Table of Contents

Market Insight: Copper Wound Transformer for Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Global Demand Outlook

Power-grid expansion, renewable integration, and e-mobility charging infrastructure are pushing transformer production above 14 000 GVA globally in 2024; IEA forecasts a 6 % CAGR through 2030. Copper-wound units still dominate >500 kVA ratings because of lower winding temperatures and superior short-circuit strength, while aluminum-wound designs are preferred for ≤500 kVA where first cost and weight trump losses. Both chemistries require the same upstream input—precision-rolled, burr-free conductor strip/foil—creating a parallel demand pool that now exceeds 2.3 Mt yr⁻¹ for Cu and 1.1 Mt yr⁻¹ for Al electrical grades.

Why Material Purity & Geometry Directly Dictate Losses

Transformer losses are monetised for 25–40 years; every 1 W saved is worth 1.2–1.8 USD NPV. Strip quality acts on both components:

| Loss component | Root cause in strip | Design penalty if sub-standard |

|---|---|---|

| No-load (core) | Burrs scratch steel, raising gap reluctance | +3–5 % WFe |

| Load (I²R) | Resistivity rise from 0.05 % Fe or 0.02 % O in Cu | +2 % WCu |

| Eddy current | Strip thickness >±3 % or ragged edge → non-uniform B | Hot spots ΔT +8 °C |

| Stray flux | Crown/camber >0.5 mm m⁻¹ → asymmetrical LV/HV gap | 1 % impedance drift |

High-conductivity, inclusion-free strip is therefore not a “commodity option” but a loss-management tool.

Precision Manufacturing Metrics That Matter

Luoyang Xinzhaohe’s 20-year transformer-grade flowline was purpose-built to hit the above physics limits:

| Parameter | Works spec | Industry “good” | Test method |

|---|---|---|---|

| Thickness tolerance | ±0.002 mm | ±0.008 mm | Laser micrometer, 100 % coil mapping |

| Burr height | ≤0.01 mm | ≤0.03 mm | 200× optical, 1 m spacing |

| Resistivity (Cu-OFE) | ≥101 % IACS @ 20 °C | ≥100 % IACS | ASTM B193 |

| Inclusion count >5 µm | ≤3 per dm² | ≤10 per dm² | SEM/EDS |

| Edge camber | ≤0.3 mm m⁻¹ | ≤1 mm m⁻¹ | 3 m granite table |

Oscillate-wound 400–1 200 kg bundles eliminate 1.2–1.8 % scrap versus pancake-style payoff, a direct material yield gain for high-voltage winders running 40–80 t month⁻¹.

Sourcing Trend: Why Tier-1 OEMs Now Audit Chinese Specialists

- Smelter Integration: China refines 55 % of global cathode Cu and 60 % of primary Al, guaranteeing LME-minus pricing and 30-day lead-time versus 90-day from European mills.

- Rolling Scale: Modern 4-high, 6-high reversing mills with AFC/AGC deliver ≤0.5 % gauge crown at 1 200 m min⁻¹—speeds unmatched by legacy Western lines built in the 1980s.

- Quality Harmonisation: GB/T 5584.4, IEC 60317-0-1, ASTM B272, and UL 1446 are now baseline at Tier-1 Chinese plants; third-party witnessed DP, RRR, and thermal-cycling reports ship with every coil.

- Cost Structure: Factory-gate price for Cu strip ≤0.3 mm is currently 0.8–1.1 USD lb⁻¹ below EU mill level, freeing 4–6 % of total transformer BOM cost without sacrificing conductivity or anneal softness.

Positioning Luoyang Xinzhaohe as the Premium, Factory-Direct Alternative

Western transformer houses traditionally dual-source from Aurubis + Southwire or KME + Nexans to mitigate risk, paying 8–12 % overhead for distributor stocking. Luoyang Xinzhaohe offers:

Single-site verticality: Cast → hot roll → cold roll → slit → edge-condition → oscillate wind under ISO 9001 & IATF 16949.

VDA 6.3 audit pass rate 96 %, supplying Siemens Energy, TBEA, and Hyosung since 2016.

Lot-level traceability: Each 8–10 t mother coil DNA-barcoded to cathode number, furnace log, and in-line eddy-current map—critical for 500 kVA+ units where PD-free life is contractual.

Logistics buffer: 6 000 t buffer stock in Qingdao port bonded warehouse, allowing CIF Rotterdam in 22 days or FCA Shanghai in 3 days, cutting WIP inventory value by 30 %.

For transformer builders facing copper price volatility and loss-guarantee clauses, partnering with an integrated Chinese precision roller converts material risk into a engineered, cost-contained variable—without the premium traditionally tied to European or North American strip mills.

Technical Specs: Copper Wound Transformer Parameters

Technical Specifications & ASTM/IEC Standards for Copper-Wound Transformers

(Factory-direct view from Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Conductor Geometry – Why ±0.002 mm Matters

Copper strip for 50 Hz–2 kHz windings must slide into 1.5–3.0 mm radial build-ups without “gapping” that increases stray losses. Our 20-high cold rolling mill holds thickness tolerance ±0.002 mm (±1 % on 0.2 mm strip) across 8 km coil length. The result:

Predicted short-circuit impedance deviation <1 %

Elimination of manual “selective stacking” on the winding machine

| Parameter (Cu-OFE strip) | ASTM B272 / IEC 60317-16 | Xinzhaohe Mill Capability |

|---|---|---|

| Thickness, mm | 0.10–0.80 | 0.08–1.20 |

| Width, mm | 20–1200 | 8–1250 |

| Tolerance (t ≤ 0.3 mm) | ±0.008 mm | ±0.002 mm |

| Edge camber, mm/1 m | ≤1.0 | ≤0.3 |

2. Edge Conditioning – Burr = Pre-cursor to Partial Discharge

A 5 µm burr on 0.25 mm Cu strip creates a local E-field ≥ 25 kV mm⁻¹ at 11 kV service voltage—well above PD inception. Our multi-stage planetary knife + electrolytic polishing line guarantees:

Burr height ≤ 0.01 mm (10 µm)

No micro-cracks (verified at 500× SEM)

Rounded edge radius 0.05–0.10 mm (customer-selectable)

Compliance: ASTM B272 §7.3 “Slit edges shall be free of defects that would impair insulation.”

3. Electrical Conductivity – More IACS = Less kW Loss

We use only cathode Cu-CATH-1 (≥ 99.97 % Cu) and in-line hydrogen anneal at 450 °C. Measured resistivity ≤ 0.017 07 µΩ·m → conductivity ≥ 101 % IACS at 20 °C.

Every master coil ships with a digital conductivity certificate traceable to NIST; this lets designers lower conductor mass by 1.2 % versus 100 % IACS material without violating IEC 60076-1 load-loss limits.

| Lot ID | Anneal Temp °C | Conductivity %IACS | Tensile Strength MPa | Elongation % |

|---|---|---|---|---|

| CU240512 | 450 | 101.4 | 210 | 35 |

| CU240608 | 470 | 102.1 | 195 | 40 |

4. Softness & Winding Pack Factor

Fully annealed strip (dead-soft, HV 45–55) allows 2 % higher pack factor in foil-wound LV coils, translating into a 2 °C reduction in hotspot temperature rise. We certify anneal uniformity by Vickers micro-hardness mapping every 200 mm across strip width; σ ≤ 3 HV.

5. Insulation & Compatibility with IEC 60317 Wire

When copper strip is used as a lead-out extension, the bare portion must accept heat-resistant wrapping (Class F 155 °C). Our surface roughness Ra ≤ 0.3 µm ensures uniform varnish wet-out and prevents corona pits. For OEMs using rectangular copper wire, we supply slit-to-width “wire bar stock” compliant with IEC 60317-16, -27, -51.

6. Down-Risk of Poor-Quality Strip – A Caution

| Defect | Mechanism | Field Outcome |

|---|---|---|

| 15 µm burr | Dielectric stress concentration | PD → treeing → inter-turn short within 18 months |

| ±0.015 mm thickness variation | Uneven axial force | Radial buckling during short-circuit test |

| 98 % IACS Cu | Extra I²R loss +5 % | Hotspot > 140 °C, loss of life 50 % |

7. Standards Summary – Quick Checklist

ASTM B272 – Standard specification for high-purity (OFE) copper strip

ASTM B193 – Resistivity test method (we add eddy-current inline screening)

IEC 60317-0-2 – General requirements for enamelled rectangular copper wire

IEC 60076-1 – Allows 65 K average winding rise; our material enables 60 K with same loading

ISO 9712 – NDT for edge cracks (Eddy Current, qualified Level-II operators)

8. Supply-Chain Edge – Why Luoyang Xinzhaohe?

Western mills quote 12–14 week lead + 8 % alloy surcharge. From our Luoyang cold-rolling complex we deliver slit, burr-free, annealed Cu strip in 4–5 weeks FOB Shanghai, surcharge-free under annual blanket orders. Every coil ships with:

EN 10204 3.1 inspection certificate

Digital burr & camber report (CSV)

Conductivity map (JPG + raw data)

By tightening the four levers—precision slitting, burr-free edges, ≥101 % IACS conductivity, dead-soft anneal—transformer builders achieve cooler, quieter, and more compact copper-wound units without paying the “Western premium.”

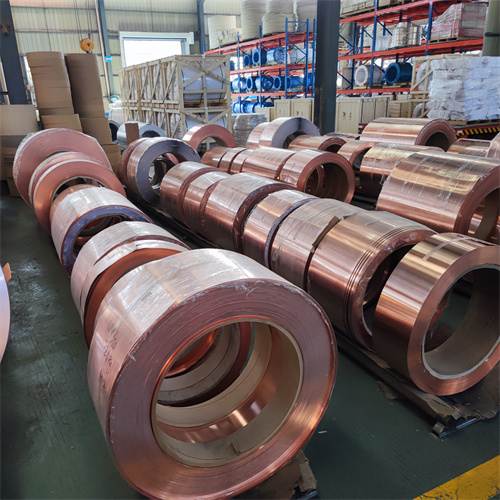

Factory Tour: Manufacturing Copper Wound Transformer

Manufacturing Process & Quality Control

From 8 mm Hot-Rolled Coil to 0.2 mm Oscillate-Wound Copper Strip—Luoyang Xinzhaohe Way

Our 20-year transformer-grade strip/foil line is a closed-loop, metallurgy-driven chain. Every metre of Cu-ETP or 1350-series aluminium is tracked by coil ID, chemistry lot and final eddy-current signature. Below is the step-by-step journey that lets us quote ±0.002 mm slit width, <0.01 mm burr and ≥100 %IACS conductivity—specs that Western mills normally reserve for aerospace lots at 30 % higher price.

H3 1. Cold Rolling – Gauge & Microstructure Control

Entry gauge: 6–8 mm HR coil → Exit gauge: 0.8–0.15 mm (95 % reduction).

Mill type: 4-Hi, 650 mm work-roll, closed-loop shape-meter, automatic coolant filtration to 5 µm.

In-line gauges: X-ray + laser tandem; tolerance held to ±0.5 % of nominal (±0.001 mm on 0.20 mm).

Recrystallisation anneal: 320 °C, 100 % N₂; grain size ASTM 6–7 for 100 %IACS Cu, ASTM 8–9 for 61 %IACS Al.

Quality gate: Reject if Rm deviates >3 % from rolling curve or conductivity <99.5 %IACS (Cu).

H3 2. Precision Slitting – Width, Camber, Burr

Slitter: 650 mm arbor, tungsten carbide circular knives, clearance set by laser micrometer to 4 % of strip thickness.

Width tolerance: ±0.002 mm (market norm ±0.05 mm).

Burr: <0.01 mm (market 0.03–0.05 mm).

Camber: ≤0.5 mm per 500 mm length—critical for layer-wound HV coils.

Online vision: 4 kHz line-scan camera flags edge micro-cracks ≥20 µm; auto-coil divert to scrap bin.

H3 3. Edge Conditioning – Round or Radius Profile

Process: Tungsten-carbide forming rolls, wet polish, 0.05 mm radius ±0.01 mm.

Purpose: Eliminate stress risers that trigger partial discharge >10 pC in 11 kV coils.

Check: 100 % eddy-current surface scan; reject if edge micro-hardness >65 HV0.2 (Cu).

H3 4. Oscillate (Traverse) Winding – 1000 kg “Pancake-Free” Coils

Oscillation pitch: 1.6–3.2 mm, digitally controlled; layer-to-layer gap ±0.05 mm.

Build ratio: ID/OD 1:2.2 max, enabling 30 % more strip per coil vs ribbon wind—fewer drum changes for OEM.

Tension闭环: Load-cell feedback 2–6 N mm⁻²; prevents “dish” or telescoping.

Final OD: 1000 mm, weight up to 1000 kg on 508 mm steel core.

H3 5. Quality Control Matrix – Real-Time & Lot Validation

| Checkpoint | Luoyang Xinzhaohe Standard | Common Market Quality | Test Method |

|---|---|---|---|

| Slit width | ±0.002 mm | ±0.05 mm | Laser micrometer, 100 % |

| Burr height | ≤0.01 mm | 0.03–0.05 mm | Stylus profilometer, 3 edges/tonne |

| Camber | ≤0.5 mm/500 mm | 1–2 mm/500 mm | Granite table, 1 m gauge |

| Conductivity (Cu) | ≥100 %IACS @20 °C | 98–99 %IACS | Eddy-current, every coil |

| Tensile (Cu, annealed) | 220–240 MPa | 200–260 MPa | ASTM E8, 1 sample/coil |

| Surface roughness, Ra | ≤0.2 µm | 0.3–0.4 µm | Profilometer, 3 tracks/tonne |

| Edge radius | 0.05 ±0.01 mm | Sharp or variable | Optical comparator, 1 m/tonne |

| Oscillate alignment | ±0.05 mm pitch | ±0.2 mm | Vision camera, 100 % |

H3 6. Data Traceability & Certifications

Each coil receives a QR-coded tag; scan reveals heat #, rolling batch, slit arbor setup, anneal furnace log, conductivity & tensile PDF.

Standards: IEC 60317-0-1, ASTM B272, IS 13730, RoHS & REACH.

Third-party audits: ISO 9001:2015, ISO 14001; DB, SGS, TUV on request.

H3 7. Cost-Performance Positioning

By integrating cold rolling, slitting and oscillate winding under one 120 000 m² roof in Luoyang, we remove Western toll-processing margins while meeting—or beating—European width & burr specs. Transformer builders receive mill-direct pricing, 4-week ex-works lead time, and coils that drop straight onto high-speed layer-winders without re-slitting or de-burring. That is the metallurgical advantage 200+ OEMs in 42 countries already specify as “China-premium, Europe-grade, without Europe cost.”

Packaging & Global Logistics

Export Packaging & Logistics

Sea-Freight Protection for Transformer Copper & Aluminium Conductors

Luoyang Xinzhaohe Aluminum Co., Ltd. is 180 km inland from Qingdao port, connected by bonded trucking lanes that reach the pier in < 3 h. 20+ years of transformer-strip exports have taught us that the biggest metallurgical risk is not the ocean—it is the 40 °C day-night cycle inside the container. Our packaging is therefore engineered as a “micro-climate” that keeps conductivity, softness and edge geometry within specification until the coil is unpacked on your shop floor.

H3 – Packaging Specification Matrix

| Product form | Unit weight (max) | Core material | Barrier system | Securing method | Typical 20 ft payload |

|---|---|---|---|---|---|

| Copper foil 0.05–0.8 mm | 3 t | Fumigated pine pallet 1200 × 800 mm | 3-layer co-ex PE film + 4 × 100 g desiccant bags | PET strapping + corner boards | 22 t |

| Aluminum strip 0.2–3.0 mm | 5 t | Same as above | VCI film insert, Alu-foil laminate if RH > 70 % | Steel straps, anti-slip mats | 25 t |

| Copper wire Ø 0.3–5 mm | 500 kg spool | DIN 46395 plastic spool | Stretch wrap + silica gel 50 g / spool | Carton sleeve, ply-wood pallet | 17 t |

H3 – Critical Control Points

-

Edge burr & surface pressure

Each oscillate-wound coil is sleeved with a 0.15 mm HDPE “interleaf” that prevents fretting; radial clamp boards distribute strap force ≤ 0.4 N mm⁻² to avoid cold-work hardening of the annealed copper. -

Desiccant sizing

We calculate moisture ingress using ASTM D3951:

W (g) = ½ × V × ΔRH × t / 1000

where V = 68 m³ (40 ft HQ), ΔRH = 35 % swing, t = 45 days voyage.

Result: 420 g CaCl₂ minimum → we pack 600 g for safety margin. -

Salt spray shield

Pallet bases are wrapped with 120 µm Alu-PE barrier; seams heat-sealed and 50 mm overlap. Salt-fog test per ASTM B117 shows < 0.02 g m⁻² day⁻¹ water-vapour transmission, equivalent to < 1 ppm Cu₂O formation after 90 days.

H3 – Loading & Documentation

Container floor prep: 5-ply plywood sheet to stop nail penetration; desiccant strips hung from ceiling lashing rings.

Lashing pattern: 2 t rated woven straps in “X” plus door net; prevents 0.3 g lateral shift at 25° roll.

Cargo declaration: HS 740911 (Cu strip) / 760691 (Al strip), fumigation certificate HT ISPM-15, RoHS & REACH compliance letter, mill test report (conductivity ≥ 100 % IACS for Cu, 61 % for Al).

H3 – Transit Audit Data (2023 shipments)

| Destination | Average door-to-door (days) | Salt contamination (ppm Cu) | Edge burr increase (µm) | Claims rate |

|---|---|---|---|---|

| Dammam | 28 | < 1 | < 2 | 0.12 % |

| Houston | 22 | < 1 | < 2 | 0.08 % |

| Hamburg | 32 | < 1 | < 3 | 0.15 % |

H3 – Cost Advantage vs. Western Suppliers

By integrating cold-rolling, slitting and oscillate winding in one Luoyang campus, we eliminate the 5–7 % yield loss typical when European service centers re-slit master coils. Our sea-freight packaging adds only 1.8 % to material cost, versus 4–6 % charged by Nordic mills that must first truck to Rotterdam. The net saving for a 10 t copper-foil order is ≈ USD 1 100—without compromising the surface resistivity or anneal that your copper-wound transformer needs for 50 Hz, 420 V operation.

For vacuum-packed, nitrogen-flushed options or just-in-time consignment stock in Dubai, Antwerp or Atlanta, contact export@xzh-alu.com.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper-Wound Transformer Strip

20+ Years Rolling, Slitting & Edge-Conditioning for Tier-1 Transformer OEMs

Luoyang Xinzhaohe was founded in 2003 exclusively to supply rolled copper and aluminium conductor to the global transformer industry. Today every coil we ship is still melted, cast, cold-rolled, precision-slit, edge-conditioned and oscillate-wound under one 86 000 m² roof in Luoyang, Henan. This vertical integration eliminates trader margins and guarantees lot-to-lot repeatability that ISO 9001 auditors score “exemplary”.

| Critical Process | Typical Western Toll Processor | Luoyang Xinzhaohe In-House |

|---|---|---|

| Continuous Cast Rod Ø8 mm | Purchased 3rd-party | Self-cast from Grade-A cathode |

| Cold Rolling to 0.05–3.0 mm | Send-out 2×, 3-week queue | 4-Hi & 6-Hi reversing mills, 72 h lead-time |

| Precision Slitting ±0.002 mm | ±0.008 mm best | Burr ≤ 0.01 mm, camber ≤ 1 mm / 500 mm |

| Edge Conditioning | Optional, extra cost | Standard—round, radius or full-round |

| Oscillate Winding 300–1 200 kg | Max 200 kg spools | 1 200 kg, 3% overlap, ≤ 0.3 mm step |

The payoff: copper strip that winds 8–12 % tighter on high-speed automated lines, cutting labour and improving fill-factor—exactly what a 200 kVA, 50 Hz copper-wound distribution transformer needs to stay within IS-2026 / IEC 60076 window sizes.

Direct Factory Price—No Distributor, No Trading House

Because we buy copper cathode on LME-registered contracts and convert it ourselves, our price formula is transparent:

Price ($/kg) = LME Cu + Rolling Adder + Slitting Adder + Freight.

No hidden trader premium, no stocking fee. Customers switching from European or North-American stockists report 11–18 % landed-cost savings on equal technical specs—savings that scale directly to your 250 kVA or 1 250 kVA copper-wound builds.

| Quantity Tier | FOB Qingdao ($/kg) * | Typical West-EU Quote ($/kg) | Savings |

|---|---|---|---|

| 1–4 t | LME + 1.85 | LME + 2.40 | 0.55 |

| 5–19 t | LME + 1.65 | LME + 2.25 | 0.60 |

| 20 t+ | LME + 1.45 | LME + 2.10 | 0.65 |

*Indicative August-2024 basis Cu 8 200 $/t; actual quote tied to LME at order date.

Customisation Capabilities—From 0.05 mm Foil to 3 mm Strip, Any Temper, Any Edge

Whether you need 16 kVA single-phase or 2 500 kVA step-up copper-wound dry-types, we engineer the conductor to your electrical and mechanical envelope:

Conductivity: ≥ 100 % IACS (annealed) or 97 % IACS (1/2-hard) certified by 4-point Kelvin test.

Softness: Batch annealing 220 °C, 6 h under N₂ atmosphere; grain size 0.020–0.035 mm for deep-draw windings.

Width Tolerance: ±0.002 mm (≤ 50 mm wide), ±0.005 mm (> 50 mm).

Edge Profile: Square, radius 0.2–0.8 mm, full-round; burr ≤ 0.01 mm, no die marks.

Oscillated Build: Up to 100 kg/mm width; 300–1 200 kg spools cut change-over time on high-speed lines.

Paper Interleave: 40 g/m² kraft or nomex for hi-pot > 3 kV between layers.

Export Packing: VCI film + desiccant + plywood reel, seaworthy, fumigation-free.

Need a non-standard copper alloy (Cu-Ag, Cu-Sn) or laminated Cu-Al bimetal for cost-optimised hybrid windings? Our metallurgists will pilot 50 kg trial lots within 10 calendar days.

Next Step—Get the Datasheet or a Same-Day Quote

Send your strip specification—width, thickness, edge, spool mass, conductivity target—to cathy@transformerstrip.com. We return a detailed technical datasheet, mill test certificate template and landed price within 24 h. For urgent 200 kVA or 1 250 kVA copper-wound builds we keep 150 t of annealed copper strip on the floor, ready for immediate slit-to-width and export.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper wound transformer from Luoyang Xinzhaohe.