Table of Contents

Market Insight: Crngo Coil

Market Analysis: Silicon Steel Demand in Transformer Applications

The global electrical steel market demonstrates pronounced specialization, with cold-rolled grain-oriented (CRGO) silicon steel—frequently misreferenced as CRNGO in non-technical contexts—serving as the critical material for power and distribution transformer cores. CRNGO (cold-rolled non-grain-oriented) silicon steel is primarily utilized in rotating machinery like motors and generators due to its isotropic magnetic properties. For transformers, CRGO is the industry standard, leveraging its anisotropic grain structure to minimize core losses along the rolling direction. This distinction is fundamental for sourcing accuracy. Transformer manufacturers constitute over 85% of CRGO demand, driven by global grid modernization, renewable energy integration, and stringent efficiency regulations such as IE4/IE5 standards and DOE 2016 rules. Annual CRGO consumption exceeds 10 million metric tons worldwide, with Asia-Pacific representing 65% of this volume due to massive infrastructure investments in China, India, and Southeast Asia.

Quality parameters in CRGO directly dictate transformer performance and lifecycle economics. Core loss (W/kg), measured at 1.7 T and 50/60 Hz per IEC 60404-2, is the paramount metric. A 0.1 W/kg reduction in core loss across a 100 MVA transformer core translates to approximately 8,760 kWh in annual energy savings, equating to $1,000–$1,500 in operational cost reduction at industrial electricity rates. Inconsistent magnetic induction (B₈₀₀) or excessive thickness tolerance (>±0.005 mm) causes flux imbalances, increasing audible noise by 3–5 dB and accelerating insulation degradation. Surface insulation resistance must exceed 100 Ω·cm² to prevent interlaminar eddy currents, which can elevate hotspot temperatures by 15–20°C. These thermal stresses directly compromise dielectric fluid integrity and reduce transformer lifespan by 30–50% under substandard material conditions.

The financial impact of CRGO quality extends beyond initial procurement. High-efficiency grades (e.g., M4, M3) command 15–25% price premiums but deliver 20–30% lower total cost of ownership over a 30-year service life. A single 10 MVA distribution transformer using M0-grade CRGO (0.90 W/kg loss) versus M4-grade (1.25 W/kg loss) incurs $8,200–$12,500 in additional energy costs over its operational lifetime. Supply chain risks further underscore quality necessity: inconsistent coil flatness or burr formation during slitting causes lamination stacking faults, increasing manufacturing scrap rates by 7–12% and delaying project timelines. Luoyang Xinzhaohe Aluminum Co., Ltd. emphasizes certified production processes (ISO 9001, IATF 16949) with real-time core loss monitoring to ensure compliance with IEC 60404-8-7 and GB/T 2521.2 standards, mitigating these operational and financial exposures for transformer OEMs.

CRGO Grade Performance Comparison

| Grade Designation | Core Loss (W/kg) @1.7T/50Hz | Magnetostriction (ppm) | Typical Application |

|——————-|—————————–|————————|———————|

| M0 | 0.90–1.00 | 10–12 | Distribution Transformers |

| M3 | 1.05–1.15 | 8–10 | Power Transformers (≤100 MVA) |

| M4 | 1.20–1.30 | 6–8 | High-Efficiency Distribution |

| M5 | 1.35–1.45 | 5–7 | Renewable Integration Transformers |

Precision in CRGO material selection is non-negotiable for transformer reliability. Suboptimal electrical steel elevates no-load losses by 15–25%, directly conflicting with global decarbonization targets and eroding OEM competitiveness. Rigorous supplier qualification—validating consistent core loss control, coating integrity, and dimensional stability—is essential to achieve design efficiency and avoid costly field failures.

Technical Specs: Crngo Coil

Technical Specifications for CRNGO Coil

Continuous Rolled Non-Grain-Oriented (CRNGO) electrical steel coil is a critical magnetic material used in the cores of transformers, motors, generators, and other electromagnetic devices. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and industrial supply chain expertise, we provide CRNGO coils engineered to meet stringent performance standards in core loss, magnetic flux density, and physical flatness. These parameters directly influence the energy efficiency, thermal performance, and manufacturability of end-use components.

Core loss, also known as iron loss, is a fundamental performance metric for CRNGO steel, representing the energy dissipated as heat under alternating magnetic fields. It is measured in watts per kilogram (W/kg) at specified magnetic flux densities and frequencies. Lower core loss equates to higher energy efficiency and reduced operating temperature. Our CRNGO coils are manufactured to achieve controlled core loss values across standard grades, with testing conducted at 1.5 T and 50 Hz or 60 Hz per IEC 60404-3 and GB/T 13789 standards. The composition, grain size, and annealing processes are precisely managed to optimize domain structure and minimize hysteresis and eddy current losses.

Magnetic flux density (B) is another critical parameter, indicating the material’s ability to carry magnetic flux. It is typically measured in Tesla (T) at a given magnetic field strength (A/m). High flux density enables compact and efficient electromagnetic designs. Our CRNGO coils are engineered to deliver consistent and reliable magnetic performance, with guaranteed minimum values at standard excitation levels such as B50 (flux density at 5000 A/m). The silicon content, typically ranging from 1.0% to 3.5%, plays a significant role in balancing permeability, resistivity, and mechanical workability.

Flatness is a key physical attribute affecting slitting, stacking, and core assembly. Poor flatness leads to air gaps, increased noise, and reduced magnetic performance. Our production process includes tension leveling and precision rolling to ensure excellent flatness, minimizing camber and edge wave. Each coil undergoes flatness inspection using laser-based measurement systems to meet industry tolerance requirements.

The following table outlines the typical technical parameters for our standard CRNGO coil product series:

| Grade Designation | Thickness (mm) | Core Loss P1.5/50 (W/kg) | Magnetic Flux Density B50 (T) | Specific Total Loss (P1.0/400) (W/kg) | Surface Insulation Coating | Flatness Deviation (mm/m) |

|---|---|---|---|---|---|---|

| 50W470 | 0.50 | ≤ 4.70 | ≥ 1.68 | ≤ 18.0 | C3 (Semi-organic) | ≤ 5.0 |

| 50W600 | 0.50 | ≤ 6.00 | ≥ 1.65 | ≤ 20.0 | C2 (Inorganic) | ≤ 5.0 |

| 50W800 | 0.50 | ≤ 8.00 | ≥ 1.62 | ≤ 22.0 | C1 (Oxide) | ≤ 5.0 |

| 35W300 | 0.35 | ≤ 3.00 | ≥ 1.70 | ≤ 15.0 | C3 | ≤ 4.0 |

| 35W440 | 0.35 | ≤ 4.40 | ≥ 1.68 | ≤ 17.5 | C2 | ≤ 4.0 |

All coils are supplied with uniform surface insulation coatings to enhance inter-lamination resistivity and reduce eddy current losses. Custom thicknesses, widths, and magnetic properties are available upon request to meet specific application requirements.

Factory Tour: Manufacturing

Manufacturing Process for CRNGO Electrical Steel Coil

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of specialized expertise in silicon steel production to deliver CRNGO (Cold Rolled Non-Grain Oriented) coils meeting stringent global standards. Our integrated manufacturing sequence ensures optimal magnetic properties, dimensional accuracy, and surface integrity for motor and generator core applications. The process initiates with precision slitting of master coils. Utilizing servo-controlled tension systems and laser-guided edge positioning, we slit coils to customer-specified widths with tolerances ≤ ±0.1 mm. This stage employs high-speed rotary shear blades maintained under strict wear protocols to eliminate edge burrs and micro-tearing, which could compromise lamination stacking factors in downstream fabrication.

Subsequently, coils undergo continuous annealing in a controlled atmosphere furnace. The annealing cycle precisely regulates temperature (800–850°C) and dwell time to achieve full recrystallization while minimizing grain growth. A critical decarburization phase reduces carbon content to <30 ppm, directly enhancing core loss performance. The furnace atmosphere—comprising nitrogen, hydrogen, and trace dew point control—prevents surface oxidation and ensures uniform magnetic domain structure. Real-time pyrometry and gas chromatography monitor process stability, with deviations triggering automatic corrective actions per our ISO 9001-certified control plan.

Following annealing, an automated insulation coating line applies a thin, dielectric layer. We deploy either C5 (chromate-based) or C6 (chromate-free) coatings via roll-coating technology, achieving uniform thickness of 0.8–1.2 g/m² per side. Coating weight is verified in-line using beta-backscatter gauges, with off-spec material automatically diverted. This layer provides essential interlaminar resistance (>50 Ω·cm²) to suppress eddy currents, directly impacting motor efficiency. Curing occurs in a secondary oven at 450–550°C, cross-linking the coating without degrading magnetic properties.

The final stage involves precision cutting to length. Servo-driven blanking presses cut laminations with positional accuracy ≤ ±0.05 mm, utilizing hardened tooling resharpened after every 50,000 strokes. Burr height is maintained below 3% of material thickness through optimized clearance settings. Each lamination batch undergoes 100% dimensional validation via optical comparators before packaging.

Integrated Quality Control Protocol

Quality assurance is embedded at every phase. Core loss (W10/400) and magnetic induction (B50) are validated per IEC 60404-2 using Epstein frame testing on every 5th coil. Surface defects are detected via high-resolution camera systems operating at line speed, rejecting coils with scratches >0.03 mm depth. Coating adhesion is tested per ASTM A976 using mandrel bend evaluation, while coating weight consistency is confirmed via gravimetric analysis. Traceability is maintained through laser-etched batch codes linking material to melt chemistry, process parameters, and test results. This end-to-end control ensures CRNGO coils consistently achieve core loss values of 3.20–3.80 W/kg (at 1.5 T, 50 Hz) and lamination stacking factors >96%, critical for high-efficiency electrical machinery.

Packaging & Logistics

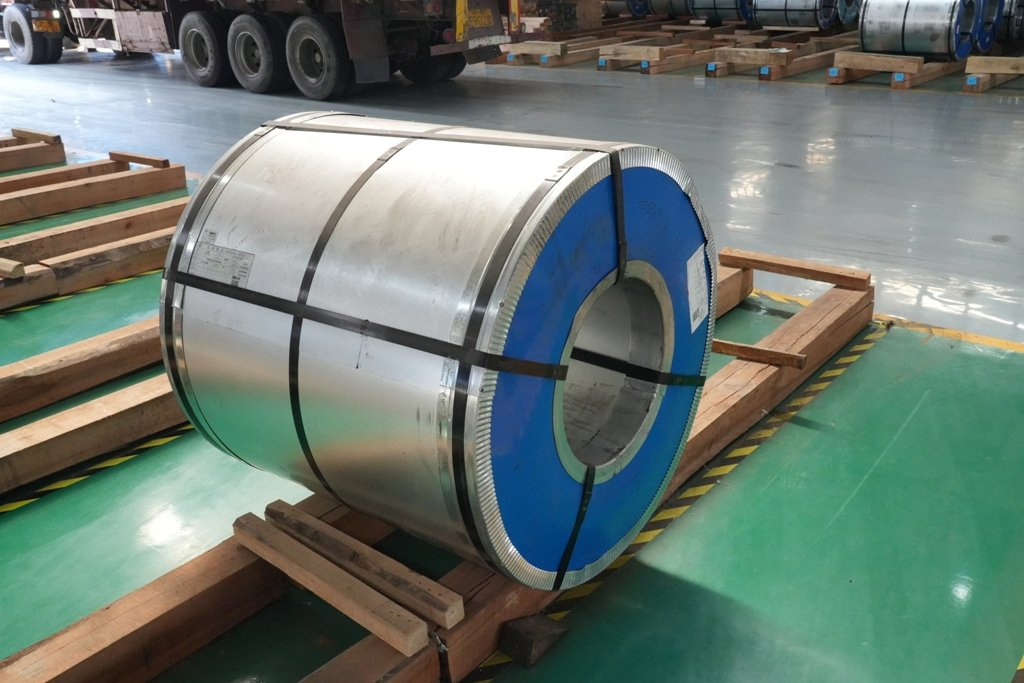

Export Packaging for CRNGO Coil: Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and global distribution of cold-rolled non-grain-oriented (CRNGO) silicon steel, we recognize that proper packaging is as critical as material quality in delivering performance-grade electrical steel to international markets. Our export packaging protocol is engineered to preserve the metallurgical and dimensional integrity of CRNGO coils throughout the rigors of sea freight, minimizing risks associated with moisture, mechanical shock, and environmental exposure.

All CRNGO coils destined for export are mounted on robust wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are designed to support coil weights ranging from 5 to 15 metric tons, ensuring structural stability during lifting, stacking, and long-haul transport. The wooden base is treated in compliance with International Standards for Phytosanitary Measures No. 15 (ISPM 15), preventing the spread of wood-borne pests and guaranteeing customs clearance in all major import jurisdictions. Each pallet is reinforced with steel strapping at multiple anchor points to prevent lateral displacement and maintain coil alignment during vessel motion.

The primary protective layer is a multi-laminate moisture-proof film, applied via automated stretch wrapping systems to achieve full circumferential coverage. This film consists of aluminum-polyethylene laminate with a vapor transmission rate of less than 0.1 g/m²/day, effectively shielding the coil from salt-laden air, condensation, and humidity fluctuations typical in maritime environments. The wrapping process includes overlapping turns at both coil faces and the outer diameter, with sealed end caps to eliminate pathways for moisture ingress. Additionally, desiccant packs are strategically placed beneath the inner layers to absorb residual humidity during transit.

For enhanced protection, each packaged coil is enclosed in a ventilated steel cage or secured within a custom-fit container frame, depending on containerization requirements. This secondary restraint prevents axial shifting during loading/unloading and protects against impact from adjacent cargo. All external labels include handling instructions, coil specifications, batch traceability codes, and orientation markers to ensure correct handling at destination.

Our packaging design is validated through accelerated climate testing and real-world logistics monitoring across key trade lanes, including trans-Pacific and Europe-Asia routes. This data-driven approach confirms that CRNGO coils arrive with surface cleanliness intact, free from rust, edge damage, or dimensional warping—critical factors for downstream processing in motor and transformer manufacturing.

By integrating industrial-grade materials with precision application techniques, Luoyang Xinzhaohe Aluminum ensures that every exported CRNGO coil maintains its technical specifications from factory to fabrication line. This commitment to packaging excellence supports reliable supply chain performance and reinforces our position as a trusted partner in the global electrical steel market.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co. Ltd for Precision CRNGO Coil Supply

Luoyang Xinzhaohe Aluminum Co. Ltd brings over two decades of specialized expertise in the production and global supply of Cold Rolled Non-Grain Oriented (CRNGO) electrical steel. As a vertically integrated manufacturer, we control the entire production chain from raw material selection to finished coil, ensuring unwavering consistency and performance critical for transformer and motor core applications. Our dedicated facility, operating continuously since 2003, is engineered specifically for high-volume CRNGO output, eliminating cross-contamination risks inherent in multi-product mills. This singular focus translates directly into superior magnetic properties and dimensional stability for your end products.

Our production capacity stands at 120,000 metric tons annually, supported by state-of-the-art tandem cold rolling mills and continuous annealing lines. We maintain strict adherence to international standards including IEC 60404-8-7 and GB/T 2521, with rigorous in-process quality control at every stage. Key technical capabilities include processing widths from 800mm to 1,250mm and thicknesses ranging from 0.35mm to 0.65mm, all within tight tolerances of ±0.005mm. Core loss (W15/50) is consistently maintained below 3.00 W/kg, while magnetic induction (B50) exceeds 1.65 T, verified through our on-site accredited laboratory using Epstein frame and single sheet testers per ASTM A343/A343M. Decarburization annealing occurs in precision-controlled atmosphere furnaces, optimizing the Goss texture development essential for low core loss performance. Laser scribing technology is optionally available to further enhance magnetic domain refinement.

Supply chain resilience is engineered into our operations. We hold ISO 9001 and ISO 14001 certifications, with raw material traceability systems meeting IATF 16949 requirements. Our strategic location in Henan Province provides direct access to major Chinese ports and rail networks, enabling reliable delivery to global markets within 30 days of order confirmation. Inventory management systems support JIT and VMI models, minimizing your working capital while ensuring uninterrupted production flow. All coils undergo 100% surface inspection via automated vision systems and are packaged to withstand ocean freight, with customizable labeling for seamless integration into your manufacturing process.

Partnering with Luoyang Xinzhaohe guarantees access to CRNGO coils where technical specifications are non-negotiable. Our engineering team collaborates directly with your R&D and procurement departments to validate material suitability against your specific lamination and core assembly parameters. Request our detailed technical datasheets and mill test certificates to verify compliance with your project requirements. For immediate sourcing consultation or customized quotation, contact Cathy Zhang, International Sales Manager, directly at cathy@transformerstrip.com. Specify your required grade, dimensions, annual volume, and application to receive a precision-engineered supply solution within 24 business hours.

Production Capacity & Key Specifications

| Parameter | Specification Range | Tolerance/Standard |

|——————–|—————————|————————-|

| Annual Capacity | 120,000 MT | – |

| Width | 800mm – 1,250mm | ±0.5mm |

| Thickness | 0.35mm – 0.65mm | ±0.005mm |

| Core Loss (W15/50) | ≤ 3.00 W/kg | IEC 60404-8-7 |

| Magnetic Induction | ≥ 1.65 T (B50) | IEC 60404-8-7 |

| Delivery Lead Time | ≤ 30 days | FOB Major Chinese Port |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing crngo coil directly from China.