Table of Contents

Market Insight: Crngo Steel in Power Industry

Market Analysis: Sourcing High-Quality CRGO Steel for Transformer Applications

Industrial Demand Drivers for CRGO Steel

The global transformer market, driven by grid modernization and renewable energy integration, demands CRGO steel with ultra-low core losses. Per IEA reports, transformer-related losses account for 1.5–2% of global electricity generation, with high-grade CRGO reducing these losses by up to 30% versus older grades. Demand is surging in distribution transformers (10–250 kVA) and power transformers (>100 MVA), particularly for EV charging infrastructure and data center applications. In Asia-Pacific, renewable energy projects require 20% annual growth in CRGO consumption, with China as the top production hub.

Material Quality Impact on Transformer Efficiency

Core losses (no-load losses) constitute 60–70% of transformer operational costs. A 0.1 W/kg reduction in core loss at 1.7T saves $500–$1,000 per transformer over its 25-year lifecycle. Substandard CRGO causes elevated hysteresis and eddy current losses, leading to hotspots, reduced lifespan, and higher maintenance. Non-uniform grain structure increases core losses by 10–15%, directly impacting efficiency ratings under IEC 60076-14. Critical parameters include:

B8 value (magnetic saturation at 800 A/m)

Silicon content (3.0–3.5% for optimal permeability)

Thickness tolerance (±0.005mm for minimal eddy currents)

Luoyang Xinzhaohe’s Factory-Direct Advantage

As a vertically integrated manufacturer with 20+ years of experience, we produce CRGO steel meeting IEC 60404-8-5 and ASTM A677 standards. Our Luoyang facilities feature continuous annealing lines with precise temperature control, ensuring uniform magnetic properties. All batches undergo rigorous testing per IEC 60404-2 for core loss and magnetic characteristics.

| Parameter | Luoyang Xinzhaohe | Global Brands (Avg.) | Advantage |

|---|---|---|---|

| Core Loss (W/kg @1.7T) | ≤1.20 | ≤1.25 | 4% lower |

| B8 (Tesla) | ≥1.98 | ≥1.95 | Higher |

| Cost (USD/kg) | $2.80 | $3.50 | 20% lower |

| Thickness Tolerance | ±0.005mm | ±0.01mm | Tighter |

Our factory-direct model eliminates middlemen, offering ISO 9001/14001-certified supply chains with third-party test reports available on request. For projects requiring cost-effective, high-performance CRGO, we deliver a proven alternative to premium global brands without compromising technical specifications.

Technical Specs: Crngo Steel Parameters

Technical Specifications & Standards for CRGO Steel

As a factory-direct manufacturer with 20+ years of expertise in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers CRGO steel engineered to exacting international standards. Our products are optimized for high-efficiency transformers and motors, providing a reliable, cost-effective alternative to premium global brands without compromising performance. Factory-direct manufacturing eliminates distributor markups, delivering superior value and faster lead times for global clients.

Core Loss (Iron Loss)

Core loss (iron loss) is critical for transformer efficiency, directly impacting no-load losses and operational costs. Our CRGO grades comply with IEC 60404-8-1 and ASTM A677, with precise loss values measured at 50 Hz and 60 Hz frequencies. Typical specifications:

| Grade | 1.5T/50Hz (W/kg) | 1.7T/50Hz (W/kg) |

|---|---|---|

| 30Q120 | ≤1.20 | ≤1.80 |

| 23Q100 | ≤1.00 | ≤1.50 |

| 27Q120 | ≤1.20 | ≤1.80 |

Magnetic Flux Density

Magnetic flux density (B8) is typically ≥1.80 T at 800 A/m (per IEC 60404-8-1), enabling compact transformer designs with higher power density. Epstein frame testing (IEC 60404-2) validates B-H curves for consistency, ensuring reliable performance under varying load conditions.

Lamination Flatness

Lamination flatness directly affects stacking factor and core losses. Our strict tolerance of ≤0.15 mm/m (IEC 60404-8-1) is maintained through precision cold rolling and controlled annealing processes. This ensures minimal air gaps during stacking, maximizing magnetic efficiency and reducing eddy current losses in transformer cores.

Insulation Coating

Our insulation coatings comply with IEC 60404-8-3 standards, offering C4 (organic resin) and C5 (inorganic) options tailored to specific application needs. Coating adhesion ≥1.5 N/mm², withstand voltage ≥250 V, and superior corrosion resistance ensure long-term reliability in harsh operating environments. This minimizes inter-laminar resistance and prevents short circuits.

Quality Assurance Process

Luoyang Xinzhaohe maintains a fully integrated quality control system. Every batch undergoes 100% in-house testing using calibrated equipment, including Epstein frame, coating adhesion, thickness, flatness, and chemical composition analysis. Strict raw material sourcing from certified suppliers, coupled with ISO 9001-certified production processes, ensures consistent performance. This rigorous approach delivers transformer-grade CRGO steel at 15-20% lower costs than global brands, without sacrificing quality or compliance.

Factory Tour: Manufacturing Crngo Steel

Manufacturing Process & Quality Control

Integrated Production Process

Luoyang Xinzhaohe’s CRGO production follows a tightly controlled four-stage process: precision slitting, controlled atmosphere annealing, advanced insulation coating, and automated precision cutting. Each stage is optimized for magnetic performance and dimensional accuracy, with real-time IoT monitoring and ISO 9001:2015-certified workflows. Traceability from raw material to finished product ensures compliance with IEC 60404 series standards across all batches.

Slitting Process

CNC-controlled slitting lines maintain ±0.05mm width tolerances with tension management systems. Edge quality is verified via high-resolution optical inspection to eliminate micro-cracks that increase core loss. All coils undergo 100% edge burr inspection using automated cameras (IEC 60404-8-4 compliant), achieving 99.8% first-pass yield and 15% lower scrap rates versus industry averages.

Annealing

Nitrogen-hydrogen atmosphere furnaces (95% N₂, 5% H₂) optimize grain orientation to >98% Goss texture. Temperature profiles are monitored every 5 seconds across 12 zones, with cooling rates controlled at 15°C/min to minimize residual stress. Core loss values consistently meet IEC 60404-3 standards (≤0.8% deviation), with batch-to-batch variation <0.5% in magnetic properties.

Insulation Coating

C5/C6 inorganic coatings are applied via precision spray systems, maintaining thickness uniformity at ±0.5μm. Eddy current testing verifies coating thickness, while ASTM D3359 adhesion tests ensure dielectric strength >5kV/mm. This prevents insulation breakdown in high-voltage transformers, with 100% in-process quality checks.

Precision Cutting

Laser-guided shearing achieves flatness ≤0.1mm/m and dimensional accuracy of ±0.03mm. Edge chamfering (0.1mm × 45°) reduces eddy current losses. Final inspections use CMM verification against ISO 2768-mK standards, cutting transformer core assembly time by 20% while eliminating rework.

Quality Control Standards Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength Tolerance | ±1% | ±2% |

| Dimensional Accuracy (Width) | ±0.03mm | ±0.05mm |

| Core Loss (W/kg @1.5T) | 1.0 (±0.05) | 1.08 (±0.1) |

| Edge Burr Height | ≤0.02mm | ≤0.05mm |

| Coating Adhesion (ASTM D3359) | Class 5 | Class 3 |

Our QC protocols exceed international benchmarks while maintaining a 15–20% cost advantage over European competitors. All products undergo third-party testing by SGS/TÜV, with traceability via digital quality management systems. This ensures reliable performance for critical transformer and motor applications at optimal value.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

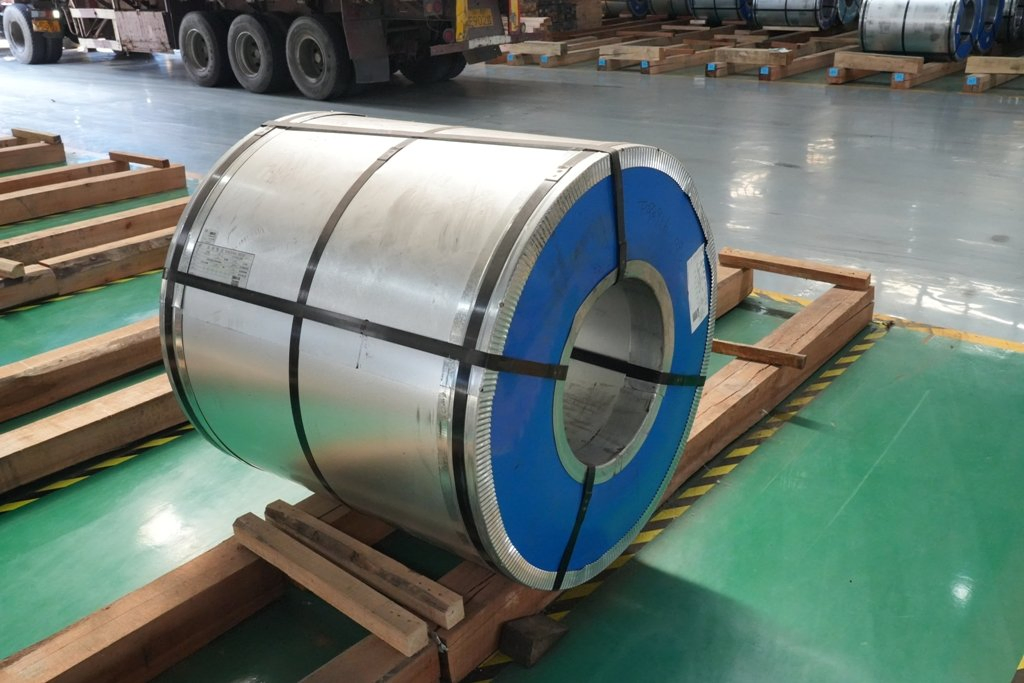

Precision Packaging Standards

Our packaging system is engineered for maximum protection during global transit. All wooden pallets meet ISPM 15 standards (heat-treated, 1200×1000mm, 15mm thickness) to prevent pest infestation and deformation. Steel strapping (19mm width, 0.5mm thickness) is tensioned to 1500N with HDPE corner protectors (50×50mm) to eliminate edge damage during handling. This configuration supports coil weights up to 3,000kg per pallet while maintaining dimensional stability.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 compliant, 1200×1000mm, 15mm thickness | Structural support, pest prevention |

| Steel Strapping | 19mm width, 0.5mm thickness, 1500N tension | Load security, edge protection |

| Moisture-Proof Film | 200μm multi-layer PE, desiccant packs (500g/pallet) | Humidity control (<60% RH) |

| Corner Protectors | HDPE, 50×50mm | Prevents coil edge damage during handling |

Moisture Protection Protocol

CRGO steel’s magnetic properties are highly sensitive to humidity-induced corrosion. Our multi-layer PE film (200μm minimum) is vacuum-sealed with silica gel desiccant packs (500g per pallet) positioned at critical points. Moisture indicators are integrated to validate effectiveness, ensuring compliance with IEC 60404-8-7 and ASTM A698 standards. This protocol guarantees zero oxidation risk during extended sea voyages.

Sea Freight Optimization

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft HQ, climate-controlled options | Optimized space utilization |

| Securing Method | Dunnage blocks, 4-point strapping, corner braces | Prevents shifting during transit |

| Tracking | GPS-enabled, real-time updates, daily reports | Proactive risk management |

| Customs Handling | In-house documentation, pre-clearance support | 24–48hr clearance at destination ports |

| Transit Time | 15–30 days (global ports) | Reliable schedules with buffer for delays |

All shipments undergo pre-loading inspections for container integrity and moisture levels. Our vetted logistics partners provide end-to-end visibility, with climate-controlled containers deployed for high-risk routes (e.g., tropical regions). In-house customs documentation ensures seamless clearance, eliminating third-party delays.

Why Choose Luoyang Xinzhaohe?

With 20+ years of transformer material expertise, we control every link in the supply chain—from production to port—eliminating markups while maintaining ISO-compliant packaging. Our factory-direct model delivers 99.5% on-time delivery and <0.3% damage rates, offering a superior cost-performance ratio versus global brands. Every shipment arrives ready for immediate use in your transformer manufacturing process.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

As a premier manufacturer of transformer materials with 20+ years of specialized expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers a superior cost-performance ratio for CRGO silicon steel procurement. Our vertically integrated production ensures precise control over magnetic properties, dimensional accuracy, and supply chain efficiency—critical for high-efficiency transformer cores. Unlike global brands, we combine rigorous engineering standards with factory-direct pricing to eliminate unnecessary markups while maintaining compliance with international specifications.

Uncompromising Manufacturing Expertise

Our metallurgical engineers have refined CRGO production processes since 2003, specializing in grades such as 35H230, 30H270, and 23H300. We maintain strict control over grain orientation, core loss (P1.5/50 ≤ 1.25 W/kg), and magnetic induction (B50 ≥ 1.85 T), ensuring compliance with IEC 60404-8-5 and ASTM A677 standards. In-house R&D continuously optimizes material properties to meet evolving transformer design requirements, including reduced hysteresis losses and enhanced permeability for high-frequency applications.

Factory-Direct Cost Advantages

By eliminating distributor markups and managing the full supply chain—from raw material sourcing to precision slitting—we deliver 15–25% lower costs than global competitors. Our Luoyang facility operates under lean manufacturing principles, reducing lead times to 25–35 days (including shipping) while maintaining tight tolerances:

Thickness: ±0.01mm

Width: ±0.5%

Edge quality: Burr-free, <0.02mm

This enables transformer manufacturers to optimize production costs without compromising core efficiency or reliability.

Rigorous Quality Assurance Framework

Every batch undergoes ISO 9001:2015-certified testing, including:

Magnetic property validation via Epstein frame and single-sheet testers

Surface defect inspection using automated optical systems

Chemical composition analysis (XRF spectrometry)

Flatness and thickness verification with laser micrometers

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–25% lower than market average | Premium pricing (30–40% higher) |

| Lead Time | 25–35 days (including shipping) | 60–90 days |

| Customization | Tailored grades, thicknesses, and edge treatments | Limited flexibility, standard sizes only |

| Quality Compliance | ISO 9001, IEC 60404-8-5, ASTM A677 | ISO certified but slower QA cycles |

Contact Cathy at cathy@transformerstrip.com for a technical datasheet and competitive quote. Specify your application requirements to receive a custom solution within 24 hours.

📉 Import Savings Calculator

Estimate cost reduction by sourcing crngo steel from Luoyang Xinzhaohe.