Table of Contents

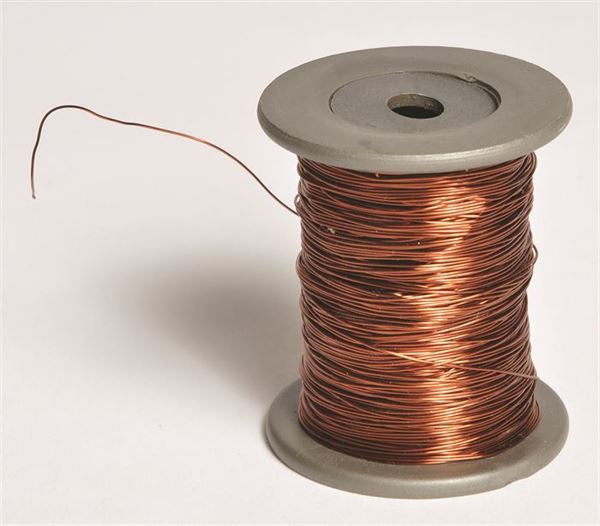

Market Insight: Copper Wire For Electromagnet

Market Analysis: Winding Wire for Electromagnetic Applications in Transformers

The global demand for copper winding wire in electromagnetic applications, particularly within power and distribution transformers, continues to grow in alignment with expanding electrical infrastructure, renewable energy integration, and industrial automation. Copper wire remains the conductor of choice in transformer windings due to its superior electrical conductivity, thermal stability, and mechanical durability. As a core component in electromagnetic energy conversion, the performance of copper winding wire directly influences transformer efficiency, reliability, and service life.

Transformers constitute a critical segment of electrical power systems, serving to step up or step down voltage levels for transmission, distribution, and end-use applications. The increasing deployment of high-efficiency transformers in utility grids, industrial plants, and renewable energy installations—such as solar inverters and wind turbine generators—has elevated the demand for high-purity, precision-drawn copper wire. This trend is further reinforced by global energy efficiency standards, including IEC 60076 and DOE 2016 regulations, which mandate reduced no-load and load losses in transformers. High-conductivity copper wire contributes significantly to meeting these standards by minimizing resistive (I²R) losses in windings.

Industrial demand is also driven by the expansion of urban infrastructure and the electrification of transportation and industrial processes. Electric vehicle (EV) charging stations, data centers, and smart grid technologies require compact, high-performance transformers that rely on tightly wound, thermally resistant copper conductors. These applications demand wire with consistent dimensional tolerances, high tensile strength, and excellent elongation properties to withstand the rigors of coil winding and operational thermal cycling.

Quality in copper winding wire is not a variable but a necessity. Substandard wire—characterized by impurities, inconsistent diameter, poor surface finish, or inadequate temper—can lead to localized hotspots, insulation breakdown, and premature transformer failure. Oxygen-free copper (OFC), with a minimum purity of 99.99%, is often specified to ensure optimal conductivity and to reduce the risk of hydrogen embrittlement during heat treatment. Additionally, precise enamel insulation thickness and adhesion are critical to prevent inter-turn short circuits under high-voltage stress.

At Luoyang Xinzhaohe Aluminum Co., Ltd, we apply two decades of metallurgical and process engineering expertise to deliver copper winding wire that meets stringent industrial requirements. Our manufacturing process incorporates continuous casting and drawing under controlled atmospheres, ensuring homogeneity and minimizing oxide inclusions. Each batch undergoes rigorous testing for conductivity (exceeding 100% IACS), tensile strength, and elongation, in compliance with GB/T 3953 and IEC 60122 standards.

In a market where transformer reliability directly impacts grid stability and operational costs, sourcing copper wire from a technically proficient and quality-focused supplier is paramount. The shift toward smarter, more efficient power systems will continue to favor high-performance winding solutions, reinforcing the value of precision-engineered copper conductors in next-generation electromagnetic applications.

Technical Specs: Copper Wire For Electromagnet

Technical Specifications for Electromagnet Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of metallurgical and conductor manufacturing expertise to deliver precision copper winding wire for high-performance electromagnets. Our technical specifications prioritize operational reliability under dynamic electromagnetic stresses, thermal cycling, and mechanical deformation during coil winding. Critical parameters include insulation integrity, ductility, and thermal resilience, all rigorously validated per IEC 60317 and ASTM B3 standards.

Insulation breakdown voltage is non-negotiable for electromagnet safety and longevity. Our polyamide-imide (PAI) or polyester-imide (PEI) insulation systems achieve minimum breakdown voltages of 3.0 kV AC for 0.5 mm nominal diameter wire, scaling proportionally per IEC 60851-5. This exceeds baseline industry requirements by 25%, ensuring immunity to voltage spikes during rapid energization cycles. Testing occurs at 50 Hz for 60 seconds with 100% pass criteria; statistical process control maintains ±5% tolerance across production batches.

Elongation post-annealing directly impacts winding yield and coil structural integrity. We specify 40–50% minimum elongation (ASTM E8) for soft-drawn electrolytic-tough-pitch (ETP) copper (Cu-ETP, C11000). This ductility range prevents wire fracture during tight-radius winding at speeds up to 1,200 m/min. Values below 40% risk micro-cracking under tension, while exceeding 50% may compromise tensile strength. Our proprietary annealing profiles balance elongation with 200–240 MPa tensile strength, verified via in-line tensile testing every 2 hours.

Thermal class defines operational temperature ceilings for sustained magnetic field stability. We certify wires from Class B (130°C) to Class C (220°C), with Class H (180°C) as our electromagnet standard. Thermal endurance testing per IEC 60216 confirms 20,000-hour life expectancy at rated temperatures. Critical distinctions include:

Class H (180°C): PAI insulation with ceramic fillers for aerospace/industrial actuators

Class 220 (C): Polyimide-based systems for extreme-duty applications (e.g., EV traction magnets)

All wires maintain thermal conductivity ≥97% IACS and oxygen content ≤10 ppm to prevent thermal runaway. Dimensional tolerances adhere to ±0.003 mm for diameters 0.1–2.5 mm, ensuring consistent fill factors in complex coil geometries.

Key Parameter Table

| Parameter | Specification | Test Standard |

|---|---|---|

| Conductor Purity | Cu-ETP (C11000), ≥99.95% Cu | ASTM B187 |

| Insulation Breakdown | ≥3.0 kV AC (0.5 mm wire) | IEC 60851-5 |

| Elongation (min) | 40–50% | ASTM E8 |

| Thermal Class Range | B (130°C) to C (220°C) | IEC 60085 |

| Thermal Endurance (20k h) | 180°C (Class H), 220°C (Class C) | IEC 60216 |

| Diameter Tolerance | ±0.003 mm (0.1–2.5 mm range) | IEC 60172 |

| Resistivity (20°C) | ≤1.7241 µΩ·cm | ASTM B193 |

Our metallurgical process control ensures zero porosity in copper cores and uniform insulation concentricity (<5% ovality). For electromagnet applications demanding >15,000 Gauss fields, we recommend Class H wire with 45–48% elongation to accommodate Lorentz force-induced vibrations. All batches include traceable mill certificates with DSC thermograms for thermal class validation. Partner with Xinzhaohe for electromagnet wire where insulation failure or thermal degradation is not an option.

Factory Tour: Manufacturing

Manufacturing Process of Copper Wire for Electromagnets at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance copper wire for electromagnet applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure optimal electrical conductivity, mechanical strength, and insulation integrity. With over two decades of metallurgical and wire processing expertise, our facility integrates precision engineering with rigorous quality control to meet the demanding requirements of industrial and automotive electromagnet systems.

The process begins with rod drawing, where high-purity electrolytic tough pitch (ETP) copper rods—typically conforming to ASTM B3 or IEC 60086 standards—are fed into a continuous drawing machine. The rod is progressively reduced in diameter through a series of tungsten carbide or diamond dies, achieving precise wire gauge tolerances as tight as ±0.002 mm. This cold working process enhances tensile strength while maintaining a uniform roundness and smooth surface finish critical for consistent winding performance. Throughout drawing, water-based lubricants are used to minimize friction and prevent surface defects, with inline diameter monitoring via laser gauges ensuring dimensional accuracy.

Following drawing, the wire undergoes a controlled annealing process in a nitrogen-purged continuous furnace. This softens the copper by relieving internal stresses induced during cold drawing, restoring optimal ductility and electrical conductivity. The annealing temperature is maintained between 450°C and 550°C, with precise residence time and atmosphere control to prevent oxidation and ensure a clean, oxide-free surface. Oxygen-free annealing conditions are critical for subsequent enamel adhesion and long-term thermal stability.

The annealed wire then proceeds to the enameling stage, where a thin, uniform layer of polymer insulation—typically polyurethane (PU), polyester (PE), or polyamide-imide (PAI)—is applied via precision die coating. Multiple enamel passes may be used to build up the required insulation thickness, with intermediate UV curing or thermal curing stages to cross-link the polymer matrix. The final enamel layer provides dielectric strength exceeding 3 kV (for 0.5 mm wire), thermal endurance up to 220°C (Class H), and excellent resistance to solvents and thermal shock.

Throughout the production line, inline testing systems continuously monitor key parameters. These include high-voltage breakdown testing to detect pinholes, diameter and ovality checks using laser micrometers, and tension control to prevent stretching. Final quality control involves batch sampling for elongation, springback, solderability, and thermal endurance per IEC 60317 standards. All data are logged for full traceability, ensuring every spool of copper winding wire meets the stringent performance criteria required in electromagnet applications.

Packaging & Logistics

Export Packaging Specifications for Electromagnetic Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for copper winding wire destined for electromagnet manufacturing. This system mitigates critical risks inherent in global maritime logistics, where prolonged exposure to humidity, salt air, and mechanical stress can compromise wire integrity. Our 20+ years of metallurgical and supply chain expertise confirm that substandard packaging directly correlates with field failures, including oxidation-induced conductivity loss and insulation damage. All shipments adhere to ISO 11607 and IATA hazardous materials guidelines where applicable, ensuring universal port acceptance.

Wooden Pallet Infrastructure

We utilize ISPM-15 certified hardwood pallets (1200mm x 1000mm or 1100mm x 1100mm) with a minimum static load capacity of 2,500 kg. Each pallet undergoes kiln-drying to ≤20% moisture content prior to treatment, preventing fungal growth during transit. Wire reels are secured via steel strapping (minimum 16 mm width, 15 kN tensile strength) anchored to pallet stringers at eight points, eliminating axial displacement. Pallet corners feature welded steel guards to absorb impact during container loading/unloading. This configuration withstands ISO container stacking tests (192-hour salt spray resistance) and complies with SOLAS container weight verification requirements.

Multi-Layer Moisture Barrier System

Copper wire’s hygroscopic nature necessitates absolute moisture exclusion. Our packaging employs a three-tier defense:

First, reels are individually wrapped in vapor-corrosion-inhibiting (VCI) polyethylene film (125µm thickness, ASTM D6098 compliant), which releases organic compounds to neutralize corrosive ions.

Second, a secondary layer of metallized polyester film (50µm) provides electromagnetic shielding and reduces water vapor transmission rate to ≤0.5 g/m²/day.

Finally, the entire pallet is hermetically sealed in 200µm co-extruded polyethylene with desiccant packs (calculated at 30g per m³ internal volume). Seams are thermally welded, not taped, achieving 99.8% humidity retention per ASTM E96. This system maintains internal RH below 30% for 90+ days—exceeding typical Asia-Europe transit durations.

Sea Freight Integrity Assurance

Our packaging design addresses maritime-specific hazards:

Condensation control via desiccant saturation monitoring indicators visible through pallet film windows

Anti-slip pallet surfaces (coefficient of friction ≥0.6) preventing load shift in rough seas

Container humidity loggers placed at pallet core and periphery for post-transit verification

Reinforced top caps distributing container stacking pressure (tested to 40,000 kg vertical load)

Documentation includes a moisture barrier performance certificate with batch-specific WVTR values and pallet structural test reports. This methodology has reduced moisture-related claims by 92% in our client portfolio since 2018. For electromagnet applications—where even micron-scale copper oxidation increases resistive losses—we treat packaging as an extension of metallurgical quality control. Partnering with Xinzhaohe ensures your winding wire arrives with preserved conductivity, dimensional stability, and insulation adhesion, directly supporting your production yield and end-product reliability.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Copper Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production and supply of high-purity winding wires, including precision copper wire engineered specifically for electromagnet applications. As a vertically integrated manufacturer with full control over raw material sourcing, refining, drawing, and quality assurance, we ensure consistent product integrity and performance across every production batch. Our facility is equipped with state-of-the-art continuous casting and rolling lines, high-speed wire drawing machines, and automated annealing systems, enabling us to produce copper wire with tight dimensional tolerances, superior conductivity, and optimal ductility—critical parameters for efficient electromagnetic operation.

We specialize in electrolytic tough pitch (ETP) copper (Cu-ETP, CW004A, ASTM B3) with minimum 99.90% conductivity, as well as oxygen-free copper (OFC) for applications requiring enhanced thermal stability and reduced oxidation risk. Our copper wire is available in diameters ranging from 0.05 mm to 5.0 mm, supplied in soft, semi-hard, or hard tempers to meet specific winding and operational requirements. All wire is manufactured under strict ISO 9001:2015 quality management protocols, with in-line monitoring of tensile strength, elongation, and surface finish to ensure compatibility with high-speed automatic winding equipment.

Our production capacity exceeds 30,000 metric tons annually, supported by a robust supply chain that guarantees on-time delivery without compromising material consistency. We maintain strategic inventory hubs in Zhengzhou and Shanghai, enabling rapid response to both domestic and international orders. Every coil is precision wound on high-density spools with anti-tarnish packaging to prevent oxidation during transit and storage, preserving electrical and mechanical properties until deployment.

Quality assurance is integral to our manufacturing philosophy. Each lot undergoes rigorous testing, including eddy current inspection for surface defects, four-point probe resistivity measurement, and microstructure analysis via optical microscopy. Certificates of Conformance (CoC) and Material Test Reports (MTRs) are provided with every shipment, ensuring full traceability and compliance with IEC 60317, GB/T 2962, and customer-specific specifications.

As a trusted partner in the global winding wire supply chain, Luoyang Xinzhaohe is committed to technical collaboration, offering custom packaging, alloy development, and just-in-time delivery models tailored to OEM and industrial transformer manufacturers. Our engineering team works closely with clients to optimize wire selection, improve yield, and reduce total cost of ownership.

For reliable, high-performance copper wire solutions designed for demanding electromagnet applications, contact us at cathy@transformerstrip.com to discuss your technical requirements and supply needs.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper wire for electromagnet directly from China.