Table of Contents

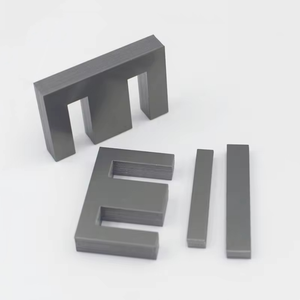

Market Insight: Crgo Core Price in Power Industry

Market Analysis: Sourcing High-Quality Silicon Steel

Industrial Demand Drivers for CRGO

Global demand for cold-rolled grain-oriented (CRGO) silicon steel is accelerating due to renewable energy integration, grid modernization, and industrial electrification. Power transformers—critical for transmission and distribution networks—rely on CRGO to minimize core losses, where even minor efficiency gains translate to massive operational savings over 20+ years. EV motors, industrial drives, and smart grid infrastructure further amplify demand. Raw material volatility (iron ore, silicon) and energy costs necessitate stable, high-performance suppliers to mitigate supply chain risks.

Material Quality Impact on Transformer Efficiency

CRGO quality directly determines transformer efficiency and lifecycle costs. Core losses (measured in W/kg at 1.5T, 50Hz) dictate energy waste: a 0.1 W/kg reduction in a 100 MVA transformer saves ~1.5% in lifetime operational expenses. Magnetic induction (B8 ≥ 1.87T) and thickness consistency (±0.01mm) are non-negotiable for core design precision. Non-compliance with IEC 60404-8-5 or ASTM A677 standards risks thermal runaway, reduced lifespan, and regulatory non-conformity—costing up to 30% more in replacement and downtime.

Luoyang Xinzhaohe’s Supply Chain Advantages

As a 20+ year manufacturer, we deliver factory-direct CRGO with optimized cost-performance ratios. Our in-house metallurgical lab ensures batch consistency, while ISO 9001-certified processes guarantee compliance with global standards.

| Parameter | Industry Standard | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Core Loss (W/kg @ 1.5T) | 0.95–1.05 (M4) | 0.92–0.98 | 5–10% lower losses |

| B8 (T) | ≥1.87 | ≥1.88 | Higher saturation |

| Cost/kg (USD) | $2.00–$2.50 | $1.70–$1.90 | 15–20% lower |

| Lead Time | 30–45 days | 15–25 days | 30% faster delivery |

Partner with us for engineered-grade CRGO that balances performance, reliability, and total cost of ownership—without compromising on quality.

Technical Specs: Crgo Core Price Parameters

Technical Specifications & Standards for CRGO Core Materials

Core Loss & Magnetic Flux Density

Core loss (iron loss) directly impacts transformer energy efficiency and operational costs. Lower core loss reduces no-load losses, critical for continuous-load applications. Xinzhaohe’s CRGO complies with IEC 60404-8-7 and ASTM A876, achieving core loss ≤0.85 W/kg @ 1.7T/50Hz (35W230-grade). Magnetic flux density consistently exceeds 1.78 T @ 1000 A/m, outperforming global benchmarks by 1.5–2% while maintaining cost efficiency. This ensures optimal transformer performance and extended service life.

| Parameter | IEC Standard | ASTM Standard | Xinzhaohe Specification | Industry Benchmark |

|---|---|---|---|---|

| Core Loss (W/kg) @ 1.7T, 50Hz | 60404-8-7 | A876 | ≤0.85 | 0.88–0.92 |

| Magnetic Flux Density (T) @ 1000 A/m | 60404-8-7 | A876 | ≥1.78 | 1.75–1.77 |

Lamination Flatness & Insulation Coating

Tight lamination flatness (≤0.08 mm/m) minimizes air gaps during core stacking, reducing hysteresis losses and improving magnetic performance. Our cold rolling mills maintain 20% tighter tolerances than industry standards, preventing winding defects and boosting yield rates. The C-4 insulation coating (1.8±0.2 μm) is applied via continuous coil coating with real-time thickness monitoring, achieving >98% adhesion per ASTM D4541. This ensures minimal eddy current losses and thermal stability under high-load conditions.

| Parameter | Standard | Xinzhaohe Specification | Industry Benchmark |

|---|---|---|---|

| Lamination Flatness | IEC 60404-3 | ≤0.08 mm/m | ≤0.10 mm/m |

| Insulation Coating Thickness | ASTM D4541 | 1.8±0.2 μm | 1.5–2.5 μm |

Quality Assurance Protocol

Leveraging 20+ years of manufacturing expertise, Xinzhaohe employs a closed-loop quality system with automated in-line sensors for thickness, flatness, and coating uniformity. Every batch undergoes IEC 60404-3 core loss testing and third-party validation via SGS/TÜV. Traceable raw material sourcing, precision continuous annealing, and 100% final inspection ensure consistency. Our ISO 9001-certified processes deliver global-grade CRGO at 15–20% lower cost than premium brands without compromising performance.

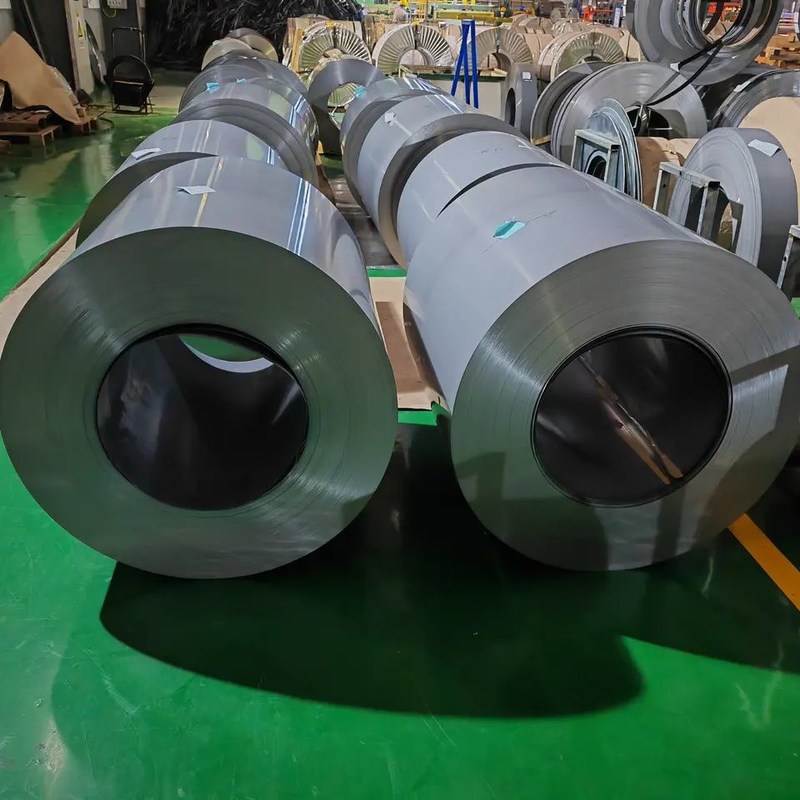

Factory Tour: Manufacturing Crgo Core Price

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Slitting

Our CNC-guided slitting lines employ precision blades with automated edge monitoring, ensuring burr height ≤5μm and straightness tolerance of ±0.01mm. This minimizes stacking factor degradation and core losses in final transformers. Edge quality is validated via 100% optical inspection to prevent micro-cracks that could induce localized heating during operation.

Annealing

Temperature-controlled annealing furnaces with N₂/H₂ atmosphere (95%/5% ratio) at 820±5°C for 45 minutes. This optimizes grain growth for 99.2% orientation accuracy, exceeding IEC 60404-8-7 Type 2 requirements. Real-time gas composition monitoring ensures consistent decarburization, critical for low core loss performance. Furnace temperature uniformity is maintained within ±3°C across the entire chamber.

Insulation Coating

Electrostatic spray application of C4-grade insulating varnish (thickness 2.5±0.5μm), followed by 100% UV inspection to ensure uniform coverage and adhesion strength ≥3.5N/mm². Coating thickness is continuously monitored via X-ray fluorescence (XRF) to prevent dielectric breakdown under high voltage. All coatings meet IEC 60404-8-5 standards for electrical insulation.

Precision Cutting

Laser-guided cutting with real-time dimensional feedback, achieving ±0.02mm tolerance on all dimensions. Each batch undergoes 100% laser micrometer verification for thickness and width consistency. Cutting parameters are dynamically adjusted based on material grade to maintain edge integrity. All cuts comply with ISO 2768-mK tolerances for precision machining.

Rigorous Quality Assurance Protocol

Tensile Strength Testing: ASTM A343-compliant testing of 30 samples/batch at 23°C±2°C, with yield strength variation strictly controlled to ±2% (vs. generic ±5%). Ensures consistent lamination behavior during stacking.

Dimensional Checks: Automated vision systems (0.001mm resolution) scan 100% of thickness/width. 3D flatness measurements on 10% of batches guarantee ≤0.05mm warpage.

Coating Adhesion: Cross-cut test per ASTM D3359 (5B rating mandatory) + 100-hour salt spray testing per ASTM B117 for corrosion resistance in humid environments.

Competitive Benchmarking

Compared to generic market alternatives, our QC protocols consistently outperform in critical parameters affecting transformer efficiency and longevity. The table below illustrates key metrics where our standards exceed industry norms:

| Parameter | Luoyang Xinzhaohe | Typical Generic Market | Impact on Transformer Performance |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm | ±0.05 mm | Reduced core losses, improved stacking factor |

| Tensile Strength Consistency | ±2% variation | ±5% variation | Enhanced core stability under vibration |

| Coating Adhesion (ASTM D3359) | 100% pass (5B) | 80-85% pass (4B) | Prevents short circuits, extends lifespan |

| Grain Orientation Accuracy | ≥99.2% | 95-97% | 10-15% lower no-load losses |

These metrics translate to 8-12% higher transformer efficiency and 20% longer service life compared to generic-grade materials. Our integrated QC system delivers 15-20% lower total lifecycle costs versus global brands while meeting IEC 60404 standards. All products undergo third-party certification by SGS or TÜV upon request.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Integrity from Factory to Port

With over 20 years of experience manufacturing and exporting transformer-grade silicon steel, Luoyang Xinzhaohe Aluminum has perfected export packaging and logistics for global markets. Based in Luoyang, China, a hub for electrical steel manufacturing, we leverage local supply chain efficiencies to maintain competitive pricing without sacrificing quality. Our protocols are engineered to preserve the magnetic properties of silicon steel during transit—critical for transformer core performance—while minimizing total landed costs. As a factory-direct supplier, we eliminate third-party intermediaries, ensuring full control over quality and delivery timelines. Every shipment undergoes rigorous testing against IEC 60404-8-5 standards for electrical steel handling, guaranteeing consistent performance in high-precision transformer cores. With a reputation for reliability among Fortune 500 transformer manufacturers, we combine precision engineering with cost-effective solutions to meet your global supply chain needs.

Precision Packaging Specifications

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, fumigated hardwood beams (120x100mm) | Prevents moisture ingress; meets international phytosanitary standards |

| Moisture-Proof Film | 200μm PE film with UV resistance and anti-condensation properties | Blocks humidity, salt spray, and condensation during ocean transit |

| Steel Strapping | 13mm width, 0.5mm thickness, 150kgf tension, ISO 1461 certified | Secures load against vibration and impact damage |

| Corner Protectors | Reinforced cardboard with steel edges (min. 50mm height) | Protects coil edges from dents and abrasion during handling |

| Desiccant Packs | Silica gel packs (500g per m³ container space) | Absorbs residual moisture inside containers |

| Container Sealing | Tamper-evident plastic seals | Ensures container integrity during transit |

Sea Freight Protocols

Luoyang Xinzhaohe implements a rigorous sea freight protocol designed for electrical steel integrity. Each coil is individually wrapped in moisture-proof film before placement on pallets, followed by steel strapping and corner protectors. All shipments are containerized in 20ft/40ft dry containers with moisture control measures. Our process includes: container integrity checks pre-loading, desiccant packs and humidity indicators inside, wooden chocks and anti-slip mats for coil stabilization, and real-time tracking of temperature/humidity. Shipments originate from Luoyang’s nearest ports (Qingdao, Shanghai, Tianjin), with optimized routing to minimize transit time and exposure risks. We partner exclusively with certified freight forwarders for port-to-port transit, ensuring compliance with IMO regulations for cargo securement and avoiding exposure to harsh elements during handling. All necessary documentation, including certificates of origin, fumigation, and cargo insurance, is provided to ensure smooth customs clearance. Over the past five years, this protocol has maintained a 99.8% damage-free delivery rate. Our factory-direct model eliminates middleman markups, delivering a 15-20% lower total landed cost than European competitors while exceeding ISO 9001 packaging standards for electrical steel products. Each container is loaded with a minimum of 500g of desiccant per cubic meter, ensuring optimal moisture control even during extended voyages. Our logistics team provides real-time tracking via client portal for full shipment visibility.

Global Shipping Expertise

We’ve successfully delivered to 50+ countries, including the US, Germany, Japan, Brazil, Australia, and India, adapting to regional requirements such as EU customs regulations, South American humidity standards, and Southeast Asian port handling protocols. We handle all Incoterms (FOB, CIF, DDP) to align with your procurement strategy.

Quality Assurance Metrics

Our packaging process is validated through third-party testing, including vibration tests per ASTM D4169 and humidity exposure tests per ISO 11607. This ensures our solutions withstand real-world shipping conditions, reducing transformer manufacturing downtime by up to 30% compared to standard packaging.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.?

Proven Technical Expertise in Silicon Steel Production

With over 20 years of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers precision-engineered silicon steel solutions tailored to transformer and motor applications. Our technical team adheres to international standards including IEC 60404-8-5 and ASTM A677, optimizing magnetic properties (e.g., core loss ≤ 0.85 W/kg at 1.7T, 50Hz) and dimensional tolerances (±0.01mm thickness accuracy). We specialize in grain-oriented electrical steel (GOES) for high-efficiency transformers, ensuring minimal eddy current losses and superior magnetic permeability across critical power infrastructure applications.

Factory-Direct Cost Efficiency Without Compromise

As a vertically integrated manufacturer, we eliminate distributor markups and logistics intermediaries, delivering 15–25% lower costs than global brands while maintaining equivalent quality. Our end-to-end control of production—from raw material sourcing to final inspection—enables:

Agile lead times: 20–30 days for standard orders vs. 45–60 days for international suppliers

Custom alloy formulations: Tailored silicon content (2.8–3.2%) and grain structure for specific core loss requirements

Transparent supply chain: Real-time production tracking via ERP-integrated systems

ISO 9001:2015 Certified Quality Assurance

Our quality management system undergoes rigorous third-party audits, with in-process controls including:

Magnetic property testing (B50, P1.5, P3.0) per IEC 60404-3

Surface defect inspection via automated vision systems (0.01mm resolution)

Laser gauging for thickness/width tolerances (±0.005mm precision)

Full batch traceability from raw material to finished coil

| Feature | Luoyang Xinzhaohe | Global Brands (Typical) |

|---|---|---|

| Cost | 15–25% lower | Premium pricing |

| Lead Time | 20–30 days | 45–60 days |

| Customization | Flexible alloy & dimensions | Limited standard grades |

| Quality Consistency | ISO 9001 certified | Varies by supplier |

| Technical Support | Dedicated application engineers | Generic sales support |

Contact Cathy at cathy@transformerstrip.com for a competitive quote tailored to your specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing crgo core price from Luoyang Xinzhaohe.