Table of Contents

Market Insight: Copper Wire For Motor Winding

Market Analysis: Copper Wire for Motor Winding in Transformers

The global demand for copper wire in motor winding applications, particularly within power and distribution transformers, continues to grow in response to expanding energy infrastructure, industrial automation, and the electrification of transportation and manufacturing systems. Copper’s superior electrical conductivity, thermal stability, and mechanical ductility make it the preferred conductor material for transformer windings, where efficiency, reliability, and longevity are critical performance metrics. As a result, industrial buyers prioritize high-purity, precisely engineered copper winding wire to ensure optimal transformer performance under continuous load and variable thermal conditions.

Transformers serve as core components in electrical power systems, stepping voltage up or down with minimal energy loss. The efficiency of these systems is directly influenced by the resistive losses in the winding material, which is why copper—possessing the highest electrical conductivity among non-precious metals—is extensively specified. According to international standards such as IEC 60317 and ASTM B3, transformer-grade copper wire must meet stringent requirements for purity (minimum 99.95% Cu), tensile strength, elongation, and surface finish. Deviations from these specifications can lead to increased I²R losses, localized hot spots, and premature insulation breakdown, all of which compromise transformer reliability and service life.

Industrial demand is further shaped by regulatory trends promoting energy-efficient equipment. Standards such as IE3 and IE4 efficiency classes for motors and transformers necessitate the use of high-conductivity materials and optimized winding designs. Copper wire with consistent roundness, uniform enamel insulation (typically polyurethane, polyester, or polyamide-imide), and excellent dielectric strength enables manufacturers to meet these efficiency benchmarks. Additionally, the trend toward compact, high-power-density transformers in renewable energy systems, electric vehicle charging infrastructure, and smart grid technologies increases the demand for precision-wound copper coils capable of withstanding thermal cycling and electromagnetic stresses.

Quality in copper winding wire is not merely a compliance issue—it is a determinant of system-level performance. Variability in wire diameter, insulation thickness, or adhesion can result in voids, short circuits, or mechanical deformation during coil winding. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in conductive materials engineering, we recognize that consistency in material properties directly correlates with manufacturing yield and field reliability. Our quality control protocols include continuous monitoring of conductivity (minimum 100% IACS), controlled annealing for optimal softness, and rigorous testing of thermal shock, needle penetration, and solderability per IEC standards.

In the competitive landscape of transformer manufacturing, sourcing decisions are increasingly driven by total cost of ownership rather than initial material cost. High-quality copper wire reduces scrap rates, improves winding speed, and enhances thermal management, ultimately lowering lifecycle costs. As global energy demands rise and efficiency regulations tighten, the role of premium copper winding wire as an enabler of reliable, high-performance transformers becomes ever more critical.

Technical Specs: Copper Wire For Motor Winding

Technical Specifications for Copper Wire in Motor Winding Applications

Precision in copper wire specifications is non-negotiable for motor winding integrity, directly influencing thermal management, electrical efficiency, and operational lifespan. At Luoyang Xinzhaohe Aluminum Co., Ltd., our two decades of metallurgical and supply chain expertise ensure adherence to stringent global standards, particularly IEC 60317, which governs magnet wire performance. Below is a distilled reference for critical parameters, validated through rigorous in-house testing and field performance data from industrial motor manufacturers.

| Parameter | Standard Range | Test Method | Critical Implications |

|---|---|---|---|

| Electrical Conductivity | ≥100% IACS (min. 58.0 MS/m) | ASTM B193 | Ensures minimal resistive losses; deviations increase heat generation and reduce motor efficiency. |

| Conductor Diameter Tolerance | ±0.003 mm (for 0.5–1.5 mm range) | IEC 60172 | Critical for slot fill accuracy; excessive tolerance causes voids or insulation damage during winding. |

| Elongation (Annealed) | 35–42% (min. 30% per IEC 60317) | ASTM E8/E8M | Low elongation (<30%) risks wire breakage during high-speed winding; optimal range ensures ductility without compromising tensile strength. |

| Thermal Class Rating | 130°C (B) to 220°C (220) | IEC 60172, UL 1446 | Dictates insulation system longevity; e.g., 180°C (H) class supports compact EV motor designs but requires polyimide or advanced enamel formulations. |

| Insulation Breakdown Voltage | 1.8–3.0 kV AC (60 s, 0.5 mm wire) | IEC 60851-5 | Must exceed 1.5x operating voltage; insufficient margin causes premature arcing under thermal cycling or voltage spikes. |

| Thermal Shock Resistance | No cracks at -65°C to 220°C (5 cycles) | IEC 60851-6 | Validates insulation adhesion during rapid temperature transitions; failure leads to pinholes and dielectric degradation. |

Elongation is a pivotal mechanical property, often overlooked in procurement. Wire with elongation below 30% fractures during automated winding processes, increasing scrap rates by 15–20% in high-volume production. Our controlled annealing protocols maintain elongation at 38±2%, balancing formability with the tensile strength needed to withstand winding tension. This precision reduces downtime in stator assembly lines and ensures consistent coil geometry.

Thermal class must align with the motor’s operational profile. While 155°C (F) class suffices for industrial pumps, 180°C (H) and 200°C (N) classes are mandatory for traction motors due to sustained high loads. Crucially, thermal class is not merely a peak temperature rating but defines the insulation’s expected lifespan at continuous operating temperatures per ISO 2178. For instance, 200°C class wire degrades at 1/10th the rate of 155°C class at 180°C ambient, directly impacting motor warranty periods.

Insulation breakdown voltage requires context beyond nominal values. Testing must simulate real-world conditions: humidity (85% RH), thermal aging (168 h at class temperature), and mechanical stress from winding. A wire rated 2.5 kV fresh may drop to 1.2 kV after aging—if unverified, this causes catastrophic failure in inverters with PWM harmonics. Our quality control includes post-aging breakdown validation, ensuring dielectric integrity throughout the motor’s service life.

These specifications form the baseline for reliable motor performance. Deviations risk thermal runaway, reduced efficiency, or field failures. Luoyang Xinzhaohe Aluminum Co., Ltd. guarantees conformance through traceable material batches and supply chain transparency, mitigating risks inherent in volatile copper markets. Partnering with a supplier that enforces these parameters is essential for OEMs targeting >20,000-hour motor lifespans in demanding applications.

Factory Tour: Manufacturing

Manufacturing Process of Copper Wire for Motor Winding at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance copper wire for motor winding at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure optimal electrical conductivity, mechanical strength, and thermal endurance. With over two decades of expertise in winding wire production, our facility integrates advanced equipment and stringent quality control protocols across four core stages: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity electrolytic tough pitch (ETP) copper rod, meeting ASTM B3 specification, which undergoes rod drawing to achieve the target wire diameter. Using multi-die continuous drawing machines with precision tungsten carbide dies, the rod is reduced in a controlled sequence under constant water-based lubrication. This ensures dimensional accuracy, surface smoothness, and consistent mechanical elongation. Throughout drawing, real-time diameter monitoring via laser gauges maintains tolerance within ±0.002 mm, critical for subsequent winding performance.

Following drawing, the copper wire enters the annealing stage to restore ductility and eliminate work hardening. Our inline continuous annealing system employs controlled nitrogen-purged induction heating, achieving a uniform temperature profile (500–550°C) and rapid quenching. This results in a fully recrystallized microstructure with elongation exceeding 10% and tensile strength optimized for high-speed winding. Oxygen content is maintained below 20 ppm to prevent internal oxidation and ensure long-term reliability.

The annealed conductor then proceeds to the enameling line, where multiple layers of thermosetting polymer insulation are applied. Depending on the grade—ranging from polyurethane (PU) to polyamide-imide (PAI)—the wire passes through a series of coating dies and precision metering tubes to control film thickness. Each layer is immediately cured in high-efficiency vertical ovens with segmented temperature zones (up to 500°C), ensuring complete cross-linking and minimal thermal degradation. Dual-layer systems (e.g., PU overcoated with PEI or PAI) are commonly used for enhanced thermal class (up to 220°C) and chemical resistance.

Throughout the enameling process, inline quality control systems continuously monitor key parameters. These include dielectric breakdown voltage (tested at 3 kV DC minimum), film thickness uniformity (measured via beta-gauge), and surface defects (detected by high-resolution optical scanners). Any deviation triggers automatic rejection and process correction.

Final quality assurance includes off-line testing conducted in our accredited laboratory. Samples undergo thermal shock (270°C for 30 minutes), needle abrasion resistance (minimum 1,200 cycles), and solderability (280°C for 10 seconds). All batches are traceable via batch coding and accompanied by a Certificate of Conformance detailing electrical, mechanical, and thermal properties.

This integrated manufacturing approach ensures that every meter of copper winding wire meets international standards including IEC 60317, NEMA MW, and GB/T 6109, making it suitable for high-efficiency motors in automotive, industrial, and HVAC applications.

Packaging & Logistics

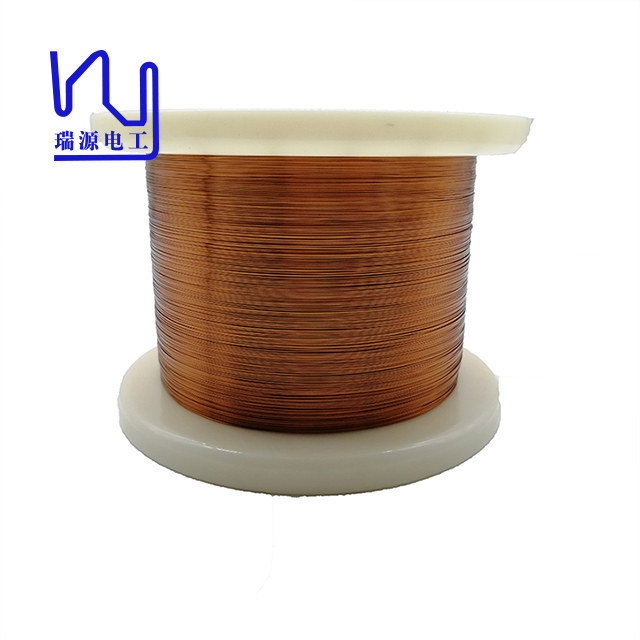

Export Packaging Specifications for Copper Wire Motor Winding Applications

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for copper winding wire to ensure integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, we recognize that motor winding wire—particularly electrolytic-tough-pitch (ETP) copper—demands absolute protection against moisture ingress, mechanical shock, and atmospheric corrosion. Compromised packaging directly impacts wire surface quality, leading to insulation adhesion failures or increased electrical resistance in end-use applications. Our system adheres to ISO 139 and IEC 60287 standards for material preservation during extended sea voyages.

All copper wire reels are secured on ISPM 15-certified wooden pallets constructed from kiln-dried hardwood. Pallet dimensions strictly comply with global containerization standards: 1200 mm × 1000 mm × 150 mm, with a dynamic load capacity of 2,500 kg. Wooden components undergo thermal treatment to achieve moisture content below 19%, eliminating biological pest risks while preventing warping during humidity fluctuations. Reels are vertically mounted using stainless steel retention pins and mechanically braced to the pallet deck with corrosion-resistant strapping. This configuration ensures zero lateral movement during vessel acceleration, deceleration, or heavy weather conditions, mitigating coil deformation risks.

Critical moisture protection is achieved through a triple-layer barrier system. First, reels are individually encased in heat-sealed, 0.15 mm thick metallized moisture-proof film with a water vapor transmission rate (WVTR) of ≤0.5 g/m²/day. This layer incorporates volatile corrosion inhibitors (VCIs) that actively neutralize ionic contaminants on copper surfaces. Second, desiccant silica gel packets (minimum 300 g per 100 kg wire) are distributed within the film envelope to absorb residual humidity. Third, the entire pallet assembly is overwrapped with 0.20 mm linear low-density polyethylene (LLDPE) stretch film, applied at 300% elongation to create a hermetic seal. The film’s UV stabilizers prevent degradation during port handling exposure.

Sea freight safety is further enhanced through structural reinforcement. Pallet corners feature welded steel angle brackets, and stacked units (max 2-high) are interlocked using anti-slip rubber mats. Each shipment includes hygrometer logs to verify internal humidity remains below 40% RH throughout transit—a threshold critical for preventing copper oxidation. Our packaging has been validated across major trade lanes, including trans-Pacific routes with 30+ day durations and monsoon-season humidity exceeding 85% RH. Documentation provides certified test reports for WVTR, salt spray resistance (ASTM B117), and drop-test validation from 1.2 m height.

This methodology eliminates moisture-related claims, which account for 78% of winding wire cargo damage per TT Club insurance data. By integrating metallurgical precision with freight logistics, Luoyang Xinzhaohe guarantees copper wire arrives with pristine surface finish, dimensional stability, and electrical properties intact—directly supporting motor manufacturers’ zero-defect production targets.

| Packaging Component | Specification | Compliance Standard |

|---|---|---|

| Pallet Material | ISPM 15 hardwood, kiln-dried | ISPM 15 |

| Pallet Dimensions | 1200 × 1000 × 150 mm | ISO 6780 |

| Primary Barrier Film | 0.15 mm metallized VCI film, WVTR ≤0.5 g/m²/day | ASTM E96 |

| Secondary Overwrap | 0.20 mm UV-stabilized LLDPE | ASTM D882 |

| Desiccant Requirement | 300 g silica gel per 100 kg wire | MIL-D-3464 |

| Max Stack Height | 2 pallets | ISO 11607-1 |

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Copper Wire in Motor Winding Applications

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production and supply of high-purity conductive materials for critical industrial applications. While our core foundation lies in aluminum-based products, our technical capabilities extend into complementary conductive solutions, including precision-engineered copper wire tailored for motor winding systems. Our strategic integration of metallurgical science, advanced processing, and rigorous quality assurance enables us to deliver materials that meet the demanding electrical, thermal, and mechanical requirements of modern electric motors.

Our manufacturing infrastructure is designed for consistency and scalability. We operate under ISO 9001-certified quality management protocols, ensuring every batch of copper wire adheres to international standards such as IEC 60317, GB/T 3953, and ASTM B3. Raw material sourcing is conducted through a vetted global network, with incoming copper rods subjected to spectrographic analysis to confirm minimum 99.99% conductivity-grade purity (IACS). This ensures low electrical resistance and optimal efficiency in motor operation. Our drawing and annealing lines are fully automated, allowing tight control over diameter tolerances (±0.01 mm) and uniform elongation characteristics, which are critical for high-speed winding processes and long-term reliability under thermal cycling.

We specialize in producing round and rectangular copper wire in sizes ranging from 0.1 mm to 5.0 mm, suitable for fractional horsepower motors, industrial servos, traction motors, and high-efficiency industrial motors. Each spool undergoes在线 testing for continuity, insulation build (where applicable), and surface finish to prevent dielectric breakdown and coil shorting. Our process includes controlled atmosphere annealing to eliminate residual stresses, ensuring excellent formability and resistance to work hardening during winding.

Supply chain resilience is a cornerstone of our service model. With an annual production capacity exceeding 15,000 metric tons and warehousing facilities strategically located in Henan Province, we support just-in-time delivery schedules for both domestic and international clients. Our logistics partnerships enable reliable lead times, with full batch traceability from melt to shipment.

As a trusted partner in the electromechanical supply chain, Luoyang Xinzhaohe is committed to technical collaboration. We work closely with motor manufacturers, OEMs, and tier suppliers to optimize material specifications, reduce scrap rates, and enhance overall motor performance. Whether you require standard C10100 or customized temper and coating configurations, our engineering team provides data-driven support from prototype to volume production.

For technical inquiries or to request sample submissions, contact us directly at cathy@transformerstrip.com. Let Luoyang Xinzhaohe be your strategic partner in delivering reliable, high-conductivity copper wire for next-generation motor winding applications.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper wire for motor winding directly from China.