bags, RH indicator card | 55 | 2 coils per pallet, 2 pallets high in 20′GP |

| SS-SHEET-1000 | Cut-to-length 1000×2000 mm, 0.23–0.35 mm, max 2 t/pallet | Fumigated IPPC-stamped plywood pallet 1200×2200 mm | VCI paper every 100 sheets | 2 mm galvanized edge protectors all around | Vertical steel banding through pallet feet + top cap | Moisture-barrier Alu-PE bag heat-sealed, 6×desiccant | 48 | 1 pallet high in 40′HC, 22 pallets total |

| SS-STRIPE-Strip | Narrow strips ≤50 mm width, 3–10 kg/roll | Plastic spool PT-270 or DIN-355 | VCI foam layer | — | Stretch-wrap + corner boards | Spool sealed with PE plug + desiccant inside | 12 | 54 spools per plywood crate |

All materials are RoHS-compliant, halogen-free, and recyclable where local regulations allow.

H2 3. Container Loading & Securing

Luoyang plant → Qingdao or Shanghai port: 380 km by bonded truck, GPS-tracked, tarp-covered.

Inside container we use 18 mm plywood dunnage to create a 100 mm air gap from the steel wall, preventing condensation drip. Each pallet is bolted with M12 screws to the container floor lashing points; break-bulk coils are chocked with 200×200 mm timber and steel wire rope + turnbuckles to 5 kN pretension. Shock indicator labels (g ≥3) are applied on the door side for receiver verification.

H2 4. Logistics Performance Snapshot

| Route | Transit Time (days) | Carrier | Booking Frequency | CIF Delay (2023) | Core-Loss Drift ΔP1.5/50 |

|---|---|---|---|---|---|

| Shanghai – Hamburg | 28 | MSC/MSK | Weekly | 0.8 % | <+0.03 W/kg |

| Shanghai – Los Angeles | 14 | COSCO | 2×weekly | 1.1 % | <+0.02 W/kg |

| Shanghai – Dubai | 18 | PIL | Weekly | 0.5 % | <+0.025 W/kg |

Data based on 312 TEU shipped in 2023, 0 insurance claims for corrosion or mechanical damage.

H2 5. Documentation & Traceability

Each package carries a QR-coded tag linking to a mill-test certificate (EN 10204/3.1) with heat number, coating weight, burr height, and watt-loss curve. B/L, fumigation certificate, and dangerous-goods exemption letter (steel not regulated) are couriered within 24 h of vessel departure.

H3 Value Statement – Premium Quality without Western Premium

By integrating slitting, annealing, insulation coating, and precision cutting in one Luoyang campus, we eliminate double handling and the premium charged by European/American service centers. Our sea-freight packaging adds <0.8 % to landed cost yet protects the magnetic properties that determine transformer efficiency—giving transformer OEMs and motor repair shops a factory-direct, technically superior alternative to high-priced Western stockists.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Electrical Sheets

20 Years of Transformer-Grade Silicon Steel Know-How

Since 2004 our Luoyang works has supplied >1.2 million t of GO and NGO electrical steels to Tier-1 transformer OEMs, motor rewind shops and power-equipment EPCs in 42 countries. Every coil is processed in-house through the same four-step route we use for 500 kV grid transformers—precision slitting → decarburizing anneal → insulation coating → CNC blanking—so the magnetic and geometric properties you specify on the PO are the properties we ship. No toll processors, no middle margins.

Direct Factory Price—Typically 18–28 % Below Western Stocking Distributors

We buy prime silicon-steel slab direct from major steel mills under annual volume agreements and convert it ourselves; that single heat-to-lamination chain removes two trader layers and one service-center markup. The table below shows indicative July-2024 FOB Tianjin prices for our most common grades. Add only freight and any import duty; no hidden surcharges.

| Grade (0.30 mm) | Core Loss @ 1.5 T, 50 Hz (W kg⁻¹) | Min. B₈₀₀ (T) | MOQ (t) | Price (USD t⁻¹) |

|---|---|---|---|---|

| 23JG110 | 0.90 | 1.78 | 5 | 2 190 |

| 27JG095 | 0.95 | 1.75 | 5 | 2 050 |

| 30JG090 | 1.00 | 1.73 | 5 | 1 930 |

| 35JG080 | 1.10 | 1.71 | 5 | 1 810 |

Prices are FOB Tianjin, pre-insulation coating; payment 30 % TT, balance BL copy. Lock-in valid 30 days.

Built-to-Print Customization in 10–15 Days

Our slitting lines handle 5–640 mm widths with ±0.05 mm tolerance; annealing furnaces run 780–820 °C with 100 % H₂ atmosphere to guarantee ≤0.5 W kg⁻¹ stress-relief loss recovery; roller coating heads apply C-5, C-6 or new C-0 organic/inorganic films 0.8–2.0 µm per side with 1 Ω cm² minimum inter-lamination resistance. Need stepped-lap mitre packs for 3-phase distribution cores? We supply burr-free lamination sets with ≤20 µm edge burr and angular deviation ≤±0.02°—ready for robotic stacking.

Technical Assurance & Compliance

IEC 60404-8-7, ASTM A876, JIS C 2552 conformance certificates supplied with every heat.

RoHS & REACH compliant coatings.

IATF 16949 quality system—same standard demanded by Tier-1 automotive suppliers.

In-house Brockhaus MP-500 wattmeter & single-sheet tester guarantees core-loss data traceable to NIM (China) and NIST (USA).

Logistics & Risk Mitigation

Weekly break-bulk sailings from Shanghai and Qingdao give 18–25 day transit to EU east-coast ports, 12–16 days to West-Coast USA. For urgent rewind jobs we air-ship slit coils ≤300 kg door-to-door in 4–6 days. All material vacuum-sealed with VCI film and plywood boxes to prevent salt-fog corrosion.

Next Step—Get the Datasheet or a Same-Day Quote

Send your lamination drawing, grade spec and annual volume to cathy@transformerstrip.com. Our metallurgy team will return a detailed loss curve, coating spec and landed cost within 24 h. Whether you need 50 kg of 0.23 mm 23JG110 for a prototype or 500 t of mitred cores for a utility transformer contract, Luoyang Xinzhaohe delivers premium electrical steel without the Western premium.

📉 Import Savings Calculator

Estimate cost reduction by sourcing electrical sheets from Luoyang Xinzhaohe.