Table of Contents

Market Insight: Copper Tape

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

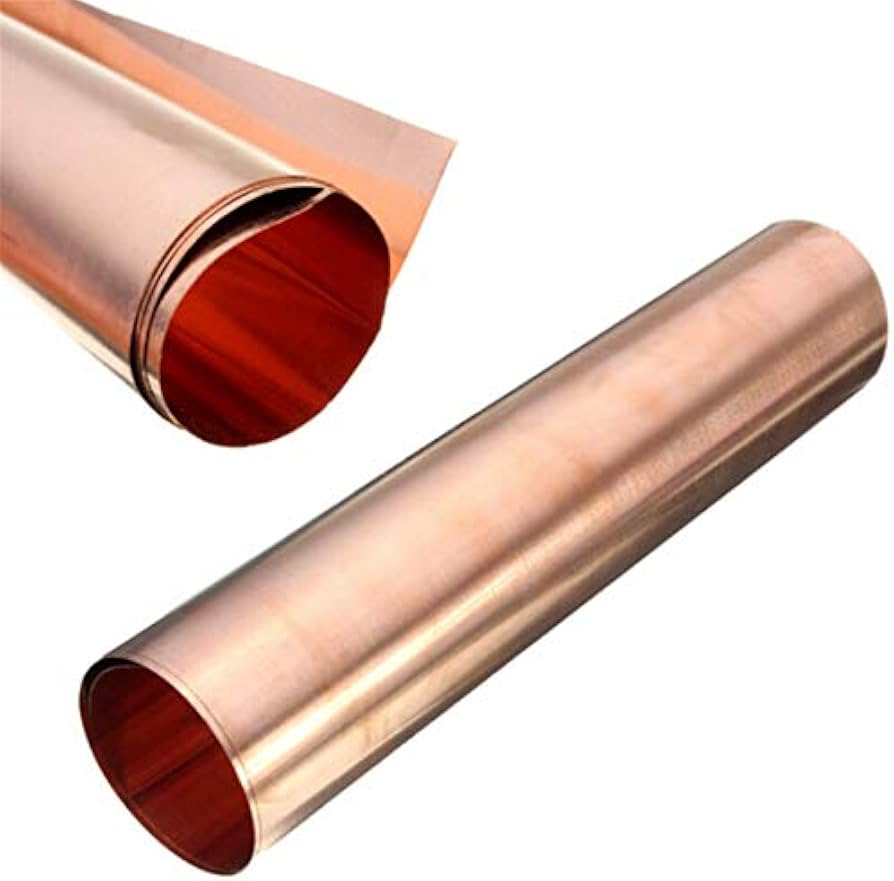

The global demand for copper tape in transformer manufacturing remains robust, driven by the continuous expansion of power transmission and distribution infrastructure, renewable energy integration, and industrial electrification. Copper tape, particularly in the form of strip and foil, serves as a critical conductive material in both power and distribution transformers, where its high electrical conductivity, thermal stability, and mechanical formability are essential. As grids modernize and energy efficiency standards tighten, the performance of core components such as windings—typically fabricated from copper or aluminum strip—has become a focal point in transformer design and reliability.

Copper tape is predominantly used in low-voltage windings and high-current applications due to its superior conductivity (approximately 100% IACS) compared to aluminum (approximately 61% IACS). This property allows for reduced resistive losses, improved thermal management, and enhanced overall transformer efficiency. In distribution transformers, especially those deployed in urban and high-load environments, copper strip enables compact designs with higher overload capacity and longer service life. The precision of the tape’s dimensional tolerances—thickness, width, and edge quality—directly influences winding consistency, which in turn affects magnetic balance, short-circuit withstand capability, and noise levels.

Industrial demand is further amplified by the rise of specialty transformers used in traction systems, renewable inverters, and industrial drives, where reliability under fluctuating loads is paramount. In such applications, the quality of copper tape cannot be compromised. Impurities, surface defects, or inconsistent mechanical properties can initiate localized heating, insulation breakdown, or premature failure. For instance, even minor edge burrs or waviness in the strip can damage insulation paper during winding, leading to dielectric weaknesses and potential in-service faults.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in non-ferrous strip production, we recognize that material quality is not a secondary attribute but a foundational element of transformer performance. Our copper tape manufacturing adheres to stringent international standards, including ASTM B187 and IEC 60137, with rigorous in-process controls on purity (minimum 99.90% Cu), tensile strength (200–250 MPa), and elongation (≥4%). All strips undergo edgewise bending tests, surface roughness evaluation, and precise thickness profiling via laser gauging to ensure compatibility with high-speed winding equipment.

The shift toward smart grids and energy-efficient transformers (e.g., meeting DOE 2016 or EU EcoDesign Level I–III standards) further elevates the importance of high-quality copper tape. Transformers designed for lower no-load and load losses rely on optimized conductor materials to meet regulatory benchmarks. Inferior tape may reduce initial costs but often results in higher lifecycle expenses due to inefficiencies and maintenance.

In summary, the industrial demand for copper tape in transformers is sustained by technical requirements rather than mere volume. As a trusted supplier in the transformer strip and foil sector, Luoyang Xinzhaohe Aluminum Co., Ltd. emphasizes precision, consistency, and metallurgical integrity to support the evolving needs of global power systems.

Technical Specs: Copper Tape

Technical Specifications for Precision Copper Tape in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and precision slitting expertise to deliver high-performance copper tape for critical transformer components. While our core specialization includes aluminum transformer strip, we maintain rigorous copper processing capabilities aligned with global electrical standards. Copper tape selection demands exacting tolerances to ensure optimal current distribution, thermal management, and core integrity in wound magnetic assemblies. Key specifications must address dimensional precision, electrical properties, and surface integrity to prevent insulation damage or eddy current losses.

Critical parameters are defined below, reflecting industry best practices for transformer-grade copper tape per ASTM B152 and IEC 60138 standards. All tolerances are maintained through controlled cold rolling, precision slitting, and in-line quality verification.

| Parameter | Specification Requirement | Measurement Standard |

|---|---|---|

| Thickness Range | 0.05 mm – 0.50 mm | ISO 11562 |

| Thickness Tolerance | ±0.002 mm | ASTM E8M |

| Width Range | 10 mm – 150 mm | ISO 7438 |

| Width Tolerance | ±0.05 mm | ISO 7438 |

| Edge Burr Height | ≤ 3 μm | Optical Profilometry |

| Edge Straightness | ≤ 0.1 mm/m | Laser Scanning |

| Electrical Conductivity | ≥ 100% IACS (min) | ASTM B193 |

| Tensile Strength | 200–250 MPa | ASTM E8M |

| Elongation | ≥ 5% | ASTM E8M |

| Surface Roughness (Ra) | ≤ 0.8 μm | ISO 4287 |

Precision slitting at ±0.002 mm thickness tolerance is non-negotiable for uniform winding tension and layer alignment in transformer cores. Deviations exceeding this threshold induce interlayer stress, increasing core loss and audible noise. Burr-free edges (≤ 3 μm) are equally critical; microscopic protrusions compromise insulation paper integrity during winding, creating pinhole defects that accelerate dielectric failure. We achieve this via diamond-tipped rotary shear systems with real-time edge monitoring, eliminating secondary deburring.

Conductivity must consistently meet or exceed 100% IACS (International Annealed Copper Standard), verified through four-point probe testing per ASTM B193. This ensures minimal resistive losses under high-frequency operation. Conductivity correlates directly with oxygen content and annealing homogeneity; our process utilizes high-purity C11000 electrolytic tough pitch (ETP) copper with controlled recrystallization to optimize grain structure. Mechanical properties balance formability and structural stability: tensile strength of 200–250 MPa prevents deformation during core stacking, while ≥5% elongation accommodates bending without cracking. Surface roughness ≤ 0.8 μm Ra minimizes air gaps between tape layers, enhancing thermal conduction and reducing hot-spot risks.

All batches undergo 100% eddy current testing for subsurface defects and conductivity uniformity, with traceable certification to ISO 9001:2015. Our supply chain integrates metallurgical process control from ingot casting through slitting, ensuring lot-to-lot consistency essential for transformer manufacturers scaling production. Partnering with Xinzhaohe mitigates yield loss risks in core fabrication while meeting stringent IEC 60204 safety compliance for electrical components.

Factory Tour: Manufacturing

Manufacturing Process of Copper Tape at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance copper tape for transformer applications at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, superior electrical conductivity, and mechanical consistency. With over two decades of expertise in non-ferrous strip and foil production, our facility integrates advanced metallurgical practices with precision engineering to meet the stringent demands of power and electronic industries.

The process begins with cold rolling, where high-purity electrolytic copper (typically C11000 or C10100 grade) is processed from hot-rolled coil stock. The incoming copper is first inspected for chemical composition and surface integrity. It is then fed into a reversing cold rolling mill under controlled tension and lubrication. Cold rolling reduces the material thickness to the target gauge, typically ranging from 0.05 mm to 0.5 mm, while enhancing mechanical strength and grain structure uniformity. The rolling parameters—roll force, speed, and interstand tension—are continuously monitored and adjusted via automated process control systems to maintain thickness tolerances within ±0.005 mm.

Following cold rolling, the copper strip undergoes precision slitting to achieve the required tape width. Utilizing high-precision rotary shear slitters with hardened tungsten carbide blades, the master rolls are longitudinally cut into narrow strips, commonly between 5 mm and 100 mm in width. The slitting line is equipped with laser-based edge tracking and tension control systems to minimize edge burr formation and ensure straight, parallel edges. Each slit coil is wound under constant tension using center-surface winding technology to prevent telescoping and edge damage.

Edge conditioning is the next critical phase, particularly for transformer-grade copper tape where edge smoothness directly impacts winding integrity and dielectric performance. The slit edges are subjected to mechanical edge rounding and deburring using precision brushing or roller burnishing systems. This step eliminates micro-burrs and sharp protrusions that could compromise insulation layers during coil winding. The degree of edge conditioning is verified through profilometric analysis, ensuring radius consistency along the entire strip length.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. In-process inspections include continuous thickness monitoring via beta-gauge systems, eddy current testing for surface defects, and periodic tensile and conductivity testing. Final product evaluation involves dimensional checks, surface roughness measurement (Ra), and visual inspection under controlled lighting. All batches are traceable through a lot-tracking system, with material test reports provided upon shipment.

This integrated approach—combining cold rolling, precision slitting, and edge conditioning within a disciplined QC framework—ensures that every copper tape product meets international standards such as ASTM B3 and IEC 60137, delivering reliable performance in high-efficiency transformer and inductor applications.

Packaging & Logistics

Export Packaging Specifications for Copper Tape

Copper tape integrity during ocean transit is critically dependent on engineered packaging systems that mitigate moisture ingress, mechanical stress, and atmospheric corrosion. At Luoyang Xinzhaohe Aluminum CO., Ltd, our 20+ years of metallurgical and supply chain expertise inform packaging protocols aligned with ISO 11607 and IATA hazardous materials handling standards for non-ferrous metals. Sea freight exposes copper to hygroscopic conditions, salt aerosols, and dynamic forces; inadequate packaging directly compromises conductivity and surface finish, leading to rejection upon customs inspection or end-use failure.

Wooden pallets form the structural foundation of our export packaging. All pallets comply with ISPM 15 regulations, utilizing kiln-dried hardwood (minimum 22 mm thickness) treated to 56°C for 30 minutes to eliminate biological hazards. Pallet dimensions are standardized at 1200 × 1000 mm to optimize ISO container cube utilization, with a static load capacity of 2500 kg and dynamic capacity of 1000 kg. Coils are secured via steel strapping (minimum 16 mm width, 15 kN tensile strength) anchored to pallet stringers, preventing lateral shift during vessel roll or crane handling. Edge protectors fabricated from 3 mm galvanized steel shield coil edges from strap-induced deformation.

Moisture protection employs a three-tier barrier system. Primary wrapping consists of 120-micron co-extruded polyethylene film with an ethylene-vinyl alcohol (EVOH) core layer, achieving a water vapor transmission rate (WVTR) of ≤0.5 g/m²/24hr per ASTM E96. Secondary encapsulation uses metallized polyester film (30-micron thickness) providing 99.9% light blockage and oxygen barrier properties ≤5 cm³/m²/day/atm. The tertiary layer is a sealed polypropylene cover reinforced at seams with butyl rubber tape. All films are applied under controlled humidity (<40% RH) using automated tension-controlled winders to eliminate air pockets. Vacuum-assisted sealing ensures zero headspace oxygen, critical for preventing cuprous oxide formation on high-purity (99.99% min) copper tape.

Validation of packaging efficacy occurs through accelerated salt-spray testing (ASTM B117) and real-time container humidity logging. Pre-shipment verification includes peel strength tests (≥1.2 N/mm) on heat seals and moisture indicator cards placed within packaging layers. Non-compliant packaging risks catastrophic outcomes: surface tarnishing increases contact resistance by 15–20%, while interlayer corrosion causes coil blocking during unwinding. Our protocols reduce moisture-related claims to <0.3% of shipments, versus industry averages exceeding 4%. Buyers must verify pallet certification marks, film WVTR documentation, and seal integrity logs—omission indicates substandard risk mitigation. For transformer-grade copper tape, packaging is not logistical overhead; it is metallurgical insurance ensuring dimensional stability and electrical performance at destination.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Copper Tape Solutions

With over two decades of specialized expertise in the production of transformer strips and foils, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the global supply of high-performance copper tape for demanding industrial applications. Our vertically integrated manufacturing platform combines advanced metallurgical engineering with rigorous quality assurance to deliver copper tape products that meet exacting international standards, including ASTM B187, GB/T 13585, and IEC 60464.

Our production facility spans over 50,000 square meters and is equipped with state-of-the-art rolling mills, precision annealing lines, and automated slitting systems designed specifically for the continuous processing of copper strip and tape. This infrastructure enables us to produce copper tape with thicknesses ranging from 0.05 mm to 3.0 mm and widths from 10 mm to 600 mm, tailored to customer specifications for use in dry-type transformers, current collectors, grounding systems, and electromagnetic shielding applications. All copper material is sourced from certified refineries, with minimum conductivity levels exceeding 98% IACS, ensuring optimal electrical performance and thermal stability.

Quality control is embedded at every stage of production. Our in-house laboratory is accredited to ISO/IEC 17025 and conducts comprehensive testing on mechanical properties, dimensional tolerance, surface finish, and electrical resistivity. Each coil is subjected to eddy current inspection and tensile testing, with full traceability maintained through batch coding and digital process logs. This commitment to consistency has enabled us to achieve long-term supply contracts with Tier-1 transformer manufacturers across Europe, Southeast Asia, and South America.

As a manufacturer, we prioritize technical collaboration with our partners. Our engineering team provides material data sheets, processing recommendations, and application-specific design support to ensure seamless integration into customers’ production lines. Whether you require soft-annealed (O-temper) copper tape for high-flexibility windings or half-hard (H02) grades for structural rigidity, we offer customizable temper, edge condition (trimmed or slit), and packaging configurations—including wooden reels with moisture protection for export shipments.

Luoyang Xinzhaohe operates under ISO 9001, ISO 14001, and IATF 16949 certifications, reflecting our adherence to quality, environmental responsibility, and process efficiency. Our logistics network supports containerized FOB or CIF shipments from Qingdao or Shanghai ports, with lead times typically within 15–25 days from order confirmation.

For sourcing managers and procurement engineers seeking a reliable, technically capable partner in copper tape supply, Luoyang Xinzhaohe offers the production capacity, material expertise, and quality discipline required for mission-critical components. We invite you to contact us directly to discuss your specifications and receive a technical quotation.

Contact us at cathy@transformerstrip.com to begin a partnership built on precision, performance, and proven manufacturing excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper tape directly from China.