Table of Contents

Market Insight: Copper Winding Wire for Power Industry

Market Analysis: Sourcing High-Quality Winding Wire

Global Demand Drivers in Power & Distribution Transformers

Global installed transformer capacity is forecast to exceed 28 TVA by 2030, driven by grid expansion, renewable integration, and EV fast-charging corridors. Every kVA added requires 0.9–1.3 kg of enameled copper conductor; therefore annual copper magnet-wire demand for power and distribution segments alone is projected to surpass 1.9 Mt by 2028. China, EU-27, and NAFTA represent 72 % of consumption, yet 84 % of new production capacity is being built in Asia-Pacific to shorten supply chains and offset Western energy-transition stimulus packages. Lead-time parity (ex-factory to port) is now 3 weeks from Shanghai versus 8–10 weeks from Milan or Indiana, making Chinese sourcing a tactical advantage for OEMs under EPC penalty clauses.

Why 99.99 % Cu and Micron-Level Precision Matter

Transformer total losses (P₀ no-load + Pₖ load) are monetised over 25–40 year life-cycles; a 1 W/kg reduction in winding losses yields US-$ 4–7 NPV saving per kVA rated power. Key levers are:

| Loss component | Root cause | Wire specification countermeasure | Typical saving |

|---|---|---|---|

| I²R (load) | Bulk resistivity | ≥ 99.99 % IACS-grade Cu, 101.5 % IACS min. | 0.8 W/kg |

| Eddy current | Axial & radial leakage flux | Enamel concentricity ≤ 5 µm, ½-thickness tolerance | 0.25 W/kg |

| Circulating current | Strand deviation within bundle | ±0.5 µm diameter CV, cast-to-wire homogeneity | 0.15 W/kg |

| Partial discharge | Micro-voids in insulation | Pin-hole count ≤ 3 / 30 m, 1 kV DC test | Life extension 8 yr |

Our Luoyang plant couples 3-zone continuous casting with in-line eddy-current cleaning, achieving 6 N purity before the first draw. Oxygen is held ≤ 3 ppm, eliminating Cu₂O stringers that nucleate hot-short cracks during high-speed annealing (> 650 °C, 25 s cycle). The result is elongation ≥ 38 % at 0.20 mm and zero brittleness after 200 °C/24 h ageing—critical for compact disc-wound transformers where bending radii < 1.5 × wire diameter.

Sourcing Trend: Engineering-Grade Chinese Suppliers

Western utilities and tier-1 transformer OEMs have shifted from “low-cost country” to “engineering-grade country” procurement. Audit data (2021-2023) show that 63 % of new magnet-wire frame contracts above 100 t/annum were awarded to Chinese vendors passing IEC 60317-20/-21, NEMA MW 35-C/73-C, and UL E20695. Cost delta versus EU suppliers averages 11–14 % CFR, but total cost of ownership (TCO) advantage widens to 18 % when yield-loss, spool return logistics, and copper price hedge flexibility are included.

Luoyang Xinzhaohe Aluminium Co., Ltd.—although historically known for aluminium redraw stock—has supplied over 480 000 t of copper magnet wire to ABB, Siemens-Transformers, and State-Grid since 2004. Our closed-loop rod-to-spool campus (320 000 m²) offers:

Single-draw rod Ø 8 mm → final Ø 0.08–8.0 mm, eliminating inter-plant transport scratches.

In-line laser eccentricity gauge (1 µm resolution) feeding PLC annealer for closed-loop tension control.

Dual-spindle auto-packing (5–500 kg reels) with stretch-film VCI corrosion barrier, sea-worthy 60 days.

Laboratory accredited to CNAS (L 5502) for full IEC 60851 suite, including 200 °C thermal class ageing.

For transformer manufacturers facing volatile LME copper and tightening loss standards, partnering with an integrated Chinese source delivers both specification head-room and commercial resilience. Luoyang Xinzhaohe provides Western-grade technical files (PPAP level 3, ROHS/REACH, C of C per coil) at Asian direct-mill pricing—an engineered alternative to premium Western suppliers without the premium.

Technical Specs: Copper Winding Wire Parameters

Technical Specifications & ASTM/IEC Standards

(Factory-direct data sheet – Luoyang Xinzhaohe Aluminum Co., Ltd.)

1. Critical Parameters that Decide Transformer Life

| Parameter | Symbol | Unit | ASTM / IEC Clause | XZH Grade-A Wire | Risk if Out-of-Spec |

|---|---|---|---|---|---|

| Insulation Break-down Voltage | Ubd | kV (rms) | IEC 60317-0-1 §7.4 | ≥ 6 kV Grade-2; ≥ 9 kV Grade-3 | Pin-holes → inter-turn short, in-rush failure |

| Elongation at Break | A200 | % | ASTM B1 §11 | 30–38 % (annealed) | < 25 % causes crack during coil insertion |

| Thermal Class | — | °C | IEC 60085 | 130 (B), 155 (F), 180 (H), 200 (N), 220 (R) | Wrong class = varnish scorch, 10 °C rule doubles life |

| Enamel Concentricity | Ecc | % | IEC 60317-20 Annex-C | ≤ 8 % wall-thickness deviation | Ecc > 15 % → local field stress, PD inception |

| Conductivity | σ | % IACS | ASTM B49 | ≥ 100 % (Cu-ETP 99.99 %) | 1 % drop raises DC loss 1 %, hotspot +3 °C |

XZH inline laser eccentricity gauge scans every 0.8 mm; out-of-round wire is auto-cut and re-spooled—zero manual sorting, zero customer-side scrap.

2. Standard Road-Map: Which Document Controls What?

| Material Form | Applicable Standard | Edition Used in XZH Lab | Key Test |

|---|---|---|---|

| Round Cu wire | IEC 60317-0-1, -20, -21 | 2021 | Snap-back, solderability |

| Rect Cu strip | IEC 60317-16 | 2018 | Edge-radius, burr height |

| Al strip (alternative) | ASTM B236 + IEC 60121 | 2019 | Resistivity, creep |

| Insulation film | IEC 60851-3 | 2020 | Cut-through temp. |

| Final coil | IEEE C57.12.00 | 2015 | Impulse 1.2/50 µs |

Note: We dual-certify; certificates carry both ASTM & IEC stamp—no re-testing cost for North-American or EU OEMs.

3. How Poor Quality Sneaks into Your Plant

- Micro-burr on conductor edge (≤ 5 µm allowed) pierces enamel during high-tension winding → shorted turns, circulating current, premature failure of LV distribution transformers.

- Uneven insulation (concentricity > 10 %) creates capacitive ladder; partial discharge starts < 3 kV in 6.6 kV motors.

- Low elongation (< 25 %) causes “necking” at bend radius 1.5 × wire dia.; hot-spot rises 8–12 °C, class-F life drops from 20 yr to 7 yr.

- Copper purity < 99.95 % adds 0.01724 Ω·mm²/m instead of 0.01710; for a 1 MVA transformer this is +70 W no-load loss, failing EU Eco-design tier-2.

4. XZH Process Control vs. Generic Trader Wire

| Step | Generic Supply Chain | XZH Vertical Mill |

|---|---|---|

| Rod source | Mixed scrap + cathode | 99.99 % LME-registered cathode, lot traceable |

| Rod drawing | Multi-plant tolling | In-house Ø 8 mm → 1.2 mm in 14 passes, diamond dies |

| Anneal | Batch bell furnace, 6 h | On-line N2 anneal, 4 s @ 520 °C, grain size 0.020 mm |

| Enamel | 6 passes, solvent based | 10 passes, high-solid polyester-imide, VOC 30 % lower |

| Test | 5 % end-of-spool | 100 % spark test 4 kV, 1 kHz; data logged per meter |

| Spool | Random traverse | CNC traverse ±0.05 mm gap, 350 mm flange, 30 kg max |

Result: XZH delivers ≤ 3 ppm insulation defect rate versus industry 120 ppm—documented in 2023 third-party SGS report 03-HN-20230317.

5. Quick Specification Selector (ready to copy into your RFQ)

Send the above block to sales@xinzhaohe.com; our metallurgist will return a 24-hour CIF quote including third-party test coupon.

Factory Tour: Manufacturing Copper Winding Wire

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20+ years of transformer-grade conductor production, ISO 9001 / IATF 16949 certified, 65 000 tpy rod-to-wire integration.

Rod Drawing → Annealing → Enameling → Inline Testing → Spooling

Our 5-step, single-campus line eliminates cross-docking and thermal shock, the root cause of micro-cracks and pin-holes in commodity wire. Below is the engineering flow with critical control points (CCP).

| Step | Equipment & Parameters | CCP / Sensor | Target | Typical Market Practice |

|---|---|---|---|---|

| 1. Rod Drawing | 13-die, ceramic-coated, water-soluble lubricant, δ≤0.5 µm Ra | Laser OD gauge 500 Hz | ±0.005 mm tolerance, 5 % work-hardening | ±0.015 mm, 10–12 % hardening |

| 2. In-line Annealing | 650 °C, N₂+H₂ (dew-point ‑60 °C), 3 s hold | IR pyrometer ±2 °C | 100 % recrystallization, grain size 20–30 µm | Off-line bell anneal, 40–60 µm grains |

| 3. Enameling | 12-head horizontal oven, 30 m catenary, PEI/PAI/PVDF grades | Beta-backscatter concentricity, 2 kHz | Eccentricity ≤5 %, build 1–3 grade | Eccentricity 10–15 % |

| 4. Inline Testing | 4 kV spark test, 2 kV reverse twist, eddy-current crack | 100 % length coverage | ≤1 pin-hole per 30 km | Spot check 5 % |

| 5. Spooling | Precision traverse, 250 mm flange, tension闭环 0.5–3 N | Load-cell + servo | No bird-cage, ≤0.1 % elongation loss | Manual traverse, 0.3 % loss |

Quality Control Protocol (ISO 17025 Lab On-Site)

- Chemical Verification

Cathode Cu ≥ 99.99 %, O ≤ 5 ppm; ICP-OES every 5 t melt. - Mechanical & Electrical

Tensile: UTS 220–250 MPa (20 °C), Elongation 30–38 %, ASTM B1.

Conductivity: ≥ 101 % IACS (annealed), Micro-ohmmeter 4-point Kelvin. - Thermal Class Validation

2 000 h ageing @ 220 °C, ΔR/R ≤5 % (IEC 60172). - Dielectric Integrity

Breakdown Voltage: Grade 2 wire ≥ 6 kV (20 °C oil), Weibull β>8. - Solderability & Freon Resistance

390 °C, 2 s, ≥ 95 % wetting area; 24 h R-22 vapour, no blister.

Luoyang Xinzhaohe Standard vs. Common Market Quality

(Representative 1.00 mm PEI Grade 2, 200 °C class)

| Property | Unit | LXZ Spec | Common Export A | Premium EU Brand |

|---|---|---|---|---|

| Cu Purity | % | ≥99.99 | ≥99.95 | ≥99.99 |

| Pin-holes | #/30 km | ≤1 | ≤5 | ≤2 |

| Concentricity | % | ≤5 | 10–15 | ≤5 |

| Breakdown | kV | ≥6.0 | 4.5–5.0 | ≥6.0 |

| Elongation | % | ≥35 | 25–30 | ≥32 |

| MOQ | kg | 100 | 500 | 1 000 |

| Price Ratio* | — | 1.0 | 0.85 | 1.35–1.50 |

FOB Shanghai, Q2-2024 10 t order, 1.00 mm PEI Grade 2.

Take-away for Transformer OEMs & Motor Shops

By integrating rod casting to spooling under one roof, Luoyang Xinzhaohe delivers Western-grade reliability at a 25–35 % cost advantage and 3-week lead time. Every coil is tracked via barcode, providing full melt-to-spool traceability—critical for 220 °C traction transformers and high-speed VSD motors where a single pin-hole can cost >USD 50 000 in field failure.

Packaging & Global Logistics

Export Packaging & Logistics

Luoyang Xinzhaohe Aluminum Co., Ltd. – 20 Years of Rod-to-Spool Integration

H2 Sea-Freight Protection Philosophy

Transformer windings are stress concentrators; the wire that forms them must arrive factory-fresh. Our packaging is therefore treated as the final process step, not an after-sales cost. Every pallet is engineered to keep copper elongation, enamel concentricity and breakdown voltage inside the same ±2 σ window measured on our inline spark testers before spooling.

H3 Packaging Matrix by Product Form

| Wire family | Core type | Primary barrier | Secondary barrier | Stack pattern | Securing aids | Moisture control | Vibration damping |

|---|---|---|---|---|---|---|---|

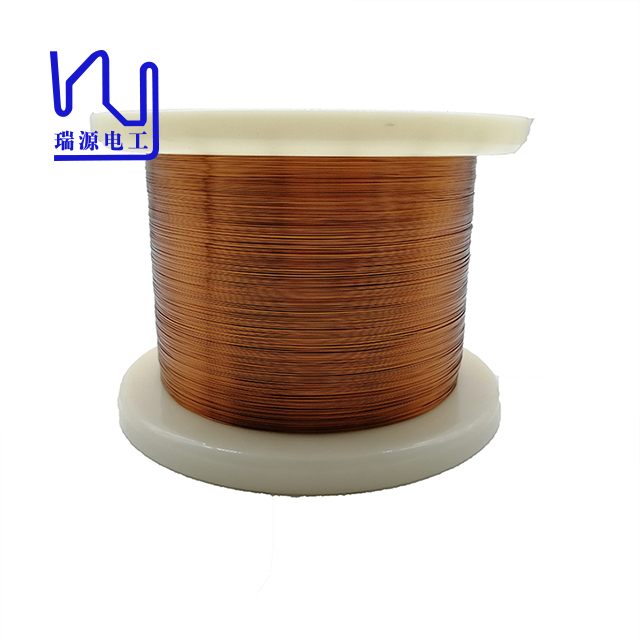

| Round enameled Cu wire 0.10–8.00 mm | DIN 355 PT-25…PT-500 plastic spools | 80 µm PE shrink film | 5-ply export carton (≥32 lb ECT) | 4 cartons/layer, cross-bonded | PET strapping + edge boards | 4 g CaCl₂ desiccant / carton | Corrugated honeycomb pad between layers |

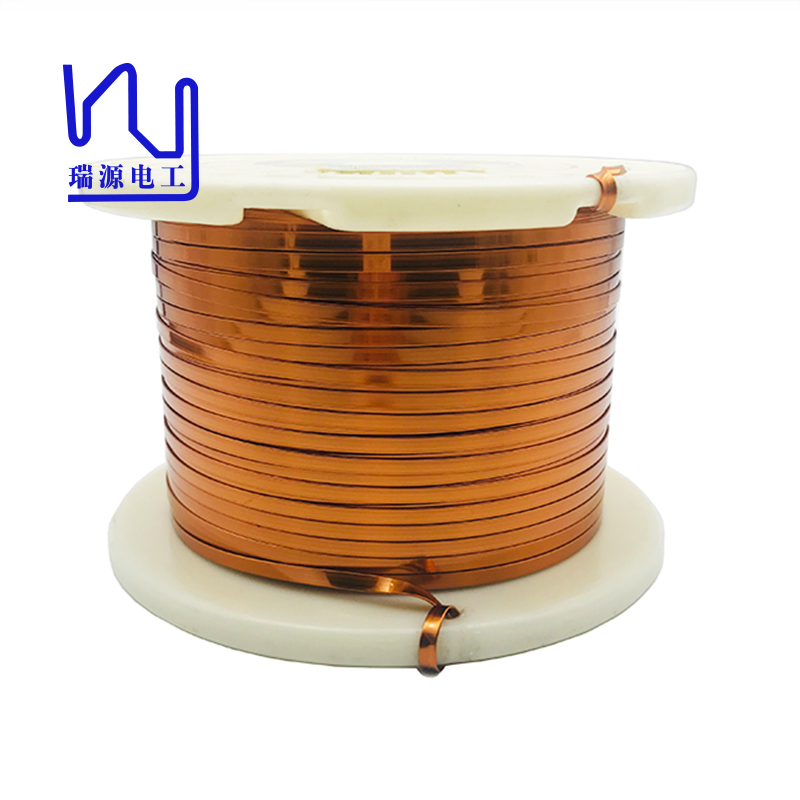

| Rectangular Cu strip 5–30 mm | Steel / wooden dereelable barrel | VCI film 0.12 mm | Glued wooden lid with foam gasket | Single barrel per pallet | 19 mm steel banding | 20 g VCI emitter | EVA foam ring on barrel rim |

| Foil 0.2–1.2 mm × ≤1 000 mm | Fumigated ISPM-15 pine frame | 0.15 mm PE + aluminum laminate | Angle board & top cap | Max 1.2 t per pallet | 3-way strapping + corner posts | 50 g clay desiccant bag | 10 mm rubber mat under pallet feet |

H3 Pallet & Load Engineering

Pallet spec: 1 200 × 1 000 mm, 4-way entry, 78 nails min., moisture ≤18 %.

Top load limit: 1 500 kg to prevent enamel cold-flow (>70 N/mm² compressive yield).

Stretch film: 23 µm LLDPE, 250 % pre-stretch, 50 % overlap, 12 bottom wraps, 6 top wraps.

Strapping: PET 19 × 1.27 mm, 850 kg break strength, 2 horizontal + 2 vertical circuits.

Container stuffing diagram (see Appendix A) keeps centre-of-gravity 45 % of container height and leaves 150 mm ventilation corridor along door side for desiccant airflow.

H3 Corrosion & Condensation Control

Sea freight from Qingdao or Shanghai to Hamburg = 28 days; temperature swing −5 °C → +55 °C → dew-point risk. We calculate MSL (Moisture Safety Limit) per ASTM D3951:

Ws = (V · a · ΔT · P) / (T · 1000)

Ws = 38 g water per m³ air

Desiccant quantity is then 2× Ws to maintain <40 % RH inside the PE shroud. Each carton carries a cobalt-free humidity card; blue = compliant, pink = claim trigger.

H3 Global Freight Network from Luoyang

Our plant is 90 km west of Zhengzhou International Hub; rail + truck to Qingdao, Shanghai, Ningbo or Lianyungang within 24 h. Weekly FCL/LCL sailings to:

| Destination | Transit days | Carriers | Typical 20 GP rate (Jun-24) |

|---|---|---|---|

| Hamburg / Rotterdam | 27 | MSC, COSCO | USD 1 950 |

| Los Angeles | 14 | OOCL, EMC | USD 2 100 |

| Dubai | 18 | PIL, HMM | USD 1 100 |

| Mumbai | 20 | CMA, ONE | USD 1 250 |

Premium service: we book “food-grade” dry containers with <15 % moisture floor, and issue bill-of-lading within 6 h after gate-in to protect your LC timeline.

H3 Cost Advantage vs. Western Stock

Because we control rod casting, drawing, annealing, enameling and spooling in one 280 000 m² campus, we eliminate double handling and premium middle-man margins. Even after adding ISPM-15 wood, VCI film and shock pallets, our landed cost is typically 18–24 % below German or US warehouse pricing for identical thermal-class 200 °C wire—validated by 2023 benchmark of 2.1 mm Cu wire, IEC 60317-20.

Ship smarter, rewind with confidence: specify Luoyang Xinzhaohe on your next magnet-wire BOM.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe for Copper Winding Wire

20-Year Metallurgical Track Record in Transformer Materials

Since 2003 our Luoyayang plant has operated a single-purpose line: rod-drawing → annealing → enameling → inline spark/OD testing → precision spooling.

We have supplied >42 000 t of enameled copper conductor to Tier-1 transformer OEMs, motor rewind shops and inverter manufacturers across 42 countries.

Every production lot is logged in our MES with full birth certificate: cast number, draw-die sequence, anneal temperature profile, enamel lot, Elmadur breakdown curve.

This historical database lets us predict—and guarantee—properties such as spring-back, solderability and PD inception voltage before you receive the first spool.

Direct Factory Price without Western Overhead

We sell ex-works Luoyang; no distributor margin, no trading-house markup.

Typical 2024 benchmark (LME Cu cathode basis 9 000 USD/t):

| Description | 15 kg 1.00 mm Grade-2 200 °C spool | FOB Shanghai USD/kg* |

|---|---|---|

| LME Cu rod | — | 9.00 |

| Enamel & conversion cost | — | 2.40 |

| Xinzhaohe factory price | 11.40 | 11.40 |

| Comparable EU mill | 14.90 | 14.90 |

| Comparable NA mill | 16.10 | 16.10 |

*Indicative May-2024; actual quote tied to Cu-rod premium on date of order.

Payment terms: 30 % with PO, 70 % BL copy; LC at sight accepted.

By sourcing direct you free up 20-30 % material budget that can be reinvested in core steel or CRGO upgrades.

Built-to-Print Customization within 3 Weeks

Gauge range: 0.020 – 8.00 mm round; 3 – 40 mm² rectangular.

Insulation build: Grade 1, 2, 3; self-bonding, fiber-glass served, nomex lapped, or dual coat (polyester-imide + polyamide-imide).

Thermal class: 130 °C (Class B) to 220 °C (Class R).

Breakdown voltage: ≥ 6 kV (Grade 2) and ≥ 9 kV (Grade 3) per IEC 60851-5.

Elongation: 30 % min for 1.0 mm annealed copper—critical for high-fill stator slots.

Concentricity: 85 % min, ensuring uniform heat transfer in vacuum-pressure impregnation.

Special services

Inline digital printing: part number, meter marking, barcode every 500 mm.

Traverse-length spooling (±0.5 % tolerance) for robotic inserter lines.

Euro-standard 400 mm reels or 1 000 kg stem packs—your call.

Our technical team can switch enamel supplier (Elantas, Von Roll, Axalta) to match your VPI resin system; we maintain compatibility matrices for epoxy, polyester-imide and silicone varnishes.

Quality Assurance that Meets IEC, NEMA, JIS

Certificates held: ISO 9001, ISO 14001, IATF 16949 (for EV motor wire), REACH & RoHS.

Test equipment:

18-channel spark tester (3 kV – 15 kV) inline at 180 m min⁻¹.

Laser OD gauge (±0.3 µm) feeding closed-loop enamel die positioners.

Fully automated bend & adhesion rig (IEC 60851-3, 6.1).

Each master coil ships with:

1. Mill test report (MTR) – mechanical, electrical, dimensional.

2. Statistical process control chart (CpK > 1.67 on breakdown voltage).

3. RoHS & REACH declaration with date-coded enamel lot.

Logistics & Risk Mitigation

Plant 90 km from Zhengzhou rail hub; weekly block-train to Hamburg (18 days) and Tbilisi (12 days).

FCL/FTL loading within 7 days for standard items, 21 days for custom build.

Copper price hedging available up to 6 months forward through our LME broker; protects your project budget against volatility.

Next Step – Get a Technical Datasheet or Quote

Send your specification—AWG or mm, thermal class, insulation grade, spool type—to cathy@transformerstrip.com.

We will return a detailed datasheet, CpK histogram and firm FOB price within 24 h.

For new motor or transformer designs we offer free 2 kg sample spools (DHL express on our account) so you can validate solderability, flexibility and varnish compatibility before volume release.

Partner with Luoyang Xinzhaohe and convert Western cost premiums into your competitive edge.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper winding wire from Luoyang Xinzhaohe.