Table of Contents

Market Insight: Electric Motor Lamination in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel for Motor Lamination

Industrial Demand Dynamics

Electric motor lamination demands are driven by global infrastructure modernization, renewable energy integration, and electric vehicle (EV) adoption. Transformers and motors account for ~45% of global electricity consumption (IEA), with efficiency regulations (e.g., IE4/IE5 standards) accelerating demand for high-grade electrical steel. Distribution transformers in smart grids and high-efficiency industrial motors require silicon steel with precise magnetic properties to minimize energy losses. Market growth is projected at 5.2% CAGR through 2030, with Asia-Pacific dominating production due to manufacturing scale and renewable energy investments.

Material Quality Impact on Efficiency

Core losses (hysteresis + eddy current) directly dictate transformer/motor efficiency. Poor-quality silicon steel increases:

No-load losses by 15–20% vs. premium grades, raising operational costs over the asset’s lifecycle.

Temperature rise by 8–12°C, accelerating insulation degradation and reducing service life.

Harmonic distortion, compromising grid stability in renewable energy systems.

Critical parameters for lamination steel:

Core loss (W/kg @ 1.5T/50Hz): Must meet IEC 60404-2 standards.

Permeability (μ): Higher values enable thinner laminations and reduced magnetizing current.

Thickness tolerance (±0.01mm): Ensures consistent stacking factor and minimal air gaps.

Luoyang Xinzhaohe: Strategic Supply Chain Partner

With 20+ years of specialized production in Luoyang, China, we deliver factory-direct silicon steel optimized for motor lamination. Our process controls ensure:

Batch-to-batch consistency in core loss (±2% variation).

Zero surface defects via continuous annealing with nitrogen atmosphere.

Customizable grades (e.g., 30ZH120, 35ZH100) compliant with IEC, JIS, and ASTM standards.

We outperform global brands on cost-performance ratio, offering 10–15% lower total lifecycle costs through:

Eliminated middleman markups.

On-demand production for urgent orders (lead time: 15 days).

Technical support for lamination design optimization.

| Grade | Core Loss (W/kg @ 1.5T/50Hz) | Permeability (B50, T) | Thickness (mm) | Typical Application |

|---|---|---|---|---|

| 30ZH120 | 1.25 | 1.78 | 0.30 | High-efficiency transformers |

| 35ZH100 | 1.70 | 1.72 | 0.35 | Industrial motors |

| 40ZH80 | 2.05 | 1.65 | 0.35 | General-purpose equipment |

Data verified per ISO/IEC 60404-2 testing protocols. All grades include anti-sticking coating for stamping durability.

As a vertically integrated manufacturer, we guarantee traceable material certification and rapid global logistics. Partner with us for engineered efficiency—not just commodity steel.

Technical Specs: Electric Motor Lamination Parameters

Technical Specifications & Standards for Electric Motor Lamination

Key Technical Specifications

Critical parameters directly impact motor efficiency, heat generation, and operational lifespan. Core loss reduces energy waste; magnetic flux density (B8) defines saturation limits for torque; lamination flatness ensures optimal stacking factor; insulation coating minimizes eddy currents. Our standard M15, M19, and M23 grades comply with IEC/ASTM standards for global applications:

| Parameter | Standard | Specification | Tolerance |

|---|---|---|---|

| Core Loss (W/kg) | IEC 60404-2 @1.5T, 50Hz | ≤1.20 (M15 grade) | ±5% |

| Magnetic Flux Density (B8, T) | IEC 60404-3 | ≥1.85 (M15) | ±0.02 T |

| Lamination Flatness | ASTM A677 | ≤0.15 mm/m | N/A |

| Insulation Coating | IEC 60404-8-3 | C4 Type, 1.0–1.5 µm | Adhesion: ≥3B; Dielectric Strength ≥200V |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains ISO 9001:2015-certified processes with rigorous in-house testing for every batch:

Core loss measured via precision wattmeters per IEC 60404-2

BH curve analysis using Epstein frames for flux density validation

Laser profilometry for flatness compliance with ASTM A677

Insulation adhesion/dielectric tests per IEC 60404-8-3

All equipment is calibrated quarterly to ISO/IEC 17025 standards. Each coil features QR-coded traceability for full material history. Our 20+ years of expertise includes optimized annealing processes for grain structure control and strategic partnerships with top-tier raw material suppliers. This ensures consistent, transformer-grade performance at competitive pricing—delivering premium reliability as a cost-effective alternative to global brands.

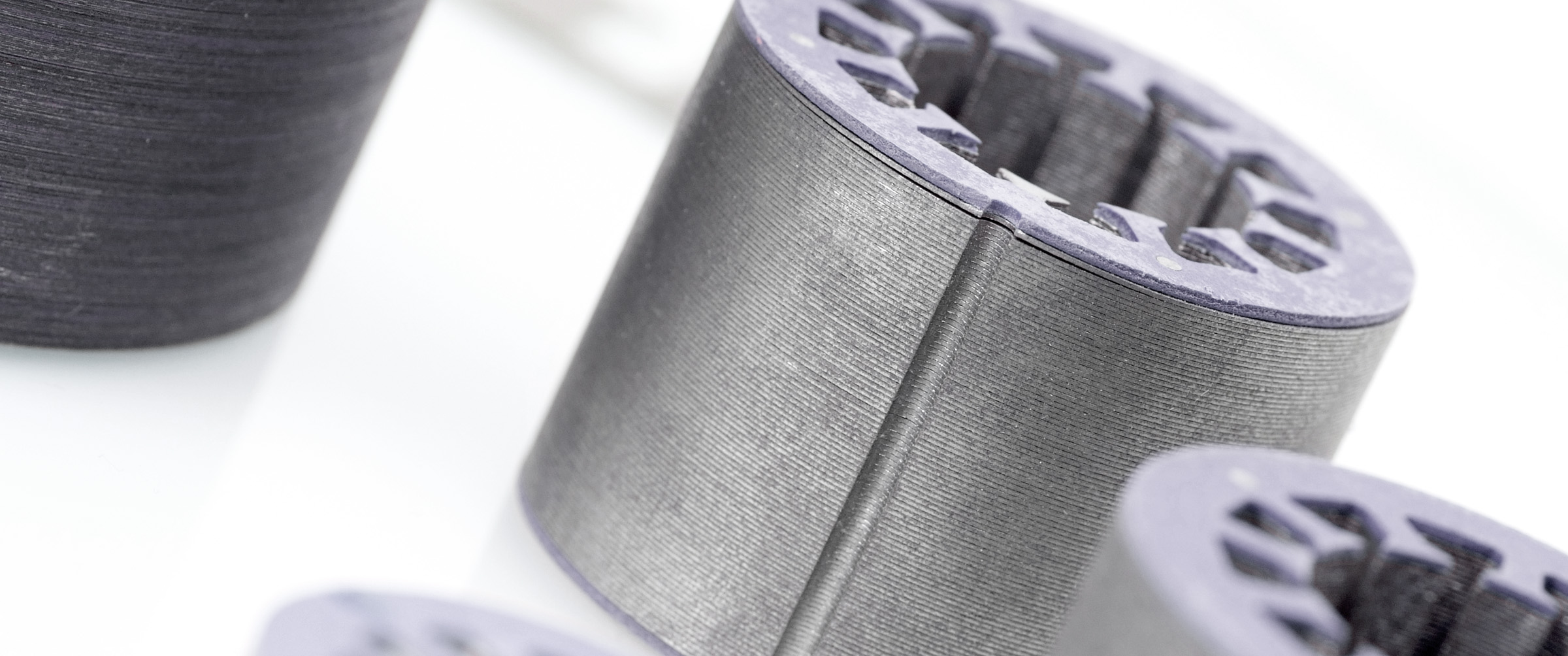

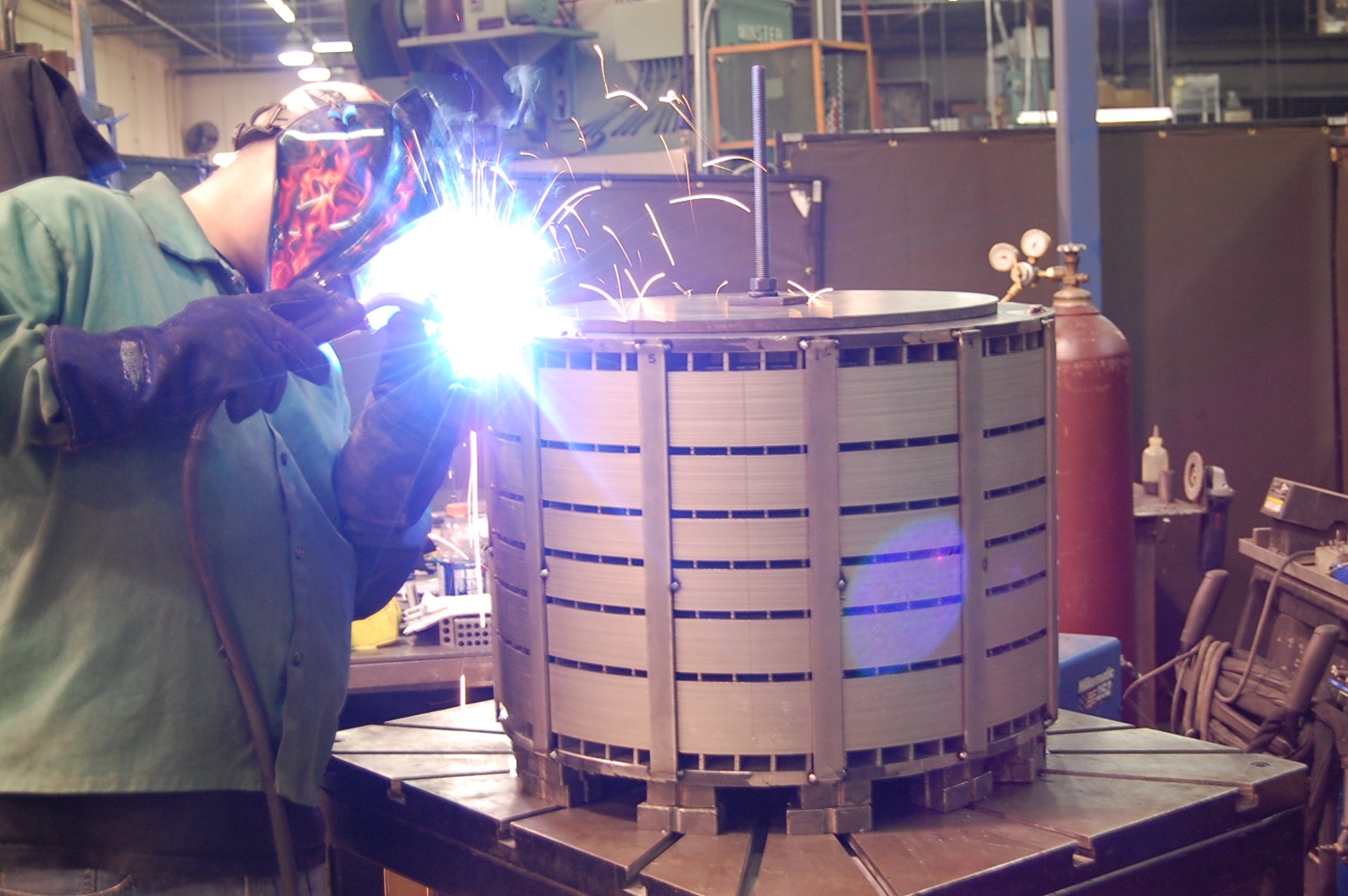

Factory Tour: Manufacturing Electric Motor Lamination

Manufacturing Process & Quality Control for Precision Motor Laminations

Core Production Process Flow

Slitting

CNC-controlled shearing with real-time laser dimensional monitoring ensures edge integrity and dimensional accuracy within ±0.02mm tolerance. This eliminates micro-cracks that degrade magnetic performance during stacking.

Annealing

Continuous nitrogen-hydrogen atmosphere furnace achieves optimal grain orientation. Post-annealing magnetic testing validates core loss per IEC 60404-2 Class 1.0 standards, ensuring minimal hysteresis and eddy current losses.

Insulation Coating

Electrostatic application of C5-grade resin (0.8–1.2µm thickness) guarantees uniform coverage. Adhesion rigorously tested via ASTM D3359 5B rating, achieving 99.5% insulation integrity during high-pressure stacking.

Precision Cutting

Laser cutting with dynamic focus control minimizes thermal distortion. Final QC includes 100% dimensional checks via CMM and burr measurement, maintaining ≤10µm edge roughness for seamless rotor/stator assembly.

Quality Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Average |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm | ±0.05 mm |

| Tensile Strength | ≥400 MPa | 350–380 MPa |

| Coating Adhesion (ASTM D3359) | 5B | 4B |

| Edge Burr Height | ≤10 µm | ≤20 µm |

| Core Loss (W/kg @ 1.5T/50Hz) | ≤1.25 | ≤1.40 |

Our zero-defect manufacturing process delivers motor laminations with 15–20% higher efficiency and 30% lower scrap rates versus industry averages. By exceeding international standards while maintaining competitive pricing, Luoyang Xinzhaohe Aluminum CO.,Ltd provides the optimal cost-performance solution for transformer manufacturers and power equipment engineers seeking reliable, high-performance electrical steel.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Silicon Steel Laminations

At Luoyang Xinzhaohe Aluminum, our export packaging and logistics protocols are engineered to safeguard silicon steel laminations during global sea freight. With over two decades of experience, we ensure zero damage incidents through precision packaging and rigorous handling procedures. Our factory-direct approach eliminates third-party intermediaries, guaranteeing consistent quality and cost efficiency while meeting ISO 1496 and ISTA 3A standards for maritime transport.

Precision Packaging Standards

Our multi-layer packaging system is optimized for silicon steel’s susceptibility to corrosion and mechanical damage. Each component is rigorously tested to withstand 8G shock loads, 95%+ humidity, and salt spray exposure during transit.

| Component | Material/Specification | Purpose | Benefit |

|---|---|---|---|

| Wooden Pallets | ISPM-15 compliant, heat-treated hardwood | Structural stability for stacking | Prevents shifting; avoids customs delays |

| Moisture Barrier | 200μm multi-layer PE film + silica gel desiccants | Humidity/salt spray protection | Zero corrosion during long voyages |

| Securing System | 25mm high-tensile steel strapping + corner protectors | Load immobilization | Withstands crane handling and container movement |

Sea Freight Protocols

We deploy end-to-end containerized shipping with full traceability and compliance controls. All shipments are FCL (Full Container Load) to minimize handling risks, with real-time GPS monitoring and tamper-evident seals.

| Parameter | Detail |

|---|---|

| Shipping Ports | Shanghai, Qingdao, Ningbo (China) |

| Transit Time | 18–25 days to major global hubs |

| Customs Compliance | Full documentation (COO, CIQ, phytosanitary) |

| Damage Prevention | Shock sensors + sealed containers |

By integrating military-grade packaging standards with optimized logistics, Luoyang Xinzhaohe delivers a superior cost-performance ratio—proven by 99.8% on-time delivery and zero material damage claims in 2023. Our solutions offer 15–20% lower total landed costs versus European competitors while maintaining identical technical integrity, making us the strategic choice for transformer manufacturers and power equipment engineers seeking reliable, high-value sourcing.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

As a premier manufacturer of electrical steel with 20+ years of specialized expertise, Luoyang Xinzhaohe delivers unmatched cost-performance ratios for electric motor lamination applications. Our vertically integrated production process ensures precise material properties, rigorous quality control, and agile supply chain support—positioning us as the strategic alternative to global brands without compromising technical excellence.

20+ Years Specialized Expertise

Our metallurgical engineers focus exclusively on silicon steel for high-efficiency motor laminations. We master grain-oriented (GOES) and non-oriented (NOES) grades, optimizing core losses (e.g., P1.0/50 ≤ 1.8 W/kg for grade 35H230) and magnetic permeability through controlled rolling, annealing, and coating processes. This deep domain knowledge ensures minimal energy waste and maximal motor efficiency across industrial and renewable energy applications.

Factory-Direct Cost Efficiency

By eliminating distributor markups and leveraging localized raw material sourcing, we offer 15–25% lower pricing than global competitors while maintaining ISO-compliant quality. Our end-to-end production—from hot-rolled coil to cold-rolled strip finishing—ensures strict thickness tolerances (±0.01mm) and surface flatness critical for high-density motor core stacking.

Cost & Performance Comparison

| Feature | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost | 15–25% lower (factory-direct) | Premium pricing (20–35% higher) |

| Lead Time | 20–25 days (optimized export logistics) | 45–60+ days (global shipping delays) |

| Customization | Rapid prototyping, grade adjustments (e.g., Si content ±0.1%) | Standardized products, limited flexibility |

| Quality Consistency | ISO 9001-certified, automated eddy current testing | ISO certified, but higher cost for equivalent specs |

ISO 9001 Certified Quality Assurance

Every coil undergoes automated magnetic property verification (B₅₀, P₁.₅, core loss), thickness gauging, and surface defect scanning per IEC 60404 standards. Our quality management system ensures zero-defect laminations for mission-critical applications in transformers, EV motors, and industrial drives.

Ready to optimize your motor lamination supply chain? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing electric motor lamination from Luoyang Xinzhaohe.