Table of Contents

Market Insight: Copper Wire Magnets

Market Analysis: Winding Wire Demand in Transformer Applications

The global demand for copper winding wire, particularly in transformer manufacturing, continues to grow due to increasing electrification, grid modernization, and the expansion of renewable energy infrastructure. Copper wire magnets—specifically electromagnetic coils fabricated from high-purity copper conductors—are a critical component in power and distribution transformers, where they serve as the primary medium for magnetic flux generation and energy transfer. The performance, efficiency, and longevity of transformers are directly influenced by the electrical and mechanical properties of the winding wire used.

Industrial demand for copper winding wire is driven by several key sectors, including utility-scale power transmission, industrial automation, electric vehicle (EV) charging infrastructure, and renewable integration systems such as solar and wind inverters. Transformers in these applications require winding wire with consistent conductivity, high thermal stability, and excellent dielectric insulation. As global energy efficiency standards become more stringent—such as the IEC 60076 and DOE 2016 regulations—transformer manufacturers are under pressure to minimize no-load and load losses. This necessitates the use of high-conductivity copper (typically ≥ 100% IACS) with precise dimensional tolerances and smooth surface finishes to reduce eddy current losses and ensure uniform winding density.

Quality in copper winding wire is not a marginal consideration; it is a fundamental determinant of transformer reliability. Substandard wire with impurities, inconsistent temper, or surface defects can lead to localized hotspots, insulation breakdown, and premature failure under thermal cycling. Oxygen-free copper (OFC) with a soft or hard drawn temper is often specified to ensure optimal ductility and resistance to work hardening during the winding process. Furthermore, the adhesion and thermal class of the enamel insulation—commonly polyurethane, polyester, or polyamide-imide—must match the operating environment to prevent dielectric failure at elevated temperatures.

At Luoyang Xinzhaoanghe Aluminum Co., Ltd, we recognize that while our core expertise includes aluminum conductor solutions, the benchmark for performance in winding applications is set by copper. Our two decades of experience in metallic conductor manufacturing have provided deep insights into material selection, process control, and failure mode analysis in electromagnetic components. We support customers in evaluating total cost of ownership, where initial material savings from lower-grade wire are often outweighed by increased maintenance, downtime, and energy losses over the transformer’s lifecycle.

In summary, the industrial market for copper wire magnets in transformers prioritizes performance, regulatory compliance, and long-term reliability. As power systems evolve toward higher efficiency and resilience, the demand for technically superior winding wire will continue to rise. Manufacturers who invest in high-quality copper conductors not only meet current technical standards but also future-proof their products against the increasing demands of modern electrical networks.

Technical Specs: Copper Wire Magnets

Technical Specifications for Electromagnetic Winding Wire (Copper Magnet Wire)

Luoyang Xinzhaohe Aluminum Co., Ltd. provides critical technical specifications for copper electromagnetic winding wire, essential for high-reliability motor, transformer, and inductor applications. Clarifying industry terminology: “Copper wire magnets” refer to magnet wire (enameled copper winding wire), not permanent magnets. Our 20+ years of metallurgical and supply chain expertise ensures strict adherence to IEC 60317 and ASTM B 354 standards. Key parameters govern performance in demanding thermal, electrical, and mechanical environments.

Insulation breakdown voltage defines the dielectric strength of the enamel coating under specified test conditions. Minimum breakdown voltage must exceed 1500 V AC RMS (tested per IEC 60851-5 at 20°C, 50 Hz, 1-minute duration) for standard grades. High-voltage applications (e.g., traction motors) require ≥3000 V AC RMS. This parameter directly correlates with insulation integrity during voltage surges and partial discharges. Elongation, measured per ASTM B 359, indicates ductility and resistance to cracking during coil winding. Standard soft-drawn copper wire exhibits 8–12% elongation; semi-hard temper grades range from 3–6%. Values below 3% risk microfractures in tight-radius windings, compromising insulation lifespan. Thermal Class defines the maximum continuous operating temperature the insulation system withstands without accelerated degradation. Classes span 130°C (B) to 220°C (C), with common industrial grades at 155°C (F), 180°C (H), and 200°C (N). Class selection depends on end-use thermal profiles—e.g., Class H (180°C) for automotive traction inverters, Class N (200°C) for aerospace actuators.

The following table summarizes critical technical parameters for sourcing evaluation:

| Parameter | Test Standard | Typical Range | Critical Tolerance | Application Impact |

|---|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60851-5 | 1500–6000 V AC RMS | ±10% | Prevents short circuits during voltage transients |

| Elongation | ASTM B 359 | 3–12% | ±1.5% | Ensures crack resistance in complex wind geometries |

| Thermal Class | IEC 60172 | 130°C (B) to 220°C (C) | Class-specific | Dictates thermal endurance and service life |

| Conductor Purity | ASTM B 3 | ≥99.95% Cu, Ag ≤0.03% | IACS ≥100% | Minimizes resistive losses and heating |

| Wrap Pin Test Pass Rate | IEC 60851-3 | ≥95% | 0% failure | Validates enamel adhesion and flexibility |

Conductor purity (minimum 99.95% Cu) ensures electrical conductivity ≥100% IACS, critical for efficiency in energy-intensive systems. The wrap pin test evaluates enamel cohesion during bending; failure rates >5% indicate poor adhesion, risking inter-turn faults. Thermal Class validation requires 20,000-hour thermal aging per IEC 60172, where insulation retains ≥50% of original tensile strength at rated temperature.

Our supply chain implements rigorous in-process controls: oxygen-free copper (OFC) rod sourcing, multi-stage annealing for elongation consistency, and infrared-cured enamel systems for thermal class compliance. Traceability from cathode to coil is maintained via blockchain-enabled lot tracking. For high-temperature classes (≥180°C), we recommend polyesterimide or polyamide-imide insulation with dual-build coatings to enhance thermal shock resistance. Always verify supplier test certificates against actual production lots—variance in elongation >0.5% or breakdown voltage <5% of spec indicates process instability. Partnering with Xinzhaohe ensures metallurgical precision and supply chain resilience for mission-critical electromagnetic components.

Factory Tour: Manufacturing

Manufacturing Process of Copper Wire Magnets at Luoyang Xinzhaoang Aluminum Co., Ltd

The production of high-performance copper wire magnets at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of metallurgical and winding wire expertise, our facility integrates advanced process controls and inline quality monitoring to deliver magnet wire that meets stringent international standards, including IEC 60317 and ASTM B75.

The process begins with rod drawing, where high-conductivity electrolytic tough pitch (ETP) copper rods, typically conforming to ASTM B187, are reduced in diameter through a series of precision dies. This cold drawing operation is performed under controlled tension and lubrication conditions to maintain uniform elongation and surface finish. The reduction ratio is optimized to achieve the target wire gauge while preserving the ductility required for subsequent winding applications. All drawn wire is spooled under constant tension to prevent deformation and ensure consistent lay.

Following drawing, the wire undergoes a continuous annealing process in a controlled atmosphere furnace. This step is critical for restoring ductility lost during cold working and achieving the desired temper—typically soft (annealed) or semi-hard, depending on customer specifications. The annealing furnace operates under a nitrogen-hydrogen atmosphere to prevent oxidation and ensure a clean, oxide-free surface, which is essential for proper enamel adhesion. Temperature profiles are precisely monitored and logged throughout the process to guarantee metallurgical consistency across production batches.

The annealed wire then advances to the enameling station, where one or multiple layers of polymer insulation are applied via precision die coating. Common insulation systems include polyurethane (PU), polyester (PE), polyamide-imide (PAI), or combinations thereof, selected based on thermal class (e.g., 130°C to 220°C) and application requirements. Each enamel pass is followed by immediate curing in high-temperature ovens with optimized dwell times and temperature gradients to ensure complete cross-linking and eliminate volatile residues. Film thickness is continuously measured using non-contact laser gauges to maintain tight tolerance, typically within ±5% of nominal.

Inline testing is integrated at every critical stage to ensure real-time quality assurance. After enameling, the wire undergoes 100% spark testing to detect pinholes or insulation defects at specified voltage levels. Additional inline checks include diameter measurement via laser micrometry, tension monitoring, and wrap testing to assess flexibility and adhesion. Final quality control includes off-line verification of key parameters such as elongation, springback, thermal shock resistance, and dielectric breakdown voltage.

Each production lot is traceable through a batch numbering system, with full documentation of process parameters and test results provided upon request. This comprehensive approach ensures that every meter of copper magnet wire shipped from Luoyang Xinzhaohe meets the highest standards of performance and reliability in demanding electromagnetic applications.

Packaging & Logistics

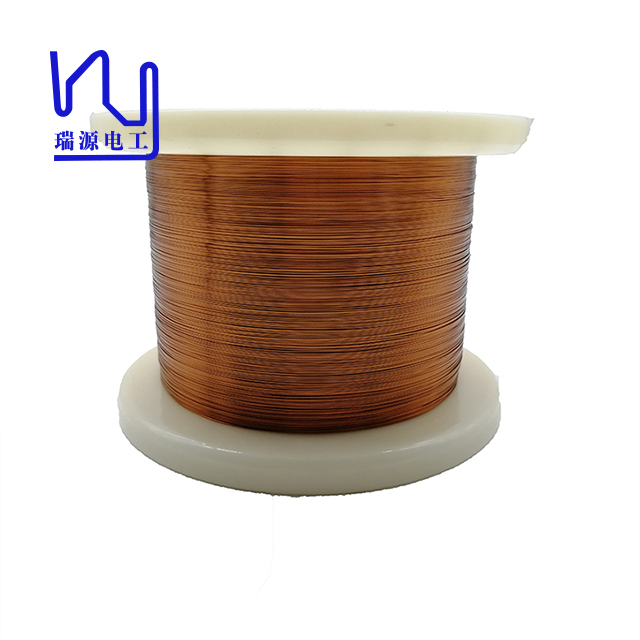

Export Packaging Standards for Copper Wire Magnet Winding Wire

Luoyang Xinzhaohe Aluminum CO.,Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard copper wire magnet integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our packaging system prioritizes moisture exclusion, mechanical stability, and regulatory compliance to prevent corrosion, deformation, or electrical property degradation. This is non-negotiable for precision winding wire, where microscopic surface contamination or dimensional shifts can compromise end-product performance in motors, transformers, and generators.

All copper wire magnet coils are secured on ISPM 15-certified wooden pallets constructed from kiln-dried, knot-free hardwood. These pallets feature a minimum load-bearing capacity of 2,500 kg and incorporate reinforced stringers to withstand dynamic stresses during containerization and ocean voyages. Coils are vertically stacked using interlocking patterns, with maximum stacking heights limited to 2.2 meters to prevent toppling under ship motion. Critical mechanical protection is achieved through edge protectors and custom-fitted cardboard spacers between layers, eliminating coil-to-coil contact and minimizing vibration-induced abrasion during rough seas.

Moisture protection constitutes the cornerstone of our packaging strategy. Each palletized load undergoes a dual-barrier sealing process. First, coils are individually wrapped in 100μm-thick moisture-proof polyethylene film with a water vapor transmission rate (WVTR) of ≤1.0 g/m²/24hr at 38°C and 90% RH. This film is heat-sealed to eliminate gaps, creating a primary vapor barrier. Subsequently, the entire pallet assembly is encased in a secondary layer of metallized polyester laminate film (120μm thickness), providing enhanced resistance to salt-laden maritime atmospheres and UV exposure. Desiccant indicators are affixed internally to monitor relative humidity levels throughout transit, ensuring conditions remain below 40% RH—the threshold for copper oxidation initiation.

Our packaging design adheres strictly to IMO and IATA hazardous materials handling guidelines for non-ferrous metals, despite copper wire’s non-hazardous classification. This ensures seamless customs clearance and compatibility with global carrier requirements. Pallet dimensions conform to standard 1200mm x 1000mm or 1100mm x 1100mm EUR/ISO footprints, optimizing container cube utilization while maintaining structural integrity under ISO container stacking loads (up to 192,000 kg). All external surfaces display tamper-evident security seals and multilingual handling labels indicating “Fragile,” “This Side Up,” and moisture sensitivity per ASTM D3951.

Validation testing includes 14-day salt spray chamber exposure (ASTM B117) and simulated sea voyage vibration profiling (ISO 13355). Historical data from 1,200+ container shipments demonstrates a 99.87% incident-free delivery rate for copper wire magnets to destinations including Rotterdam, Singapore, and Los Angeles. This reliability stems from integrating metallurgical knowledge of copper’s susceptibility to chloride-induced stress corrosion cracking with supply chain pragmatism. Partnering with Xinzhaohe guarantees that your winding wire arrives with surface cleanliness conforming to IEC 60172 and dimensional tolerances unchanged from factory release—eliminating costly rework or scrap upon receipt.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Copper Winding Wire Solutions

With over two decades of specialized expertise in the production and supply of precision winding wire, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global electromagnetic materials market. While our name reflects our origins in aluminum technology, our advanced manufacturing capabilities extend decisively into high-purity copper winding wire—engineered to meet the rigorous demands of transformers, motors, generators, and high-efficiency electrical systems. Our strategic integration of metallurgical science and industrial-scale production ensures that every coil we deliver meets exacting standards for conductivity, thermal stability, and mechanical integrity.

Our manufacturing facility in Luoyang, China, spans over 50,000 square meters and operates under an ISO 9001-certified quality management system. This enables us to maintain tight process control from raw material sourcing to final product testing. We utilize oxygen-free copper (OFC) with purity levels exceeding 99.99%, drawn through precision dies to achieve dimensional tolerances within ±0.005 mm. Our fully automated drawing lines, combined with continuous annealing and enamel coating systems, ensure consistent surface finish and insulation integrity across all wire gauges—from ultra-fine 0.05 mm up to heavy-duty 5.0 mm conductors.

We specialize in producing a comprehensive range of copper winding wire types, including polyurethane (PU), polyester (PE), polyamide-imide (PAI), and self-bonding enamel-coated variants, each tailored for specific thermal classes—from 130°C up to 220°C. Our R&D team collaborates closely with electrical design engineers to customize dielectric strength, flexibility, and solderability parameters based on application requirements. In addition to standard products, we support OEM formulations and rapid prototyping for specialized industrial and renewable energy applications.

Quality assurance is embedded at every stage. Each production batch undergoes rigorous electrical resistance testing, thermal shock evaluation, pinhole detection, and elongation verification. Our in-house laboratory is equipped with advanced spectrometry, tensile testing machines, and high-voltage breakdown testers, enabling full traceability and compliance with IEC 60317, GB/T 6109, and NEMA MW standards.

As a vertically integrated supplier, we maintain direct control over cost structures, enabling competitive pricing without compromise on performance. Our supply chain is optimized for reliability, with monthly production capacity exceeding 1,200 metric tons and inventory management systems that support just-in-time delivery for global clients.

For engineering teams and procurement managers seeking a technically capable, responsive, and scalable partner in copper winding wire, Luoyang Xinzhaoanghe delivers proven performance backed by two decades of industrial experience.

Contact us today to discuss your specifications and discover how we can support your next generation of electromagnetic designs.

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper wire magnets directly from China.