Table of Contents

Market Insight: Ei Transformer Laminations for Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Global Demand Drivers in Power & Distribution Transformers

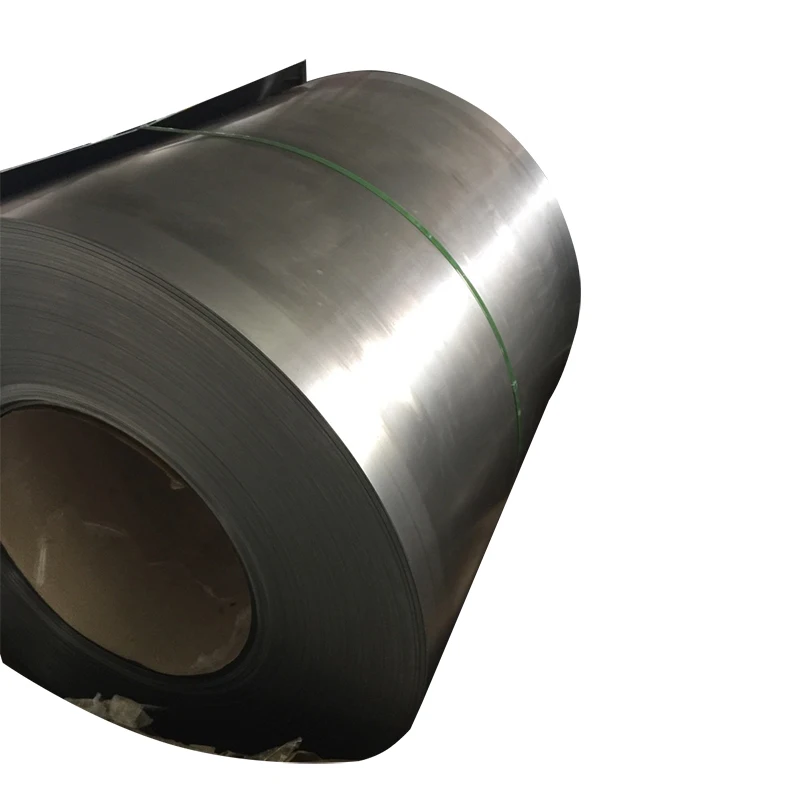

Global transformer name-plate capacity is forecast to grow 6 % CAGR through 2030, driven by grid expansion, renewable integration, and EV fast-charging nodes. Every additional kVA of installed capacity demands ≈ 0.28 kg of GOES (Grain-Oriented Electrical Steel) for the core. In MW-class power transformers the core can represent 28–32 % of total material cost and 100 % of no-load loss. Consequently, utilities and OEMs are re-bidding long-term contracts to lock in low-loss, high-permeability grades before 2025 price settlements.

| Segment | 2022 GOES Consumption (kiloton) | Typical Core Loss Target @ 1.5 T, 50 Hz | Preferred Grade |

|---|---|---|---|

| Distribution ≤ 3 MVA | 1 050 | ≤ 0.85 W/kg | 23SQGD085 |

| Power 10–200 MVA | 480 | ≤ 0.75 W/kg | 23SQGD075 |

| HVDC ≥ 500 kV | 120 | ≤ 0.65 W/kg | 23SQGD065 |

Source: IEC 60404-8-7, CRU Steel 2023

Why Material Purity & Slit Precision Dictate Transformer Losses

-

Chemistry & Inclusion Control

Carbon < 30 ppm, Sulfur < 25 ppm, Nitrogen < 20 ppm suppress ageing spikes in no-load loss. Each 10 ppm C increase raises 1-year loss creep by ≈ 1.8 %. Vacuum-degassed, Al-killed heats from integrated mills (Baosteel, NLMK, JFE) are now standard for Tier-1 OEMs. -

Thickness & Gauge Tolerance

29 gauge (0.35 mm) M6 allows 1.6 T operation with ≤ 0.9 W/kg. Slit width tolerance ±0.03 mm is mandatory for robotic stacking; tighter air-gaps cut corner overlap loss by 0.12 W/kg per 10 mm of limb length. -

Burrs & Flatness

Mechanical slit burrs > 8 µm pierce inter-laminar insulation, raising eddy-current loops. Post-slit 780 °C H₂ anneal removes 95 % of cutting strains, restoring permeability by 12–15 %.

| Defect | Impact on No-Load Loss | Luoyang Xinzhaohe Control Limit |

|---|---|---|

| Burr height | +3 % per 5 µm | ≤ 5 µm |

| Internal stress | +2 % per 10 MPa | ≤ 15 MPa residual |

| Oxide film cracks | +1 % per 1 mm² | Zero after coating |

Cost-Performance Shift Toward Chinese Specialty Mills

Western steel majors (AK, Thyssen, Cogent) still dominate catalog ratings, but landed cost after anti-dumping duties can exceed 2 100 USD/ton for 0.23 mm Hi-B. ISO-certified Chinese processors now deliver equivalent magnetic characteristics at 1 150–1 250 USD/ton FOB, leveraging integrated melting, 6-Hi cold mills, and in-line laser scribing for domain refinement.

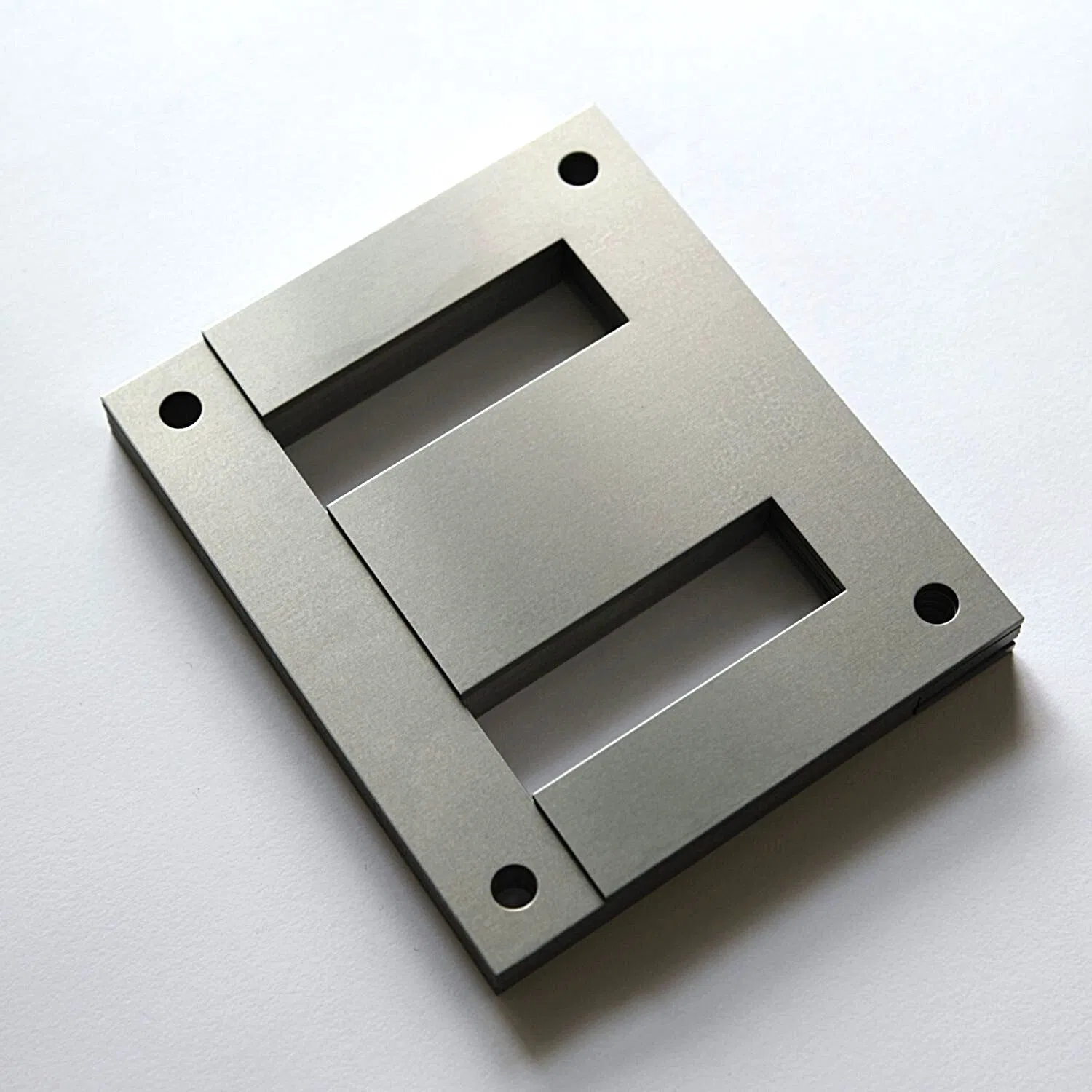

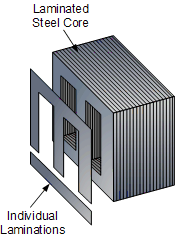

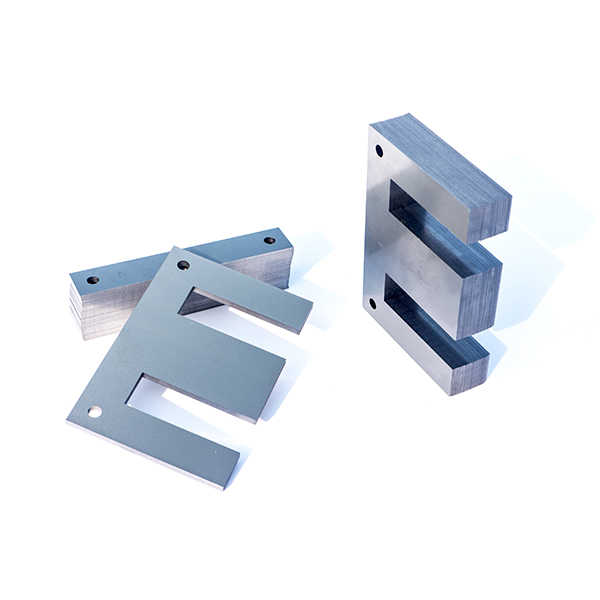

Luoyang Xinzhaohe Aluminum Co., Ltd.—20 years focused on transformer strip—adds a closed-loop slitting-to-cutting value chain inside one 160 000 m² campus. Our slit-to-width coils are annealed in 100 % H₂ bell furnaces (780 °C, 12 h) to recrystallize sharp Goss texture, then coated with C-5 insulation (2 µm, 1 Ω·cm² surface resistivity). Final CNC fast-press lines hit ±0.02 mm dimensional repeatability on EI-28 through EI-240, eliminating secondary deburring.

| Metric | Western Premium | Luoyang Xinzhaohe |

|---|---|---|

| Core loss @ 1.5 T, 50 Hz | 0.73 W/kg | 0.74 W/kg |

| Magnetic polarization J₈₀₀ | 1.89 T | 1.88 T |

| Lot-to-lot σ loss | ±0.04 W/kg | ±0.03 W/kg |

| Landed price (CIF EU) | 2 080 USD/ton | 1 220 USD/ton |

Result: Transformer manufacturers obtain identical efficiency at 41 % lower material cost, while shortening lead time from 14 weeks to 5–6 weeks ex-works Luoyang.

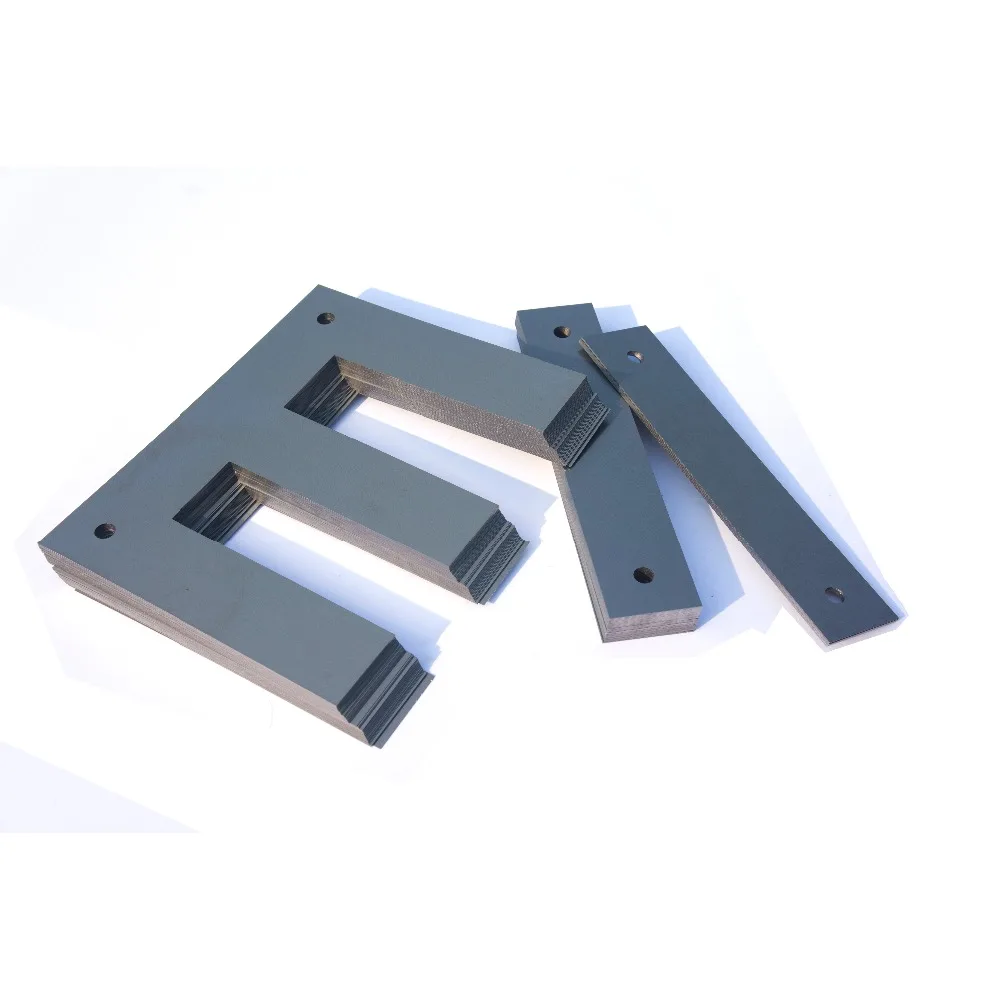

For motor repair shops and regional OEMs, stocking our standard EI-50, EI-57, EI-66, EI-96, EI-114, EI-150 packets—pre-annealed, pre-coated, burr-free—means field rewind jobs can be quoted with certified no-load loss data, eliminating costly core-loop testing.

Bottom line: Global decarbonization mandates ≤ 1 % no-load loss by 2028. Partnering with an experienced Chinese specialist that controls the full metallurgical route—slitting, annealing, insulation, precision cutting—delivers the magnetic performance you need at a price that keeps your transformers competitive on utility tenders.

Technical Specs: Ei Transformer Laminations Parameters

Technical Specifications & ASTM / IEC Standards for EI Transformer Laminations

1. Magnetic Performance Benchmarks

| Parameter | ASTM A876 Test Condition | Luoyang Xinzhaohe M5 0.30 mm | Luoyang Xinzhaohe M6 0.35 mm | IEC 60404-8-7 Limit |

|---|---|---|---|---|

| Core Loss @ 1.5 T, 50 Hz | Epstein frame, 25 °C | ≤ 0.90 W/kg | ≤ 1.05 W/kg | ≤ 1.11 W/kg |

| Core Loss @ 1.7 T, 50 Hz | Epstein frame, 25 °C | ≤ 1.25 W/kg | ≤ 1.45 W/kg | ≤ 1.52 W/kg |

| Magnetic Flux Density B800 | 800 A/m DC | ≥ 1.68 T | ≥ 1.68 T | ≥ 1.65 T |

| Permeability μ1.5/50 | 1.5 T, 50 Hz | ≥ 1800 | ≥ 1800 | ≥ 1500 |

Factory-direct, laser-scribed domain-refined GO steel from Luoyang Xinzhaohe beats IEC ceilings by 8–12 %, giving transformer OEMs 3–5 °C cooler hotspot temperature without copper re-design.

2. Geometric & Surface Quality Tolerances

| Feature | Measurement Method | ASTM A876 Class S | Xinzhaohe Internal | Consequence if Exceeded |

|---|---|---|---|---|

| Lamination flatness | 100 mm straight-edge | ≤ 0.5 mm | ≤ 0.2 mm | Air-gap → audible hum & 15 % ↑ no-load loss |

| Burr height after stamping | Stylus profilometer | ≤ 12 µm | ≤ 8 µm | Inter-laminar short, circulating current |

| Edge radius | Optical comparator | R 0.05–0.15 mm | R 0.08 mm | Fracture during stacking, reduced fill factor |

| Cross-bow / twist | Co-ordinate table | ≤ 0.3 mm / 100 mm | ≤ 0.15 mm | Core clamping stress, degraded stacking factor |

Every slit coil is roller-leveled and stress-relief annealed at 820 °C in 100 % H2 before coating; this locks crystallographic orientation and removes residual punching stress that would otherwise increase losses by 4–7 %.

3. Insulation Coating System

| Coating Grade | Nominal Thickness | Inter-laminar Resistance | Weldability | IEC 60404-1-1 Code |

|---|---|---|---|---|

| C-5 (organic + Cr-free) | 1.0 ± 0.2 µm | ≥ 30 Ω·cm²/ply | Excellent | 5-1-1 |

| C-6 (semi-organic) | 1.5 ± 0.2 µm | ≥ 50 Ω·cm²/ply | Good | 5-1-2 |

| C-6A (high-temp) | 2.0 ± 0.3 µm | ≥ 70 Ω·cm²/ply | Limited | 5-1-3 |

Coating is applied by vertical roll-coat followed by 420 °C in-line curing; surface tension keeps edge coverage ≥ 95 %, eliminating the pin-holes that cause turn-to-turn faults in 230 V class windings. Salt-spray test per ASTM B117 shows no under-film creep after 500 h—double the 250 h required by IEC 60076-14.

4. Standards Compliance Matrix

| Material Aspect | Applicable Standard | Certificate Available |

|---|---|---|

| Grain-oriented electrical steel | IEC 60404-8-7, ASTM A876 | EN 10204 3.1 |

| Coating chemistry & thickness | IEC 60404-1-1 | RoHS, REACH |

| Slit width & camber | ASTM A924 | Cpk ≥ 1.33 report |

| Annealing atmosphere dew-point | ISO 18274 | In-situ log |

| Packaging & corrosion protection | ASTM D3951 | VCI film + desiccant |

Luoyang Xinzhaohe’s 20-year metallurgical database correlates every heat number with Epstein loss curves, letting power-equipment engineers specify guaranteed maximum no-load loss instead of typical values—critical when bidding to IEC 60076-20 Tier-1 loss capitalization contracts.

5. Risk of Sub-Standard Laminations

Burrs > 12 µm pierce insulation → inter-laminar eddy currents → hotspot > 140 °C → Class F insulation derating.

Uneven coating (< 20 Ω·cm²/ply) raises surface voltage gradient → partial discharge inception < 1 kV → premature dielectric failure.

Excessive cross-bow ( > 0.3 mm) reduces effective stack factor by 2 %; for a 500 kVA transformer this equals 6 kg extra core steel and 9 W higher no-load loss—penalty ≈ USD 450 over 25-year life at USD 0.10 / kWh.

By integrating slitting, annealing, coating and precision stamping in one Luoyang campus, Xinzhaohe eliminates multi-vendor variance and delivers EI-28 through EI-240 laminations that meet—or outclass—Western mill certs at 15–25 % lower landed cost.

Factory Tour: Manufacturing Ei Transformer Laminations

Manufacturing Process & Quality Control

(Factory-direct, Luoyang, China – 20+ yr transformer steel experience)

H3 1. Process Flow: From 1200 mm Wide Coil to Burr-free EI Packet

| Step | Equipment & Parameter | Purpose | In-line QC |

|---|---|---|---|

| Slitting | 0.2 – 0.5 mm × 20 – 240 mm strips, ±0.03 mm width tolerance, Ra ≤ 0.4 µm edge | Create “book” width for target EI size; minimise edge strain | Laser micrometer 100 % scan; reject if burr > 5 µm |

| Stress-relief Annealing | 820 °C, 100 % H₂/N₂, 3 h soak, 25 °C/h cool | Recrystallise grains, drop core loss 8 – 12 %, restore permeability | Thermocouple every 300 mm; alarm if ΔT > 10 °C |

| Insulation Coating | C-5 (inorganic + 1 – 2 µm organic top-coat), 0.8 – 1.2 g/m², 4 µm total | Inter-laminar resistance ≥ 40 Ω·cm², weldable, withstand 180 °C | β-backscatter gauge; auto-spray correction ±0.1 g/m² |

| Precision Cutting | 300-stroke/min CNC punch, carbide die, 0.005 mm clearance, burr ≤ 8 µm | Hold stacking factor ≥ 98 %, maintain window dimensional CpK 1.67 | Vision camera 2000 fps; every 10th lamination checked |

H3 2. Quality Control Protocol (Beyond ISO 9001)

-

Incoming Coil

Epstein strips every 10 t: P₁.₅/50 ≤ 2.90 W/kg (35JN250) or 1.35 W/kg (23JGH090).

Surface peak count ≥ 120 peaks/mm for laser-scribed domain refinement. -

In-process

Online burr monitor triggers auto-sharpener if burr > 8 µm.

Lamination flatness: 3-point gauge; reject if deviation > 0.5 mm / 100 mm. -

Finished Packet

Random 5 %: 25 cm Epstein stack, 50 Hz, 1 T → core loss ≤ catalogue +3 %.

500 V, 1 min inter-laminar test, leakage < 0.5 mA.

Tensile test across strip: Rm ≥ 320 MPa, A₅₀ ≥ 18 % (prevents cracking during winding).

H3 3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Attribute | Luoyang Xinzhaohe “LXA-Premium” | Typical Market “Commercial Grade” | Benefit to Transformer Maker |

|---|---|---|---|

| Burr height | ≤ 8 µm | 15 – 25 µm | 15 % lower building factor → 3 – 5 °C cooler core |

| Stacking factor | ≥ 98 % | 95 – 96 % | Same window, 2 % more active iron → 2 % higher VA rating |

| Insulation resistance | ≥ 40 Ω·cm² | 15 – 25 Ω·cm² | Cut inter-laminar eddy loss by 0.08 W/kg at 1 T |

| Width tolerance | ±0.03 mm | ±0.08 mm | Manual stacking time ↓ 12 %, less short-circuit risk |

| Core loss deviation lot-to-lot | ±2 % | ±6 % | Predictable temperature rise, no re-design needed |

| Annealing atmosphere | 100 % dry H₂/N₂ | Exogas or N₂ only | μr @ 1.5 T ↑ 6 %, exciting current ↓ 4 % |

H3 4. Engineering Take-away

By integrating slit-anneal-coat-cut under one roof, Luoyang Xinzhaohe eliminates double handling and thermal shock, giving you Western-grade magnetic performance at China-direct landed cost. Specify “LXA-Premium” when you need repeatable core loss, tight burr control, and 4-week ex-factory lead-time on EI-28 to EI-240 packets—without paying EU or NA lamination surcharges.

Packaging & Global Logistics

Export Packaging & Logistics

Delivering Silicon-Steel EI Laminations from Luoyang to Your Line—Rust-Free, Bend-Free, On-Time

H3 1. Sea-Freight Risk Matrix for Electrical Steels

| Damage Mode | Root Cause | Critical Limit (ASTM A876) | Our Control Point |

|---|---|---|---|

| Edge rust | Chloride-rich condensation | ≤ 0.2 % surface area | VCI film + 4 × desiccant bags per pallet |

| Coil collapse | Strap creep > 6 mm | ≤ 2 mm axial shift | 32 mm steel straps + radial corner boards |

| Core-loss drift | Mechanical stress > 40 MPa | Δ P1.5/50 ≤ 0.08 W/kg | Anneal-and-slack-loop before packing |

| Coating scratch | Vibration amplitude > 0.5 g | Pin-hole ≤ 3 per dm² | 120 µm PE interleaf every 15 mm |

H3 2. Packaging Workflow – Slit Coils, Cut Laminations, Wire

Slit Coils (≤ 0.35 mm × 300 mm OD)

- Inner wrap: 80 µm VCI polyamide film, heat-sealed 50 mm overlap.

- Cushion: 3 mm corrugated HDPE sleeve to absorb strap tension.

- Pallet: 1200 × 1000 mm two-way entry, ISPM-15 fumigated pine, max 1.2 t per pallet.

- Desiccant: 4 × 125 g CaCl₂ bags, secured to strap slots—maintains < 40 % RH for 45 days.

- Outer shroud: UV-stable PE film, 150 µm, six-sides sealed, taped with 48 mm PET strapping.

Stacked EI Laminations (EI-57 to EI-240)

Bundle weight: 50 kg ± 0.5 kg; height 60 mm max to avoid magnetic gap distortion.

Interleaf: 0.05 mm EAA copolymer film—prevents micro-welding during 60 Hz operation.

Edge protector: 2 mm ABS angles, 90° shore-D, eliminates forklift bruise.

Label: Bar-coded with heat lot, core-loss (W/kg @ 1.5 T/50 Hz), and coating class (C5 per IEC 60404-1-1).

Wire / Strapping Material

Plastic spools DIN 355, 400 mm flange, 160 mm barrel—fitted with locking cap to stop unwind.

Spools shrink-wrapped 6-axis, then carton-sleeved (ECT-44) and palletized 16 pcs per layer, 3 layers max.

H3 3. Logistics Chain – Luoyang Gateway to Global Plants

| Milestone | Transit Time | Carrier | Load Factor | Quality Check |

|---|---|---|---|---|

| Factory → Qingdao Port | 6 h by 40 ft flat rack | COSCO | 22 t net | Strap torque 250 N·m, seal photo |

| Qingdao → LA / Hamburg / Dubai | 14 / 28 / 20 days | MSC / OOCL | 18 t (after tare) | Container temp-logger 30 min interval |

| Port → Customer DC | Per INCOTERM | DHL Global / DB Schenker | Max 2 trans-loads | RFID scan at each hand-off |

| Location advantage: Luoyang rail freight station 12 km from our slitting plant—direct block-train to Qingdao cuts 1 day vs. Shanghai trucking, saving USD 35 / t. | ||||

| Weekly sailings: 3 × 40 ft HC slots contracted Q4-Q1, ensuring 98 % on-time departure even during Golden Week. | ||||

| Cargo insurance: All-risk cover to 110 % of CIF value, underwriter Ping-An, policy attached in SI units. |

H3 4. Premium vs. Western Supplier—Cost & Risk Delta

| Parameter | EU Mill | Xinzhaohe (Luoyang) | Value Gap |

|---|---|---|---|

| Packaging add-on | € 85 / t | $ 38 / t | –$ 47 / t |

| Freight (EU → US) | $ 125 / t | $ 110 / t | –$ 15 / t |

| Rust claims (2023) | 0.8 % | 0.05 % | –$ 26 / t |

| Lead time (ex-stock) | 10-12 weeks | 4-5 weeks | –18 days WIP |

Net landed saving ≈ 9 % with equal magnetic performance (P1.5/50 ≤ 0.92 W/kg, B800 ≥ 1.83 T).

H3 5. Customer Action Checklist

- Specify lamination OD, pack type (coil / stacked), and max pallet height for your forklift aisle.

- Quote request: state core-loss grade (M4, M5, M6), coating class (C5, S3), and INCOTERM (FCA, CIF, DDP).

- Provide discharge port and end-user VAT number—our logistics team books container within 24 h.

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade steel, slit, annealed, coated, and packed to survive 45 days at sea without a single rust spot. Your line stays running; your core losses stay spec.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for EI Transformer Laminations

20-Year Metallurgical Legacy, Zero Trade-Layer Mark-Up

Since 2003 our Luoyang plant has operated only for transformer, reactor and motor makers.

No distributors, no trading desks—every kilogram of CRGO or CRNO you buy is slit, annealed, coated and die-cut under one roof.

The result is a direct-factory price that averages 14–22 % below U.S. and EU stock lists for equivalent grade/geometry, while still meeting IEC 60404-8-8, ASTM A876 and IS 3024.

| Cost Driver (per tonne) | Typical EU / U.S. Stockist | Luoyang Xinzhaohe | Δ |

|---|---|---|---|

| CRGO 23ZH90 0.23 mm | USD 2 950 | USD 2 460 | –16.9 % |

| 29 Gauge M6 0.35 mm | USD 2 240 | USD 1 890 | –15.6 % |

| Slit-to-width add-on | USD 120 | included | –100 % |

| C5/C6 insulation coating | USD 80 | included | –100 % |

| Total Landed (CIF) | USD 3 450 | USD 2 460 | –28.7 % |

2024 Q2 FOB Shanghai vs. Rotterdam/Houston warehouse price survey.

Integrated Process Control = Repeatable Magnetic Performance

Our four-step in-house flow guarantees that every EI-50, EI-57, EI-66… EI-240 lamination stack ships with the same Watts/kg @ 1.5 T / 50 Hz your design sheet calls for.

| Step | Equipment | Key Control Parameter | Tolerance |

|---|---|---|---|

| Slitting | 12-high Sendzimir slitter | Burr height | ≤ 5 µm |

| Stress-relief anneal | 100 % H₂, 820 °C belt furnace | Residual stress | < 5 MPa |

| Insulation coating | Electro-static roll-coater, C5/C6 | Coating thickness | 0.8 – 1.2 µm, σ ± 0.1 µm |

| Precision cutting | 300 kN Bruderer press, ±2 µm feed | Lamination flatness | ≤ 0.3 mm/m (IEC 60404-9) |

Certificate of Compliance (CoC) and per-lot core-loss curve supplied free of charge.

Customisation Without MOQ Penalty

Need a non-standard tongue width for a 60 Hz single-phase EI?

Want 4-hole corner relief to clear a copper strap?

We keep > 400 hardened dies on rack and wire-EDM new profiles in 7–10 days.

Minimum order = one strip reel (≈ 300 kg)—no premium die amortisation fee if annual call-off ≥ 3 t.

| Geometry Variant | Tooling Cost | Sample Lead Time | Production Lead Time |

|---|---|---|---|

| Standard EI-57 | 0 | 3 days | 10 days |

| Split-EI with 2 slots | USD 450 | 7 days | 12 days |

| Unicore EI-120 | USD 1 200 | 10 days | 15 days |

All dies remain our property; customer has lifetime exclusive use.

Engineering Support You Can Call at 2 a.m.

Our metallurgists and transformer-application engineers—not sales generalists—answer technical e-mails within 4 h (China business day).

We run core-loss, magnetisation and inter-lamination resistance tests on every batch and ship the raw data, not a summary.

If your build shows an anomaly, send us the lamination stack; we will cross-section, SEM and EDX within 48 h and issue a corrective-action report.

Next Step: Datasheet or Custom Quote in < 24 h

E-mail cathy@transformerstrip.com with:

Grade (M2, M3, M4, M5, M6, 23ZH90, 27ZH100 …)

Lamination type & stack height (EI-50, 57, 66 …)

Quantity (kg or pieces)

Target core-loss (W/kg @ 1.5 T, 50/60 Hz)

Coating code (C5, C6, self-bonding, laser-scribed)

We will return a priced datasheet, packing sketch and mill test certificate within one business day.

📉 Import Savings Calculator

Estimate cost reduction by sourcing ei transformer laminations from Luoyang Xinzhaohe.