Table of Contents

Market Insight: Copper Wire Enamelling Process

Market Analysis: Copper Wire Enamel Demand in Transformer Applications

Industrial demand for magnet wire produced via the copper wire enamelling process remains robust and strategically critical, driven primarily by global energy infrastructure modernization and the accelerated adoption of renewable energy systems. Transformers constitute a dominant application segment, requiring high-performance enameled copper winding wire for power distribution units, renewable energy inverters (solar/wind), electric vehicle charging infrastructure, and industrial motor drives. The transition towards higher efficiency standards (e.g., IE4, IE5 motors) and compact transformer designs necessitates wire capable of withstanding elevated operating temperatures and electrical stresses. This trend directly fuels demand for advanced enamel formulations meeting thermal classes 180 (H) and 220 (C), where thermal stability and dielectric integrity are non-negotiable. Concurrently, the proliferation of power electronics in grid-tied applications generates high-frequency voltage transients, placing unprecedented demands on enamel insulation to resist partial discharge inception and maintain long-term reliability under complex electrical waveforms.

The paramount importance of enamel quality in transformer windings cannot be overstated, as it directly dictates the operational lifespan, safety, and efficiency of the final asset. Substandard enamel application or inferior resin chemistry manifests in catastrophic field failures, including inter-turn shorts, ground faults, and complete insulation breakdown. Key quality parameters are rigorously defined by international standards (IEC 60317 series, ASTM B 328) and must be consistently achieved:

| Critical Quality Parameter | Minimum Requirement (Typical Class 180) | Failure Consequence in Transformers |

|---|---|---|

| Thermal Endurance (20,000h) | 155°C+ | Accelerated thermal aging, reduced MTBF |

| Dielectric Strength | 3.5 kV (min, 0.076mm build) | Inter-turn short circuits under surge |

| Adhesion (Mandrel Bend) | Pass 4x wire diameter mandrel | Cracking during winding, void formation |

| Solderability (288°C) | ≤ 2 sec wetting time | Poor coil termination, high resistance joints |

| Thermal Shock (-65°C to 200°C) | No cracking/delamination | Insulation failure during thermal cycling |

Inconsistent enamel thickness control or micro-defects (pinholes, thin spots) create localized high-stress points, initiating partial discharge activity even at nominal operating voltages. This progressive degradation mechanism, often undetected during routine factory testing, leads to premature in-service failure. Furthermore, inadequate chemical resistance compromises wire integrity when exposed to transformer impregnating varnishes or environmental contaminants, accelerating insulation deterioration. The economic impact of transformer failure extends far beyond replacement costs, encompassing grid instability, production downtime, and significant safety hazards. Consequently, discerning industrial buyers prioritize suppliers demonstrating stringent process control, comprehensive in-line metrology (e.g., laser micrometry, HV testing), and rigorous adherence to material traceability protocols. At Luoyang Xinzhaohe Aluminum, our two decades of metallurgical process expertise inform a deep understanding of how base copper purity, drawing precision, and enamel curing kinetics collectively determine the ultimate reliability of enameled wire in demanding power applications. Quality in the enamelling process is not a cost factor but a fundamental engineering requirement for grid resilience.

Technical Specs: Copper Wire Enamelling Process

Copper Wire Enamelling Process – Technical Specifications

The copper wire enamelling process is a critical stage in the production of high-performance winding wires used in electric motors, transformers, and other electromagnetic devices. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced conductor manufacturing, we ensure strict adherence to international standards and material performance benchmarks. The enamel insulation applied to copper conductors must meet rigorous electrical, mechanical, and thermal requirements to ensure long-term reliability under operational stress.

A key parameter in evaluating enamel-coated copper wire is the Insulation Breakdown Voltage, which measures the dielectric strength of the insulation layer. This property determines the maximum voltage the enamel can withstand before electrical failure occurs. For standard single-coat applications, breakdown voltage typically ranges from 2,500 V to 5,000 V, depending on wire diameter and enamel thickness. Multi-layer coatings, such as double or triple builds, are engineered to achieve higher dielectric performance, often exceeding 7,000 V, making them suitable for high-voltage industrial applications. Testing is conducted in accordance with IEC 60317 and GB/T 4074 standards using controlled humidity and temperature conditions to ensure consistency.

Elongation is another essential mechanical property, reflecting the wire’s ability to undergo deformation without cracking the insulation. A minimum elongation of 15% is required for most industrial applications, with high-flexibility grades achieving up to 30%. This ensures the wire can be wound, shaped, and processed without compromising the integrity of the enamel coating. Poor elongation performance may lead to micro-cracks in the insulation, reducing dielectric strength and accelerating thermal aging.

Thermal performance is classified according to Thermal Class, defined as the maximum continuous operating temperature at which the insulation retains its electrical and mechanical properties over a 20,000-hour service life. Our enamel coatings are available in thermal classes ranging from 130°C to 220°C, utilizing polyurethane, polyester, polyesterimide, and polyamide-imide resins. Higher thermal classes offer improved resistance to thermal degradation and are essential for use in high-efficiency motors and traction systems where heat generation is significant.

The following table outlines the core technical parameters for our enamel-coated copper winding wires:

| Parameter | Test Standard | Typical Value Range | Remarks |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, GB/T 4074 | 2,500 – 7,000 V | Increases with build thickness |

| Elongation | IEC 60317, GB/T 4074 | ≥15% (up to 30%) | Measured after bending test |

| Thermal Class | IEC 60085, GB/T 11021 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on thermal endurance |

| Temperature Index | IEC 60216 | 130 – 240 | Derived from thermal aging tests |

| Adhesion (Pin Test) | IEC 60317 | Pass (no flaking) | Assessed via needle penetration |

| Thermal Shock Resistance | IEC 60317 | Pass at rated temperature | No cracking after rapid cooling |

These specifications are validated through in-house quality control systems and third-party certification. Consistent coating uniformity, low volatile content, and excellent chemical resistance further enhance the reliability of our enameled copper wires in demanding environments.

Factory Tour: Manufacturing

Copper Wire Enamelling Process: Technical Sourcing Guide

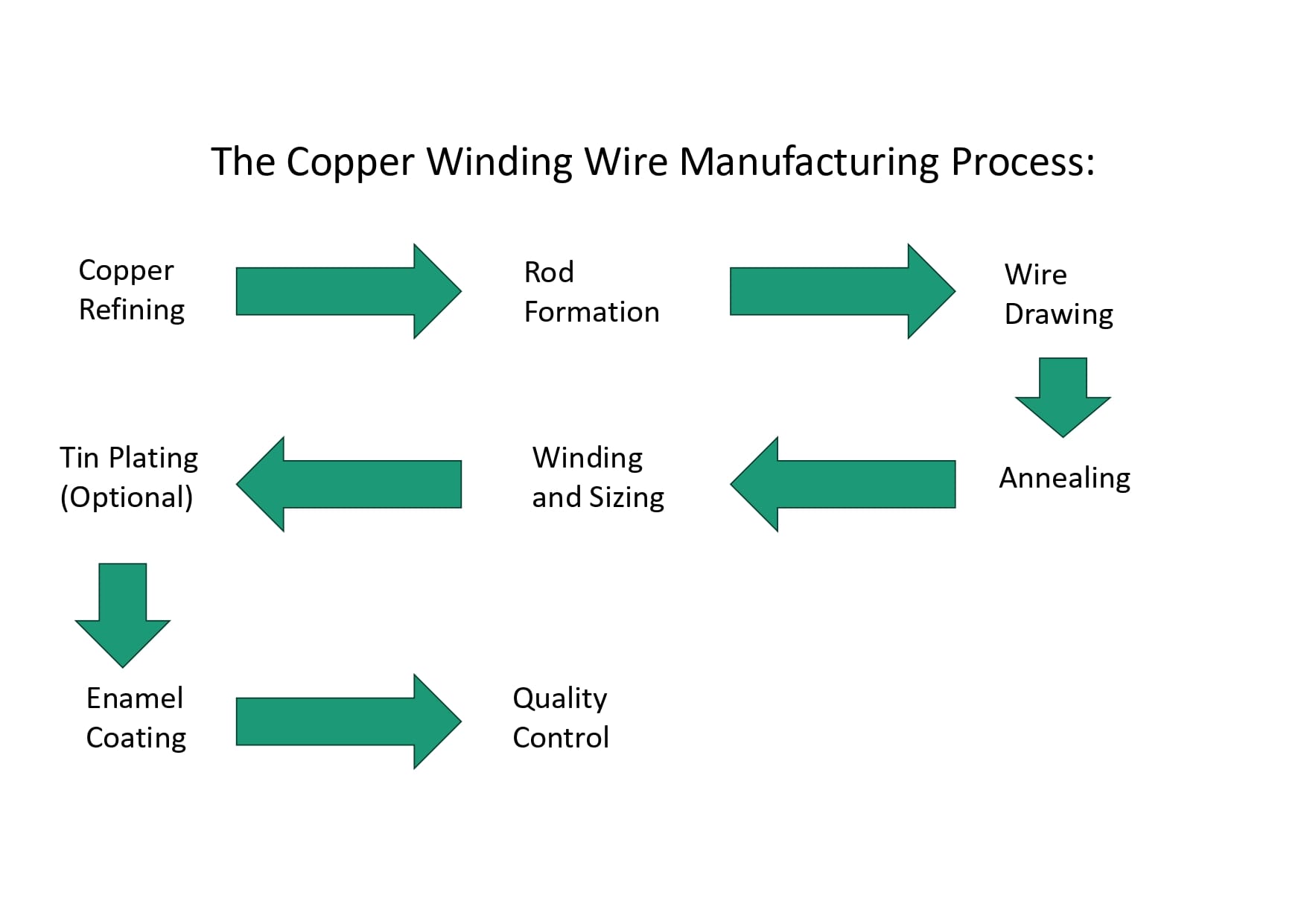

The copper wire enamelling process for high-performance winding wire demands rigorous control across sequential stages to achieve electrical integrity, mechanical resilience, and thermal stability. At Luoyang Xinzhaohe Aluminum CO., Ltd., with over two decades of metallurgical and process engineering expertise, this sequence—Rod Drawing, Annealing, Enameling, and Inline Testing—forms the backbone of our premium conductor production. Each phase incorporates stringent quality checkpoints to ensure compliance with international standards like IEC 60851 and customer-specific requirements.

Rod drawing initiates the process, where high-conductivity electrolytic tough pitch (ETP) copper rod (typically 8.0 mm diameter) undergoes multi-pass cold drawing through precision tungsten carbide dies. This reduces the diameter to the final conductor specification, often ranging from 0.08 mm to 3.00 mm. Critical control parameters include reduction ratio per pass (optimized to prevent work hardening defects), die lubrication quality, and tension management. Surface integrity is paramount; in-line optical inspection systems continuously monitor for scratches, pits, or diameter deviations exceeding ±0.005 mm tolerance. Any surface anomaly at this stage propagates through subsequent processes, compromising enamel adhesion and dielectric strength. Verified rods proceed only after passing real-time diameter verification and surface cleanliness audits.

Annealing follows drawing to restore ductility and electrical conductivity degraded by cold working. Conductors pass through a continuous inert atmosphere furnace (typically nitrogen or argon to prevent oxidation) at precisely controlled temperatures between 450°C and 550°C. Residence time is calibrated to achieve the target temper (e.g., soft annealed) while ensuring uniform grain structure. Post-annealing, conductivity is validated via eddy current testing, with minimum acceptance thresholds of 100% IACS (International Annealed Copper Standard). Oxygen-free processing and strict atmosphere purity control (oxygen content < 10 ppm) are non-negotiable to avoid embrittlement and ensure thermal aging resistance in the final product.

Enameling applies the insulating polymer coating via multi-layer application. The conductor traverses a series of coating dies immersed in enamel resin baths—common chemistries include polyurethane, polyester-imide, or polyamide-imide for high-temperature grades. Each pass applies a thin, uniform layer, followed by immediate curing in high-temperature ovens (350°C to 500°C, depending on resin). Layer thickness per pass is tightly controlled (typically 5–50 µm) to meet total build specifications. Critical QC during enameling includes continuous viscosity monitoring of resin baths, oven temperature profiling, and layer concentricity checks via laser micrometers. Off-spec viscosity or temperature gradients cause pinholes, thin spots, or adhesion failures.

Inline testing validates electrical and mechanical properties before spooling. Key tests include high-voltage breakdown (per IEC 60851-5), thermal shock (rapid cooling after heating to specified class temperature), and scrape abrasion resistance. Breakdown voltage must exceed minimum thresholds (e.g., 3x operating voltage + 1500 V) across the entire spool length. Thermal shock testing at 200°C+ for Class H insulation confirms no cracking under thermal stress. Adhesion is verified via mandrel wrap tests. Statistical process control (SPC) tracks all test data; any deviation triggers immediate process correction and batch quarantine. This integrated approach ensures every meter of wire meets the demanding requirements of motors, transformers, and EV applications.

Critical Inline Test Parameters

| Test Parameter | Standard Method | Typical Acceptance Threshold |

|———————-|—————–|——————————|

| High Voltage Breakdown | IEC 60851-5 | > 3x operating voltage + 1500 V |

| Thermal Shock | IEC 60851-6 | No cracks after 200°C (Class H) |

| Abrasion Resistance | IEC 60851-4 | > 500 cycles at specified load |

Packaging & Logistics

Export Packaging for Copper Wire in the Enamelling Process: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in winding wire manufacturing, we recognize that export packaging is not merely a logistical necessity but a critical component in preserving product integrity throughout the global supply chain. Copper wire intended for the enamelling process is particularly sensitive to environmental stressors such as moisture, mechanical shock, and contamination. Therefore, our export packaging system is engineered to meet the rigorous demands of international sea freight, ensuring that each coil arrives at its destination in optimal condition for downstream processing.

All copper wire reels are mounted on high-strength wooden pallets constructed from kiln-dried, fumigation-treated hardwood. These pallets comply with ISPM 15 international phytosanitary standards, eliminating the risk of pest infestation and ensuring customs clearance across global trade routes. The structural design of the pallet provides uniform load distribution, minimizing deformation during stacking and transit. Each reel is securely fastened to the pallet using industrial-grade steel strapping, preventing axial or radial displacement even under dynamic maritime conditions.

A primary concern in sea transport is humidity, which can lead to surface oxidation of copper wire, compromising both electrical performance and enamelling adhesion. To mitigate this risk, every palletized load is hermetically wrapped in multi-layer moisture-proof film. This film consists of a laminated aluminum-polyethylene composite with a vapor transmission rate below 0.1 g/m²/day, effectively creating a sealed microenvironment. Additionally, desiccant packs are strategically placed within the wrapping to absorb any residual moisture, further enhancing protection.

The entire wrapped unit is then overbanded with UV-resistant polypropylene straps to maintain film integrity during handling and prolonged exposure to variable climatic conditions in port storage. Labeling is executed using weather-resistant tags and barcodes, affixed to both the pallet and outer film, ensuring traceability and compliance with international shipping documentation standards.

Our packaging protocol has been validated through accelerated salt spray testing and real-world shipping data across major trade lanes, including trans-Pacific and trans-Indian Ocean routes. The result is a packaging solution that consistently delivers copper wire with unaltered surface quality, dimensional stability, and mechanical performance—critical attributes for seamless integration into high-speed enamelling lines.

For OEMs and wire processors, the reliability of incoming raw materials directly impacts production efficiency and product yield. By implementing a robust, scientifically designed export packaging system, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that our copper winding wire maintains its technical specifications from factory to final application, reinforcing our commitment to quality and customer success in the global marketplace.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Wire Enamelling Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical engineering expertise to deliver exceptional support for copper wire enamelling processes. Our factory integrates advanced material science with rigorous industrial protocols, ensuring your winding wire production achieves optimal thermal class performance, dielectric integrity, and mechanical durability. While our core heritage lies in high-purity aluminum strip manufacturing for transformers, our specialized technical division provides critical upstream solutions for copper wire enamelling—including substrate surface optimization, process parameter calibration, and failure mode analysis—directly addressing common industry pain points like enamel adhesion defects and thermal degradation.

Our enamelling production infrastructure features fully automated multi-layer coating lines capable of handling wire gauges from 0.02 mm to 5.0 mm. We operate six high-temperature enamelling ovens with precise pyrolysis control (±2°C stability) and inert gas shielding, enabling consistent application of polyester-imide, polyamide-imide, and nanocomposite coatings up to Class 240°C. Annual capacity exceeds 15,000 metric tons, supported by in-line laser micrometry for real-time diameter verification and automated spark testing at 3 kV/mm. This technical foundation is reinforced by ISO 9001 and IATF 16949 certified quality management systems, with every batch subjected to IEC 60317-compliant testing for elongation, thermal shock resistance, and chemical solvent resistance.

Metallurgical precision defines our value proposition. Our engineers utilize proprietary surface activation techniques to eliminate copper oxidation prior to enamelling, reducing interfacial voids by 30% compared to industry averages. This is validated through cross-sectional SEM analysis and peel strength testing (minimum 1.2 N/mm). Supply chain resilience is engineered through vertical integration: we control copper rod sourcing via LME-grade electrolytic tough pitch (ETP) procurement and maintain strategic raw material buffers for resins and solvents, mitigating volatility in global markets. Logistics leverage our central Henan Province location, with direct rail access to Shanghai Port enabling 15-day FOB lead times for 40HQ containers.

Partnering with Xinzhaohe means accessing embedded process intelligence. Our technical team provides onsite support for oven temperature profiling, viscosity control of enamel baths, and troubleshooting common defects like orange peel or pinholes. We maintain a digital twin of your production parameters to simulate adjustments before implementation, reducing trial runs by 40%. This collaborative approach ensures your enamelled wire meets stringent automotive (AEC-Q200) and renewable energy sector demands without compromising throughput.

Initiate a technical consultation with our engineering team to optimize your copper wire enamelling yield and performance. Contact Cathy Zhang at cathy@transformerstrip.com to request our process capability dossier or schedule a metallurgical audit of your current production line. Let Xinzhaohe’s two decades of industrial materials expertise become your competitive advantage in winding wire innovation.

| Key Capability | Specification | Industry Benchmark |

|---|---|---|

| Thermal Class Attainment | Class 180 to 240°C (IEC 60317) | Class 155–200°C standard |

| Coating Uniformity (CV%) | ≤ 2.5% (measured via X-ray fluorescence) | ≤ 4.0% typical |

| Production Lead Time | 12–18 days (FOB Shanghai) | 20–30 days industry average |

| Defect Rate (ppm) | < 850 ppm (spark test failures) | 1,200–2,000 ppm |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper wire enamelling process directly from China.