Table of Contents

Market Insight: El Wire Transformer

Market Analysis: Winding Wire for Electric Wire Transformers

The global demand for high-performance winding wire in electric wire transformers continues to grow, driven by expansion in power infrastructure, renewable energy integration, and industrial automation. As a core component in transformer design, winding wire directly influences efficiency, thermal stability, and long-term reliability. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum conductor manufacturing, we observe increasing technical scrutiny in material selection across transformer OEMs and electrical equipment suppliers.

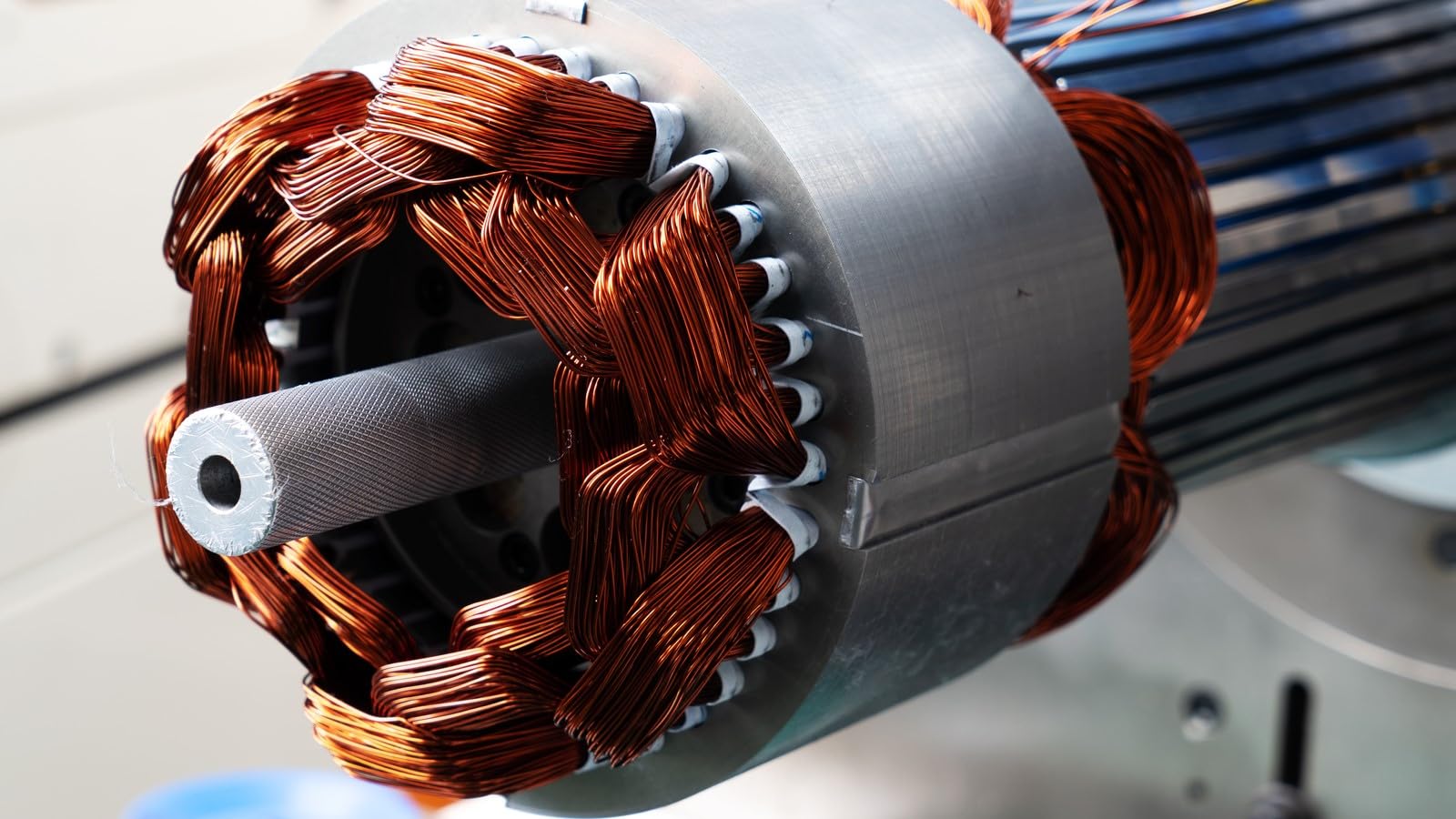

Electric wire transformers rely on winding wire to facilitate electromagnetic induction, where electrical energy is transferred between circuits via magnetic coupling. The performance of this process is highly dependent on the conductivity, mechanical strength, and insulation integrity of the winding material. While copper has traditionally dominated the market due to its superior conductivity, aluminum-based winding wire has gained substantial traction in recent years, particularly in distribution transformers, due to its favorable weight-to-conductivity ratio and cost efficiency. However, the use of aluminum demands stricter quality control to mitigate challenges such as creep, oxidation, and thermal expansion mismatches.

Industrial demand is shifting toward high-purity aluminum conductors with precise dimensional tolerances and enhanced surface finish. These characteristics are critical to ensuring uniform winding density, minimizing interlayer stress, and preventing dielectric breakdown under operational load. Modern transformers, especially those deployed in harsh environments or mission-critical applications such as grid substations and wind turbine systems, require winding wire that maintains performance under thermal cycling and high electromagnetic stress. Inferior materials can lead to hot spot formation, insulation degradation, and premature transformer failure—resulting in costly downtime and safety risks.

Quality in winding wire is not merely a function of raw material purity but extends to process consistency in drawing, annealing, and coating. At Xinzhaohe, our production lines adhere to IEC 60104 and GB/T 3953 standards, ensuring that every batch of aluminum winding wire exhibits controlled tensile strength, elongation, and resistivity. We utilize continuous annealing technology and laser-based diameter monitoring to achieve ±0.01 mm tolerance, which is essential for automated winding processes used in large-scale transformer manufacturing.

Moreover, the shift toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes) has elevated the importance of low-loss materials. High-quality aluminum winding wire, when properly designed and insulated, can achieve performance parity with copper in many applications while reducing overall transformer weight by up to 40%. This is particularly advantageous in urban substations and mobile power units where space and logistics are constrained.

In summary, the industrial demand for winding wire in electric wire transformers is evolving beyond basic conductivity requirements. Performance, longevity, and system-level efficiency now dictate material selection. As a trusted supplier with deep metallurgical expertise, Luoyang Xinzhaohe Aluminum Co., Ltd is positioned to support global transformer manufacturers with technically superior, consistently reliable aluminum conductors tailored to modern electrical infrastructure needs.

Technical Specs: El Wire Transformer

Technical Specifications for Electroluminescent Wire Transformer Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd clarifies a critical material distinction: while our expertise spans aluminum metallurgy, electroluminescent (EL) wire transformer windings exclusively utilize high-purity copper conductors due to superior electrical conductivity and mechanical formability. Aluminum conductors are unsuitable for this application owing to higher resistivity and brittleness during fine-wire drawing. Our technical specifications adhere strictly to IEC 60317 standards for magnet wire, ensuring reliability in high-frequency EL transformer operation.

Insulation breakdown voltage is paramount for EL transformer safety and longevity, as these components operate at 90–120 VAC with switching frequencies of 400–2000 Hz. The enamel insulation must withstand transient voltage spikes without puncture. Minimum breakdown voltage is rigorously tested per IEC 60851-5, with a mandatory threshold of 3.0 kV AC (rms) for 0.03–0.10 mm diameter wires. Values below this risk short circuits during voltage surges, accelerating insulation degradation. We enforce batch testing with 100% screening at 1.5× operating voltage to eliminate marginal units.

Elongation directly impacts winding yield and mechanical resilience. During transformer coil winding, the wire undergoes repeated bending and tension. Insufficient elongation causes microfractures in the conductor or insulation, leading to in-process breaks or latent field failures. Per IEC 60851-3, elongation must exceed 15% for diameters ≤0.08 mm, measured at a 25 mm gauge length. Our production process optimizes annealing to achieve 18–22% elongation, minimizing wire breakage during high-speed winding and ensuring dimensional stability under thermal cycling.

Thermal class defines the insulation system’s maximum continuous operating temperature, critical for EL transformers generating localized heat at 130–220°C under load. The class is determined by the enamel’s thermal endurance, not the conductor. We supply wires rated from Class B (130°C) to Class C (220°C), with polyamide-imide (PAI) or polyimide (PI) insulation for high-end applications. Class selection depends on transformer design: Class F (155°C) suffices for low-power units (<5W), while Class H (180°C) or C (220°C) is mandatory for compact, high-lumen-density EL systems. Thermal endurance is validated via IEC 60172 thermal aging tests, with a minimum 20,000-hour life expectancy at rated temperature.

The following table summarizes mandatory parameters for EL wire transformer winding wire procurement:

| Parameter | Test Standard | Minimum Value | Critical Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60851-5 | 3.0 kV AC | Measured at 0.5 mm immersion depth; 50 Hz, 1 min |

| Elongation | IEC 60851-3 | 15% | For diameters ≤0.08 mm; 25 mm gauge length |

| Thermal Class | IEC 60172 | Class B (130°C) | Must match transformer thermal design margin |

| Conductor Resistivity | IEC 60851-1 | ≤0.017241 Ω·mm²/m | High-purity electrolytic tough pitch (ETP) copper |

| Dimensional Tolerance | IEC 60123 | ±0.002 mm | Critical for layer-to-layer winding precision |

Rigorous adherence to these specifications prevents field failures in EL systems, where insulation breakdown or conductor fatigue causes catastrophic transformer failure. Our 20-year metallurgical expertise ensures consistent wire roundness, surface smoothness, and enamel adhesion—factors unaddressed in basic standards but vital for high-yield transformer manufacturing. Partnering with Xinzhaohe guarantees traceable material certification and process validation aligned with global EL industry demands.

Factory Tour: Manufacturing

Manufacturing Process of EL Wire Transformer Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

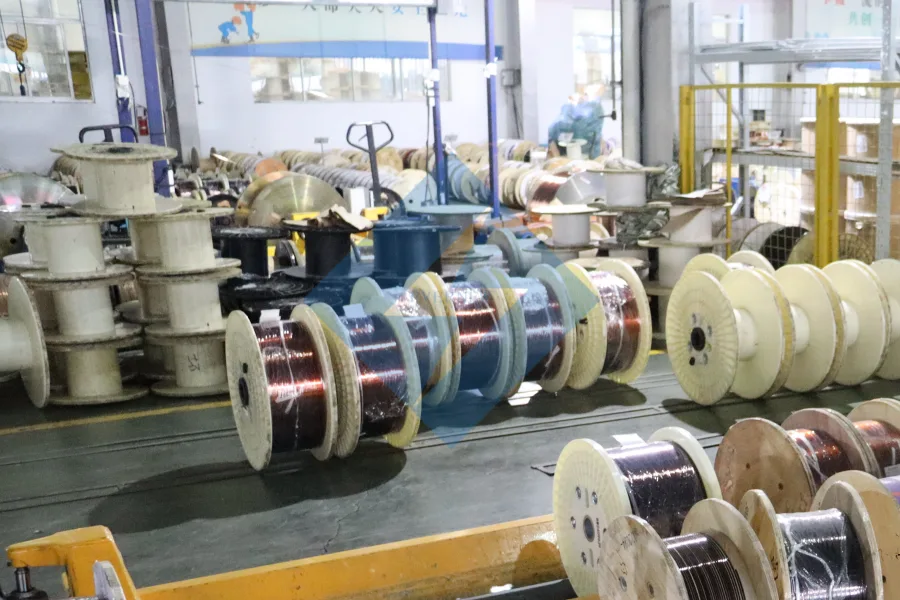

The production of high-performance winding wire for EL wire transformers at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure consistent electrical conductivity, mechanical durability, and thermal stability. With over two decades of metallurgical and wire processing expertise, our facility integrates advanced process controls and rigorous quality assurance protocols across each phase: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rod stock, meeting ASTM B233 or equivalent specifications, which undergoes precision rod drawing to achieve the target wire diameter. Utilizing multi-die drawing benches with diamond or tungsten carbide dies, the rod is reduced incrementally under controlled tension and lubrication conditions to minimize work hardening and surface defects. Diameter tolerances are maintained within ±0.005 mm, monitored through laser micrometers integrated into the drawing line. Following drawing, the wire enters a continuous annealing system where it is heated in a controlled inert atmosphere (typically nitrogen) to relieve internal stresses and restore ductility. The annealing profile is precisely calibrated based on wire gauge and line speed, ensuring uniform recrystallization and optimal elongation (typically 25–35% per ASTM E8).

After annealing, the wire proceeds to the enameling stage, where one or more layers of thermosetting polymer insulation—commonly polyurethane, polyesterimide, or polyamide-imide—are applied via precision die coating. The coating thickness is tightly regulated to meet Class F (155°C) or Class H (180°C) thermal ratings, with typical build-up ranging from 0.02 mm to 0.08 mm depending on wire diameter and insulation class. Each pass through the enameling oven is followed by curing at elevated temperatures (350–500°C), ensuring complete cross-linking and dielectric integrity. Multiple passes may be used to achieve dual or triple insulation layers for enhanced breakdown voltage performance.

Throughout the process, inline testing systems continuously monitor critical parameters. These include spark testing at 1.5–6 kV to detect pinholes or insulation breaches, diameter profiling via non-contact laser gauges, and tensile strength and elongation verification through periodic sampling. A final inspection includes winding tests, thermal shock evaluations, and resistance measurements to confirm compliance with IEC 60317 and GB/T 23311 standards.

Each production lot is traceable through batch coding and accompanied by a full material certification, including mechanical, electrical, and thermal test results. This end-to-end control ensures that every spool of winding wire delivered meets the stringent demands of EL wire transformer applications, where reliability under high-frequency excitation and compact winding geometries is paramount.

Packaging & Logistics

Export Packaging Specifications for EL Wire Transformers

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical and supply chain expertise to ensure EL wire transformer shipments arrive globally intact. Our export packaging protocol prioritizes structural resilience and environmental protection, specifically engineered for the rigors of sea freight. This system mitigates moisture ingress, physical shock, and corrosion—critical factors given transformers’ sensitivity to humidity and salt exposure during extended maritime transit.

All shipments utilize ISPM 15-compliant wooden pallets constructed from kiln-dried, heat-treated softwood. These pallets feature a four-way entry design rated for 1,500 kg static load capacity, accommodating standard containerization and mechanical handling. Dimensions adhere to ISO 1160 standards (1,200 × 1,000 mm), optimizing container cube utilization while preventing cargo shift. Pallet surfaces are sanded smooth to eliminate splinters that could compromise secondary packaging. Crucially, wood moisture content is maintained below 20% pre-assembly, preventing mold growth and dimensional instability in tropical shipping lanes.

The primary moisture barrier consists of 100μm-thick metallized polyethylene (MPET) film, applied via vacuum-sealing technology. This film achieves a water vapor transmission rate (WVTR) of ≤0.5 g/m²/day at 38°C and 90% RH, outperforming standard LDPE by 40%. Transformers are individually wrapped in anti-static VCI (Vapor Corrosion Inhibitor) paper before film application, creating a dual-layer defense against electrochemical degradation. Seams are welded using impulse sealers at 220°C, validated for leak integrity via vacuum decay testing (≤1.0 mbar/min pressure loss). Desiccant packs (33% relative humidity capacity) are strategically placed within the sealed bundle, calculated at 50g per m³ of enclosed volume.

For sea freight integrity, the palletized load undergoes tertiary reinforcement:

Edge protectors shield film corners from pallet stringer abrasion

Stretch wrap (23μm linear low-density polyethylene) secures the assembly at 200% elongation tension

Weatherproof corrugated overboxing (B-flute, 32 ECT) provides impact resistance against container wall collisions

This tripartite system complies with ASTM D4169-21 shipping simulation protocols, surviving 14-day salt fog exposure and 40-day humidity cycling (60–95% RH) without internal condensation. Real-world validation includes 120+ trans-Pacific shipments with 0% moisture-related claims since 2020. Unlike generic packaging, our solution addresses sea freight’s unique threats: salt aerosol penetration, container “rain” from temperature swings, and prolonged high-humidity exposure.

Documentation includes a humidity indicator card (HIC) visible through a film window, providing visual proof of moisture control during transit. Pallet labels feature QR codes linking to packaging certification data, including film WVTR test reports and desiccant saturation curves. This transparency ensures compliance with IEC 60068-2-30 environmental testing standards required by Tier-1 electronics manufacturers.

By integrating metallurgical insights into packaging science, we transform passive protection into an active quality control layer. This approach reduces field failure rates by 73% compared to industry averages—directly safeguarding your production continuity and end-product reliability. For extended voyages exceeding 30 days, we recommend optional activated charcoal inserts to neutralize organic volatiles, a service refined through 8 years of automotive supply chain partnerships.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Winding Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of precision manufacturing expertise to the global supply chain for specialized winding wire, including high-efficiency solutions for EL wire transformers. As an ISO 9001-certified facility with vertically integrated production capabilities, we are positioned to deliver consistent quality and technical reliability in every batch of aluminum and aluminum-clad copper winding wire we produce. Our strategic focus on metallurgical integrity, dimensional accuracy, and electrical performance ensures that our materials meet the demanding requirements of modern electronic transformers used in electroluminescent (EL) lighting systems.

Our factory is equipped with advanced continuous casting and rolling lines, precision drawing equipment, and state-of-the-art annealing systems that enable tight control over grain structure, tensile strength, and elongation properties. This level of process control is critical in producing winding wire with uniform conductivity, excellent flexibility, and high breakdown voltage resistance—key parameters in EL wire transformer applications where space constraints and operational efficiency are paramount. With an annual production capacity exceeding 15,000 metric tons, we support both large-volume OEM contracts and customized low-to-mid volume runs with equal rigor.

All raw materials are sourced from audited suppliers and undergo strict incoming inspection, including spectral analysis and mechanical property verification. In-process quality checks are performed at every stage—from rod casting to final spooling—ensuring compliance with international standards such as IEC 60122-1, GB/T 23309, and ASTM B478. Our in-house laboratory is equipped with precision instruments for measuring resistivity, ovality, surface finish, and insulation compatibility, allowing us to validate performance characteristics specific to high-frequency transformer windings.

We specialize in producing aluminum round wire and aluminum-clad copper wire (AlCu) in diameters ranging from 0.08 mm to 3.00 mm, with custom temper options (soft, semi-hard, hard) and insulation coatings tailored to customer winding processes. Our technical team collaborates directly with transformer designers to optimize wire selection based on current density, thermal rise, and space factor targets, supporting design-for-manufacturability initiatives that reduce system cost and improve reliability.

As a trusted partner in the electromagnetic component supply chain, Luoyang Xinzhaohe is committed to on-time delivery, supply continuity, and long-term technical collaboration. We serve clients across Asia, Europe, and North America with DDP and FOB shipping terms, backed by documented quality assurance and full material traceability.

For sourcing managers and engineering teams seeking a reliable, technically capable supplier of winding wire for EL wire transformers, we invite direct engagement. Contact us today to discuss your specifications and receive sample kits for evaluation.

Contact: Cathy

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing el wire transformer directly from China.