Table of Contents

Market Insight: Copper Strip Roll

Market Analysis: Copper Strip Roll Demand in Transformer Applications

Global demand for copper strip rolls in transformer manufacturing remains robust despite aluminum’s cost advantages in distribution transformers. Copper’s superior electrical conductivity (100% IACS minimum for C10100/C10200 grades) ensures minimal resistive losses, making it indispensable for high-efficiency power transformers (>99% efficiency targets) and compact designs in urban substations, renewable integration hubs, and EV fast-charging infrastructure. The International Energy Agency projects a 6.1% CAGR in global transformer demand through 2030, driven by grid modernization and renewable energy expansion. While aluminum strip dominates distribution-class transformers below 69 kV due to weight savings, copper strip rolls maintain critical market share in transmission-class units (≥115 kV) and specialty applications where space constraints and thermal stability are paramount.

Quality parameters directly dictate transformer performance and lifecycle costs. Impurities exceeding 50 ppm (e.g., oxygen, sulfur) or inconsistent annealing create localized hot spots, accelerating insulation degradation. Dimensional tolerances must adhere to IEC 60138 standards: thickness variation ≤±2% and width tolerance ≤±0.5 mm to prevent winding misalignment and magnetic flux distortion. Surface roughness (Ra ≤1.0 μm) is equally critical; micro-imperfections concentrate electrical stress, increasing partial discharge risk by up to 35% in high-voltage windings. Industry data from CIGRÉ indicates that substandard strip contributes to 22% of premature transformer failures, with repair costs exceeding 300% of initial material value.

The following technical specifications define market-grade copper strip rolls for critical transformer applications:

| Parameter | Standard Requirement | Consequence of Deviation |

|---|---|---|

| Conductivity | ≥100% IACS (C10100) | +0.5% resistive loss per 1% IACS drop |

| Thickness Tolerance | ±0.02 mm (0.5–3.0 mm) | Winding voids → localized overheating |

| Surface Roughness | Ra ≤1.0 μm | Partial discharge initiation |

| Grain Size | ASTM E112 Class 4–6 | Anisotropic expansion → mechanical stress |

Material traceability and process control are non-negotiable. Oxygen-free electronic (OFE) copper (C10100) requires vacuum melting and continuous casting to prevent hydrogen embrittlement, while precise intermediate annealing (550–650°C in inert atmosphere) ensures uniform recrystallization. Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to implement rigorous in-line eddy current testing and laser profilometry, achieving defect detection sensitivity down to 10 μm. This precision mitigates field failure risks and aligns with IEEE C57.12.00 efficiency mandates. As grid operators enforce stricter lifecycle emission targets, the total cost of ownership increasingly favors premium copper strip despite initial material premiums—underscoring why technical sourcing criteria must prioritize metallurgical integrity over nominal price points.

Technical Specs: Copper Strip Roll

Technical Specifications for Copper Strip Rolls

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision copper strip rolls designed for critical applications in power transformers, electrical connectors, and high-efficiency conductive systems. Our copper strips are engineered to meet stringent international standards, ensuring optimal electrical performance, dimensional accuracy, and mechanical reliability. Each roll undergoes rigorous quality control, including continuous in-line monitoring and post-processing inspection, to guarantee consistency across batches.

Dimensional precision is paramount in transformer and busbar applications where tight assembly tolerances and uniform current distribution are required. Our copper strip rolls are slit using advanced precision slitting lines equipped with servo-controlled tension management and laser-guided edge tracking systems. This enables a thickness tolerance of ±0.002 mm across the full length of the coil, ensuring uniform cross-sectional area and predictable current-carrying capacity. Width tolerances are maintained within ±0.05 mm, with straightness deviations not exceeding 2 mm per 1,000 mm of strip length.

Edge quality is a critical factor in preventing dielectric breakdown and ensuring safe handling during coil winding and assembly. All copper strip rolls are processed to achieve burr-free edges through optimized slitting knife geometry, controlled blade clearance, and post-slitting edge brushing. Burr height is consistently maintained below 5 μm, minimizing the risk of insulation damage and enhancing long-term reliability in high-voltage environments.

Electrical conductivity is measured in accordance with ASTM B3 and IEC 60162 standards. Our electrolytic tough pitch (ETP) copper strips (C11000) achieve a minimum conductivity of 98% IACS at 20°C, with typical batch averages exceeding 99% IACS. This high conductivity ensures minimal resistive losses and superior thermal performance in continuous-load applications. All material is certified to meet or exceed ASTM B152 and GB/T 5121 requirements for chemical composition and electrical properties.

Mechanical properties are tailored through controlled cold rolling and optional annealing processes. Tensile strength ranges from 200 to 380 MPa, with elongation values between 5% and 40%, depending on temper condition (H01 to H04 tempers available). Surface finish is maintained at Ra ≤ 0.4 μm to support uniform insulation coating adhesion and reduce corona discharge risks.

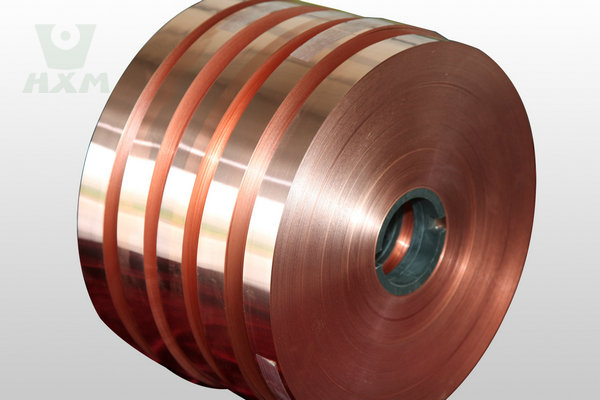

All copper strip rolls are supplied in coil form with protective interleafing, precision wound on robust steel mandrels, and packaged in moisture-resistant, export-grade containers to prevent oxidation and mechanical damage during transit.

Key Technical Parameters

| Parameter | Specification |

|---|---|

| Material Grade | C11000 (ETP Copper) |

| Thickness Range | 0.10 – 3.00 mm |

| Thickness Tolerance | ±0.002 mm |

| Width Range | 10 – 300 mm |

| Width Tolerance | ±0.05 mm |

| Edge Burr Height | ≤ 5 μm (burr-free) |

| Straightness | ≤ 2 mm per 1,000 mm |

| Electrical Conductivity | ≥ 98% IACS (typical ≥ 99%) |

| Tensile Strength | 200 – 380 MPa |

| Elongation | 5 – 40% (based on temper) |

| Surface Roughness (Ra) | ≤ 0.4 μm |

| Temper Options | H01, H02, H03, H04 (half-hard to hard) |

| Standard Compliance | ASTM B152, IEC 60162, GB/T 5121 |

Factory Tour: Manufacturing

Manufacturing Process for High-Purity Copper Strip Rolls

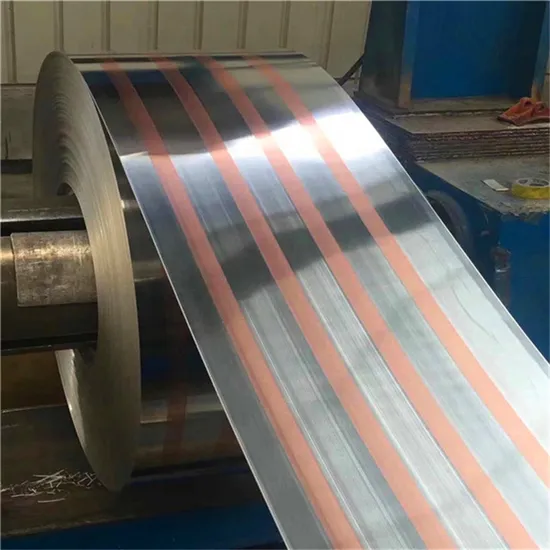

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in non-ferrous strip production to deliver precision copper strip rolls meeting stringent transformer and electrical component requirements. While renowned for aluminum transformer foil, our facility maintains dedicated, optimized production lines for high-conductivity copper strip, ensuring material integrity from raw ingot to finished coil. The core manufacturing sequence comprises Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating rigorous quality control protocols.

Cold Rolling Process

High-purity electrolytic tough pitch (ETP) or oxygen-free electronic (OFE) copper cathodes undergo initial hot rolling to produce master coils typically ranging from 1.5 mm to 3.0 mm in thickness. These master coils feed into our computer-controlled 4-high or 6-high cold rolling mills. Precise tension management and interstand tension control systems are critical during this stage to achieve the target final thickness, commonly between 0.05 mm and 0.50 mm for transformer applications. Reduction ratios exceeding 90% are standard, demanding exacting roll gap calibration and coolant filtration to maintain surface finish and dimensional stability. In-line X-ray thickness gauges provide continuous real-time feedback, ensuring thickness tolerances are held within ±0.002 mm. A final skin-pass rolling operation may be applied to eliminate yield point elongation and optimize the strip’s mechanical properties for subsequent winding and transformer core lamination.

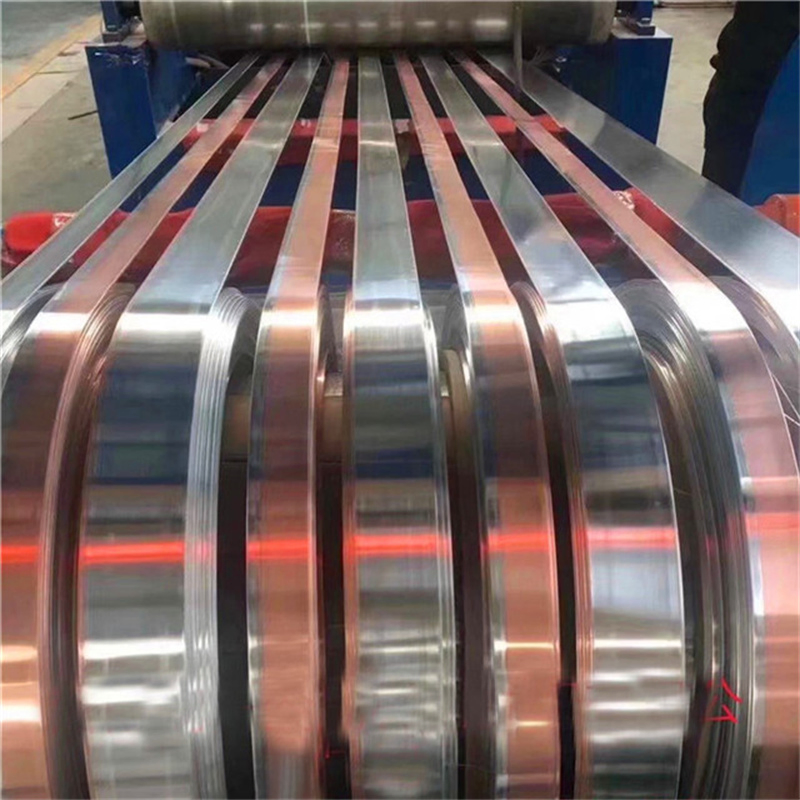

Precision Slitting Operation

The cold-rolled master coil proceeds to our high-precision slitting lines. Utilizing hardened tool steel rotary knives with precisely engineered knife geometry and optimal blade overlap settings, the wide master strip is longitudinally divided into multiple narrower strips meeting the customer’s specified width. Width tolerance control is paramount, with our systems consistently achieving ±0.05 mm accuracy across the entire coil length. Laser micrometers and optical width monitoring systems continuously verify slit dimensions. Tension control throughout the slitting process prevents edge wave or center buckle, ensuring flatness critical for automated transformer winding equipment. Each slit strip is immediately recoiled onto precision arbors under controlled tension to prevent telescoping or edge damage.

Edge Conditioning

Following slitting, the strip edges undergo dedicated conditioning to eliminate micro-burrs and achieve the required edge profile. This stage employs precision brushing, edge rolling, or controlled abrasive techniques tailored to the specific copper alloy and final application. Burr height is reduced to less than 2% of the strip thickness, typically below 1 micron for critical transformer foil applications. This minimizes the risk of dielectric breakdown within transformer windings and ensures smooth handling during high-speed coil winding processes. Edge profile is verified using high-magnification optical comparators or laser scanning systems.

Integrated Quality Control

Quality verification is embedded throughout the production flow. Beyond in-line thickness and width monitoring, samples undergo periodic laboratory testing for electrical conductivity (minimum 100% IACS for ETP), tensile strength, elongation, and surface roughness (Ra). Final inspection includes 100% surface defect detection via automated optical inspection (AOI) systems and meticulous edge profile validation. Each shipment is accompanied by full material test reports (MTRs) confirming compliance with ASTM B152/B152M or customer-specific specifications, guaranteeing the copper strip roll’s performance in demanding electrical applications.

Packaging & Logistics

Export Packaging for Copper Strip Rolls: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in the production and international distribution of transformer-grade aluminum and copper strip rolls, we recognize that packaging is not merely a logistical necessity but a critical component in maintaining product integrity throughout the supply chain. For copper strip rolls destined for global markets, our export packaging system is engineered to meet the rigorous demands of sea freight, where prolonged exposure to humidity, temperature fluctuations, and mechanical stress can compromise material quality.

All copper strip rolls are mounted on high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support the significant weight of densely wound copper coils, typically ranging from 500 kg to 5,000 kg per roll, without deformation or structural failure. The use of treated wood ensures resistance to insect infestation and microbial degradation, which is particularly critical during extended maritime transit through tropical and coastal zones.

Immediately after winding and inspection, each copper strip roll is wrapped in multiple layers of industrial-grade moisture-proof film, specifically formulated to provide a vapor barrier with a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24hr. This multilayer wrapping effectively isolates the copper surface from ambient humidity, preventing oxidation and the formation of surface patina that could impair electrical conductivity or complicate downstream processing. The film is heat-sealed at all seams to ensure continuity and is reinforced at the core and outer edges—zones most vulnerable to moisture ingress.

To further enhance protection, desiccant packs are strategically placed between the inner layers of wrapping, actively absorbing any residual moisture within the sealed environment. Additionally, each roll is fitted with edge protectors made from high-density polyethylene (HDPE), which safeguard the strip’s longitudinal edges from mechanical damage during handling, crane lifts, and container stowage.

The entire packaged unit is then secured to the wooden base using steel strapping applied under controlled tension to prevent lateral movement. This stabilization is essential during vessel motion, where rolling and pitching can generate significant inertial forces. Labeling is performed using UV-resistant, marine-grade adhesive tags affixed to multiple sides of the pallet, displaying critical shipment data including coil ID, dimensions, weight, alloy type, temper, and handling instructions.

Our packaging protocol is validated through accelerated aging tests and real-world performance tracking across major trade lanes, including trans-Pacific and Europe-Asia routes. Compliance with international maritime safety standards, including the CTU (Cargo Transport Unit) Code, is rigorously maintained.

This systematic approach ensures that copper strip rolls arrive at their destination with preserved surface finish, dimensional accuracy, and metallurgical properties—delivering consistent value to transformer manufacturers and electrical component suppliers worldwide.

Sourcing from Luoyang Xinzhaohe

Partnering with Luoyang Xinzhaohe for Copper Strip Roll Excellence

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages over two decades of specialized metallurgical engineering and precision manufacturing expertise to deliver copper strip roll solutions meeting the most stringent transformer and electrical component requirements. Our integrated production facility, purpose-built for high-performance electrical conductors, provides global OEMs and tier suppliers with a reliable, technically superior sourcing partner for critical copper applications.

Our core manufacturing strength lies in dedicated, state-of-the-art copper processing lines. We operate advanced cold rolling mills, including high-precision Sendzimir configurations, capable of producing copper strip rolls from 0.05mm to 3.0mm in thickness with exceptional dimensional control. Typical thickness tolerances consistently achieve ±0.005mm for critical foil applications and ±0.01mm for thicker strip, directly supporting transformer efficiency and winding integrity. Width capabilities span 100mm to 1200mm, accommodating diverse core designs. We specialize in high-conductivity electrolytic tough pitch copper (C11000) and oxygen-free electronic (OFE) copper (C10100, C10200), processed under strictly controlled inert atmospheres during annealing to prevent oxidation and ensure optimal electrical properties. Annual copper strip production capacity exceeds 15,000 metric tons, providing scalability for large-volume programs.

Quality assurance is embedded within our metallurgical process control systems. Every production lot undergoes rigorous in-line and final inspection per ASTM B152 and customer-specific specifications. Our ISO 9001 and IATF 16949 certified quality management system governs critical parameters including electrical conductivity (min 100% IACS for ETP), surface roughness (Ra < 0.2µm achievable), mechanical properties (tensile strength, elongation), and edge quality. An on-site metallurgical laboratory equipped with OIM analysis, SEM/EDS, and high-precision conductivity testers enables real-time process validation and rapid root cause analysis, minimizing defect rates and ensuring batch-to-batch consistency essential for automated transformer winding lines.

Our technical advantage stems from deep domain knowledge in copper microstructure-property relationships. Engineering teams collaborate directly with customers to optimize annealing profiles, temper designations (H00, H01, H02), and surface treatments for specific lamination or foil applications, enhancing formability, fatigue resistance, and long-term reliability in demanding electrical environments. This metallurgical precision is complemented by a responsive, vertically integrated supply chain. We manage the entire value stream from cathode sourcing through casting, hot/cold rolling, annealing, tension leveling, and precision slitting, enabling reliable lead times of 15-25 days and mitigating raw material volatility risks for our partners.

Partner with Luoyang Xinzhaohe to secure a technically proficient, high-capacity copper strip roll supplier committed to the exacting standards of the transformer industry. Contact Cathy Zhang directly at cathy@transformerstrip.com to discuss your specific alloy, dimensional, and performance requirements and receive a detailed technical capability statement.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper strip roll directly from China.