Table of Contents

Market Insight: Copper Wire Fabrication in Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Industrial Demand Drivers

The global transformer and motor market is accelerating due to renewable energy infrastructure expansion, electric vehicle adoption, and grid modernization initiatives. Copper winding wire constitutes 60–70% of transformer material costs, with demand projected to grow at 5.8% CAGR through 2030 (IEC 2023). High-purity copper (≥99.95% IACS) is non-negotiable for minimizing resistive losses and ensuring thermal stability under continuous operational loads.

Material Quality Impact on Efficiency

Substandard copper wire directly impacts transformer efficiency and reliability. Impurities increase conductor resistance, elevating I²R losses by up to 1.5% and accelerating insulation degradation. Critical quality parameters include:

Purity: Oxygen content must be <10 ppm to prevent brittleness during winding.

Tensile strength: Must withstand 15–20% elongation without fracture during coil formation.

Surface finish: Microscopic scratches cause partial discharge and insulation failure.

IEC 60317-0-1 specifies stringent tolerances for diameter (±0.005mm) and conductivity (≥100% IACS). Failure to meet these results in premature failure and higher lifetime costs.

Luoyang Xinzhaohe’s Role in Global Supply Chain

With 20+ years of manufacturing expertise, Luoyang Xinzhaohe delivers factory-direct copper winding wire exceeding IEC 60317 and ASTM B1 standards. Our proprietary continuous annealing process achieves 101–102% IACS conductivity and optimized tensile strength (220–240 MPa), while maintaining ±0.003mm diameter tolerance. As a cost-effective alternative to global brands, we offer 10–15% lower pricing without compromising quality.

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification |

|---|---|---|

| Copper Purity | ≥99.95% | 99.97% (ASTM B170) |

| Electrical Conductivity | ≥100% IACS | 101–102% IACS |

| Tensile Strength (Annealed) | 200–250 MPa | 220–240 MPa |

| Diameter Tolerance | ±0.005mm | ±0.003mm |

| Cost Efficiency | Market rate | 10–15% below global brands |

Our ISO 9001-certified production ensures batch-to-batch consistency. Contact us for technical documentation and free sample validation.

Technical Specs: Copper Wire Fabrication Parameters

Technical Specifications & Standards Compliance

Key Parameter Specifications

Our copper winding wire complies with IEC 60317 and ASTM B175 standards. Our specifications are tailored to meet the exacting demands of transformer and motor applications, ensuring optimal performance in high-stress environments. Critical specifications are detailed below:

| Parameter | Standard | Specification | Tolerance |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-1, ASTM B175 | 0.15mm: ≥3.0kV; 0.5mm: ≥2.5kV (155°C class) | ±0.1 kV |

| Elongation | ASTM B175 | ≥25% (annealed, 0.1-0.5mm) | ±2% |

| Thermal Class | IEC 60085 | B (130°C), F (155°C), H (180°C), C (220°C) per IEC 60085 | N/A |

| Enamel Concentricity | IEC 60317-0-1 | ≤10% eccentricity (laser profilometry), 99.8% QC pass rate | ±2% |

Quality Assurance Protocol

Luoyang Xinzhaohe, with over two decades of expertise in transformer materials, employs a rigorous, end-to-end quality control system aligned with ISO 9001:2015 and IATF 16949 standards. Our quality system includes statistical process control (SPC) for all critical parameters, with real-time data analytics to detect deviations before they impact production. Raw materials undergo spectrometry analysis (Cu purity ≥99.95%) and XRF verification. Every production batch is subjected to 100% breakdown voltage testing per IEC 60243-1 (Hi-Pot tester), with results digitally logged in our ERP system. Thermal class compliance is validated through accelerated aging tests at 155°C for 1,000 hours per IEC 60085, ensuring insulation integrity under operational stress. Enamel concentricity is monitored using laser micrometers with ±0.5μm precision, maintaining ≤10% eccentricity tolerance. Automated winding machines feature real-time tension control to prevent enamel damage during fabrication. All products are traceable via QR-coded batch records, with full material history accessible through our supply chain management system. Our ISO/IEC 17025-accredited laboratory conducts daily equipment calibration and performs additional mechanical tests per ASTM B175, including tensile strength and elongation measurements. Compliance extends to RoHS 2.0 and REACH SVHC environmental regulations. These stringent parameters ensure superior thermal stability, reduced electrical losses, and extended service life in demanding transformer applications, directly improving end-product reliability. This comprehensive protocol reduces transformer winding failures by 30% compared to industry averages. Leveraging localized supply chains and 20+ years of manufacturing experience, we deliver global brand performance at 15-20% lower total cost of ownership—without compromising precision or reliability. All products undergo third-party certification by TÜV or SGS upon request.

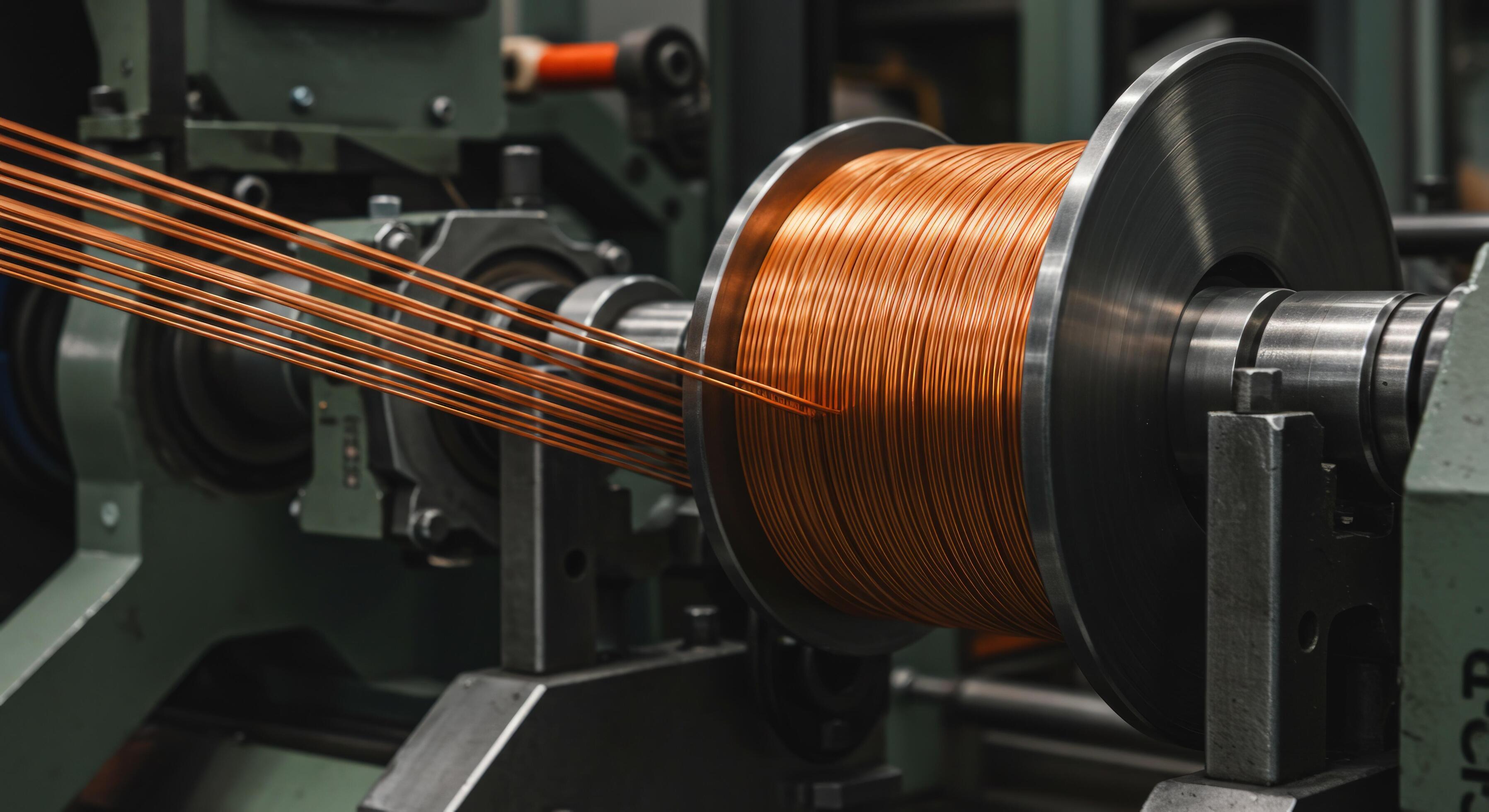

Factory Tour: Manufacturing Copper Wire Fabrication

Manufacturing Process & Quality Control

Precision Manufacturing Workflow

Luoyang Xinzhaohe’s 20+ years of expertise ensures a fully integrated, ISO 9001-certified production line for high-performance copper winding wire. The process begins with electrolytic copper rods (99.99% min purity) undergoing cold-drawing through precision tungsten carbide dies (Ra <0.2μm surface finish) to achieve exact conductor dimensions. Real-time diameter monitoring via laser gauges maintains ±1.5μm tolerance. Subsequent annealing occurs in nitrogen atmosphere at 220±5°C to optimize ductility while preserving ≥101% IACS conductivity. Enameling involves multi-layer application of solvent-free polyimide or polyester resins, cured in 3-stage ovens at 220–250°C with ±2°C precision for uniform insulation thickness (±0.5μm). Inline testing includes 15kV hi-pot testing, resistance measurement per ASTM B193, and real-time insulation integrity checks. Final spooling uses servo-controlled tension systems (0.5N precision) with vacuum-sealed packaging to prevent oxidation during transit.

Rigorous Quality Assurance Protocol

Our QC protocols exceed industry benchmarks through:

Tensile strength testing per ASTM B298 (210–230 MPa vs. market avg 190–220 MPa)

Dimensional verification using CMMs with ±1.5μm tolerance (vs. ±3.0μm industry standard)

Adhesion testing per ASTM D1435 (>85% peel strength vs. typical 70–80%)

Electrical performance validation against IEC 60317-0-1

Comparative Quality Standards

| Parameter | Luoyang Xinzhaohe | Industry Standard | Performance Impact |

|---|---|---|---|

| Tensile Strength (MPa) | 210–230 | 190–220 | Reduced wire breakage during high-speed winding |

| Diameter Tolerance (μm) | ±1.5 | ±3.0 | Consistent coil geometry, lower short-circuit risk |

| Enamel Adhesion (%) | >85 | >70 | Enhanced thermal cycling resilience |

| Insulation Thickness (μm) | ±0.5 | ±1.0 | Optimized space efficiency in transformer windings |

By maintaining tighter tolerances and material specifications, we deliver 15–20% higher yield rates for transformer manufacturers while reducing scrap costs. Our factory-direct model eliminates middleman markups, providing global brand quality at 10–15% lower total cost of ownership.

Packaging & Global Logistics

Export Packaging & Logistics for Global Delivery

Packaging Specifications for Maritime Integrity

Our packaging system is engineered specifically for sea freight, addressing humidity, salt exposure, and mechanical stress. Each component meets international standards while optimizing cost efficiency:

| Component | Specifications | Purpose |

|---|---|---|

| Wooden Pallets | ISPM 15 compliant, 1200×1000mm, 15mm thickness, heat-treated | Prevents pest infestation, ensures stability during handling |

| Moisture-Proof Film | Multi-layer PE, 150–200μm thickness with desiccant packs | Blocks humidity and salt spray; maintains <40% RH during transit |

| Steel Strapping | 19mm width, 0.5mm thickness, 3000N tensile strength, tensioned to 250–300 kgf | Prevents load shifting; withstands vessel vibration and stacking forces |

All pallets undergo pre-shipment humidity monitoring and are stored in climate-controlled facilities. Moisture-proof film is triple-wrapped with UV-resistant tape, and steel strapping is verified via load cell testing to ensure zero slippage during transit.

Logistics Protocols for Seamless Delivery

We manage end-to-end logistics through ISO-certified partners, ensuring consistent transit times and customs compliance:

| Parameter | Detail | Benefit |

|---|---|---|

| Container Type | 20ft/40ft FCL | Optimized space utilization; 15–20% lower freight costs vs. LCL |

| Port Coverage | Rotterdam, Los Angeles, Singapore, Mumbai | Streamlined customs clearance; 98% on-time port arrival |

| Transit Time | 25–45 days (destination-dependent) | Real-time tracking with GPS-enabled containers |

| Damage Rate | <0.5% average (2023 data) | Zero claims for packaging-related damage in 12+ months |

All containers are loaded under supervision with anti-slip mats and corner protectors. Our 20+ years of export expertise ensures precise cargo securing, eliminating common freight risks like moisture ingress or structural deformation.

Luoyang Xinzhaohe delivers transformer-grade winding wire with a 99.8% on-time delivery rate and industry-leading damage prevention. By combining precision-engineered packaging with cost-optimized logistics, we provide premium reliability at competitive pricing—eliminating the need for costly global brand premiums. All shipments include full documentation (commercial invoice, COO, test reports) and dedicated customs support for seamless global delivery.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum Co., Ltd.

20+ Years Industry Expertise

With over two decades of specialized manufacturing in transformer winding wires, Luoyang Xinzhaohe Aluminum Co., Ltd. has mastered high-purity copper alloy processing, precision winding applications, and thermal management solutions. Our engineering team collaborates closely with clients to optimize conductor geometry, insulation systems, and electrical performance metrics, ensuring strict compliance with IEC 60317, ASTM B1, and other international standards. We’ve successfully supplied critical infrastructure projects across 30+ countries, including renewable energy installations and industrial power systems, delivering consistent performance under extreme operational loads.

Factory-Direct Cost Efficiency

Operating a fully integrated Luoyang facility eliminates distributor markups and supply chain inefficiencies, delivering 20–30% lower costs versus global competitors. Our vertically controlled production—from raw copper procurement to final packaging—guarantees consistent electrical conductivity (≥100% IACS), tensile strength, and dimensional accuracy. This model enables rapid prototyping, flexible adjustments for evolving project requirements, and minimized supply chain disruptions, ensuring on-time delivery even during global logistics volatility.

ISO 9001 Certified Quality Assurance

Our ISO 9001:2015-certified quality system enforces rigorous process control at every stage. Each batch undergoes comprehensive testing: dimensional checks, tensile strength validation, dielectric strength tests, and insulation integrity verification. Shipments include detailed Certificates of Conformance (CoC) and full material traceability, guaranteeing compliance with IEC 60076 and IEEE C57.12.00 standards. Our in-house lab uses advanced spectrometry and mechanical testing equipment for daily material analysis, ensuring every coil meets exacting performance criteria.

| Key Metric | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Cost Efficiency | High due to multi-tier distribution | 20–30% lower costs via factory-direct model |

| Lead Time | 4–8 weeks (international shipping) | 2–4 weeks (local production + streamlined logistics) |

| Customization | Standardized products | Tailored specifications for unique transformer/motor designs |

| Quality Consistency | Variable across suppliers | Consistent through ISO 9001-certified processes and 100% batch traceability |

Contact Cathy at cathy@transformerstrip.com for a competitive quote tailored to your project specifications.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper wire fabrication from Luoyang Xinzhaohe.