Table of Contents

Market Insight: Copper Wound Transformer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer manufacturing sector exhibits robust and sustained demand for high-conductivity strip and foil, primarily driven by the critical need for efficient electrical energy conversion and distribution. While aluminum strip/foil represents a significant and growing segment, particularly in distribution transformers due to cost and weight advantages, copper wound transformers remain the dominant technology in medium and high-voltage applications, large power transformers, and scenarios demanding maximum efficiency and compact design. Current market analysis indicates copper maintains approximately 70-80% share in global transformer conductor material by value for these demanding segments, underpinned by its superior electrical conductivity and established manufacturing protocols. This dominance persists despite aluminum’s competitive advantages in specific applications, reflecting the stringent performance requirements of critical grid infrastructure, industrial motor drives, and renewable energy integration systems where minimizing resistive losses is paramount.

Industrial Demand Drivers for Copper Wound Transformers

Demand for copper strip and foil in transformer windings is intrinsically linked to global electrification trends, grid modernization initiatives, and the expansion of renewable energy generation and electric vehicle charging infrastructure. Utilities and industrial OEMs prioritize copper for applications requiring the highest possible efficiency ratings (e.g., DOE Tier 4, IEC 60076-21), extended operational lifespans exceeding 30 years, and superior thermal management under continuous load. The material’s inherent properties directly influence transformer performance metrics critical to operational expenditure and reliability. The following table summarizes key comparative properties:

| Property | Copper (Electrolytic Tough Pitch) | Aluminum (1350-H19) |

|---|---|---|

| Electrical Conductivity | 100% IACS (Minimum) | 61% IACS (Minimum) |

| Density (g/cm³) | 8.89 | 2.70 |

| Tensile Strength (MPa) | 200 – 250 | 120 – 165 |

| Coefficient of Thermal Expansion (10⁻⁶/K) | 17.0 | 23.0 |

Quality Imperatives in Copper Conductor Material

The criticality of uncompromising quality in copper strip and foil for transformer windings cannot be overstated. Minor deviations in material specifications directly translate to significant operational risks and financial consequences. Precise control over electrical conductivity (consistently meeting or exceeding 100% IACS per ASTM B187/B548) is non-negotiable; even slight reductions increase I²R losses, elevating operating temperatures and accelerating insulation degradation, ultimately shortening transformer life. Surface finish must be flawless—free from scratches, pits, oxides, or residual lubricants—to prevent partial discharge initiation and ensure uniform varnish impregnation during coil processing. Dimensional tolerances (thickness, width) must be held within tight limits (typically ±0.01mm) to guarantee precise winding geometry, optimal magnetic performance, and reliable cooling channel formation. Crucially, metallurgical purity is essential; trace elements like oxygen, sulfur, or metallic impurities above stringent thresholds (e.g., O₂ < 200 ppm) act as nucleation sites for hotspots under load, drastically increasing failure probability. Contaminants also impair weldability during terminal attachment. Luoyang Xinzhaohe Aluminum leverages two decades of metallurgical expertise to understand that while copper sets the performance benchmark, achieving the required quality demands rigorous process control from cathode sourcing through continuous casting, cold rolling, and precision slitting. For buyers, selecting a supplier with demonstrable in-process quality assurance, full material traceability, and adherence to international standards (IEC 60138, ASTM B187) is not merely a specification requirement—it is a fundamental safeguard for grid reliability, operational efficiency, and long-term asset value. The cost of inferior material pales against the cost of premature transformer failure in critical infrastructure.

Technical Specs: Copper Wound Transformer

Technical Specifications for Copper Wound Transformer Strip

Luoyang Xinzhaohe Aluminum Co., Ltd. delivers precision-engineered copper strip products engineered specifically for high-performance copper wound transformers. With over two decades of metallurgical and supply chain expertise, we ensure that each coil meets stringent electrical, mechanical, and dimensional requirements essential for reliable transformer operation. Our copper strip is cold-rolled to exacting tolerances and undergoes precision slitting to meet the narrow width demands of modern transformer winding processes. Dimensional stability is critical in minimizing interlayer stress and ensuring uniform magnetic flux distribution. Our slitting process maintains a tolerance of ±0.002 mm, ensuring consistent strip width across production batches. This level of precision reduces edge misalignment during winding, directly enhancing coil integrity and thermal performance.

Edge quality is paramount in transformer applications. Our proprietary deburring technology ensures burr-free edges, eliminating the risk of dielectric breakdown between winding layers. Burr formation can compromise insulation systems, leading to premature transformer failure. Each batch undergoes edge profile inspection using optical profilometry to verify surface smoothness and absence of micro-tears or raised edges. This commitment to edge perfection supports high-voltage reliability and long-term operational safety.

Electrical conductivity is a defining characteristic of our copper strip. We utilize high-purity electrolytic tough pitch (ETP) copper (C11000) with a minimum conductivity of 98% IACS at 20°C. This ensures minimal resistive losses and superior thermal management within the transformer core-coil assembly. Conductivity is verified through four-point probe resistivity testing in accordance with ASTM B3 and IEC 60164 standards. Additionally, our material exhibits uniform grain structure and controlled tensile properties, with typical tensile strength ranging from 250 to 300 MPa and elongation of 4–6%, balancing formability with mechanical robustness during high-speed winding.

All strips are supplied in controlled atmospheres to prevent oxidation, and surface cleanliness is maintained to meet ISO 8501-1 Sa 2½ standards, ensuring optimal adhesion of insulating varnishes or tapes.

The following table outlines the key technical parameters for our copper strip used in wound transformer applications:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Grade | C11000 (ETP Copper) | ASTM B187 |

| Thickness Range | 0.10 – 3.00 mm | ASTM E29 |

| Width Tolerance | ±0.002 mm | ISO 9001 |

| Edge Condition | Burr-free, precision slit | Internal Optical Inspection |

| Electrical Conductivity | ≥98% IACS | ASTM B3, IEC 60164 |

| Tensile Strength | 250 – 300 MPa | ASTM E8 |

| Elongation | 4 – 6% | ASTM E8 |

| Surface Cleanliness | Free of oxides, oils, particulates | ISO 8501-1 Sa 2½ |

| Coil Inner Diameter | 200 mm, 300 mm, 508 mm (custom available) | Customer Specification |

| Packaging | Vacuum-sealed with desiccant, wooden reel | Custom Export Standards |

These specifications reflect our commitment to delivering material that meets the rigorous demands of transformer manufacturers focused on efficiency, reliability, and compliance with international standards.

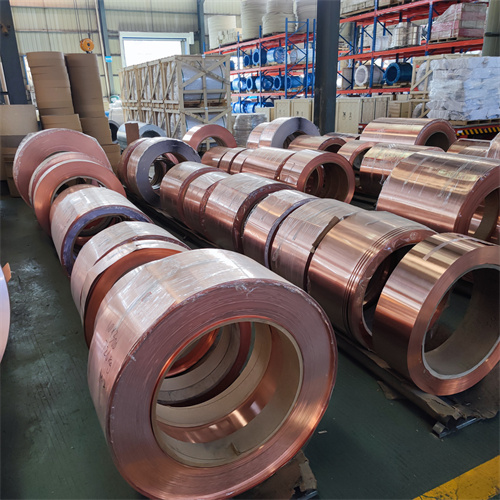

Factory Tour: Manufacturing

Manufacturing Process for High-Performance Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in producing precision aluminum and copper strip and foil for critical transformer applications, particularly copper wound transformers where dimensional stability and surface integrity are paramount. Our integrated manufacturing process ensures material properties meet the stringent demands of modern transformer design and manufacturing efficiency.

The foundation of our process begins with Cold Rolling. High-purity aluminum or copper ingots undergo rigorous homogenization and hot rolling to achieve an intermediate gauge. This material then enters precision cold rolling mills operating under tightly controlled tension and roll gap parameters. Multiple rolling passes progressively reduce the thickness to the final specification, typically ranging from 0.10 mm to 3.00 mm for transformer applications. Critical to achieving the required mechanical properties and grain structure for subsequent winding, intermediate and final annealing cycles are precisely managed. Annealing parameters, including temperature profile, dwell time, and atmosphere composition, are optimized based on the specific alloy and final temper requirement (e.g., H14, H18, O-temper) to ensure consistent yield strength, elongation, and surface oxide control essential for reliable insulation adhesion and low core loss.

Following cold rolling and annealing, the master coils undergo Precision Slitting. This stage employs state-of-the-art slitting lines equipped with high-precision, hardened tooling and advanced tension control systems. The objective is to divide the wide master coil into narrow strips of exact width required for the transformer winding process, commonly between 20 mm and 300 mm. Width tolerances are maintained within ±0.05 mm across the entire coil length, a critical factor for consistent layer build-up during winding. Edge tracking systems and servo-controlled knives minimize width variation and ensure straight, parallel edges. The slitting process is meticulously monitored to prevent edge damage, excessive burr formation, or residual stresses that could compromise the foil’s performance during high-speed winding operations.

Edge Conditioning represents a vital, often underestimated step where Xinzhaohe implements significant value. Immediately following slitting, the strip edges pass through a dedicated conditioning module. This process utilizes precision abrasive or brushing techniques to remove microscopic burrs and feathering generated during slitting. Unconditioned edges can snag during high-speed winding, cause insulation punctures, or create localized field concentrations impacting dielectric strength. Our proprietary edge conditioning achieves a smooth, radius-controlled edge profile, significantly enhancing winding reliability and the long-term dielectric integrity of the finished transformer coil. This step is non-negotiable for premium transformer strip intended for demanding applications.

Rigorous Quality Control is embedded throughout the production flow. Incoming billet purity is verified via OES spectroscopy. During cold rolling, strip thickness is continuously monitored by laser gauges with automatic feedback to mill stands. Post-annealing, mechanical properties (tensile strength, yield strength, elongation) are tested per ASTM E8 on representative samples at defined intervals. After slitting and edge conditioning, 100% of the strip undergoes eddy current testing to detect subsurface defects and surface imperfections. Final coil inspection includes meticulous measurement of width, edge quality under magnification, surface roughness (Ra typically < 0.8 µm), and visual assessment for scratches, dents, or contamination. Dimensional and property conformance is documented against customer specifications and relevant standards like IEC 60404-9.

The following table summarizes key Xinzhaohe quality parameters versus typical industry baselines:

| Parameter | Xinzhaohe Standard | Typical Industry Baseline | Critical Impact |

|---|---|---|---|

| Width Tolerance | ±0.03 mm to ±0.05 mm | ±0.10 mm to ±0.15 mm | Winding layer consistency |

| Edge Burr Height | < 3 µm (measured) | < 10 µm (often unmeasured) | Insulation integrity, winding jams |

| Surface Roughness | Ra ≤ 0.6 µm (avg) | Ra ≤ 1.0 µm | Insulation adhesion, core losses |

| Thickness Variation | ≤ ±1.5% over coil length | ≤ ±3.0% | Magnetic flux density uniformity |

| Eddy Current Test | 100% coverage, 50 µm min | Sample basis, 100 µm min | Detection of critical defects |

This integrated approach, combining precise metallurgical control with advanced processing and exhaustive QC, ensures Xinzhaohe delivers transformer strip and foil that maximizes winding yield, enhances transformer efficiency, and guarantees long-term operational reliability.

Packaging & Logistics

Export Packaging for Transformer Strip and Foil – Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in aluminum and copper transformer strip and foil, we recognize that reliable packaging is a critical extension of product quality—particularly in international logistics. Our export packaging system is engineered to protect material integrity throughout extended sea freight cycles, where exposure to humidity, mechanical stress, and prolonged transit times pose significant risks.

All transformer strip and foil shipments destined for export are secured on high-strength wooden pallets constructed from kiln-dried, ISPM 15-certified hardwood. These pallets are designed to meet international phytosanitary standards while providing structural stability under dynamic load conditions encountered during containerized shipping. Each coil is axially aligned and firmly fixed to the pallet using galvanized steel strapping, minimizing lateral movement and preventing edge damage during handling and ocean transit.

Prior to palletization, every coil is wrapped in multiple layers of industrial-grade moisture-proof film, specifically formulated to act as a vapor barrier against salt-laden maritime atmospheres. This multi-layer encapsulation prevents condensation ingress, which is especially critical for copper and aluminum products susceptible to surface oxidation. The film is heat-sealed at all seams to ensure a continuous protective envelope, significantly reducing the risk of tarnishing or corrosion during voyages that may span several weeks.

For enhanced protection, desiccant packs are strategically placed within the sealed film layers to absorb residual moisture and maintain a low-humidity microenvironment around the coils. Additionally, each package includes humidity indicator cards to allow receiving parties to verify environmental exposure upon arrival. This proactive monitoring supports quality validation and reduces the likelihood of disputes related to transit-induced degradation.

Our packaging protocol is validated through internal accelerated aging tests and real-world performance tracking across major global trade lanes, including trans-Pacific and trans-Indian Ocean routes. These tests confirm the system’s effectiveness in maintaining coil surface quality, dimensional stability, and electrical performance characteristics post-shipment.

All export packages are clearly labeled with permanent, weather-resistant markings indicating product specifications, batch numbers, net and gross weights, handling instructions, and destination details. Barcodes and QR codes are applied for seamless integration into automated warehouse systems and supply chain traceability platforms.

By integrating robust materials, moisture mitigation strategies, and compliance with international shipping standards, Luoyang Xinzhaohe ensures that our transformer strip and foil arrive at their destination in the same condition as when they left our facility. This commitment to packaging excellence underscores our role as a dependable partner in the global transformer manufacturing supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Transformer Conductor Solutions

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical aluminum and copper strip and foil for transformer windings, including demanding copper wound transformer applications. Our vertically integrated manufacturing ecosystem, engineered for precision and consistency, directly addresses the core requirements of transformer OEMs and tier suppliers seeking reliable conductor material performance and supply chain resilience.

Our core manufacturing strength resides in state-of-the-art rolling facilities capable of producing ultra-precise strip and foil down to 0.08mm thickness with exceptional dimensional tolerances maintained across widths up to 2800mm. This precision is achieved through computer-controlled 20-high cluster mills and continuous annealing lines operating under strict atmospheric control, ensuring optimal electrical conductivity (exceeding 61.0% IACS for EC aluminum) and mechanical properties essential for efficient winding and long-term transformer reliability. We strictly adhere to international standards including ASTM B227, IEC 60137, and GB/T 3880, with in-process monitoring tracking critical parameters like thickness profile, surface roughness (Ra), and edge quality in real-time. Comprehensive final inspection utilizes advanced eddy current testing, tensile testing, and microstructure analysis to guarantee material integrity meets the stringent demands of high-voltage and distribution transformer designs.

Beyond material specifications, our integrated supply chain provides significant strategic advantages. Controlling the process from high-purity billet casting through cold rolling, annealing, slitting, and precision rewinding minimizes external dependencies and quality handoff risks. This vertical integration, coupled with our dedicated logistics management system, ensures consistent on-time delivery performance exceeding 98% globally. We maintain robust inventory buffers of key alloys and gauges specifically for transformer conductor applications, mitigating raw material volatility and enabling rapid response to production schedule changes. Our technical team, comprising experienced metallurgists and process engineers, collaborates directly with client R&D and procurement departments to resolve material-specific challenges, optimize winding parameters, and support qualification processes, translating material science into tangible manufacturing efficiency for your transformer lines.

Partnering with Luoyang Xinzhaohe means securing a supplier whose operational excellence is validated by long-term relationships with major global transformer manufacturers. We understand that conductor strip and foil performance directly impacts transformer efficiency, thermal management, and lifecycle costs. Our commitment extends beyond transactional supply to becoming a technical extension of your engineering and sourcing functions, ensuring material consistency that underpins your product quality and production throughput.

To discuss how our precise aluminum and copper conductor solutions can enhance your copper wound transformer production efficiency and reliability, contact Cathy Zhang directly at cathy@transformerstrip.com. Provide your specific alloy, gauge, width, and volume requirements for a tailored technical and commercial proposal within 24 business hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper wound transformer directly from China.