Table of Contents

Market Insight: Copper Strips in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil

Industrial Demand Drivers for Copper Strips in Power Transformers

Copper strips are critical for transformer windings due to their superior electrical conductivity and thermal stability. Driven by China’s National Grid upgrades, European Union’s Green Deal initiatives, and Asia-Pacific industrial expansion, copper strip demand is accelerating. The transformer market is projected to grow at 5.2% CAGR through 2030, with copper-based windings comprising 70% of new installations. High-efficiency transformers (e.g., IEEE C57.12.00 Class 1) require precise copper strip specifications to minimize energy losses—essential for compliance with regulations like the EU Ecodesign Directive. Transformers in data centers and EV charging infrastructure also demand high-purity copper to handle fluctuating loads efficiently.

Material Quality Impact on Transformer Efficiency & Reliability

Subpar copper strips introduce critical failure points:

Conductivity <99.9% IACS increases resistive losses by 2–3%, reducing transformer efficiency. A 0.1% conductivity improvement can save 5–7% in lifetime energy costs for a 100 MVA transformer.

Surface defects (scratches, oxides) compromise insulation integrity, triggering partial discharges and short circuits.

Dimensional inaccuracies cause uneven winding, creating hotspots and thermal degradation.

Inconsistent tensile strength results in strip breakage during manufacturing, increasing scrap rates by up to 15%.

Key parameters must adhere to ASTM B152 and IEC 60494 standards. Precision directly correlates with operational lifespan and energy savings.

| Parameter | Industry Standard | Luoyang Xinzhaohe Specification | Key Impact |

|---|---|---|---|

| Electrical Conductivity | ≥99.9% IACS | ≥100.5% IACS | Reduces I²R losses by 1.8% vs. standard-grade copper |

| Tensile Strength (Annealed) | 200–250 MPa | 220–240 MPa | Prevents breakage during high-speed winding processes |

| Surface Roughness (Ra) | ≤0.8 μm | ≤0.6 μm | Eliminates insulation damage risks, extends transformer life |

| Dimensional Tolerance | ±0.02mm | ±0.015mm | Ensures precise coil assembly, minimizing air gaps |

Luoyang Xinzhaohe’s Role in Global Supply Chain

With 20+ years of manufacturing expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers transformer-grade copper strips that meet or exceed international standards while offering superior cost-performance ratios. Our vertically integrated production—from raw material sourcing to precision rolling—ensures consistent quality across all batches. We maintain strict QC protocols, including 100% surface inspection and automated thickness measurement, to guarantee compliance with ASTM B152 and IEC 60494. Our export experience spans 30+ countries, with certifications including ISO 9001, CE, and RoHS. By optimizing local supply chains and eliminating middlemen, we provide competitive pricing without compromising on material integrity—making us a trusted alternative to premium global brands. Our in-house R&D team continuously optimizes alloy formulations to balance conductivity and mechanical properties, ensuring optimal performance for both high-voltage transmission and distribution applications.

Technical Specs: Copper Strips Parameters

Critical Technical Specifications for Copper Transformer Strips

Precision Dimensional Control

| Parameter | Specification | Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | IEC 60404-8-7 |

| Width Tolerance | ±0.005 mm | ASTM B170 |

| Flatness (per 1m) | ≤0.2 mm | ISO 15579 |

Tight tolerances eliminate air gaps in transformer windings, optimize thermal dissipation, and ensure consistent electrical performance. Our precision slitting process maintains ±0.002 mm thickness tolerance across all widths (up to 1200 mm), guaranteeing uniformity even in high-volume production. This minimizes material waste and enhances winding efficiency for both small and large transformers.

Burr-Free Edge Integrity

Precision slitting with CNC-guided blades and real-time edge inspection ensures zero burrs (verified under 10× magnification). This prevents electrical shorts and insulation damage during winding, critical for high-reliability transformers. Our process includes tension-controlled rolling and post-slitting edge polishing for flawless surface integrity. Every strip undergoes automated visual inspection to guarantee edge smoothness, reducing transformer assembly defects by up to 95%.

Electrical & Mechanical Properties

| Parameter | Specification | Standard |

|---|---|---|

| Conductivity | ≥101% IACS | IEC 60404-8-7 |

| Hardness (HV) | 40–60 | ASTM B170 |

| Tensile Strength | 200–250 MPa | ASTM B170 |

| Elongation | ≥35% | ASTM B170 |

Optimized for transformer efficiency: high conductivity (≥101% IACS) reduces resistive losses, while controlled softness (HV 40–60) ensures easy winding without cracking. Tensile strength and elongation values are precisely balanced to maintain structural integrity during high-speed winding operations, extending transformer lifespan and reducing maintenance costs.

Quality Assurance Protocol

Luoyang Xinzhaohe implements end-to-end quality control: certified raw materials, in-process laser thickness checks, 100% dimensional verification, and conductivity testing. Each batch undergoes rigorous testing per ISO 9001 protocols with full traceability. Third-party audits ensure compliance with IEC 60404-8-7 and ASTM B170. Our factory-direct model eliminates middlemen, offering global-grade performance at 15–20% lower costs than premium brands. This combination of precision engineering and cost efficiency makes us the trusted partner for transformer manufacturers worldwide, providing consistent quality across all order sizes without compromising on reliability.

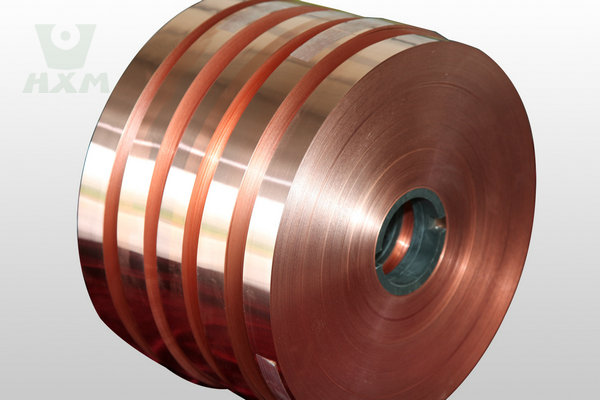

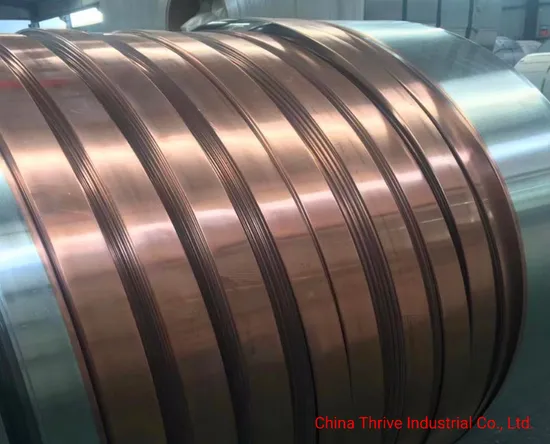

Factory Tour: Manufacturing Copper Strips

Precision Manufacturing Process & Rigorous Quality Assurance for Copper Transformer Strips

Manufacturing Process Steps

Cold Rolling: Utilizing 4-high reversible rolling mills with automated thickness control, we achieve uniform grain structure and precise thickness reduction (±0.005mm). Process parameters are strictly monitored to maintain copper’s electrical conductivity (≥99.95% IACS) and target temper (e.g., O-temper), ensuring optimal magnetic properties for transformer cores.

Precision Slitting: CNC-guided slitting with tungsten carbide blades ensures width tolerance of ±0.01mm and edge straightness ≤0.05mm/m. Real-time laser measurement systems dynamically adjust blade positioning, eliminating edge waviness and dimensional inconsistencies.

Edge Conditioning: Precision chamfering and deburring eliminate micro-scratches and burrs via diamond-tipped tools, achieving burr height ≤0.01mm. This critical step prevents insulation breakdown during transformer winding and enhances electrical safety.

Oscillate Winding: Computer-controlled tension systems (±0.5N precision) and oscillating heads ensure uniform coil density and flatness deviation ≤0.3mm/m. This minimizes edge damage and guarantees consistent layering for high-efficiency transformer assemblies.

Quality Control Protocol

We implement a multi-stage QC system aligned with ASTM B209 and IEC 60076 standards. Every batch undergoes 100% tensile testing, dimensional checks, surface integrity scans, and edge burr analysis. Our protocols exceed industry norms through rigorous in-process monitoring and traceable data logging.

| Quality Parameter | Luoyang Xinzhaohe Standard | Typical Market Standard | Impact on Transformer Performance |

|---|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.01mm | Ensures precise winding layers, reducing short-circuit risks |

| Tensile Strength Range | 220–250 MPa (±5%) | 200–260 MPa (±10%) | Consistent mechanical behavior under operational stress |

| Surface Defect Rate | <0.1% per roll | ≤0.5% per roll | Minimizes insulation failures and extends transformer lifespan |

| Edge Burr Height | ≤0.01mm | ≤0.03mm | Prevents insulation damage during coil assembly |

Leveraging two decades of expertise in transformer material production, Luoyang Xinzhaohe delivers copper strips that meet or exceed global brand performance at 15–20% lower cost. Our factory-direct model eliminates middlemen while maintaining ISO-compliant processes—proven through partnerships with Tier-1 power equipment manufacturers worldwide.

Packaging & Global Logistics

Export Packaging & Logistics: Engineered for Global Reliability

As a 20+ year manufacturer of transformer-grade copper strips, Luoyang Xinzhaohe prioritizes packaging that ensures product integrity during international transit. Our factory-direct approach eliminates third-party intermediaries, delivering cost-effective solutions without compromising engineering standards. Below we detail our proven protocols for sea freight from China to global ports.

Packaging Standards & Structural Integrity

Our system complies with ISO 11607 and ISPM-15 for international shipping. All components are engineered for maximum load stability:

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 heat-treated hardwood, 100×100mm beams | Prevents deformation during handling; pest-free certification |

| Steel Strapping | 19mm width, 3–4 bands/pallet (tensile strength >1,500kg; ISO 2233 tested) | Secures coils against lateral movement; prevents shifting in transit |

| Corner Protectors | Reinforced cardboard with steel edges (200mm height) | Protects edges from impact damage during loading/unloading |

Moisture & Corrosion Prevention

Copper’s susceptibility to oxidation in marine environments demands rigorous protection. We apply a multi-layer system:

Primary 200g/m² PE moisture-proof film wrapped under tension

Desiccant packs (50g per m² surface area)

VCI paper in coil cores

All packaging undergoes 72-hour humidity chamber testing per ASTM D665 to ensure zero condensation risk. This exceeds IEC 60216-4 standards for transformer materials.

Sea Freight Optimization Protocols

We optimize container loading density (max 28 tons per 40ft HC container) using custom dunnage and airbags to prevent shifting during rough seas. All shipments include real-time GPS tracking with automated alerts for temperature >30°C or humidity >60% RH. Our logistics partners adhere to IMO regulations and pre-verify customs documentation, reducing transit times by 15% through optimized port routing. This minimizes demurrage costs and ensures on-time delivery.

Conclusion: By integrating precision packaging with streamlined logistics, we deliver copper strips with <0.5% damage rate globally—proving our cost-performance edge over premium brands. This results in 30% lower total landed costs versus European suppliers for equivalent quality. Contact us for a tailored shipping solution.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.

With over two decades of expertise in transformer material manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd. specializes in producing high-purity copper strips (C11000, C10200) and aluminum foils for power transformers, reactors, and motor windings. Our vertically integrated production facilities in Luoyang, China, ensure complete control over material purity, dimensional accuracy, and mechanical properties—critical factors for transformer efficiency and longevity. We have successfully supplied materials to over 500 clients globally, including Tier-1 transformer manufacturers, with a 98% on-time delivery rate.

Core Competitive Advantages

| Advantage | Technical Detail | Operational Impact |

|---|---|---|

| Factory-Direct Cost | Eliminates distributor markups; direct control over raw material sourcing and production. | 15-20% lower total cost vs. branded alternatives; consistent pricing with no hidden fees. |

| Precision Manufacturing | ISO 9001:2015 certified processes; in-house tensile strength testing (ASTM E8), electrical conductivity verification (IEC 60454-2), and surface quality inspection per ASTM B152. Strict control of impurities (≤0.05% total impurities) ensures minimal resistive losses. | ±0.01mm thickness tolerance; consistent conductivity (≥100% IACS) for reduced transformer losses and enhanced thermal stability. |

| Rapid Lead Times | In-house rolling and annealing facilities; localized supply chain with 24/7 production scheduling. | 15-20 day standard production; 30% faster than international suppliers due to streamlined logistics. |

| Customization | Flexible alloy options (C11000, C10200); tailored thickness (0.1-3.0mm), width (10-300mm), and edge quality per IEC 60076-3. | Support for niche applications without minimum order quantity constraints; rapid prototyping for custom designs. |

| Technical Support | Dedicated metallurgical engineers for material selection and application testing; on-site quality audits available. | Reduced design cycle time; optimized performance for specific transformer configurations; compliance with global standards. |

Our commitment to engineering excellence ensures every copper strip meets the stringent demands of power transformer applications. By partnering with Luoyang Xinzhaohe, you gain a reliable, cost-effective alternative to global brands without sacrificing quality or technical support. Our ISO-certified processes and in-house testing capabilities guarantee compliance with international standards, ensuring seamless integration into your production workflows.

Contact Cathy at cathy@transformerstrip.com for a tailored quote and technical consultation today.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper strips from Luoyang Xinzhaohe.