Table of Contents

Market Insight: Ctc Cable

Market Analysis: Winding Wire – Industrial Demand for CTC Cable in Transformers

The demand for continuously transposed conductor (CTC) cable in the global transformer industry is driven by the increasing need for high-efficiency, reliable, and thermally stable power transmission and distribution systems. As electrical grids modernize and renewable energy integration accelerates, transformers are required to operate under higher loads, variable cycling, and tighter efficiency standards. In this context, CTC cable has become a critical component in large power transformers, particularly in high-voltage and extra-high-voltage applications where eddy current losses and uneven current distribution can significantly degrade performance.

CTC cable is engineered to mitigate circulating currents in transposed conductors by ensuring that each strand occupies every possible position within the cable cross-section over a defined transposition length. This geometric symmetry equalizes the electromagnetic exposure of individual strands, minimizing eddy current losses and improving current-carrying capacity. The result is enhanced thermal performance, reduced hotspot formation, and improved long-term reliability—factors that are paramount in utility-scale transformers operating continuously under full or partial load.

Industrial demand for CTC cable is particularly strong in sectors such as power generation, transmission infrastructure, industrial manufacturing, and renewable energy installations. Wind farms and solar parks, for example, rely on step-up transformers equipped with high-quality CTC windings to efficiently transmit power over long distances with minimal losses. Similarly, urban substations and data center power systems demand compact, high-performance transformers where thermal management and electrical efficiency directly impact operational cost and system uptime.

The quality of CTC cable directly influences transformer performance and lifecycle cost. Substandard materials or imprecise transposition can lead to localized overheating, insulation degradation, and premature failure. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in aluminum winding wire production, we emphasize metallurgical purity, dimensional precision, and consistent transposition geometry. Our CTC cables are manufactured using high-conductivity aluminum (EC grade), with strict control over strand diameter, surface finish, and transposition pitch to meet IEC 60317 and IEEE C57 standards.

Moreover, aluminum-based CTC cables offer a favorable balance of conductivity, weight, and cost compared to copper alternatives, making them ideal for large transformers where weight reduction and material efficiency are critical. However, aluminum’s lower mechanical strength and higher thermal expansion require precise design and manufacturing control—underscoring the importance of sourcing from technically proficient suppliers.

In summary, the industrial demand for CTC cable is inextricably linked to the performance requirements of modern power systems. As transformers are pushed to deliver higher efficiency and reliability under dynamic operating conditions, the quality of winding materials—particularly CTC cable—becomes a decisive factor in system longevity and operational safety.

Technical Specs: Ctc Cable

Technical Specifications for CTC Cable: Critical Performance Parameters

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical and wire drawing expertise to produce CTC (Circular Tinned Copper) cable meeting the most stringent industrial demands. Our technical specifications are engineered not merely to comply with international standards but to exceed them, ensuring superior reliability and longevity in demanding applications. Key parameters defining performance integrity are rigorously controlled throughout our manufacturing process, from high-purity raw material selection to final quality assurance testing. Understanding these specifications is paramount for B2B sourcing decisions where operational safety and system efficiency are non-negotiable.

Insulation Breakdown Voltage represents the fundamental dielectric strength of the cable insulation system. This parameter directly correlates to the cable’s ability to withstand electrical stress without failure, preventing catastrophic short circuits. Xinzhaohe implements a dual-stage testing protocol: 100%在线 spark testing during extrusion per IEC 60851-5, followed by destructive sampling at elevated voltages. Our standard minimum breakdown voltage significantly surpasses IEC 60851 requirements, ensuring robust dielectric integrity even under transient overvoltage conditions common in industrial power systems. Consistent high breakdown voltage is achieved through precise control of insulation extrusion parameters and material homogeneity, minimizing voids or impurities that could initiate electrical trees.

Elongation at break is a critical mechanical property indicating the conductor’s ductility and resistance to fracture during installation bending or operational thermal cycling. For aluminum-based CTC conductors, achieving optimal elongation requires meticulous control over the alloy composition, annealing temperature profiles, and drawing reduction rates. Xinzhaohe’s proprietary annealing process ensures uniform microstructure, delivering elongation values that consistently meet or exceed ASTM B3/B3M specifications. This high ductility is essential for preventing conductor breakage during pull-in, especially in complex conduit systems, and for accommodating thermal expansion/contraction cycles without work hardening or fatigue failure. Our process guarantees minimum elongation retention even after severe forming operations.

Thermal Class defines the maximum continuous operating temperature the cable insulation system can withstand without significant degradation of electrical or mechanical properties. Xinzhaohe offers CTC cable across a comprehensive thermal class spectrum from 130°C (Class B) up to 220°C (Class H+), catering to diverse application environments from standard industrial machinery to high-temperature aerospace or downhole equipment. The thermal class is intrinsically linked to the specific polymer formulation and cross-linking density of the insulation. Higher classes (e.g., 180°C, 200°C, 220°C) utilize advanced materials like cross-linked polyethylene (XLPE), ethylene tetrafluoroethylene (ETFE), or polyimide, demanding stringent process control during extrusion and curing. Our QA protocols include rigorous thermal aging tests per IEC 60216 to validate long-term thermal endurance at the rated class.

The following table details the critical performance parameters against industry benchmarks and Xinzhaohe’s controlled specifications:

| Parameter | Standard Range (Typical) | Xinzhaohe Specification | Testing Method |

|---|---|---|---|

| Insulation Breakdown Voltage | ≥ 15 kV/mm (IEC Min) | ≥ 35 kV/mm (Min) | IEC 60851-5, ASTM D149 |

| Conductor Elongation | ≥ 10% (Al, ASTM B3) | ≥ 25% (Typical) | ASTM E8/E8M, IEC 60884-1 |

| Thermal Class | 130°C to 220°C | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60216, UL 1581 Sec 2400 |

These specifications are not static targets but dynamic outputs of our integrated metallurgical and process engineering discipline. Xinzhaohe’s supply chain rigor ensures traceability from certified raw material lots through every process stage, guaranteeing consistent parameter performance batch after batch. This technical precision forms the foundation of our reliability commitment to global industrial partners.

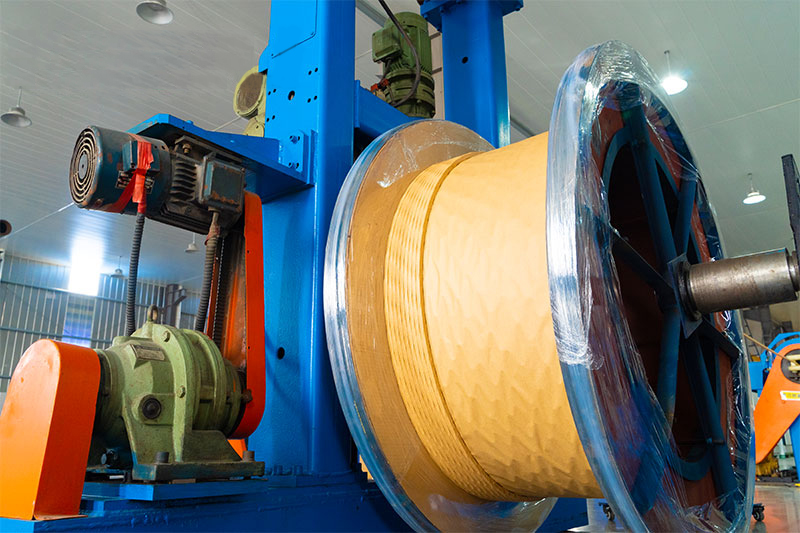

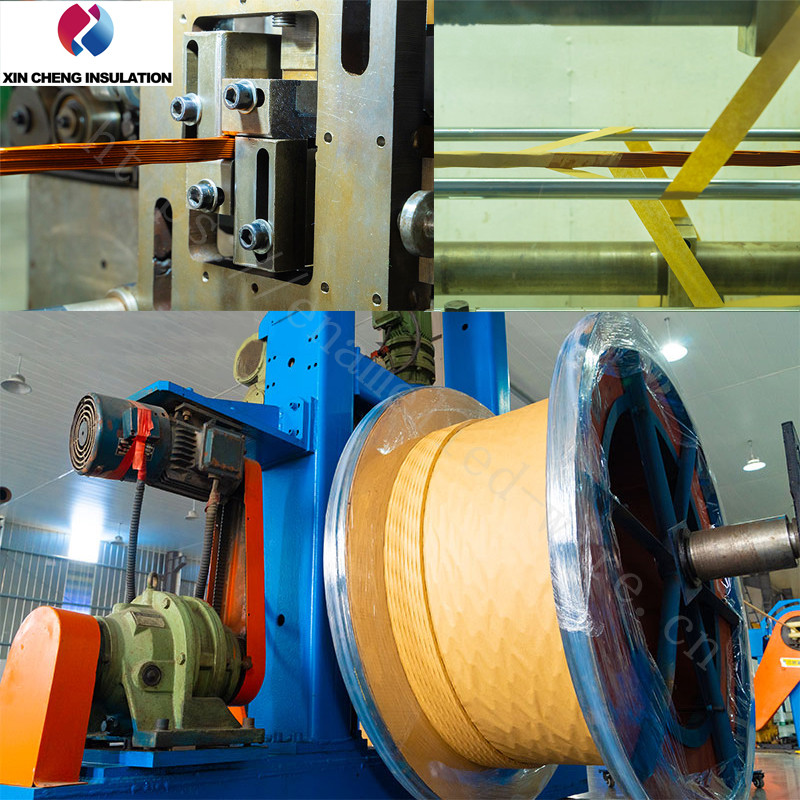

Factory Tour: Manufacturing

Manufacturing Process for CTC Cable Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance winding wire for CTC (Continuous Transposition Cable) applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure mechanical integrity, electrical efficiency, and long-term reliability. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment with rigorous quality control to meet the stringent demands of power transformer and high-current transmission systems.

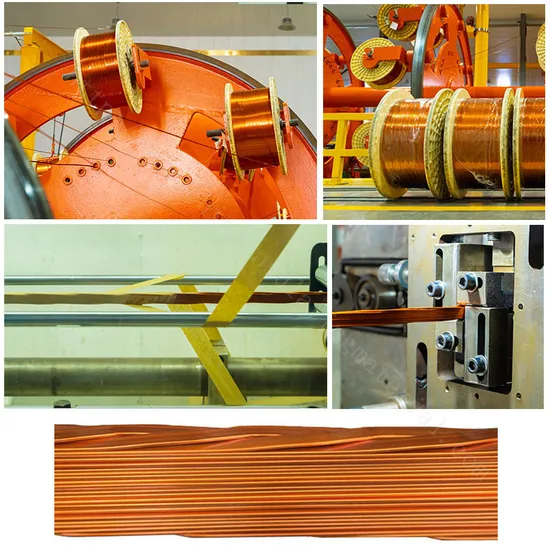

The process begins with rod drawing, where high-purity aluminum rod (typically 9.5 mm diameter, meeting GB/T 3954 standards) is pulled through a series of tungsten carbide or diamond dies to achieve the target wire diameter, commonly ranging from 1.0 mm to 3.5 mm depending on customer specifications. This cold working process enhances tensile strength while maintaining dimensional accuracy, with diameter tolerances held within ±0.01 mm. Lubrication and temperature are continuously monitored to prevent surface defects and ensure uniform elongation.

Following drawing, the wire undergoes continuous annealing in a controlled nitrogen-purged furnace. This softens the work-hardened aluminum, restoring optimal electrical conductivity (minimum 61% IACS) and ductility required for subsequent transposition and winding operations. The annealing profile is precisely regulated to avoid overheating or oxidation, ensuring a consistent microstructure across production batches. Post-annealing, the wire is cooled under inert atmosphere to prevent surface oxidation prior to coating.

The enameling stage applies multiple layers of thermosetting polymer insulation—typically polyester-imide or polyamide-imide—to provide dielectric strength, thermal stability, and mechanical protection. The wire passes through a series of coating dies and precision metering systems, followed by stepwise curing in high-temperature ovens. Each layer is cured before the next is applied, enabling total build thicknesses from 0.05 mm to 0.15 mm with pinhole-free integrity. Adhesion, flexibility, and thermal class (up to 200°C) are validated in-line and through periodic laboratory testing.

Throughout the production line, inline testing systems provide real-time quality assurance. These include spark testing for insulation defects (per IEC 60317), diameter laser gauging, and tension monitoring. Any deviation triggers immediate alerts and corrective action. Additionally, periodic off-line QC checks are performed, including elongation and tensile strength (per GB/T 4909), winding test for adhesion, thermal shock resistance, and dielectric breakdown voltage.

All process parameters are logged and traceable to batch numbers, supporting full documentation for industrial audits. This integrated approach—combining advanced process control with systematic quality validation—ensures that every spool of winding wire meets the exacting performance standards required for CTC cable assembly in high-efficiency power systems.

Packaging & Logistics

Export Packaging Specifications for CTC Cable Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard aluminum winding wire integrity during extended international sea freight. Our 20+ years of metallurgical and supply chain experience confirm that inadequate packaging is the primary cause of in-transit degradation, particularly moisture-induced oxidation which critically compromises electrical conductivity and surface quality. We prioritize robust solutions validated for global ocean transport cycles.

All winding wire reels are secured to custom-engineered wooden pallets meeting ISPM 15 international phytosanitary standards for heat-treated lumber. Pallet construction utilizes kiln-dried, defect-free hardwood components with a minimum load-bearing capacity of 2500 kg, exceeding standard ISO pallet specifications. Dimensions are precisely calculated to maximize container cube utilization while ensuring a minimum 100mm clearance from container walls, mitigating impact damage during handling. Reels are mechanically fastened using corrosion-resistant steel straps tensioned to 300 daN, preventing axial shift during vessel motion. Critical stress points incorporate plywood deck reinforcement to distribute load evenly and eliminate reel deformation.

The primary moisture barrier employs a multi-layer polyethylene film system incorporating Volatile Corrosion Inhibitor (VCI) technology. A base layer of 150-micron black LDPE film provides initial vapor resistance, followed by a dedicated VCI-impregnated film layer (120 microns) releasing protective molecules that form a molecular shield on the aluminum surface. The outermost layer is a 200-micron UV-stabilized, high-density polyethylene film with a moisture vapor transmission rate (MVTR) ≤ 1.0 g/m²/24hr at 38°C and 90% RH. This tri-laminate structure is hermetically sealed using industrial heat-welding equipment, achieving seam integrity tested to withstand 0.5 bar internal pressure without leakage. All seams are double-welded and visually inspected per ASTM D3078 standards.

Critical film performance characteristics are detailed below:

| Property | Value | Test Standard |

|---|---|---|

| Total Film Thickness | 470 ± 20 microns | ASTM D5947 |

| MVTR (38°C, 90% RH) | ≤ 1.0 g/m²/24hr | ASTM E96 |

| VCI Protection Duration | ≥ 24 months | ASTM D6154 |

| Tensile Strength (MD) | ≥ 25 MPa | ASTM D882 |

Palletized and film-wrapped units undergo desiccant conditioning, placing silica gel canisters (calculated at 5% of cargo volume) within the sealed envelope to absorb residual humidity. Final units are over-palled with a marine-grade corrugated cardboard shroud, secured with steel banding, and labeled with moisture-sensitive indicators and handling instructions compliant with IMDG Code Section 5.2. This integrated system maintains internal relative humidity below 40% throughout typical 45-60 day voyages, even when external container conditions experience dew point fluctuations exceeding 20°C. Our packaging methodology directly prevents oxide layer formation, ensuring reels arrive in factory-fresh condition, ready for immediate processing without costly cleaning or rejection. This precision approach minimizes total landed cost by eliminating moisture-related claims and production downtime.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance CTC Cable Winding Wire

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the production of high-purity aluminum winding wire for ctc cable applications. Our facility integrates advanced metallurgical processing with stringent quality control systems to deliver aluminum conductors that meet the exacting demands of power transmission, transformer, and industrial cable manufacturers worldwide.

Our production infrastructure is engineered for precision and consistency. We operate fully automated continuous casting and rolling lines, ensuring uniform microstructure and mechanical properties across every coil. The aluminum used in our winding wire is sourced from 99.99% pure Al99.99, processed through controlled atmosphere melting and degassing systems to minimize hydrogen content and non-metallic inclusions. This results in material with superior electrical conductivity—typically exceeding 61% IACS—critical for minimizing losses in ctc cable systems.

We specialize in producing rectangular and square-section aluminum strip conductors tailored for transformer and reactor windings, with dimensional tolerances maintained within ±0.02 mm. Our in-house drawing and annealing lines allow for precise control over temper, enabling delivery in soft (O-temper), semi-hard (H14), or full-hard (H18) conditions based on customer specifications. Surface finish is optimized through multi-stage cleaning and polishing, reducing the risk of insulation damage during high-speed winding operations.

Quality assurance is embedded at every stage of production. Our laboratory is equipped with OES spectrometers, universal testing machines, and eddy current inspection systems to verify chemical composition, tensile strength, elongation, and electrical resistivity. Each batch is traceable through our integrated MES system, supporting full documentation for ISO and IEC compliance.

As a vertically integrated supplier, we maintain control over raw material procurement, processing, and final packaging. This enables us to offer competitive lead times and consistent supply continuity, even under fluctuating market conditions. Our export experience spans over 30 countries, with established logistics partnerships ensuring timely delivery to global customers.

For sourcing managers and technical procurement teams, partnering with Luoyang Xinzhaohe means access to technically validated materials, responsive engineering support, and long-term supply stability. We welcome the opportunity to collaborate on material specifications, provide sample coils for qualification, and support your ctc cable production with reliable, high-performance aluminum winding wire.

Contact us today to discuss your requirements.

Cathy Zhang

Sales Manager, International Division

cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing ctc cable directly from China.