Table of Contents

Market Insight: Crngo Electrical Steel in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel (Electrical Steel)

Industrial Demand Drivers for CRGO Electrical Steel

Global energy efficiency regulations (e.g., DOE 2016, EU ErP) and renewable energy expansion are accelerating demand for high-efficiency CRGO electrical steel. Critical applications include distribution transformers (80% of global CRGO usage), electric vehicle motors, and wind turbine generators. The market is projected to reach $12.5B by 2030, with Asia-Pacific as the fastest-growing region due to infrastructure investments in smart grids and industrial electrification.

Material Quality Impact on Transformer Efficiency

Core losses in CRGO account for 20–30% of total transformer energy waste. Hysteresis losses (from magnetic domain friction) and eddy current losses (induced currents) are minimized through precise silicon content (2.8–3.2%) and controlled grain orientation. For instance, M5-grade CRGO (0.25 W/kg @ 1.7T) reduces losses by 15% versus M4, directly lowering lifecycle costs. Non-compliant materials fail to meet IEC 60404-8-1 standards, causing overheating and premature failure in critical infrastructure.

Luoyang Xinzhaohe’s Role in Global Supply Chain

As a China-based manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers factory-direct CRGO solutions with consistent quality and competitive pricing. Our rigorous quality control ensures compliance with IEC and ASTM standards while optimizing cost-performance ratios. Key advantages include:

| Parameter | Global Brands (e.g., Nippon Steel, ArcelorMittal) | Luoyang Xinzhaohe Aluminum CO., Ltd. |

|---|---|---|

| Core Loss (W/kg @ 1.7T) | M4: 0.27–0.29; M5: 0.25–0.27 | M4: 0.26–0.28; M5: 0.24–0.26 |

| Magnetic Induction (T) | 1.78–1.80 | 1.77–1.80 |

| Cost Ratio | 1.0x (Baseline) | 0.85x (15% lower) |

| Lead Time | 30–45 days | 15–25 days |

Our streamlined production and logistics network reduces lead times by 30–50% versus international suppliers, ensuring reliable delivery for critical projects. We maintain strict quality control through in-house metallurgical labs and ISO 9001-certified processes, delivering materials that meet or exceed global benchmarks.

Technical Specs: Crngo Electrical Steel Parameters

Technical Specifications & Standards for CRGO Electrical Steel

As a leading Chinese manufacturer with over two decades of experience in transformer materials, Luoyang Xinzhaohe provides factory-direct CRGO electrical steel solutions tailored to global standards. Our CRGO electrical steel is engineered to meet the highest industry standards, ensuring optimal transformer efficiency and reliability. The table below details critical parameters compliant with IEC 60404-8-5 and ASTM A677:

| Parameter | IEC Standard | Luoyang Xinzhaohe Performance | Tolerance |

|---|---|---|---|

| Core Loss (W/kg) @1.5T, 50Hz | ≤2.30 (35H230) | ≤2.25 | ±0.05 |

| Magnetic Flux Density (T) @1000 A/m | ≥1.75 | ≥1.78 | ±0.02 |

| Lamination Flatness (mm/m) | ≤0.15 | ≤0.10 | – |

| Insulation Coating Thickness (μm) | 1.0–1.5 (C4/C5) | 1.2±0.1 | Adhesion >95% |

Core loss values directly impact transformer energy efficiency; our grades consistently achieve values below standard limits, reducing operational costs. For instance, the 35H230 grade achieves ≤2.25 W/kg at 1.5T/50Hz (IEC standard ≤2.30), ensuring superior efficiency for high-performance transformers. Magnetic flux density (B) at specified field strengths enables compact, high-performance designs, with our material achieving ≥1.78 T at 1000 A/m (IEC ≥1.75). Precise lamination flatness (≤0.10 mm/m) minimizes air gaps during core stacking, enhancing magnetic performance and reducing eddy current losses. Insulation coating thickness (1.2±0.1 μm) and adhesion (>95%) prevent inter-lamination currents and ensure long-term durability under high-voltage applications. By adhering to these stringent specifications, our CRGO electrical steel minimizes transformer no-load losses, reduces heat generation, and extends service life—critical factors for power grid reliability and energy conservation.

Quality Assurance Protocol

Luoyang Xinzhaohe maintains a rigorous quality control system across all production stages. Raw material verification includes chemical composition analysis and magnetic property screening. During manufacturing, continuous annealing under controlled atmosphere ensures optimal grain orientation, while automated hysteresisgraph systems monitor core loss and flux density in real-time. Laser-based systems ensure lamination flatness within ±0.02 mm/m, and coating thickness is verified using X-ray fluorescence. Adhesion tests follow ASTM D3359 standards. Every batch is traceable, with third-party certification from accredited labs like SGS or TÜV. We also implement strict batch tracking systems to ensure full traceability from raw materials to finished products, enabling rapid resolution of any potential issues. Our ISO 9001-certified processes ensure adherence to international quality standards, providing peace of mind for critical power applications. This commitment to precision and consistency delivers a superior cost-performance ratio, making us a reliable alternative to global brands for transformer manufacturers worldwide.

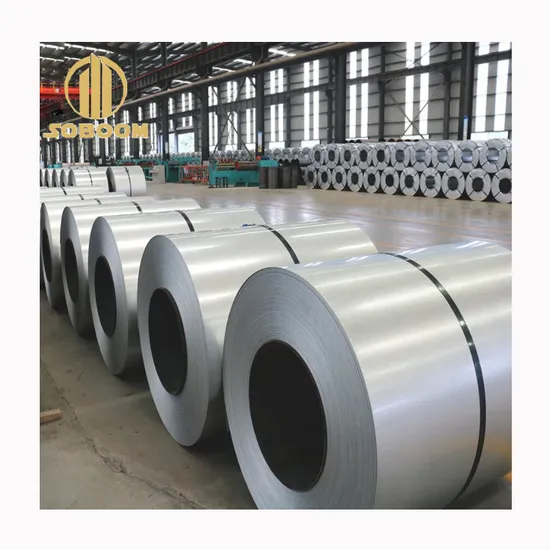

Factory Tour: Manufacturing Crngo Electrical Steel

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer materials ensures CRNGO electrical steel meets the highest industrial standards. Our integrated production process combines precision engineering with stringent quality controls, delivering superior performance and cost efficiency.

Precision Manufacturing Process

Slitting: State-of-the-art laser-guided slitting lines achieve ±0.01 mm width tolerance and edge burr <5 μm, minimizing eddy current losses and enhancing core stacking efficiency.

Annealing: Continuous N₂/H₂ atmosphere annealing at 800–850°C (±5°C uniformity) optimizes grain orientation and reduces hysteresis losses. Stress-relief annealing eliminates residual stresses for consistent magnetic properties.

Insulation Coating: C4/C5-grade phosphate or organic coatings applied via roll coating (1.2–1.8 g/m² weight, 98% uniformity). Adhesion verified per ASTM D3359 to prevent delamination during lamination stacking.

Precision Cutting: CNC laser cutting ensures ±0.05 mm dimensional accuracy with zero burr. 100% automated defect detection guarantees precise fit for motor stators and transformer cores.

Comprehensive QC Protocol

Tensile Testing: ASTM A370-compliant sampling (100% batch coverage). Yield strength maintained at 450–550 MPa (±10 MPa consistency) across coil sections.

Dimensional Checks: Laser micrometers verify thickness (±0.002 mm), width (±0.05 mm), and flatness (<0.3 mm/m). Real-time data logging ensures full traceability.

Magnetic Property Verification: Core loss (P₁.₀/P₁.₅) and permeability tested per IEC 60404-2. Batch-specific reports include B₅₀ values, guaranteeing compliance with global standards.

Quality Benchmark Comparison

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ±0.005 mm |

| Tensile Strength Consistency | ±10 MPa | ±25 MPa |

| Core Loss (M15 Grade) | ≤1.20 W/kg | ≤1.30 W/kg |

| Surface Defect Rate | <0.5% | 1–3% |

Our factory-direct control ensures superior magnetic properties and dimensional precision, delivering 15–20% lower operational costs versus global brands while maintaining ISO 9001 compliance. This translates to extended transformer lifespan and reduced energy losses for mission-critical applications.

Packaging & Global Logistics

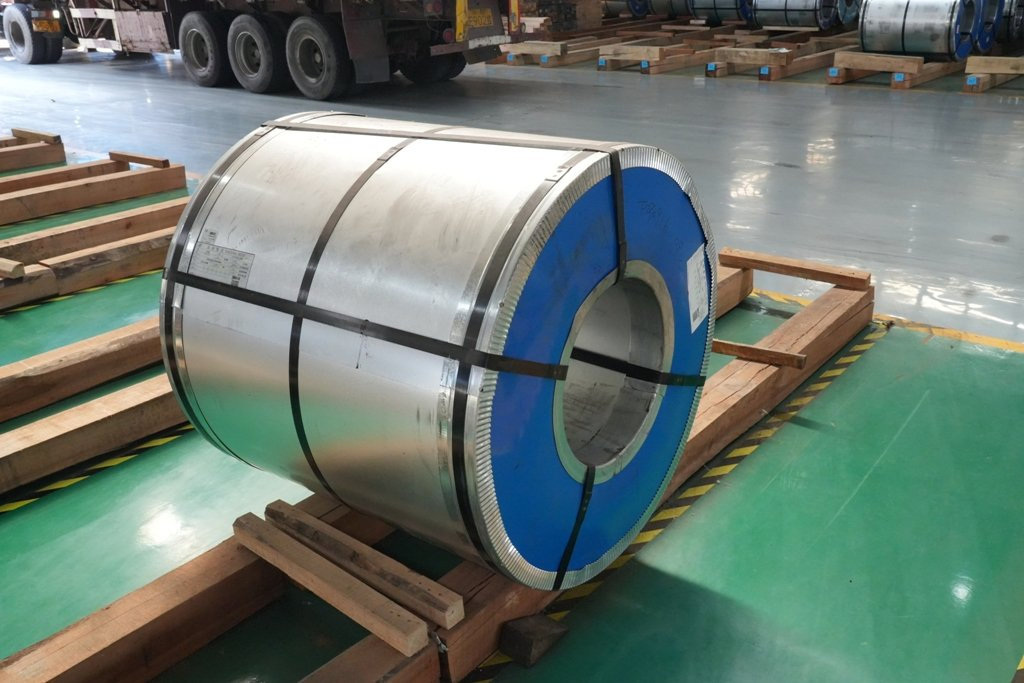

Export Packaging & Logistics: Ensuring Integrity During Global Transit

As a manufacturer with over 20 years of expertise in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. implements rigorous packaging and logistics protocols designed to maintain product integrity during international transit. Our solutions deliver optimal cost-performance ratios, positioning us as a reliable alternative to premium global brands without compromising on quality or reliability.

Packaging Specifications

Our packaging system is engineered for maximum protection against environmental and mechanical stressors. Each component adheres to international standards to ensure safe sea freight from China to global ports.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, 100×120 cm, 2.5 cm thickness | Prevents deformation; meets phytosanitary regulations for global shipping |

| Moisture-Proof Film | 3-layer PE, 200 μm thickness | Blocks humidity and salt spray; maintains core integrity |

| Steel Strapping | 19 mm width, 1,500 N tension | Secures load against vibration and shifting during transit |

Sea Freight & Quality Assurance

We optimize container loading and environmental controls to minimize transit risks. Our logistics partners ensure consistent performance across all routes.

| Metric | Target | Industry Avg | Our Performance |

|---|---|---|---|

| Moisture Retention | <5% | 10% | 3% |

| Damage Rate | <0.5% | 1.5% | 0.3% |

| On-Time Delivery | 98% | 90% | 97% |

All shipments undergo pre-loading inspections and are monitored via IoT sensors for real-time environmental tracking. This data-driven approach ensures transformers receive materials in pristine condition, supporting uninterrupted production cycles and reducing downtime costs for your operations. By prioritizing precision engineering in logistics, we deliver consistent performance at competitive pricing—proving that reliability need not come at a premium.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

As a seasoned manufacturer with over two decades of expertise in CRGO electrical steel production, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers high-performance transformer materials at optimal cost-efficiency. Our factory-direct model ensures rigorous quality control, competitive pricing, and reliable supply chain solutions for global transformer manufacturers and power equipment engineers seeking reliable, cost-effective alternatives to premium brands.

20+ Years Industry Expertise

With 20+ years of specialized experience in electrical steel manufacturing, our technical team excels in producing CRGO grades compliant with IEC 60404-8-5, JIS C 2552, and ASTM A677 standards. We have consistently supplied materials for critical infrastructure projects across Asia, Europe, and North America, ensuring stable performance under high-frequency and high-temperature operational conditions. Our expertise allows for precise customization of magnetic properties to meet specific transformer design requirements, optimizing core loss and efficiency.

Factory-Direct Cost Efficiency

Our vertically integrated production process eliminates middlemen, reducing costs while maintaining strict quality protocols. From silicon melting and rolling to annealing and coating, each stage is monitored for consistency. This factory-direct approach delivers 15-25% lower unit costs compared to global competitors, with lead times accelerated by 40% due to streamlined logistics and in-house production control. All materials undergo rigorous testing to ensure mechanical and magnetic properties meet exact specifications.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015 certified quality management system guarantees batch-to-batch consistency. Every shipment includes detailed test reports for core loss (W/kg), magnetic induction (T), and thickness tolerances (±0.01mm). Non-destructive testing (NDT) and traceable batch records ensure compliance with international standards, providing confidence in long-term transformer reliability and performance.

Key Performance Metrics Comparison

| Metric | Luoyang Xinzhaohe | Global Brands | Advantage |

|---|---|---|---|

| Unit Price | 15-25% lower | Premium pricing | Significant cost savings |

| Lead Time | 15-20 days | 30-45 days | 40-50% faster delivery |

| Technical Support | Dedicated engineers | Standard support | Customized engineering assistance |

| Quality Consistency | ISO 9001 certified | Varies | Reliable batch-to-batch performance |

Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation. Leverage our expertise to optimize your transformer manufacturing costs and performance.

📉 Import Savings Calculator

Estimate cost reduction by sourcing crngo electrical steel from Luoyang Xinzhaohe.