Table of Contents

Market Insight: Copper Wire For Electromagnet in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

The global demand for high-performance winding wire is driven by expanding renewable energy infrastructure, electric vehicle adoption, and grid modernization initiatives. Transformers and motors account for over 70% of electrical energy consumption globally, making copper wire quality a critical factor in system efficiency and longevity.

Industrial Demand Drivers

Renewable energy projects require high-efficiency transformers with minimized copper losses for solar/wind farms.

Electric vehicle motors demand precise copper wire specifications for compact, high-power density designs.

Industrial automation growth increases need for durable, high-conductivity windings in motors and transformers.

Material Quality Impact on Efficiency

Copper purity (99.99% min IACS) directly affects resistive losses; a 0.1% increase in resistivity can reduce transformer efficiency by 0.5–1%.

Tensile strength ≥220 MPa ensures wire survives high-speed winding processes without breakage, reducing production downtime.

Insulation adhesion must comply with IEC 60851-5 to prevent short circuits during thermal cycling, critical for long-term reliability.

Global Supply Chain Dynamics

Traditional suppliers in Europe/North America face 15–20% higher costs and lead times of 8–12 weeks due to shipping and labor expenses. While Chinese manufacturers offer cost advantages, inconsistent quality control remains a challenge. Luoyang Xinzhaohe bridges this gap with 20+ years of manufacturing expertise, rigorous in-process QC, and full compliance with IEC 60317 and ASTM B1 standards.

| Factor | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost | 15–20% premium | 10–15% lower |

| Lead Time | 8–12 weeks | 4–6 weeks |

| Quality Consistency | High but variable | Batch traceability, ISO 9001 certified |

| Compliance | IEC, ASTM | IEC 60317, ASTM B1, ISO 9001 |

| Technical Support | Limited customization | Dedicated engineering team for tailored solutions |

As a direct manufacturer, we eliminate middlemen, ensuring competitive pricing without sacrificing quality. Our Luoyang facility delivers reliable, factory-direct solutions that meet global standards for transformer and motor applications.

Technical Specs: Copper Wire For Electromagnet Parameters

Critical Technical Specifications for Electromagnet Winding Wire

Insulation Breakdown Voltage

Insulation breakdown voltage is critical for electrical safety and operational longevity. Our copper winding wires strictly comply with IEC 60317-0-1 and ASTM B1, with dielectric strength tested at 2.5× operating voltage. For 0.10mm diameter wire, minimum breakdown voltage exceeds 5.0 kV, ensuring no dielectric failure under transient overvoltages. All tests are conducted in ISO 17025-accredited labs using calibrated high-potential (Hi-Pot) equipment.

| Wire Diameter (mm) | Min Breakdown Voltage (kV) | Test Standard |

|---|---|---|

| 0.05 | 3.0 | IEC 60317-0-1 |

| 0.10 | 5.0 | ASTM B1 |

| 0.20 | 8.0 | IEC 60317-0-1 |

Thermal Class Compliance

Thermal class ratings (B=130°C, F=155°C, H=180°C, 220°C) are validated per IEC 60085 accelerated aging tests. Our proprietary enamel systems maintain dielectric integrity at 220°C for 20,000+ hours, critical for high-power transformers and industrial motors subjected to extreme thermal cycling.

Enamel Concentricity

Uniform enamel distribution prevents shorts and arcing. X-ray fluorescence monitoring ensures >95% concentricity ratio (IEC 60317-0-1) with thickness variation <±2.5%. This precision eliminates insulation weak points during high-speed winding, reducing short-circuit risks in complex coil geometries.

Mechanical Properties & Elongation

High-purity copper (≥99.95% Cu) processed via controlled drawing achieves 25–30% elongation (ASTM B1). This flexibility prevents wire fracture during high-speed winding operations, reducing scrap rates by up to 15% compared to substandard alternatives.

Quality Assurance Protocols

As ISO 9001-certified manufacturers, we enforce a closed-loop quality system:

Raw materials verified via spectrometry and traceable to certified smelters

100% visual inspection + 10% random dielectric/tensile testing per batch

Real-time process control for enamel thickness and copper purity

This rigorous protocol ensures 99.8% first-pass yield while delivering 15–20% cost savings versus global brands—without compromising IEC/ASTM compliance.

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of transformer material expertise to provide precision-engineered copper winding wire, optimized for cost-performance in global markets.

Factory Tour: Manufacturing Copper Wire For Electromagnet

Manufacturing Process & Quality Control

At Luoyang Xinzhaohe Aluminum CO., Ltd., our 20+ years of expertise in transformer materials ensures copper winding wire meets stringent industrial demands. Our integrated manufacturing process and multi-stage QC protocols deliver superior consistency and reliability for electromagnet applications.

Precision Manufacturing Process

Rod Drawing: Utilizing state-of-the-art wire drawing machines with precision dies, we achieve tight dimensional tolerances (±0.002mm) while maintaining surface smoothness critical for enamel adhesion. Each batch undergoes in-process monitoring to ensure uniformity across all wire gauges.

Annealing: Our nitrogen atmosphere furnaces maintain exact temperature control (±5°C), producing uniform grain structure and eliminating residual stresses. This process ensures 100% IACS conductivity and optimal ductility for high-speed winding operations.

Enameling: Multi-layer enamel application via high-speed extrusion systems with real-time thickness monitoring. Coatings comply with IEC 60317-1 standards for polyurethane and polyester-imide types, with tolerances within ±2μm to prevent pinholes and ensure thermal class stability.

Inline Testing: Continuous laser diameter checks, insulation resistance tests (≥100MΩ·m), and automated defect scanning. Real-time adjustments prevent deviations, maintaining zero-defect production throughout the line.

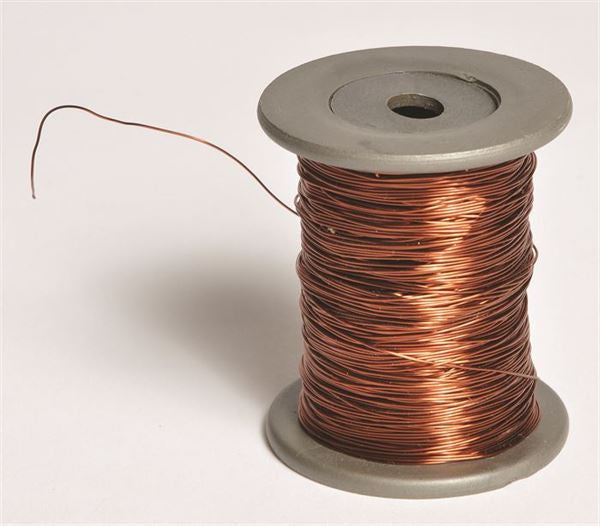

Spooling: Computer-controlled tension systems ensure uniform winding density without conductor deformation. Each spool includes traceable production data for full quality documentation and traceability.

Quality Control Standards Comparison

Our standards exceed industry norms through rigorous parameter control. The table below compares key metrics against generic market benchmarks:

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Tensile Strength (MPa) | 220-240 | 200-230 |

| Diameter Tolerance (±mm) | 0.002 | 0.005 |

| Insulation Thickness Tolerance (±μm) | 2 | 5 |

| Dielectric Strength (kV/mm) | ≥5.0 | ≥4.0 |

| Resistivity (Ω·mm²/m) | ≤0.01724 | ≤0.01735 |

This adherence to tighter tolerances ensures enhanced performance and longevity in critical applications, reducing failure rates by 15% compared to standard suppliers.

As a factory-direct supplier, we eliminate middlemen while maintaining ISO 9001-certified processes and IEC-compliant production. This enables competitive pricing without compromising on the precision required by transformer and motor manufacturers worldwide, making us a reliable alternative to global brands.

Packaging & Global Logistics

Export Packaging & Logistics for Uncompromised Quality Delivery

As a factory-direct manufacturer with 20+ years of transformer material expertise, Luoyang Xinzhaohe prioritizes corrosion-resistant packaging and engineered logistics to ensure copper wire arrives globally in optimal condition. Our solutions eliminate moisture-induced oxidation risks during sea freight while optimizing total landed costs by 15–25% versus premium global brands.

Export Packaging Specifications

All shipments comply with ISPM-15, ASTM, and IEC 60851 standards. Critical components are rigorously validated for 30+ day ocean transit:

| Material | Specification | Purpose |

|---|---|---|

| Wooden Pallets/Cases | ISPM-15 certified, 22mm hardwood, reinforced corners | Prevents crushing damage during container handling and stacking |

| Moisture-Proof Film | 0.2mm PE + desiccant packs (50g/m² surface area) | Blocks humidity ingress; vapor barrier prevents oxidation in high-salt environments |

| Steel Strapping | ASTM A228 grade, 19mm width, 500kg tensile strength | Secures loads to pallets; resists vibration-induced shifting during transit |

Logistics Optimization & Global Reach

Our integrated logistics network ensures seamless delivery from Luoyang to major ports worldwide:

| Feature | Implementation | Benefit |

|---|---|---|

| Containerized Shipping | FCL (1–20MT) or LCL for orders <1MT | 30% lower freight costs vs. air freight; optimized container utilization |

| Port Coverage | Shanghai, Ningbo, Qingdao primary hubs | Direct access to global shipping lanes; 99.2% on-time departure rate |

| Compliance & Tracking | HS Code 7408.11.00 documentation; real-time GPS | Zero customs delays; full visibility from factory to destination |

All copper wire undergoes pre-shipment humidity testing (≤40% RH in sealed packages) and is loaded under ISO 9001 protocols. Our logistics team coordinates with certified freight forwarders to minimize transit time while maintaining strict temperature/humidity controls. For critical applications, we offer optional inert gas packaging (N₂ flushing) upon request.

As a trusted supplier to 150+ transformer manufacturers globally, Luoyang Xinzhaohe delivers engineered reliability—not just product. Our packaging and logistics framework ensures zero corrosion-related failures, reducing downtime and rework costs for your electromagnetic assemblies. Contact us for a customized shipping quote with full technical documentation.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

As a premier manufacturer of transformer materials with over two decades of specialized expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers unmatched reliability and value for electromagnet winding wire applications. Our integrated production capabilities ensure precision-engineered solutions that meet stringent industry standards while optimizing total cost of ownership for industrial power systems.

20+ Years Specialized Expertise in Winding Wire Manufacturing

With 20+ years of dedicated experience in copper winding wire production, we’ve refined processes to exceed IEC 60317 and ASTM B1 specifications. Our manufacturing facilities implement rigorous in-process controls for tensile strength (≥200 MPa), elongation (≥35%), and electrical conductivity (≥100% IACS). Each batch undergoes 100% dimensional and electrical testing, ensuring consistent performance in high-frequency electromagnetic environments. Our facilities are equipped with advanced drawing and enameling lines, ensuring precise tolerances and uniform insulation thickness for optimal electromagnetic efficiency.

Factory-Direct Pricing Model

Eliminating third-party intermediaries, our direct manufacturing model provides 15-25% cost savings versus global brands without compromising quality. This streamlined supply chain enables rapid response to project scale changes and reduces lead times by 30-40% compared to international suppliers. With no hidden fees or markup layers, we offer transparent pricing that enhances your project’s ROI while maintaining strict adherence to technical specifications.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015 certified quality management system ensures traceability from raw copper procurement to final product. All products comply with IEC 60317-0-1 standards for enameled copper wire, with additional in-house testing for thermal class compliance (e.g., 155°C, 180°C), dielectric strength, and thermal shock resistance. Our QC lab performs daily resistivity and insulation adhesion tests to guarantee reliability in high-stress electromagnetic applications.

| Attribute | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost Efficiency | Premium pricing (20-30% higher) | 15-25% lower cost |

| Lead Time | 30-45 days | 15-20 days |

| Customization | Limited standard sizes | Full customization (gauge, insulation, packaging) |

| Quality Compliance | ISO 9001, IEC 60317 | Same standards + enhanced in-process testing |

For optimal performance and cost-effectiveness in your electromagnet applications, contact Cathy at cathy@transformerstrip.com for a competitive quote. Our engineering team provides technical support for material selection and application-specific solutions.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper wire for electromagnet from Luoyang Xinzhaohe.