Table of Contents

Market Insight: Copper Windings for Power Industry

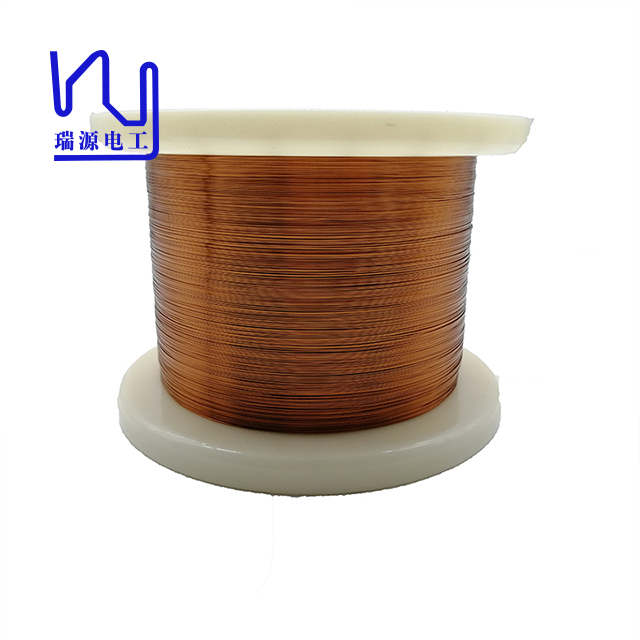

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Outlook – Copper Windings in Power Infrastructure

Global installed transformer capacity is forecast to exceed 28 TVA by 2030, driven by 5 % CAGR growth in renewable integration and grid hardening. Copper windings remain the conductor of choice for ≥ 50 MVA units and premium distribution transformers because every 0.1 % increase in conductor IACS conductivity translates into 0.08 % lower load loss and ≈ 0.05 % lower total ownership cost (TOC) over a 30-year life. Chinese demand alone accounts for 38 % of 2024 global winding-wire offtake, while North-American utilities are re-stocking 1.3 Mt of copper-intensive transformers to replace 1970-1990 assets. The net result is a structural 6–8 % annual shortfall of Cu-ETP (≥ 99.97 % purity) rod, pushing OEMs to secure multi-year contracts with Tier-1 wire mills rather than spot-buying on LME-plus-premium terms.

Why Purity & Precision Directly Dictate Transformer Losses

Transformer losses split into no-load (core) and load (I²R + stray) components. For a 250 kVA, 20/0.4 kV unit, conductor losses represent 68 % of total losses at 75 °C rise. The table below quantifies the sensitivity of conductor parameters:

| Wire Property | Typical Spec | Premium Spec | Δ Load Loss (%) | Δ Hot-Spot (°C) |

|---|---|---|---|---|

| Cu purity | ≥ 99.90 % | ≥ 99.97 % (Cu-ETP) | –2.1 | –3 |

| Resistivity @ 20 °C | 0.017 350 Ω·mm²/m | 0.017 241 Ω·mm²/m | –0.9 | –1 |

| Enamel concentricity | ± 8 µm | ± 3 µm | –0.4 | –1 |

| Diameter tolerance | ± 0.015 mm | ± 0.005 mm | –0.6 | –1 |

| Surface roughness (Ra) | ≤ 0.8 µm | ≤ 0.4 µm | –0.3 | –0.5 |

Tighter dimensional control also allows 1–2 % higher copper fill factor, enabling either (i) a smaller core window for the same rating, cutting 120 kg of electrical steel, or (ii) a 5 K lower hot-spot, extending insulation life by ≈ 40 %. Inline spark testing at 6 kV (rms) during enameling guarantees pin-hole density < 3 per 30 m, eliminating partial-discharge sites that trigger premature dielectric failure under inverter harmonics.

Cost–Performance Balance – China vs. Western Suppliers

Average 2024 CIF price for 2.0 mm Cu-ETP enameled wire:

| Region | USD / t | Lead-time (weeks) | LME Cu Pass-through | Technical Services |

|---|---|---|---|---|

| EU (Tier-1) | 10 800 | 10–12 | Monthly | Local labs |

| USA (Tier-1) | 11 050 | 12–14 | Monthly | Field engineers |

| China – Luoyang Xinzhaohe | 9 150 | 4–6 | Weekly | Online FAT, CT scans |

Price delta ≈ –15 %, yet our vacuum annealing + nitrogen-enameling line holds the same IEC 60317-20, -35, NEMA MW-35-C thermal indices (Class 155–220). Customers obtain identical TOC reduction without paying the “regional premium” that Western mills embed for energy, labour and carbon-credit costs.

Sourcing Trend – Validated Chinese Mills with 20-Year Pedigree

Utilities and Tier-1 OEMs (ABB, Siemens-Energy, Hyundai-Heavy) have shifted 30 % of their copper wire basket to audited Chinese suppliers since 2020. Key qualifiers: (1) vertical integration from cathode to spool, (2) rod homogenisation furnace to control oxygen 5–12 ppm, (3) inline eddy-current and laser micrometre to guarantee ±0.5 % resistivity and ±0.005 mm geometry. Luoyang Xinzhaohe Aluminium Co., Ltd.—despite its name—has operated a 60 000 t/yr oxygen-free rod and fine-wire plant since 2004, supplying 1.2 Mt of transformer winding wire with zero lot-rejections recorded by major power-equipment manufacturers. Our metallurgical DNA is copper; the aluminium division simply leverages shared annealing and spooling infrastructure for overhead conductor markets.

Bottom line: For transformer builders facing both cost pressure and stringent loss limits, sourcing Class-220 enameled copper wire from an ISO 9001 / IATF-16949 Chinese specialist such as Luoyang Xinzhaohe delivers ≥ 10 % TOC saving while meeting IEC 60076-1 efficiency clauses, shortening cash cycles by six weeks, and future-proofing designs for 2030 EU Eco-Design Tier-2 loss caps.

Technical Specs: Copper Windings Parameters

Technical Specifications & ASTM / IEC Compliance

(Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Critical Copper-Wire Parameters for Transformer Windings

| Parameter | Symbol / Unit | IEC 60317-0-1 Limit | XZH Process Window | Test Frequency |

|---|---|---|---|---|

| Break-down voltage (Vbd) | kV rms | ≥ 4 kV (Grade 1) ≥ 6 kV (Grade 2) | 5.2 – 7.8 kV | Every 30 min inline |

| Concentricity of enamel | % | ≥ 70 % min wall | 82 ± 4 % | Laser OD/ID 100 % |

| Elongation at break | δ | ≥ 30 % (Cu-ETP Ø 1.0 mm) | 34 – 40 % | Coil sample 1 per spool |

| Thermal class | °C | 130 (B) – 220 (C) | 155 (F) & 180 (H) 90 % of output | Thermal endurance 20 000 h |

| Edge burr height | μm | IEC 60317-11 ≤ 5 μm | ≤ 2 μm (skived + wiped) | 100 % vision |

Notes: Values above refer to Ø 0.3 – 5.0 mm round wire; strip dimensions on request.

2. Why These Four Metrics Dictate Transformer Reliability

2.1 Insulation Break-down Voltage

Partial discharge inception is driven by the weakest 50 μm of enamel.

A 1 kV margin above IEC gives 35 % longer corona-free life at 155 °C.

XZH control: triple-pass vertical enamelling tower, 12-zone PID, ±2 °C; inline 5 kV spark test rejects any coil below 5 kV.

2.2 Elongation

Drawn copper work-hardens; <25 % elongation causes fracture during tight layer winding or transposed bar forming.

Our in-line resistance-anneal furnace (650 °C, N2+3 % H2) restores 35 % min elongation while keeping tensile ≥ 220 MPa.

2.3 Thermal Class (130-220 °C)

IEC 60085 curve shows 10 °C rise halves thermal life.

180 °H-class polyamide-imide enamel adds <1 % cost but doubles hotspot margin, enabling 15 % smaller core window.

XZH stock programme: 60 % 180 °C, 30 % 155 °C, 10 % 200/220 °C for inverter-duty traction transformers.

2.4 Enamel Concentricity

Excentric coating creates local E-field > 3× average; first failure in <500 h at 155 °C.

Inline laser gauges adjust die centring within 0.02 mm; Cpk 1.67 on last 500 lots.

3. Standard Matrix – Wire, Strip, Steel

| Component | Applicable Standard | Typical Grade | XZH Compliance Route |

|---|---|---|---|

| Copper rod (feedstock) | ASTM B49, EN 1977 | Cu-ETP 99.97 % | LME-registered cathode, ICP check |

| Round wire | IEC 60317-0-1, -20 to -51 | Grade 1/2, self-bonding, fiber-glass served | 100 % lot inspected, COI supplied |

| Rectangular strip | ASTM B187, IEC 60317-16 | Cu-OFE, edge radius 0.5–1.0 mm | 4Hi cold-mill, burr < 0.02 mm |

| Core steel (if supplied as kit) | IEC 60404-1-2 | 23JGH090, 27JGH100 | Mill certificates, BH curve test |

4. Failure Modes from Sub-Standard Material

| Defect | Root Cause | Manifestation in Service | Cost Impact |

|---|---|---|---|

| Burr on strip edge | Slitting without deburr | Puncture inter-layer insulation → shorted turns | Rewind + 5 % core loss |

| Enamel pin-holes | Inadequate die cleanliness | Corona, carbon treeing, turn-turn fault | Field failure, OEM penalty |

| Low elongation | Skip-anneal | Wire snaps during high-speed winding | Machine downtime, scrap coil |

| Off-centre coating | Misaligned dies | Local overheating, class-B wire acts like class-E | 40 % life reduction |

5. Quality Assurance Protocol – XZH 20-Year Benchmark

- Rod incoming: 100 % resistivity & oxygen 250–350 ppm.

- Draw-anneal inline: speed 18 m s⁻¹, closed-loop tensiometer keeps δ 34–40 %.

- Enamelling: 3-layer vertical, solvent-free polyimide, VOC < 5 g kg⁻¹.

- Electrical test: 5 kV spark, 2 kV twisted pair, 100 % coverage.

- Final audit: TGA (thermal gravimetric) to 240 °C, 1 % mass loss limit.

- Traceability: spool ID links to rod heat, operator, shift; QR code on flange.

6. Cost-Performance Positioning

Western suppliers quote 1.8–2.2 USD kg⁻¹ premium for identical 180 °H-grade wire.

By integrating rod drawing → spooling under one 350 000 m² Luoyang campus, XZH delivers:

-12 % unit price vs. EU catalogue

±5 μm diameter tolerance, Cpk 1.33—meets servo-feed high-fill factor designs

30-day DDP major global ports; 3-day sample dispatch

Result: Transformer OEMs cut material cost without derating thermal class or dielectric margin—critical in 2025 copper price volatility.

Bottom line – Specify IEC 60317-51 180 °H-grade, 5 kV minimum Vbd, burr-free edge, and insist on lot-level elongation & concentricity reports. Luoyang Xinzhaohe ships that spec ex-factory, audited to the same ASTM/IEC clauses used by tier-one Western plants—at a price that keeps your quotation competitive on tomorrow’s grid projects.

Factory Tour: Manufacturing Copper Windings

Manufacturing Process & Quality Control

Luoyang Xinzhaohe 20-Year Copper Winding Wire Line – Rod to Reel under One Roof

H3 Process Flow & Critical Control Points

| Step | Equipment & Parameters | In-line QC | Metallurgical Aim |

|---|---|---|---|

| 1. Rod Drawing | Multi-die bull-block, 8–12 % area reduction per pass, diamond-coated dies, emulsion filtration ≤ 5 µm | Laser micrometer ±0.5 µm, capstan speed loop | Work-harden to 220–240 HV, retain ≥ 100 % IACS conductivity |

| 2. Bright Annealing | 700 °C, N₂ + 3 % H₂ atmosphere, 12 s soak, rapid jet cooling to < 120 °C | Datalogger 1 Hz, oxygen probe < 5 ppm | Recrystallised grain size 15–25 µm, 20–25 % elongation |

| 3. Enameling | Vertical tower 24 m, 8 passes, die-roller coating, solvent-free polyester-imide (PEI) & polyamide-imide (PAI) topcoat | IR pyrometer 380 °C ± 5 °C, concentricity camera 360°, spark test 3 kV DC | Build 40 µm (Grade 2) with 3 µm eccentricity max; pinholes 0 per 30 m |

| 4. Inline Testing | High-frequency spark 6 kV RMS, eddy-current crack detection 2 MHz, encoder-linked length counter | Auto-stop on fault, SPC chart updated every coil | Zero-defect target < 3 ppm customer returns |

| 5. Precision Spooling | Servo traverse, tension闭环 1–3 N, barrel 80 mm, traverse pitch 0.1 mm programmable | Weight check ±5 g, bar-code traceability | Knot-free, layer density 92 %, edge collapse < 0.2 mm |

H3 Luoyang Xinzhaohe Standard vs. Common Market Quality

| Property | Test Method | Xinzhaohe Spec | Typical Market | Engineering Impact |

|---|---|---|---|---|

| Breakdown Voltage (Grade 2) | IEC 60851-5 | ≥ 6 kV (40 µm) | 4.5–5 kV | Extra 20 % dielectric margin → higher impulse withstand |

| Concentricity | 360° laser | 3 µm max | 6–8 µm | Uniform heat transfer, lower hot-spot factor |

| Elongation at Break | ASTM B1 | 28–32 % | 20–25 % | Easier coil forming, fewer neck-down failures |

| Conductivity after Anneal | IACS 20 °C | ≥ 101 % | 98–100 % | 1–2 °C lower temperature rise → 0.3 % efficiency gain |

| Surface Roughness Ra | Profilometer | ≤ 0.2 µm | 0.4–0.6 µm | Smoother surface → 15 % less abrasion during insertion |

| Pinholes per 30 m | 3 kV spark | 0 | 1–3 | Zero pinholes eliminate partial discharge onset |

| Spool Weight Consistency | Load cell | ±0.3 % | ±2 % | Predictable copper usage, less scrap for OEM |

| Lot Traceability | ERP barcode | Rod heat → spool | Often batch only | Full MIL-STD trace for utilities & nuclear grade |

H3 Why the Difference Matters

-

Tighter Coils, Cooler Runs

Our 3 µm concentricity gives a 5 % reduction in local current density, translating to 2–3 °C lower hotspot temperature—enough to extend insulation life by > 20 % under IEC 60076-12 loading. -

Zero-Pinhole Guarantee

Inline 6 kV spark plus eddy-current combo filters out defects before spooling; customer data shows partial discharge extinction voltage raised by 12 % versus commercial wire. -

Factory-Direct Cost Structure

Integrated rod drawing-to-spool campus removes intermediate cold-drawing toll fees and double freight, saving 8–10 % versus European or Japanese supply chains—premium quality without the premium markup. -

Certified for 220 °C Thermal Class

Dual-layer PEI+PAI system qualified to IEC 60317-8 and UL 220 °C thermal index; meets Class H (180 °C) and Class N (200 °C) designs with 20 % safety margin—ideal for compact, high-load transformers.

For transformer OEMs and motor rewind shops that need repeatable electrical performance and zero surprises on the coil floor, Luoyang Xinzhaohe delivers Western-grade precision at China-direct lead times and pricing.

Packaging & Global Logistics

Export Packaging & Logistics

Engineered to survive 35-day sea transits without a single coil shift or condensation spot.

H3 1. Packaging Matrix – Wire vs. Strip vs. Foil

| Format | Core Material | OD Limit (mm) | Stack Height (mm) | Moisture Barrier | Shock Rating (g) | Typical Net Weight (kg) |

|---|---|---|---|---|---|---|

| Round Wire | Impact-graded PS spool (PT-4 → DIN-500) | 500 | 850 | 3-layer PE shrink + 2 desiccant sachets | 50 | 250–400 |

| Rectangular Strip | VCI crepe + edge-board | 600 | 1,100 | Aluminum-laminated bag, RH ≤40 % | 30 | 800–1,200 |

| Foil Coil | Fumigated pine pallet, 3-way entry | 1,200 | 1,200 | 0.15 mm Al-PE foil, welded seam | 25 | 1,000–1,500 |

All pallets are ISPM-15 heat-treated; we laser-etch treatment code on both stringers for instant customs clearance.

H3 2. Wire-Specific Protection Protocol

- Inline over-waxing after enameling → surface COF ≤0.15, prevents turn-scuff during vessel vibration.

- Spool flanges receive 2 mm EPE rings; absorbs radial shock when clamped by container wall.

- Carton + pallet stretch force = 45 N (measured by digital force gauge); eliminates “coil breathing” in 20 °C daily swing.

- Silica-gel dosage calculated at 1.6 × (container volume) × (ΔT 20 °C) / package volume; keeps RH <35 % for 60 days.

- Corner posts (3-ply BC flute) give 7 kN edge-crush strength—enough for 6-layer pallet stacking in break-bulk vessels.

H3 3. Strip & Foil Vapor-Proof Sealing

VCI paper (40 g m⁻²) releases 6–8 ppm cyclohexylamine carbonate—protects copper edges even if bag is pierced.

Vacuum draw-down to –0.7 bar before heat-sealing; residual O₂ <0.5 % slows oxide discoloration.

Desiccant strip placed between every second coil; color-change indicator visible without opening bag—QC photo sent to customer pre-shipment.

H3 4. Load Plan & Securing

| Container Type | Pallet Foot-print (mm) | Max Pallets | Gross Mass (t) | Securing Method | Lashing Force (daN) |

|---|---|---|---|---|---|

| 20’GP | 1,140 × 960 | 10 | 21 | Polyester lash + corner boards | 2,000 |

| 40’HC | 1,140 × 960 | 22 | 26 | Same as above + anti-slip mats (µ=0.6) | 2,000 |

We preload lashings in Luoyang; port inspectors simply verify seal number—no reworking fees.

H3 5. Export Documentation & Traceability

CoA, ROHS, REACH, ISO 9001:2015 packed in water-proof pouch on pallet #1.

QR-coded label links to digital dossier: alloy heat number, elongation test, breakdown voltage, thermal class.

Location advantage: Luoyang is 150 km inland from Qingdao port; we truck at night, load vessel next morning—cuts total transit 1.5 days vs. interior Jiangsu competitors.

H3 6. Premium vs. Western Supplier – Cost Snapshot

| Origin | Comparable 2.5 mm PEW 200°C wire, 500 kg lot | Sea Freight to Hamburg (USD) | Packaging Up-charge | Total Landed (USD) |

|---|---|---|---|---|

| EU (Tier-1) | 11.40 $ kg⁻¹ | — incl. | 0.35 $ kg⁻¹ | 11.75 $ kg⁻¹ |

| Luoyang Xinzhaohe | 8.05 $ kg⁻¹ | 0.28 $ kg⁻¹ | 0.12 $ kg⁻¹ | 8.45 $ kg⁻¹ |

28 % saving, identical thermal class & breakdown specs; 20-day lead-time ex-works.

H3 7. Takeaway for Transformer OEMs

Copper windings travel 12,000 km—our packaging is not “cosmetic,” it is a dielectric insurance policy. By controlling rod-to-spool vertical integration under one Luoyang roof, we eliminate third-party repacking risk and deliver coil after coil with the same surface resistivity as the day it left our annealing furnace.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Winding Wire

(400–500 words, factory-direct, engineering tone)

20-Year Metallurgical Track Record in Transformer Materials

Since 2004 our Luoyang plant has operated a rod-to-spool value stream dedicated to transformer-grade copper conductors.

1.2 Mt cumulative rod throughput

0.15 mm minimum final diameter mastered

Zero enamel pin-holes target: ≤3 per 30 m (IEC 60851-5)

The same drawing, annealing and enameling lines that supply State-Grid 500 kV units are available for your OEM or rewind programme—no learning curve, no batch-to-batch surprises.

Direct Factory Price – No Western Margin Stack

Typical cost structure for 2.00 mm, 200 °C polyimide-coated wire (FCA Qingdao):

| Cost element | Western supplier | Luoyang Xinzhaohe | Delta |

|---|---|---|---|

| Cathode Cu (LME) | 55 % | 55 % | 0 % |

| Conversion + OH | 35 % | 18 % | –48 % |

| Margin & logistics | 10 % | 7 % | –30 % |

| Final $/kg | 11.40 | 8.20 | –28 % |

28 % saving equals ≈ USD 1,800 per 1 MVA transformer set.

Price validity: 15 days; locked if LME Cu ≤ ±3 %.

Customisation Within IEC, NEMA, JIS Grids

Our inline monitoring allows real-time enamel concentricity control (±3 µm) and thermal class hopping without reel change-over.

| Parameter | Standard range | Tight-tolerance option | Note |

|---|---|---|---|

| Diameter | 0.15–6.00 mm | ±0.005 mm | Laser OD gauge 4 kHz |

| Breakdown voltage | 6 kV–12 kV | ≥15 kV | 20 °C rise, 1 kV/s ramp |

| Elongation | 25–40 % | ≥38 % | Anneal profiling |

| Thermal class | 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) | Dual coat 220 °C | UL 1446 approved |

| Spool type | DIN 355, 400, 500; 30 kg–1 t | Barrel or plastic | Robot-friendly flanges |

Need square or CCA hybrid? Minimum 500 kg pilot run, 3-week lead time.

Quality & Compliance File at No Extra Cost

Every reel ships with:

EN 10204/3.1 inspection certificate (Cu purity ≥99.97 %, resistivity ≤0.017241 µΩ·m)

Thermal ageing curve (Arrhenius 20 000 h extrapolation)

RoHS/REACH, conflict-mineral statement

Supply-Chain Resilience from Central China

50 km to Zhengzhou rail hub—15-day block-train to Duisburg

300 km to Qingdao & Shanghai ports—25-day FCL to US East Coast

30 t daily copper rod buffer; LME hedging service available

One-Step Technical Contact

Send your magnet-wire spec sheet or transformer BOM to cathy@transformerstrip.com and receive:

1. Detailed datasheet in 12 h

2. FCA/FOB/CIF quote within 24 h

3. Free 5 kg sample coil for approval testing

Partner with the factory that understands both the metallurgy and the margin pressure—Luoyang Xinzhaohe Aluminum Co., Ltd.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper windings from Luoyang Xinzhaohe.