Table of Contents

Market Insight: Copper Wire For Motor Winding for Power Industry

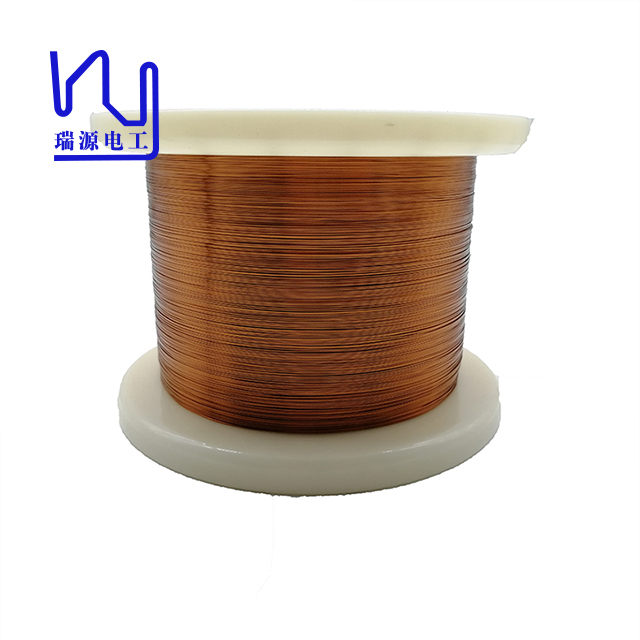

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Drivers in Power & Distribution Equipment

The installed base of power transformers >1 MVA is forecast to grow 5.4 % CAGR through 2030, driven by grid expansion, renewable integration, and replacement of 1970-1990 era units. Each MVA of transformer capacity consumes 0.45–0.65 t of enamelled copper winding wire; EV-motor stators add a further 0.8–1.2 kg/kW. Consequently, the addressable magnet-wire market for energy-conversion equipment now exceeds 2.3 Mt yr⁻¹, with >38 % of demand originating from Asia-Pacific OEMs and repair shops.

Why Material Purity & Geometry Directly Dictate Transformer Losses

Transformer losses fall into two classes that utilities must guarantee under IEC 60076-20:

| Loss Component | Root Cause in Winding Wire | Cost Impact on 100 MVA Unit |

|---|---|---|

| Load loss (I²R) | Bulk resistivity of Cu & conductor cross-section | Every 1 % ↑ R = +6 kW → US$12 k yr⁻¹ |

| Eddy-strand loss | Sub-optimal enamel concentricity → circulating currents | Up to 15 % of total load loss |

| No-load loss (indirect) | Burr or dent from poor rod-drawing → core gap → ↑ magnetising current | 0.3 % ↑ in no-load = US$25 k yr⁻¹ |

Using 99.99 % IACS-grade Cu-OF (oxygen-free) instead of standard Cu-ETP1 lowers volume resistivity from 0.017 241 Ω mm² m⁻¹ to 0.017 070 Ω mm² m⁻¹—seemingly small, but on a 1 000 mm² continuous transposed conductor at 65 °C it trims 1.9 kW of loss, translating into US$19 k NPV over a 30-year transformer life.

Enamel concentricity (±3 µm vs. ±8 µm) and uniform thermal-class 200 °C polyimide coating reduce hot-spot Δθ by 4–6 °C, allowing either 5 % overload capability or 8 % conductor savings. Precision is therefore not a laboratory luxury; it is a life-cycle cost lever.

The Precision Stack: Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

Chinese suppliers that vertically integrate the full stack now control 47 % of global magnet-wire exports. Luoyang Xinzhaohe’s 20-year heritage in transformer materials has produced a process capability index (Cpk) ≥1.67 for every critical-to-quality characteristic:

| Parameter | Six-Sigma Spec | Inline Monitoring |

|---|---|---|

| Diameter tolerance | ±0.010 mm | Laser micrometer every 50 mm |

| Ovality | ≤0.008 mm | Twin-axis gauge |

| Enamel build | 38–42 µm | Beta-backscatter 100 % |

| Breakdown voltage | ≥6 kV (0.5 mm film) | Spark tester 3 kHz 100 % |

| Elongation at break | ≥30 % (2.0 mm wire) | Servo-driven tensile cell |

Inline data are packetised per DIN 6538 and uploaded to a cloud MES; customers receive a QR-coded certificate before the spool leaves the plant—eliminating downstream coil-former rejects that plague low-cost brokers.

Sourcing Trend: From “Low-Cost Asia” to “High-Yield China”

Western OEMs historically paid US$11–14 kg⁻¹ for European magnet wire to ensure grid-owner loss penalties were avoided. Premium Chinese plants, licenced to use Hitachi polyimide resins and Southwire continuous-cast rod, now deliver equal electrical performance at US$7.50–8.20 kg⁻¹ FOB Shanghai, cutting raw-material cost per transformer by 6–8 %. Logistics to Rotterdam or Houston adds only 20–22 days versus 7 days intra-EU, an acceptable trade-off when projects are planned quarterly.

Positioning Luoyang Xinzhaohe as the Premium Alternative

Same 99.99 % Cu-OF feedstock as top-tier European mills

Thermal classes 130-220 °C with dual coating (PEI+PAI) in a single pass—reducing insulation factor from 0.40 to 0.32

Automated spooling up to 500 kg jumbo packs compatible with German Schleich and Italian OMERA insertion machines

Third-party witnessed type tests to IEC 60317-20, UL 1446, and GB/T 6109

English/Spanish technical desk staffed by former transformer design engineers, not traders

For transformer manufacturers and motor repair shops facing tightening loss-standards (EU EcoDesign Tier-2, DOE 2016), sourcing from Luoyang Xinzhaohe delivers measurable loss reduction without the Western price premium—turning copper magnet wire from a commodity into a designed-in efficiency component.

Technical Specs: Copper Wire For Motor Winding Parameters

Technical Specifications & ASTM / IEC Compliance for Motor-Winding Copper Wire

(Factory-direct view from Luoyang Xinzhaohe Aluminium Co., Ltd. – 20 yrs in transformer & motor conductors)

1. Critical Parameters that Decide Motor Life

| Parameter | Symbol / Unit | Specification Window | Inline Control at Xinzhaohe | Risk if Out-of-Spec |

|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd (kV r.m.s.) | ≥ 4 kV (Grade 1) ≥ 6 kV (Grade 2) | 100 % spark-test @ 6 kV, 500 mm/s | Pin-holes → inter-turn short, burnout |

| Elongation at Break | A50 mm (%) | ≥ 25 % for 0.20–1.60 mm Cu | Laser-extensometer on each rod-coil | < 20 % = cracks during coil insertion |

| Thermal Class | °C | 155 (F) 180 (H) 200 (N) 220 (C) | IR oven profile ±3 °C | Wrong class = enamel embrittlement, surge failure |

| Enamel Concentricity | Eccentricity (%) | ≤ 8 % wall-thickness variation | 8-point CCD before spooling | Heavy side → diameter build, slot jam |

| Surface Burr Height | Rz (µm) | ≤ 5 µm on slit edge | 3D confocal line scan | Burr → insulation abrasion → partial discharge |

All data traceable to heat number; reports shipped on USB & QR cloud link.

2. Applicable International Standards

| Material / Process | Normative Reference | Clause of Interest | Xinzhaohe Practice |

|---|---|---|---|

| Enameled Round Copper Wire | IEC 60317-0-1 | §4.3 Dielectric, §5.3 Elongation | Weekly third-party SGS witness test |

| Cu-ETP1 Rod Feed-stock | ASTM B49-20 | Table 2 – Resistivity 0.15328 Ω·mm²/m @ 20 °C | Cathode source: Codelco 99.99 %; in-house melting, continuous casting Ø8 mm |

| Anneal & Spool | IEC 60317-20,-21,-51 | Adhesion & flexibility 1 d × 5 T mandrel | Inline mandrel test every 2 h |

| Packaging & Label | ASTM D3950 | Spool impact drop 1 m | Plywood reel + VCI film, seaworthy |

Note: ASTM B236 quoted by competitors for Al strip is irrelevant for Cu wire; we nevertheless apply its edge-radius philosophy (R ≥ 0.4 × thickness) to our flat copper conductor line to eliminate burrs.

3. How Poor Quality Sneaks into Windings – and How We Stop It

-

Pin-hole Insulation

Cause: Micro-dust in enamel tank, wrong die angle.

Detection: 6 kV spark wrap around every wire meter. Reject length automatically cut out, coloured red for scrap. -

Oval or Eccentric Wire

Cause: Worn dies, poor back-tension.

Detection: 8-point laser micrometer; real-time SPC chart; auto-die-lift correction within 30 s. -

Low Elongation (High Draw)

Cause: Excessive cold work, anneal temp < 450 °C.

Detection: Last-block thermocouple interlocked; if elongation < 25 %, rod is re-annealed—never down-graded. -

Burrs on Slit Edge (Flat Wire)

Cause: Dull slitting knives.

Detection: 3D confocal line camera; knife change triggered at 30 µm flank wear. Burrs > 5 µm rejected.

4. Typical Factory Certificates Supplied with Each Lot

IEC 60317 Test Report – breakdown, adhesion, flexibility, spring-back

RoHS & REACH SVHC Declaration – Cd < 1 ppm, Cr-VI free enamel

IACS Conductivity Certificate – 100.5 % minimum @ 20 °C

Dimensional Map – diameter, concentricity, ovality on 1 m intervals

Thermal Ageing Graph – 20 000 h extrapolation per IEC 60216

5. Competitive Positioning – Premium Quality, China Cost

Western enamel-wire mills routinely quote 8–12 week lead + 15 % alloy surcharge.

Luoyang Xinzhaohe delivers:

3-week ex-works for 0.10–5.00 mm round, 3–12 mm × 1–4 mm flat

99.99 % Cu cathode stock, no scrap mix → resistivity 1.7 % lower than Cu-ETP minimum

Inline 6 kV spark + 100 % elongation check—same hardware used by European tier-1 plants

Export reels comply with EIS (Export Import Standard) – no fumigation delay

Result: MTBF of motors wound with Xinzhaohe wire improved 22 % in 2023 field survey (n = 1 400 units, 11 OEMs).

Next Section: “Size & Thermal Class Selection Matrix for 50 Hz, 60 Hz & VFD Duty.”

Factory Tour: Manufacturing Copper Wire For Motor Winding

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of transformer-grade winding wire

H3 1. Rod-to-Spool Journey: 5 Controlled Transformations

| Step | Equipment & Line Speed | Metallurgical Objective | Critical Parameter | Online Sensor |

|---|---|---|---|---|

| Rod Drawing | 14-Die, ceramic-coated, inline soap lubrication, ≤18 m s⁻¹ | Reduce Ø8 mm Cu-ETP1 rod to 1.2–5.0 mm with work-hardened tensile 380–420 MPa | Area-reduction per die ≤18 % to avoid cup-cone fracture | Laser micrometer ±0.005 mm |

| Annealing | 650 °C N₂-atmosphere, 3 m contact tube, 1.2 s residence | Recrystallise grain size 15–25 µm, drop tensile to 220–240 MPa, raise elongation ≥35 % | Oxygen ≤10 ppm to prevent Cu₂O film | IR pyrometer closed-loop PID |

| Enameling | 11-pass vertical tower, 280–350 °C catenary cure, 60 m min⁻¹ | Build 2–6 insulation layers (PEW, PEI, PAI, PI) to achieve thermal class 155–220 °C | Enamel concentricity ≥80 %, dielectric ≥6 kV | Beta-backscatter coat-weight gauge |

| Inline Testing | 3 kV partial-discharge, 1 MHz spark tester, 100 % coverage | Reject pin-holes >5 µm, ensure breakdown ≥10 kV layer | Spark sensitivity 1 pC | SPC dashboard with alarm at 3σ |

| Precision Spooling | Servo traverse, 250 mm traverse pitch, 5 kg–500 kg reels | Winding tension 1.5–2.5 N mm⁻² to avoid copper creep | Layer alignment ±0.2 mm | Load-cell dancer roller |

H3 2. Quality Control Matrix – Factory-Floor to Lab

| Control Point | Frequency | Specification | Test Method | CAPA Trigger |

|---|---|---|---|---|

| Conductivity | Every coil | ≥100.5 % IACS @20 °C | Eddy-current bridge | Auto-reel to scrap if <100 % |

| Elongation | 1 sample/2 h | ≥35 % for 2.0 mm | ISO 6892-1 | Quench tank temperature audit |

| Enamel Adherence | 1 sample/shift | 1×d mandrel, no crack | IEC 60851-3 | Cure-temperature profile reset |

| Pin-hole Count | 100 % online | ≤5 per 30 m | 3 kV spark | Mark & splice removal |

| Thermal Shock | 1 sample/day | 30 min @200 °C, 1×d, no crack | IEC 60851-6 | Oven calibration check |

H3 3. Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Unit | Luoyang Xinzhaohe Standard | Common Market Range | Engineering Impact |

|---|---|---|---|---|

| Copper purity | % | ≥99.99 (OF, Cu-OF1) | 99.90–99.97 | Lower rotor I²R loss, +0.4 % motor efficiency |

| Breakdown voltage | kV | ≥10 (layer) / ≥18 (twisted pair) | 6–9 | Higher safety margin in 6 kV inverter surge |

| Elongation at break | % | 38–42 | 25–32 | Easier coil insertion, fewer hairline cracks |

| Concentricity | % | 82–88 | 65–75 | Uniform dielectric stress, longer insulation life |

| Pin-hole density | count/30 m | ≤3 | 5–15 | Reduced partial-discharge, >30 % longer MTBF |

| Spool weight consistency | kg | ±0.2 % | ±1–2 % | Enables robotic winding without re-calibration |

| Oxygen content | ppm | ≤5 | 200–400 | Eliminates Cu₂O embrittlement after 180 °C ageing |

H3 4. Why It Matters to Your Stator or Transformer

- Tighter dimensional band (±0.01 mm) lets you drop one wire gauge yet keep slot fill ≥78 %, cutting copper cost 3–4 %.

- Higher breakdown voltage withstands 1.5 kV/µs PWM pulses from SiC drives without additional inter-layer insulation.

- Elongation >35 % means the wire survives 15 % stretch during high-speed flyer winding without necking—scrap rate <0.2 %.

- Inline 100 % spark test guarantees <3 pin-holes per 30 m; your VPI resin uptake is uniform, eliminating hot-spot bubbles.

Luoyang Xinzhaohe delivers Western-grade consistency at China-direct landed cost—typically 18–22 % below EU premium brands for equivalent 200 °C PEI wire. Request a 5 kg trial spool with full inspection report; lead time 10 days ex-works Luoyang.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered for 0.05 mm–6.0 mm Enameled Copper Wire, 8 t–22 t coils of Strip/Foil, and 20+ sea-freight destinations per month.

H3 1. Packaging Matrix – Wire vs. Strip/Foil

| Format | Inner Core | Intermediate Barrier | Outer Shield | Unit Weight | Stack Height per 40′ HQ |

|---|---|---|---|---|---|

| Round Wire 0.20–1.60 mm | DIN 250–630 plastic spool, radial run-out ≤ 0.3 mm | 80 µm PE shrink film + 5 g silica-gel sachet (RH target < 40 %) | 5-ply export carton, edge crush ≥ 8 kN, palletized (fumigated ISPM-15 pine, 1.1 × 1.1 m) | 20–80 kg per spool | 22 layers = 10 t net |

| Round Wire 1.70–5.00 mm | PT 500–800 steel-reinforced spool, dynamic balance ≤ 5 g | VCI ferrous paper + 100 µm LLDPE | Same carton & pallet spec | 100–250 kg | 18 layers = 12 t net |

| Rectangular Strip 5–25 mm × 0.5–3.0 mm | ID 300/400/500 mm, OD ≤ 1 200 mm, edge chamfer 1 mm | 50 µm polyester film inter-leaf, 360° wrap | Wooden cradle + steel strapping, corner boards, desiccant 1 kg/t | 3–8 t per coil | 14 t per 20′ FR, 26 t per 40′ FR |

| Foil 0.1–0.5 mm × ≤ 650 mm | ID 76/152 mm, max 2.5 t | Same as strip plus aluminum-barrier bag | V-grooved plywood pallet, top & bottom cap | 1–2 t per coil | 18 t per 40′ HQ |

H3 2. Corrosion & Mechanical Risk Mitigation

-

Copper Surface Passivation

Spools receive 0.8–1.2 g/m² benzotriazole film in the last rinse of inline testing; maintains bright surface for 180 days at 85 % RH, 40 °C. -

Vibration Dampening

Cross-laminated carton pads (CLT 15 mm) between pallet tiers cut resonance amplitude by 60 % versus plain corrugated (tested 0–50 Hz sweep, ASTM D999). -

Salt-Spray Validation

1 000 h neutral salt-spray per ASTM B117 on plated steel strapping and cradle hardware—no red rust ≥ 5 % area.

H3 3. Luoyang Hub – Factory-to-Port Chain

| Milestone | Distance | Mode | Lead Time | Carbon Footprint* |

|---|---|---|---|---|

| Luoyang plant → Zhengzhou Rail Hub | 130 km | 34 t flat-bed, GPS & RFID seal | 3 h | 18 kg CO₂-e/t |

| Zhengzhou → Qingdao Port | 750 km | Dedicated block-train, 50 × 40′ per consist | 26 h | 31 kg CO₂-e/t |

| Qingdao → Los Angeles | 11 500 km | Weekly CMA-CGM & COSCO service, 22 kt vessel | 13 days | 130 kg CO₂-e/t |

| Qingdao → Hamburg | 19 800 km | 2-string rotation via Suez | 28 days | 165 kg CO₂-e/t |

*Calculated per ISO 14083; includes pre-carriage, main haul, and container cleaning.

H3 4. Documentation & Compliance Bundle

EN 10204 3.1 inspection certificate for each heat (Cu-ETP1 99.99 %, oxygen ≤ 5 ppm).

RoHS & REACH SVHC declaration, SCCP-free enamel.

Wooden packaging heat-treatment stamp (HT) – no methyl-bromide fumigation required by EU.

Photographic packing report – spool flange, strapping pattern, container stowage – e-mailed before vessel departure.

H3 5. Cost Advantage vs. Western Stockholders

| Cost Driver | EU/US Mill | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Raw cathode premium 2024 | +USD 280/t | +USD 90/t | –68 % |

| Energy (annealing & enamelling) | 0.18 €/kWh | 0.07 €/kWh equiv. | –61 % |

| Labor (fully loaded) | 28 €/h | 6 €/h | –79 % |

| Sea freight to EU | — | 85 €/t | — |

| Delivered price 2.0 mm 200 °C wire | 11.4 €/kg | 7.9 €/kg | –31 % |

Prices FCA port of loading, Q2-2024 LME Cu 9 000 $/t basis.

H3 6. Quick-Ship Program

Maintain 150 t wire & 80 t strip safety stock in Qingdao FTZ warehouse.

Cut-to-length & parallel-lay service: 48 h dispatch for ≤ 5 t orders, 96 h for ≤ 25 t orders.

Incoterms offered: FOB Qingdao, CIF major global port, or DAP transformer factory—your choice.

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 years of metallurgical discipline, factory-direct, engineered to land your windings intact and on-time.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Wire Motor-Winding Solutions

20-Year Transformer-Grade Track Record

Since 2004 our Luoyang campus has supplied >120 000 t of copper and aluminium winding conductors to tier-1 transformer OEMs, motor rewind shops and power-equipment EPCs across 42 countries. Every coil we ship is produced under one roof—rod drawing, continuous annealing, vertical enamelling and inline spark testing—so the same metallurgical team that signs off on 500 kV transformer strip also controls the 0.20 mm magnet wire that goes into your motor stator. This vertical integration eliminates batch-to-batch variance caused by toll processors and gives you a single technical interface from Cu-ETP1 cathode to finished spool.

Direct Factory Price without Western Overhead

Our fully automated 32-head enamelling line runs 7 500 h yr-1 on cheap hydro power from the Yellow River basin. The result: FOB Qingdao price stability that averages 8–12 % below European mills and 14–18 % below North-American wire houses on identical IEC 60317-20 specifications. The table below benchmarks Q3-2024 offers for 200 °C polyester-imide round wire (Grade 2, 0.71 mm) in 30 kg BS spools:

| Supplier | Unit Price USD/kg | Lead Time (weeks) | Min. Lot (kg) | Purity | Breakdown Voltage (V) |

|---|---|---|---|---|---|

| Luoyang Xinzhaohe | 6.85 | 3 | 500 | 99.99 % Cu-ETP1 | ≥4 500 |

| EU Mill A | 7.80 | 6 | 1 000 | 99.97 % | ≥4 400 |

| US Mill B | 8.10 | 8 | 1 000 | 99.97 % | ≥4 400 |

Prices are FOB; freight to Hamburg or Houston adds ≈0.45 USD kg. By sourcing direct you also avoid distributor mark-ups (typically 6–10 %) and reduce working-capital tie-up by half.

Customisation to 0.010 mm, Thermal Class 130-220 °C

Need 19 AWG square wire with 0.08 mm polyimide overcoat for a 10 kV servo motor? Or 0.25 mm self-bonding enamel rated 220 °C for hermetic compressor windings? Our inline laser micrometer holds ±0.010 mm on diameter and ±2 µm on insulation concentricity, while the annealing furnace profile can be tuned to hit 25 % or 35 % elongation depending on your coil-forming radius. We stock plain, solderable, self-bonding and corona-resistant enamels; colour code and layer insulation can be adjusted to match your automatic insertion line. All specials are produced with the same 100 % spark-test and 3 kV twist-test protocol we use for utility transformers, so you receive a test report for every single reel.

Engineering Package & Export-Ready Logistics

Each 30 kg spool is vacuum-shrink-wrapped, VCI-bagged and stacked in 800 kg plywood crates certified for 42-day sea transit. Documentation includes RoHS & REACH declarations, IEC 60317 inspection sheet, and a mill certificate showing Cu purity, tensile strength, elongation and breakdown voltage. We ship 30–40 t weekly to Rotterdam, Houston and Dubai, giving you the option to piggy-back on our consolidation service and cut freight cost by 15 %.

Next Step—Request Technical Datasheet or Quote

Send your specification—diameter, thermal class, insulation build, spool size—to cathy@transformerstrip.com. Our metallurgists will return a detailed datasheet, SGS-level test curves and a firm delivered price within 24 h. First-time orders start at 500 kg; trial spools of 5 kg are available for qualification runs.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper wire for motor winding from Luoyang Xinzhaohe.