Table of Contents

Market Insight: Electric Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for electric copper coil in power and distribution transformers remains robust, driven by accelerating grid modernization, renewable energy integration, and industrial electrification. As renewable sources like solar and wind require extensive power conversion infrastructure, transformers constitute critical nodes in transmission and distribution networks. Copper’s superior electrical conductivity (100% IACS minimum per IEC 60138) ensures minimal resistive losses, directly impacting system efficiency and lifecycle costs. While aluminum alternatives gain traction in specific weight-sensitive applications, copper dominates high-reliability transformer segments due to its thermal stability, mechanical strength, and proven performance under cyclic loading. Current market expansion is particularly pronounced in Asia-Pacific and emerging economies, where aging grid replacements and new substations demand 15-20% annual growth in high-purity transformer windings.

Quality parameters for electric copper coil are non-negotiable in transformer manufacturing. Impurities such as oxygen, sulfur, or metallic inclusions exceeding 10 ppm degrade conductivity and accelerate thermal aging. For instance, oxygen content above 200 ppm promotes hydrogen embrittlement during vacuum pressure impregnation (VPI), risking catastrophic coil delamination. Grain structure uniformity—achieved through precise annealing kinetics—is equally critical; coarse grains reduce fatigue resistance under electromagnetic forces, while fine grains enhance creep resistance but may compromise formability. Surface defects like scratches or pits exceeding 5 µm depth initiate partial discharges, compromising dielectric integrity and accelerating insulation breakdown. Industry data indicates that substandard copper coils contribute to 30% of premature transformer failures in harsh operating environments, translating to millions in grid downtime costs annually.

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to mitigate these risks. Our copper coil production adheres to stringent IEC 60138 and ASTM B3 standards, with in-line monitoring of oxygen content (maintained below 10 ppm), grain size distribution (ASTM E112 compliant), and surface roughness (Ra ≤ 0.8 µm). Advanced continuous casting and precision rolling ensure axial homogeneity, while proprietary annealing protocols optimize recrystallization for superior bendability without microcracking. Supply chain traceability from cathode to coil guarantees batch-specific mechanical and electrical certifications, essential for Tier-1 transformer OEMs facing ISO 55000 asset management compliance.

In high-stakes applications, marginal deviations in copper purity or dimensional tolerances directly correlate with reduced transformer lifespan and increased total cost of ownership. Partnering with suppliers possessing integrated metallurgical control—from raw material sourcing to final inspection—is imperative to sustain grid resilience amid rising energy demands. Quality is not a cost factor but a foundational requirement for operational safety and efficiency.

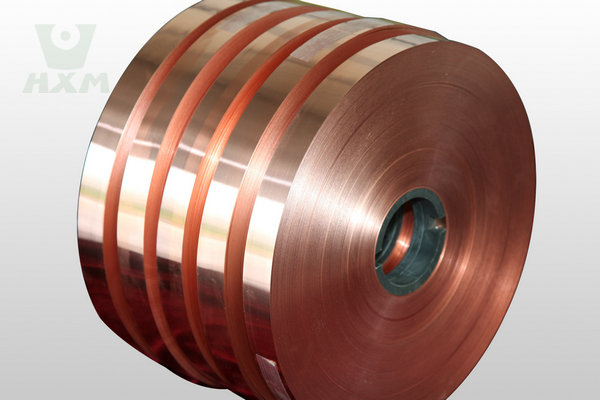

Technical Specs: Electric Copper Coil

Technical Specifications for Electric Copper Coil

Luoyang Xinzhaoanghe Aluminum Co., Ltd. manufactures high-performance electric copper coils designed for precision applications in power transformers, inductors, and high-efficiency electrical systems. With over two decades of metallurgical expertise, our production processes ensure strict adherence to international standards, including ASTM B3 and IEC 60138, to deliver copper strip and foil with optimal electrical and mechanical properties. The following technical specifications define the performance benchmarks for our electric copper coil products, emphasizing dimensional accuracy, edge quality, and conductivity.

Dimensional precision is critical in transformer windings and coil fabrication, where even minor deviations can lead to inefficiencies or mechanical interference. Our electric copper coils are produced through advanced precision slitting technology, ensuring width tolerances within ±0.002 mm. This level of control is achieved using servo-guided slitting lines with laser-based edge detection systems, minimizing edge wander and ensuring uniform coil geometry across full production runs. Thickness tolerances are maintained within ±0.005 mm for foils and ±0.01 mm for strips, depending on the nominal gauge, supporting consistent layer stacking and thermal management in transformer cores.

Edge quality is paramount to prevent dielectric breakdown and ensure safe handling during coil winding. All electric copper coils are processed to deliver burr-free edges through optimized shear slitting parameters and post-slitting edge conditioning. Burr height is consistently controlled below 2% of material thickness, verified through routine profilometric inspection. Smooth, clean edges reduce the risk of insulation puncture and enhance the reliability of wound components, particularly in high-voltage applications.

Electrical conductivity is a defining characteristic of our oxygen-free copper (OFC) material, which achieves a minimum of 101% IACS at 20°C. This exceeds standard electrolytic tough pitch (ETP) copper and ensures minimal resistive losses in operation. Conductivity is verified through four-point probe resistivity testing in accordance with ASTM E1004, with batch certification provided for traceability. The copper used in our coils is 99.99% pure (Cu-ETP1, CW008A), with controlled oxygen content below 10 ppm to prevent hydrogen embrittlement and ensure long-term stability.

Mechanical properties are tailored to balance formability and strength. Typical tensile strength ranges from 200–240 MPa, with elongation of 4–6%, enabling tight winding radii without cracking or deformation. Coils are supplied in half-hard or full-hard tempers, depending on application requirements, and are free from surface oxides, laminations, or inclusions.

| Parameter | Specification | Test Standard |

|---|---|---|

| Material | Oxygen-Free Copper (OFC), Cu-ETP1 | ASTM B3, IEC 60138 |

| Conductivity | ≥101% IACS | ASTM E1004 |

| Thickness Tolerance | ±0.005 mm (foil), ±0.01 mm (strip) | ISO 1156 |

| Width Tolerance | ±0.002 mm | ISO 7806 |

| Burr Height | ≤2% of thickness | Optical Profilometry |

| Tensile Strength | 200–240 MPa | ASTM E8 |

| Elongation | 4–6% | ASTM E8 |

| Surface Finish | Clean, oxide-free, no laminations | Visual & Microscopic |

| Coil Inner Diameter | 200 mm, 300 mm, 508 mm (custom available) | Customer Specification |

| Packaging | Vacuum-sealed, anti-corrosion protection | JIS Z 0301 |

All electric copper coils undergo 100% inline width verification and batch-based electrical and mechanical testing. Certificates of Conformance (CoC) and Material Test Reports (MTRs) are available upon request, ensuring full compliance with customer and regulatory requirements.

Factory Tour: Manufacturing

Manufacturing Process for Electric Copper Coil: Precision Execution for Critical Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages dual-material expertise in transformer strip/foil production, applying stringent copper-specific protocols derived from our 20+ years of non-ferrous metallurgical experience. While aluminum remains our core focus, our copper coil manufacturing adheres to identical precision standards required for high-efficiency transformer windings. The process begins with high-conductivity electrolytic tough pitch (ETP) copper cathodes, melted and continuously cast into billets meeting IACS 101% minimum conductivity. These undergo homogenization at 750°C to eliminate segregation before hot rolling to intermediate gauge.

Cold rolling constitutes the most critical phase for dimensional and structural integrity. Coils pass through 6-high Sendzimir mills under computer-controlled tension, achieving final thicknesses from 0.1mm to 3.0mm with tolerances held to ±0.002mm. Precise interpass annealing at 450°C in oxygen-free nitrogen atmospheres prevents oxidation while optimizing grain structure for bendability and electrical performance. In-line laser micrometers continuously monitor thickness deviation, triggering automatic roll gap adjustments to maintain flatness within 0.5mm/m. Tension leveling during coil winding eliminates residual stresses that could cause edge wave or center buckle in downstream processing.

Precision slitting follows strict geometric control. Coils are processed through servo-driven slitters with tungsten carbide rotary knives, achieving slit width tolerances of ±0.05mm for widths ranging from 10mm to 500mm. Critical edge quality is ensured via real-time vision systems scanning for burrs exceeding 5μm. Slit edges undergo immediate edge conditioning through our proprietary brush-deburring system, which removes micro-burrs while preserving the native oxide layer essential for insulation adhesion. This step prevents insulation puncture during coil winding—a common failure point in substandard materials.

Quality control is embedded at each stage through our integrated ISO 9001:2015-certified protocol. Key verification points include:

| Process Stage | Critical Parameter | Xinzhaohe Specification | Test Method |

|---|---|---|---|

| Cold Rolling | Thickness Variation | ≤ ±0.002mm | Laser Micrometer (100% inline) |

| Cold Rolling | Surface Roughness (Ra) | 0.3–0.8μm | Profilometer (per ASTM E1077) |

| Slitting | Edge Burr Height | ≤ 5μm | Optical Comparator (per IPC-TM-650) |

| Final Coil | Conductivity | ≥ 101% IACS | Eddy Current (per ASTM E1004) |

| Final Coil | Tensile Strength | 220–250 MPa | Universal Tester (per ASTM E8) |

All coils undergo 100% eddy current testing for subsurface defects and final dimensional certification. Traceability is maintained via laser-etched batch codes linking to melt chemistry reports and process logs. This end-to-end control ensures copper coils meet IEC 60137 and IEEE C57.12.00 requirements for transformer applications where dimensional precision directly impacts thermal performance and dielectric reliability. Our integrated approach eliminates supply chain fragmentation—delivering coils engineered for zero-waste integration into automated winding lines.

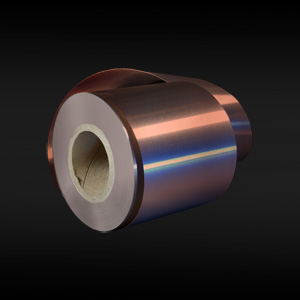

Packaging & Logistics

Export Packaging for Electric Copper Coil – Technical Specification

Luoyang Xinzhaohe Aluminum Co., Ltd. adheres to rigorous international standards in the export packaging of electric copper coil to ensure product integrity during maritime transportation. Given the sensitivity of copper coil to mechanical damage, moisture, and environmental contamination, our packaging system is engineered to withstand the demanding conditions of sea freight, including prolonged exposure to high humidity, salt air, and dynamic load stresses.

All electric copper coils are mounted on high-strength wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. These pallets are designed to provide structural stability and uniform load distribution, minimizing the risk of coil deformation during handling and transit. The wood is treated to prevent pest infestation and decay, meeting global phytosanitary requirements for cross-border shipments. Each pallet is reinforced with steel strapping or tensioned plastic banding to secure the coil core and prevent axial or radial movement during ocean transport.

Immediately following coil placement on the pallet, the entire assembly is wrapped in multiple layers of industrial-grade moisture-proof film. This laminated polyethylene-aluminum foil composite film acts as a vapor barrier, effectively isolating the copper surface from ambient humidity. The film is heat-sealed at all joints and extends beyond the base of the pallet to form a fully enclosed protective shroud. An additional layer of UV-resistant polypropylene outer wrap may be applied for extended voyages or regions with elevated solar exposure.

To further enhance moisture protection, desiccant packs are strategically placed within the sealed film envelope. These silica gel units absorb residual moisture and mitigate the risk of condensation during temperature fluctuations common in intercontinental shipping. Relative humidity within the package is maintained below 40% throughout transit, preventing oxidation and maintaining the surface quality critical for downstream electrical performance.

For large-volume shipments, coils are arranged within 20-foot or 40-foot dry container units using optimized stacking patterns that prevent point loading and ensure even weight distribution. Container interiors are inspected for cleanliness and dryness prior to loading, and flooring is lined with moisture-resistant kraft paper or plastic sheeting to isolate the pallets from direct contact with the container base.

Our packaging protocol is validated through accelerated environmental testing and real-world logistics monitoring. Every shipment undergoes pre-shipment inspection to confirm compliance with internal quality benchmarks and customer-specific requirements. Documentation includes packaging schematics, material certifications, and humidity control records.

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages over two decades of metallurgical and supply chain expertise to deliver electric copper coil in optimal condition, regardless of destination. This comprehensive approach to export packaging underscores our commitment to reliability, performance, and customer satisfaction in the global transformer and electrical equipment markets.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Electric Copper Coil Supply

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver electric copper coil solutions meeting the stringent demands of modern transformer and electrical equipment manufacturing. While our corporate name reflects historical focus, our core competency encompasses high-purity copper conductor production alongside aluminum transformer strip and foil. We operate dedicated copper processing lines engineered specifically for electrolytic tough pitch (ETP) and oxygen-free electronic (OFE) copper coil, ensuring consistent performance in critical winding applications. Our facility integrates advanced melting, casting, hot rolling, cold rolling, and precision annealing processes under rigorously controlled atmospheres to achieve target conductivity levels exceeding 100% IACS and eliminate surface defects detrimental to insulation integrity.

Metallurgical precision defines our copper coil production. Raw material sourcing adheres to strict chemical composition protocols, with incoming cathodes verified via optical emission spectroscopy to guarantee impurity levels below 50 ppm for critical elements like sulfur and oxygen. Our proprietary annealing furnaces utilize nitrogen-hydrogen atmospheres with dew point control to ±5°C, preventing oxidation and ensuring uniform recrystallization essential for optimal ductility and winding reliability. Dimensional tolerances are maintained to ±0.005 mm on thickness and ±0.1 mm on width through laser-guided rolling mills and real-time profilometry systems. This level of control directly translates to reduced scrap rates during coil processing and enhanced transformer efficiency through minimized eddy current losses.

Our integrated quality management system, certified to ISO 9001 and IATF 16949 standards, implements multi-stage verification protocols. Every production batch undergoes mandatory electrical resistivity testing per ASTM B3, tensile strength and elongation validation per ASTM E8, and surface roughness analysis via profilometer to meet IEC 60468 specifications. Full material traceability from cathode to finished coil is maintained through our digital MES platform, providing customers with comprehensive mill test reports including chemical composition, mechanical properties, and dimensional certificates. This systematic approach mitigates supply chain risk by ensuring absolute compliance with international electrical conductor standards.

Supply chain resilience is engineered into our operations through strategic inventory management of critical raw materials and dedicated logistics coordination. We maintain buffer stocks of certified copper cathodes and operate flexible production scheduling to accommodate urgent requirements without compromising quality timelines. Our partnerships with Tier-1 logistics providers enable reliable just-in-sequence delivery to global manufacturing hubs, supported by real-time shipment tracking and customs documentation expertise. This operational agility minimizes customer inventory carrying costs while guaranteeing on-time delivery performance exceeding 98.5%.

For transformer manufacturers requiring electric copper coil with uncompromised metallurgical integrity and supply chain certainty, Luoyang Xinzhaohe provides a technically validated partnership. Our engineering team stands ready to collaborate on custom specifications, material certifications, and process optimization to support your next-generation product development. Contact Cathy directly at cathy@transformerstrip.com to initiate a technical consultation and receive a detailed capability dossier outlining our copper coil production parameters and quality assurance framework. Partner with a supplier whose precision metallurgy powers global energy infrastructure.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing electric copper coil directly from China.