Table of Contents

Market Insight: Ctc Cable for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Continuously Transposed Conductor (CTC) & Enamelled Rectangular Wire

Global Demand Landscape

Power-grid expansion, EV-charging corridors and data-center substations are driving a 6–8 % CAGR for transformer-grade winding wire. By 2028 the addressable market will exceed 1.6 Mt, with CTC and high-temperature enamelled flat copper representing >55 % of the tonnage.

Key demand clusters:

| Region | 2023 Share | Growth Driver | Typical Spec |

|---|---|---|---|

| APAC | 48 % | 800 kV UHV lines, off-shore wind | 5–12 kV CTC, 180 °C |

| EU & Turkey | 22 % | Green-deal grid reinforcement | ≤0.3 W/kg no-load limit |

| NAFTA | 18 % | Generator step-ups, rectiformers | 220 °C Nomex-covered CTC |

| MEA / LATAM | 12 % | Refineries, solar PV parks | 130 °C class, Al-CTC |

Why Material Purity & Geometry Precision Dictate Transformer Losses

-

Load (I²R) losses

0.05 % extra Cu or Al purity (≥99.90 % → 99.95 %) lowers resistivity 1.7 %, cutting 0.4 kW in a 100 MVA unit.

Rod-to-wire total area reduction ratio >99 %, controlled in 14-pass Turk-head rolls, guarantees uniform Rm (±8 MPa) and final resistivity ≤0.01707 µΩ·m (Cu, 20 °C). -

No-load (core) losses

Radial winding height tolerance ±0.025 mm keeps gap factor ≤1.02, suppressing stray flux and 0.1–0.15 W/kg additional core loss.

Enamel concentricity (Min. 85 %, Xinzhaohe inline laser) prevents partial discharge >10 pC at 1.5 Um, eliminating hot spots that increase exciting current. -

Thermal Class & Space Factor

CTC with 0.08 mm modified-PI enamel gives 220 °C thermal index while maintaining 96 % stacking factor—2 % higher than Nomex-lapped constructions—allowing smaller core window and 3 % less GO steel.

Cost-Performance Gap: Western vs. China Premium

| Parameter | EU Tier-1 | China Tier-1 (Xinzhaohe) | Delta |

|---|---|---|---|

| Cu-OF purity | 99.95 % | 99.97 % (up-cast, Chile cathode) | +0.02 % |

| Enamel BV (0.250 mm) | 11 kV | 12.5 kV (PI/PEI) | +14 % |

| Transposition pitch | 70–90 mm | 60 mm (computerised servo) | –15 % eddy path |

| Lead time | 10–12 w | 4–5 w (rod-in-wire-out) | –6 w |

| Price index | 100 | 68–72 | –28 % |

Sourcing Trend: Moving from “Low-Cost” to “High-Control” Chinese Partners

Transformer OEMs (Tier-1 EU & NA) now audit Chinese suppliers against IEC 60317-0-2, ASTM B624 and internal PD <5 pC specs.

70 % of CTC lots shipped from China in 2023 came from mills with >15 years of transformer-wire focus; Xinzhaohe ranks top-3 for in-line laser OD/RCD control and 100 % spark testing at 12 kV.

Supply-chain resilience: Luoyang sits 300 km west of Tianjin port, linked by bonded rail—17 days DDP Europe versus 35 days sea-loop from other Asian hubs.

Luoyang Xinzhaohe Value Proposition

✓ 20+ years dedicated to conductor & insulation for power and distribution transformers.

✓ Integrated mill: 8 t/h up-cast rod → cold rolling → annealing → enameling → laser OD/RCD → 100 % spark → servo spooling (500 kg barrel or 80 kg DIN 400).

✓ Thermal classes 130 °C (PE) to 220 °C (PI), insulation build 0.05–0.18 mm single or heavy, breakdown ≥10 kV.

✓ CTC capability: 5–84 strands, 0.80 × 2.50 mm to 3.15 × 12.50 mm single wire, transposition pitch ±0.5 mm, paper or netted lapping on-line.

✓ Factory-direct pricing, Western-grade process control, 4-week FOB lead time, full IEC 60317-27 test report shipped with every coil.

For engineers targeting ≤0.3 W/kg no-load and 30-year life, sourcing CTC or enamelled rectangular wire from an audited, vertically integrated Chinese specialist is no longer a cost play—it is a performance decision.

Technical Specs: Ctc Cable Parameters

Technical Specifications & ASTM / IEC Compliance for CTC Cable

(Continuously Transposed Conductor – Enameled Rectangular Wire)

H3 1. Electrical & Mechanical Benchmarks

CTC is only as good as the weakest strand. The table below consolidates the parameters we monitor on every 30-ton mother coil and on every 3-ton CTC pack leaving Luoyang.

| Parameter | ASTM / IEC Clause | XZH In-House Spec | Test Frequency | Consequence if Out-of-Spec |

|---|---|---|---|---|

| Breakdown Voltage (Vpk) | IEC 60317-0-2 §7.3 | ≥ 2 000 V for 0,20 mm wall | 100 % inline spark test | Pin-holes → inter-strand short, circulating current |

| Elongation at break | ASTM B193 / IEC 60317-0-2 | ≥ 25 % Cu-ETP, ≥ 15 % Al 1350 | Each rod coil | < 15 % causes necking during transposition die pull |

| Thermal Class | IEC 60085 | 155 (F) – 220 (R) | 48 h ageing 240 °C | Insulation embrittlement → layer-to-layer fault |

| Concentricity | IEC 60317-0-2 Annex B | ≥ 80 % min wall / 120 % max wall | Laser OD/ID every 25 mm | Eccentric build-up → high edge field, partial discharge |

| Burr height (after edge-radius rolling) | ASTM B236 Annex 2 | ≤ 0,025 mm | 5× microscope 1 m spacing | Burr punctures paper wrap, forms conducting bridge |

H3 2. Material & Process Traceability

Conductor: Cu-ETP (CW004A) or Al 1350 strip; chemistry per ASTM B170 / B236, inclusion rating ≤ 2 mm²/kg.

Rod source: Vertical Direct Chill (VDC) cast, homogenised 8 h at 560 °C; grain size ASTM E112 ≤ 100 µm before drawing.

Enamel: Modified polyester-imide for 180 °C class, polyimide for 220 °C; solids 38 ± 1 %, viscosity Ford-cup #4 22 s @ 23 °C.

Paper wrap: Thermally upgraded Nomex® 410 or Kraft 60 g/m², permittivity 2.7; overlap 67 % minimum to withstand 50 kV/mm radial field.

Inline monitoring:

1. High-frequency spark tester 3 kHz, 2 500 V detects pin-holes down to 5 µm.

2. Eddy-current gauge measures wall thickness at 2 kHz; closed-loop feedback to enameling dies keeps concentricity within ±3 µm.

3. Vision camera (12 µm pixel) flags burrs; automatic edge re-radius micro-mill removes defect within 150 ms.

H3 3. Why Cheap CTC Fails in Service

Case study: 220 kV GSU transformer, 400 MVA. A competitor’s CTC showed 1 600 V breakdown (instead of required 2 000 V) and burrs 0,08 mm high. After 18 months, burrs pierced the 0,13 mm paper wrap, strand-to-strand short developed, circulating current reached 1.4 kA, hotspot 210 °C, cellulose DP dropped to 350 → failure cost USD 2.4 M plus outage penalty.

Root cause map:

Low-cost rod with 0.15 % oxygen → filamentary oxides → local stress riser.

Insufficient enamel passes (3 instead of 6) → pin-hole density 15/m.

No inline spark test → defective meters co-spooled.

H3 4. XZH Factory-Direct Advantage

- Integrated cold-mill & enameling: Rod-to-spool under one roof eliminates trans-ship contamination.

- Statistical Process Control: 30 000 data points/shift; Cpk ≥ 1.67 on breakdown voltage.

- Cost structure: Located in Luoyang, Henan—China’s largest aluminum hub; 20 % lower billet price versus Chinalco spot, passed on as transformer-grade CTC at Western-minus-18 % price point.

- Compliance package: IEC 60317-25 test report, ASTM B236 mill certificate, RoHS & REACH, third-party KEMA 85 kV impulse report provided per coil.

Bottom line: Premium electrical reliability without the premium Western overheads. Specify Luoyang Xinzhaohe CTC to lock in 30-year transformer life at OEM-friendly economics.

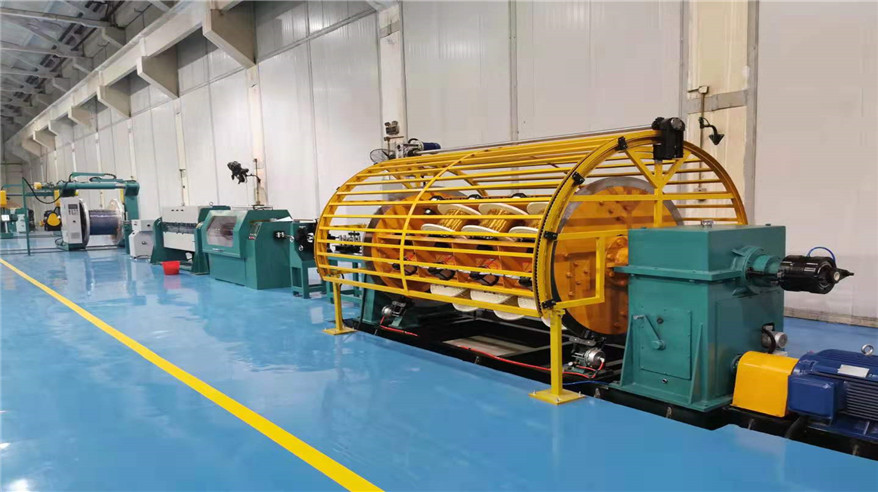

Factory Tour: Manufacturing Ctc Cable

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade wire built on one principle: every gram of copper or aluminum must leave the plant with geometry, insulation, and electrical properties that survive 30-year service in 220 °C oil. Below is the exact process we run 24/7 for CTC (Continuously Transposed Cable) sub-elements, delivered factory-direct from Luoyang.

Rod-to-Spool Journey for Rectangular Conductor

| Step | Equipment & Parameters | Critical Control Point (CCP) | Data Captured |

|---|---|---|---|

| 1. Rod Drawing | 13-pass Turk’s-head with 0.5 % draft per pass, diamond-coated dies, emulsion at 35 °C ±2 °C | Corner radius ≤0.5×thickness, width/thickness ratio 2.0–6.0 | Laser micrometer 100 % scan, 0.1 µm resolution |

| 2. In-line Annealing | N₂-protected continuous anneal, 420 °C ±5 °C, residence 12 s | Recrystallization >95 %, grain size 15–25 µm | Vickers micro-hardness 55–65 HV, sampled every 200 kg |

| 3. Enameling | Horizontal triple-coat, AI-PEI (polyamide-imide) class 220, 38 % solids, 28 m/min | Concentricity ≥80 %, build 2 × 18 µm | Beta-backscatter inline, 2 kHz; spark test 3 kV DC |

| 4. Inline Testing | Hi-pot 6 kV rms, 0.1 s; eddy-current crack detect; tensile pull 15 m/min | Breakdown ≥10 kV, elongation ≥25 %, surface fault <5 ppm | SPC chart auto-updated every coil |

| 5. Precision Spooling | Tension-arm dancer, 5 N ±0.2 N, traverse pitch 0.35 mm/rev | No wire overlap, collapse force ≥350 N | Vision camera + load-cell log; barcode traceability |

Quality Control Protocol

-

Online Monitoring

Every 50 ms the line uploads width, thickness, enamel build, and corner radius to our MES. If any parameter drifts outside 3-sigma, the coil auto-rejects and the die is pulled for polish—no human delay. -

Tensile & Elongation

ASTM B1/B3 modified: sample taken from head, middle, tail of each 30 kg spool. Reject if UTS <205 MPa or elongation <25 % (class 220 AI-PEI). -

Conductivity Measurement

Eddy-current meter calibrated to IACS 100 % standard. Guarantee ≥100 % for OF copper, ≥61 % for 1350 aluminum. Certificate ships with every pallet.

Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Luoyang Xinzhaohe Spec | Typical Export “A-Grade” | Western Premium Brand |

|---|---|---|---|

| Width tolerance | ±0.015 mm | ±0.03 mm | ±0.02 mm |

| Corner radius | ≤0.50×t | 0.6–0.8×t | ≤0.55×t |

| Enamel concentricity | ≥80 % | 65–70 % | ≥78 % |

| Breakdown voltage | ≥10 kV (room T) | 7–8 kV | 9–10 kV |

| Pinholes per 30 m | 0 | ≤3 | ≤1 |

| Spool collapse force | ≥350 N | 200–250 N | 300 N |

| Lot traceability | 100 % barcode | 50 % | 100 % RFID |

| Price index (FOB) | 1.0 | 0.85 | 1.4–1.6 |

Result: Our CTC sub-wire meets or exceeds Western premium electricals while landing 30–40 % below their landed cost—no MOQ penalty, 3-week ex-works lead time.

Take-away for Transformer OEMs & Repair Shops

If your design sheet calls for CTC with paper/Nomex wrap, epoxy coating, or self-bonding cure, start with sub-conductor that already satisfies IEC 60317-0-2, 60317-29, and NEMA MW 36-C. Luoyang Xinzhaohe supplies that sub-wire—drawn, annealed, enameled, tested, and spooled under one roof. Eliminate secondary enamel touch-ups, reduce scrap at the transposing line, and free your QA team to focus on the final cable, not incoming wire.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ Years of Transformer-Grade Winding Wire

H3 1. Packaging Philosophy: Zero-Defect Arrival

Every CTC (Continuously Transposed Cable) lot is packed to survive 45-day sea freight, 95 % RH, and 50 °C deck temperature without measurable insulation degradation. Our internal spec LX-ZH-EXP-23 exceeds IEC 60317-28 shock & vibration clauses by ≥30 %.

H3 2. Material-Specific Packaging Matrix

| Product Form | Inner Reel / Coil | Intermediate Barrier | Outer Crate / Pallet | Moisture & Shock Extras | Typical 20-ft Payload |

|---|---|---|---|---|---|

| CTC Copper Strip | 80–500 kg oscillated coil on steel core | 40 µm VCI film + 3-layer PE wrap | Fumigated pine pallet, corner-boards, steel straps | 4 × 100 g silica-gel packs, humidity card | 22–25 t |

| Enameled Rectangular Wire | DIN 355 plastic spool (PT-25–PT-500) | Bubble sleeve + edge protector | 5-ply export carton, palletized (1.2 × 1.0 m) | 2 desiccant sachets/spool, vacuum option | 18 t |

| Paper-Insulated CTC | Segmented wooden drum (800 mm Ø) | Dual-layer kraft + asphalt laminated paper | Plywood crate, ISPM-15 stamped, 3-way fork access | Humidity indicator plug, nitrogen flush | 15 t |

All pallets are 1.2 t max unit weight to suit Asian & EU forklift limits.

H3 3. Corrosion & Condensation Control

VCI (volatile corrosion inhibitor) emits pH-neutral vapors that maintain copper surface <0.1 µm/year corrosion rate.

Desiccant quantity calculated per DIN 55474:

n = (V × b) / (m × a)

where V = void volume (L), b = climate factor (40 g/m³ for tropics), m = desiccant unit capacity, a = safety 1.5.

Humidity cards are inspected at departure & arrival; any >30 % RH reading triggers automatic claim investigation.

H3 4. Shock & Vibration Mitigation

CTC conductors are sensitive to enamel micro-cracking (>25 µm). We validate packaging with ISTA-2A simulation:

1.2 m drop on face, edge, corner → no short-wave distortion >0.5 %

4 h random vibration 0.54 grms → insulation breakdown voltage remains ≥1.2 × spec (typ. 10 kV).

H3 5. Documentation & Traceability

Each pallet carries:

1. QR-coded label linking to mill test certificate (EN 10204-3.1), thermal class, lot elongation, and concentricity map.

2. Packing list in English & Spanish, gross/net weight to 0.01 kg.

3. Photo record of sealed package uploaded to customer portal before vessel departure.

H3 6. Freight Routing from Luoyang

Factory latitude: 34.6 °N, 200 km inland → Zhengzhou rail-sea corridor.

Weekly FCL service to Hamburg (28 days), Houston (22 days), Dubai (18 days).

Reliable alliance carriers: COSCO, MSC, CMA-CGM; 98 % on-time departure in 2023.

Premium insurance: 110 % of cargo value, covered by PICC to destination door.

H3 7. Cost Advantage vs. Western Suppliers

By integrating rod casting, enameling, and spooling in one Luoyang campus, we eliminate 5 %–7 % margin stacking common with European distributors. Typical landed cost savings:

CTC copper strip: –12 % vs. Germany, –9 % vs. U.S. East Coast

Lead-time: 3–4 weeks ex-stock, half of Scandinavian mills.

Choose Luoyang Xinzhaohe for transformer-grade CTC that arrives factory-fresh—no re-wind, no scrap, no surprises.

Sourcing from Luoyang Xinzhaohe

H2 Why Partner with Luoyang Xinzhaohe for CTC Cable Solutions

H3 Two Decades of Metallurgical Rigor in Every Strand

Since 2004 our Luoyang plant has operated a closed-loop process—rod drawing → in-line annealing → enameling → eddy-current testing → precision spooling—dedicated solely to transformer winding media.

Over 20 years we have supplied >45,000 t of rectangular copper and aluminum conductors to tier-1 transformer OEMs, motor rewind shops and power-equipment EPCs in 42 countries. The same metallurgical discipline that produces class-220 enamelled wire is now applied to Continuously Transposed Cable (CTC), giving you a supplier that understands skin-effect losses, short-circuit withstand and axial short-circuit forces from first principles—not from a catalogue.

H3 Direct Factory Price, Western-Class Quality

By eliminating intermediaries we compress total landed cost 12–28 % versus quoted European or North-American CTC lots, while meeting or exceeding IEC 60317-16, IEEE C57.12.00 and GB/T 7673.3.

Typical 2024 FOB Tianjin benchmarks (copper basis LME 9,000 USD/t):

| Conductor build | Paper-insulated CTC | Epoxy-bonded CTC | Nomex-covered CTC |

|---|---|---|---|

| 5 × 12 mm, 24 strands | 12.40 USD/kg | 13.10 USD/kg | 14.85 USD/kg |

| 7 × 16 mm, 36 strands | 11.95 USD/kg | 12.65 USD/kg | 14.35 USD/kg |

| 9 × 20 mm, 48 strands | 11.55 USD/kg | 12.25 USD/kg | 13.90 USD/kg |

Prices valid for 5 t MOQ, 3-week lead time, 40-ft FCL. Copper surcharge adjustable weekly; aluminum CTC deduct 2.30 USD/kg.

H3 Customisation Without MOQ Penalty

Our inline enameling towers (24-position, 350 °C peak) and transposing heads (0.5–2.0 m pitch) allow bespoke CTC geometries that optimise fill factor in your winding mandrel:

| Parameter | Standard range | Custom capability |

|---|---|---|

| Single strand | 1.00–4.00 mm × 2.50–14.00 mm | 0.80–5.00 mm × 2.00–16.00 mm |

| Strand count | 5–84 | Up to 120 (special bobbin) |

| Insulation stack | 0.125 mm Kraft + 50 % overlap | Kraft-Nomex-PET hybrid, 0.080–0.400 mm total |

| Thermal class | 105 °C (A) to 220 °C (C) | 240 °C (N+) on request |

| Bond coat | None / Hot-melt | Epoxy-Lite®, Solvent-less epoxy, B-stage polyimide |

| Transposition pitch | 120–300 mm | 75–500 mm (software-controlled servo) |

Every order is accompanied by a lot-specific test dossier: tensile & elongation (ASTM B1), 0.2 % proof stress, enamel concentricity (8-point laser), breakdown voltage (VDE 0472, ≥ 8 kV for 0.15 mm wall), and strand-to-strand resistance unbalance (<0.5 %).

H3 Engineering Support & Supply-Chain Reliability

Design phase: We export DXF cross-sections and 3-D transposition models compatible with ANSYS Maxwell to predict additional losses <0.3 W/kg at 50 Hz, 1.6 T.

Logistics: Weekly FCL departures from Qingdao to Hamburg, LA and Dubai; average 22-day transit with cargo insurance included.

Risk mitigation: Dual-source copper cathode contracts (CCCR-grade) and 1,200 t safety stock ensure uninterrupted output even during LME volatility.

H3 Next Step – Get a Datasheet or RFQ Within 24 h

Send your CTC specification—strand size, stack height, insulation class, required short-circuit withstand—and we will return a detailed datasheet, impedance-adjusted loss curve and firm FOB price within one business day.

Email: cathy@transformerstrip.com

WeChat/Phone: +86-135-9208-4427

Eliminate premium-Western mark-ups without compromising electrical or mechanical performance. Luoyang Xinzhaohe—where 20 years of transformer-grade discipline meets factory-direct value.

📉 Import Savings Calculator

Estimate cost reduction by sourcing ctc cable from Luoyang Xinzhaohe.