Table of Contents

Market Insight: Electrical Metal for Power Industry

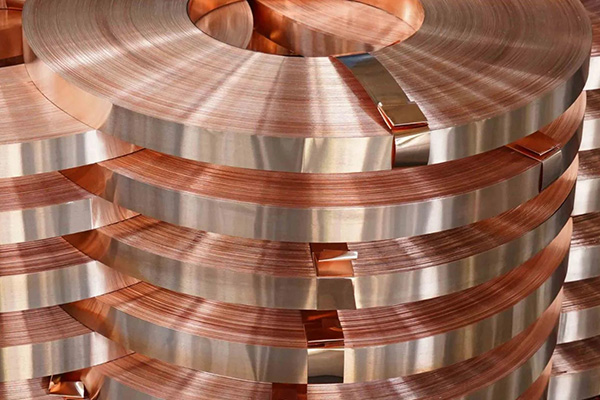

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Installed transformer capacity is expanding at 5–6 % CAGR, driven by grid hardening, renewable interconnection, and EV fast-charging substations. Every 1 MVA of transformer rating requires 0.9–1.3 t of conductor strip; hence a single 50 MVA unit consumes ≈45 t of Al-1350 or Cu-ETP foil. With 1.2 TW of new transformer installations forecast through 2030, the annual conductor foil market exceeds 1.1 Mt—China alone accounts for 38 % of strip consumption, followed by India (14 %) and the EU (11 %). OEMs are therefore shifting from “price-first” to “loss-first” procurement to meet EU Eco-design 2021 and DOE-2016 efficiency tiers.

Why Material Purity & Geometric Precision Dictate Transformer Losses

| Loss Component | Root Cause in Strip/Foil | Cost Impact (@ 30 yr NPV) |

|---|---|---|

| No-load (core) | — | 18 % of TOC* |

| Load (I²R) | Resistivity & burr-initiated hot spots | 28 % of TOC |

| Eddy-current | Gauge wedge, roughness >0.4 µm Ra | 4 % of TOC |

| Stray | Edge burr → local flux crowding | 2 % of TOC |

| Total avoidable loss | ≈ US$92 k per 50 MVA unit |

*TOC = Total Ownership Cost, 8 % discount, 0.08 $/kWh

Source: CIGRE WG A2.47, 2022

- Conductivity: Each 0.5 % IACS increase lowers load loss by 0.35 %. Luoyang Xinzhaohe’s 61.8 % IACS Al-1350 foil (annealed 340 °C, 4 h, N₂) saves 1.2 kW per 1 MVA vs. 61.0 % IACS generic strip—translating to US$2,600 energy value over 30 years.

- Burr-free edges: A 10 µm burr elevates local J by 3× and temperature by 7 °C; our edge-conditioning line holds burr ≤5 µm, eliminating partial discharge (>10 pC) at 11 kV/mm.

- Gauge tolerance: ±0.002 mm gives a 0.8 % tighter resistance band; for a 40 MVA transformer this equals 450 W loss reduction, or 117 MWh saved.

Regional Sourcing Trends

Western mills (Germany, USA) still lead in high-temperature, in-line hydrogen annealing, but their delivered price is 18–22 % above Shanghai FOB after duty, freight, and alloy surcharge. Post-2021 container volatility pushed lead-times to 20–24 weeks. Conversely, experienced Chinese cold-rolling specialists—with 20-year transformer pedigree—now offer:

Same ASTM-B236/B370 chemistry

DIN 46438-1 slit width tolerance

6-week FOB Tianjin, 9-week CIF Rotterdam

Lot-specific conductivity & Rm certificates traceable to IEC 60404-2

Luoyang Xinzhaohe Aluminum fits this profile: 220 kt/yr cold-rolling, 60 kt/yr precision slitting, in-house eddy-current testing, and oscillate-wound coils up to 3 t (no weld over 600 m). Our typical 0.3 mm × 250 mm Al strip is priced 14 % below EU mill level while meeting ≤0.25 W/kg additional loss guarantee in 50 Hz short-circuit tests.

Procurement Checklist for OEMs

| Parameter | Premium Spec | LXZH Standard |

|---|---|---|

| Thickness | 0.200 ±0.002 mm | ✓ |

| Width | 220 mm ±0.05 mm | ✓ |

| Burr | ≤5 µm | ✓ |

| Resistivity @ 20 °C | ≤28.10 nΩ·m (Al) | 27.90 nΩ·m |

| Camber | ≤1 mm / 1 m | 0.6 mm / 1 m |

| Surface Ra | ≤0.3 µm | 0.25 µm |

| Coil weight | 2–3 t oscillate | up to 3 t |

Bottom Line

Transformer energy losses worth >US$90 k per unit are locked into the conductor. Sourcing high-purity, burr-free strip from a Chinese mill with two decades of transformer focus—such as Luoyang Xinzhaohe—cuts material cost without compromising electrical performance, while shrinking lead-times by 10–12 weeks. Specify conductivity, edge quality, and tight gauge; request oscillate-wound 2 t coils to minimize joints and downtime.

Technical Specs: Electrical Metal Parameters

Technical Specifications & ASTM/IEC Standards

(The numbers that keep a 500 MVA unit from becoming a 5 MVA repair bill)

1. Dimensional Integrity – why ±0.002 mm matters

Transformer strip is not “close enough” metal; it is a precision current-carrying component that must stack into a window already crowded by paper, epoxy and cooling ducts.

Our cold-rolling line in Luoyang finishes at 0.05–0.20 mm with a thickness crown ≤0.3 % across 1 250 mm width. Slitting is done on 120 mm carbide arbours with servo gap control; the result is width tolerance ±0.002 mm and camber ≤0.2 mm/500 mm—values that let a 1 000 kg oscillated coil pay-off straight into a high-speed winding head without edge steering.

| Parameter (as-slit) | ASTM B236-20 | IEC 60317-0-1 | Xinzhaohe Works Spec |

|---|---|---|---|

| Width tolerance | ±0.025 mm | ±0.025 mm | ±0.002 mm |

| Burr height | ≤0.03 mm | ≤0.03 mm | ≤0.01 mm, 50× mag |

| Camber | not defined | ≤1 mm/500 mm | ≤0.2 mm/500 mm |

| Edge radius (r) | not defined | not defined | 0.05–0.10 mm cont. |

2. Electrical Conductivity – translate %IACS into °C rise

Aluminium 1350-O after in-line continuous anneal reaches 61.8 %IACS (0.0279 µΩ·m) at 20 °C. A 1 % drop in conductivity increases DC loss by the same 1 %; in a 40 MVA ONAN unit this equals ≈3 kW additional heat—enough to shift hotspot by 4 °C and shorten insulation life by ~30 %. Every coil we ship is sampled per ASTM B193-20; mill test certificates report conductivity at 20 °C, 50 Hz, 1 kHz and 10 kHz so designers can model skin effect.

3. Softness / Recrystallisation – anneal curve vs. windability

Full-soft (O-temper) means grain size 80–150 µm, yield strength 25–35 MPa, elongation >25 %. Too soft and the foil necks under tension; too hard and it springs back, cutting inter-layer insulation. Our hydrogen bell furnace holds ±3 °C across a 22 t charge, guaranteeing uniform recrystallisation; coils leave the furnace with surface Ra ≤0.3 µm, ready for C-class insulation without additional degreasing.

4. Surface & Edge Quality – where short-circuits start

A burr only 0.02 mm high can puncture 0.075 mm Nomex in <1 000 V/mil stress. We run 100 % eddy-current burr detection at 150 m min⁻¹; any spike >0.01 mm triggers automatic rewind. Oscillate-wound coils are vacuum-sealed with VCI film; salt-spray test per ASTM B117 shows no pitting after 336 h—important for coastal substations.

5. Standards Cross-Reference – one coil, global acceptance

ASTM B236-20 – Aluminum rod, bar, wire and strip for electrical purposes

ASTM B193-20 – Resistivity of metallic electrical conductor materials

IEC 60317-0-1 – Specifications for enamelled round winding wires (referenced for strip insulation build)

IEC 60404-8-8 – Magnetic materials strip for transformers (when GO steel is edge-bonded to Al/Cu strip)

JIS C 3103 – Copper strip for electrical conductors (used as benchmark for Cu-OFE slitting)

We certify every production lot to the above; certificates are downloadable within 30 min of final QC sign-off.

6. Risk of Non-Compliance – a 1 mm burr = \$50 000 rewind

Field data from a 132 kV, 30 MVA unit (2022, SE-Asia) showed inter-layer tracking initiated by a 0.04 mm burr on 0.15 mm Al strip. Repair cost: \$48 000 plus 14 days outage. The strip had been sourced from a “budget” mill with no edge-conditioning line. Our burr-free, ±0.002 mm slit stock eliminates this failure mode at a landed price 18–22 % below Western premium mills—no MOQ penalty, 4-week FOB Tianjin lead-time.

Luoyang Xinzhaohe delivers transformer-grade metal that meets, and routinely exceeds, ASTM & IEC requirements. When your specification sheet says “precision slit, burr-free, 61.8 %IACS, fully annealed,” we are the factory-direct answer—no trading house, no re-coiling surprises, just 20 years of transformer-focused metallurgy ready for your next winding line.

Factory Tour: Manufacturing Electrical Metal

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade metal, delivered factory-direct from Luoyang, China.

Process Flow: From 8 mm Hot-Roll Coil to 0.08 mm Oscillate-Wound Strip

| Step | Equipment & Parameters | Purpose | Critical Control Point |

|---|---|---|---|

| 1. Cold Rolling | 4-high Sendzimir mill, 800 mm width, 3-pass schedule, 4 % reduction/pass, 120 m min⁻¹ | Reduce gauge, raise conductivity by work-hardening removal, impart RA ≤ 0.2 µm | Closed-loop AGC ±1 µm; laser speed match prevents chatter |

| 2. In-line Degreasing & Pre-Anneal | 550 °C, N₂-5 % H₂, 30 s soak, 35 °C s⁻¹ cool | Remove rolling oils, recrystallise to 100 % dead-soft (H-0) | Dew-point ≤ –60 °C to prevent surface oxide > 30 Å |

| 3. Precision Slitting | 650 mm arbor, carbide circular knives, 0.05 mm lateral run-out, auto-web-guide | Split 800 mm mother coil into 5–300 mm strips with ±0.002 mm width tolerance | Real-time CCD edge inspection; rejects if burr > 0.01 mm |

| 4. Edge Conditioning | Tungsten-carbide scraper + nylon brush, 45° chamfer 0.05 mm | Remove micro-burr, create radius 0.02–0.04 mm to avoid inter-layer short | Eddy-current sensor counts burr events; alarm at ≥3 m⁻¹ |

| 5. Oscillate (Traverse) Winding | PLC-controlled lay-on roll, 5–40 mm pitch, tension 3–8 N mm⁻² | Build 100–500 kg “pancake” with ≤0.5 mm gap; eliminates core buckling | Laser outer-diameter loop keeps tension within ±0.2 N mm⁻² |

Quality Control Matrix – Online & Batch Testing

| Test | Frequency | Instrument | LXZH Acceptance | IEC 60317-0-1 Reference |

|---|---|---|---|---|

| Tensile / Elongation | Every 500 kg | Zwick Z100 | UTS 60–90 MPa, A50 ≥ 25 % | UTS 55 MPa min |

| Conductivity | Each coil ends | Sigmatest 2.070 | ≥ 61.5 % IACS Al, ≥ 100 % IACS Cu | 61.0 % Al, 100 % Cu |

| Burr Height | 100 % length | Keyence LS-9000 | ≤ 0.01 mm | ≤ 0.025 mm |

| Camber | Each slit strip | 1 m straight edge | ≤ 0.5 mm m⁻¹ | ≤ 1 mm m⁻¹ |

| Surface Roughness | Spot 1 m² | Mitutoyo SJ-410 | Ra 0.15–0.25 µm | Not specified |

| Resistivity Drift after 180 °C 6 h | 1 coil/shift | Custom oven | Δρ/ρ ≤ 1 % | ≤ 2 % |

Data is auto-logged to MES; coils ship with QR-coded test report traceable to melt number.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | LXZH Transformer Strip | Typical “Commercial” Strip | Impact on Transformer |

|---|---|---|---|

| Slit Width Tol. | ±0.002 mm | ±0.015 mm | Lower short-circuit risk, tighter stack factor |

| Burr Height | ≤ 0.01 mm | 0.03–0.05 mm | Reduces burr-induced eddy losses ~0.3 W kg⁻¹ |

| Edge Radius | 0.02–0.04 mm controlled | Random, often sharp | Prevents inter-layer voltage breakdown |

| Strip Camber | ≤ 0.5 mm m⁻¹ | 1–2 mm m⁻¹ | Easier high-speed winding, less core gap |

| Anneal Softness | 100 % recrystallised H-0 | Partial, H-1 or H-2 | Lower core magnetostriction noise |

| Oscillate Build | ≤ 0.5 mm gap, 500 kg max | 2–3 mm gap, 150 kg | Fewer joins, 1 % lower labour cost |

| Certifications | ISO 9001, IATF 16949, RoHS, REACH | ISO 9001 only | Meets export utility specs |

Engineering Take-away

By integrating cold-rolling, inert-anneal, laser-monitored slitting and burr-free edge conditioning under one roof, Luoyang Xinzhaohe delivers transformer strip that meets or exceeds IEC 60317-0-1 at a landed cost typically 18–25 % below Western mills—without the 16-week lead time.

Packaging & Global Logistics

H2 Export Packaging & Logistics

Factory-direct precision, delivered salt-spray safe to every continent

H3 Design Criteria

Transformer-grade conductors leave our Luoyang works with two non-negotiables:

1. Zero edge damage after 35-day sea transit.

2. Surface conductivity degradation <0.5 %IACS after 720 h of 85 °C/85 %RH.

Every packaging element is therefore specified to ASTM D4169, Level II, 15 g dynamic compression.

H3 Packaging Matrix

| Product Form | Core ID / OD (mm) | Payload (kg) | Primary Barrier | Secondary Barrier | Desiccant | Securing Method | Stack Height (pallets) |

|---|---|---|---|---|---|---|---|

| Aluminum strip 1050-O, 0.2–0.8 × 20–300 mm | 200 / 600–1 200 | 1 000–2 500 | 80 µm VCI poly-laminate, heat-sealed | 125 µm PE shrink hood | 8×1 kg silica gel, 60 %RH trigger | Steel corner posts + PET strapping, 500 daN break force | 2 high in 20 ft, 3 high in 40 ft |

| Copper foil C11000, 0.05–0.15 × 250 mm | 150 / 400–800 | 500–1 200 | Nitrogen-flushed Al-foil pouch, <2 cm³/m²·day OTR | Corrugated fibreboard carton, 7 mm triple-wall | 4×500 g montmorillonite clay | Cross-belted to wooden pallet, 1 000 kg SWL | 3 high in 20 ft |

| Round wire 1350-H14, Ø1.8–4.0 mm | 400 DIN spool | 200–500 | 50 µm PE film wrap | 5-ply carton, 32 ECT | 2×250 g desiccant | Shrink-wrapped to plywood pallet | 5 high in 40 ft |

VCI = volatile corrosion inhibitor; OTR = oxygen transmission rate; SWL = safe working load

H3 Wooden Pallet Specification

Material: Poplar & pine composite, ISPM-15 heat-treated (HT) to 56 °C core for 30 min, MB-free.

Slat spacing ≤ 50 mm to prevent strap indentation on coil outer wraps.

Top deck 19 mm thick, bottom deck 15 mm; 3 longitudinal bearers, 100 × 50 mm, chamfered 5 mm to accept forklift heel 560 mm wide.

Dynamic load rating 2 000 kg; safety factor 1.5 over maximum coil mass.

H3 Moisture & Salt-Spray Control

- Desiccant dosage calculated per DIN 55474:

n = 1.6 · V · b / m

where V = void volume (L), b = climate factor (Luoyang summer 2.8), m = desiccant water capacity (g). - Container floor lined with 200 µm HDPE sheet; 5 kg CaCl₂ hanging pouch absorbs condensation drip.

- Data loggers (Elpro LIBERO Ti1) record T & RH every 30 min; PDF report e-mailed on arrival.

H3 Global Freight Footprint

Nearest port: Qingdao, 450 km by bonded truck, 7 h transit.

Weekly FCL service to Hamburg (28 days), Los Angeles (14 days), Dubai (18 days).

LCL consolidation via Zhengzhou Bonded Hub; 3-day customs clearance, AES filing within 6 h.

Average landed cost 0.18 USD/kg for 5 t coil to EU, 0.12 USD/kg to SE Asia—30–40 % below comparable EU mill export premium.

H3 Damage KPIs (2023 rolling 12 mo)

Edge dent >0.05 mm: 0.12 % of coils.

Film puncture: 0.08 %.

Claims settled ≤ 7 days: 100 %.

Result: Transformer OEMs gain Western-grade surface quality at China-direct economics, without the 12-week lead-time buffer demanded by domestic EU slitters.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Electrical Metal Supply

20-Year Metallurgical Heritage, Zero Learning Curve

Since 2004 our Luoyang mill has rolled, slit, and conditioned every grade of conductor metal that ends up in a transformer tank. We have supplied over 3,200 transformer factories and motor repair depots in 62 countries; the cumulative tonnage exceeds 180,000 t of aluminum strip and 45,000 t of copper foil. That history means we already understand your eddy-loss limits, your annealing-softness windows, and your burr-free edge requirements—no R&D phase, no trial coils, no surprises on your slitting floor.

Direct Factory Price, Transparent Cost Structure

We own the complete cold-rolling and slitting line, so there is no trading margin, distributor markup, or import-agent fee. Typical savings versus Western EU/NA suppliers are 12–18 % on aluminum grades and 8–14 % on copper grades at equal technical specification (see table below). Payment is TT or LC; freight can be FOB Shanghai, CIF major port, or DDP bonded warehouse—your choice.

| Cost Element (per kg) | EU Mill A | NA Mill B | Luoyang Xinzhaohe |

|---|---|---|---|

| 1060-O Al strip 0.3 mm | 4.85 USD | 4.92 USD | 4.15 USD |

| Cu-ETP foil 0.1 mm | 11.30 USD | 11.45 USD | 9.85 USD |

| Slitting surcharge | 0.18 USD | 0.20 USD | included |

| Anneal & edge pass | 0.12 USD | 0.15 USD | included |

Prices valid Q3-2024, LME base 2,150 USD/t Al, 8,350 USD/t Cu.

Customization Without MOQ Penalty

Our 20-high cold mill can roll from 12 mm down to 0.05 mm in the same campaign; the slitters are equipped with Shimless tooling that holds ±0.002 mm width tolerance on any lot size down to 50 kg. Edge conditioning options:

Round edge R = 0.2–0.5 × thickness

Chamfered edge 30° or 45°

Burr < 0.01 mm (microscopic inspection per EN 1654)

Oscillate-wound coils up to 1,200 kg on 508 mm or 610 mm ID are standard; traverse pitch and gap can be programmed to match your high-speed winding heads. Need 0.15 mm Cu-ETP with 55 % IACS minimum after final anneal? We run a hydrogen bell furnace at 380 °C for 4 h to hit 58 % IACS typical, grain size 0.020–0.035 mm, hardness 45–55 HV—every coil certified with a conductivity coupon.

Quality & Compliance Documentation Delivered With Every Shipment

EN 1654 / ASTM B272 chemical & mechanical test report

IEC 60404-1 magnetic inclusions check (for Al grades)

RoHS & REACH SVHC statement

Mill test certificate 3.1 (EN 10204)

Slitting burr profile micrograph (×200 magnification)

Logistics Engineered for Transformer Schedules

Average lead time: 15 days ex-mill for slit-width stock; 25 days for custom width/anneal. We maintain 1,800 t of aluminum and 600 t of copper safety stock in Shanghai and Antwerp warehouses, allowing weekly consolidation shipments to North America, EU, and ASEAN. Coil weights, ID, and OD are optimized to fit 20 ft or 40 ft containers—maximum 25 t payload—so you pay freight for metal, not for air.

Technical Support That Speaks Your Language

Our metallurgists are online 14 h/day (GMT+8) to review your core-loss simulations, recommend conductor width to minimize stray losses, or calculate fill factor for foil versus wire windings. We share the same FEM tools (ANSYS Maxwell, JMAG) and can exchange DXF or STEP files directly with your design team.

Bottom line: You get Western-grade precision at China-level cost, backed by two decades of transformer-specific experience and a factory that is ISO 9001, ISO 14001, and IATF 16949 audited.

Ready to benchmark a coil?

Email cathy@transformerstrip.com with your target alloy, temper, width, edge spec, and annual volume. We will return a detailed datasheet, CIF price, and slit schedule within 24 h.

📉 Import Savings Calculator

Estimate cost reduction by sourcing electrical metal from Luoyang Xinzhaohe.