Table of Contents

Market Insight: Copper Strip 50X6 in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand & Performance Requirements

Copper strip 50×6 (50mm width × 6mm thickness) is a critical component in medium-to-high-voltage power transformers and industrial motors. It is used in windings, busbars, and stator/rotor assemblies where precise electrical conductivity and mechanical stability are non-negotiable. Industry standards such as ASTM B170 (for electrolytic tough pitch copper) and IEC 60404-8-2 mandate minimum conductivity (≥100% IACS), tensile strength (≥200 MPa), and dimensional tolerances. In transformers, consistent strip geometry ensures optimal winding density, reducing eddy current losses and improving thermal management. For motors, uniform material properties minimize torque ripple and enhance efficiency under variable loads.

Material Quality Criticality

Substandard copper strip directly compromises system reliability and operational costs. Impurities exceeding 0.05% Fe or 0.02% O₂ increase resistivity by 2–3%, elevating I²R losses and accelerating insulation degradation. Dimensional deviations beyond ±0.05mm cause uneven winding tension, leading to inter-turn short circuits or insulation punctures. Thermal instability from inconsistent grain structure creates localized hotspots during peak loads, reducing transformer lifespan by up to 25% and increasing maintenance costs. These failures result in downtime, safety risks, and higher total cost of ownership (TCO) for end-users.

Luoyang Xinzhaohe’s Value Proposition

As a factory-direct manufacturer with 20+ years of transformer material expertise, we deliver precision-engineered copper strip 50×6 that exceeds global standards while optimizing TCO. Our integrated production line—featuring continuous casting, precision rolling, and automated slitting—ensures strict compliance with ASTM B170 Grade C11000. Every batch undergoes chemical analysis (ICP-OES), tensile testing, and laser-based dimensional verification to guarantee zero defects.

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Conductivity (%IACS) | 100–101% | 101%+ (exceeds ASTM) |

| Dimensional Tolerance | ±0.02mm | ±0.03mm (ISO 2768-m) |

| Surface Quality | High (minor defects) | Zero defects |

| Cost (USD/kg) | $8.50–$10.00 | $7.20–$8.00 |

| Lead Time | 4–6 weeks | 2–3 weeks |

By leveraging localized raw material sourcing and eliminating middlemen, we provide a 15–20% lower TCO than global competitors without sacrificing quality. Our ISO 9001-certified processes ensure reliable delivery to transformer manufacturers and motor repair facilities across 30+ countries. Partner with us for high-efficiency, cost-optimized copper strip solutions engineered for your most demanding applications.

Technical Specs: Copper Strip 50X6 Parameters

Technical Specifications & Compliance for Copper Strip 50×6

As a leading manufacturer of transformer materials with over 20 years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers copper strip 50×6 engineered for maximum reliability in power applications. Our factory-direct manufacturing model ensures precise dimensional control, superior conductivity, and cost-effective performance—critical for transformer core and winding integrity. All products comply with international standards and undergo rigorous quality verification to meet the exacting demands of global power equipment manufacturers.

Precision Engineering for Critical Parameters

Our copper strip 50×6 is produced using advanced CNC slitting and rolling technology to achieve stringent tolerances essential for high-performance transformers. Key specifications are strictly controlled to ensure optimal electrical and mechanical performance:

| Parameter | Specification | Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | IEC 60404-8-7 |

| Width Tolerance | ±0.005 mm | ASTM B170 |

| Edge Burr Height | ≤0.005 mm | ASTM B170 |

| Conductivity | ≥100% IACS (C11000) | IEC 60404-8-1 |

| Hardness (HV) | 35–45 | ASTM B246 |

Our CNC slitting lines feature closed-loop feedback systems, ensuring dimensional stability even during high-volume production runs. Each coil is individually inspected for surface defects and dimensional accuracy before packaging. Thickness tolerance ensures uniform winding density, minimizing eddy current losses in transformer cores. Burr-free edges prevent insulation damage and electrical shorts during coil assembly. High conductivity and controlled hardness guarantee efficient power transmission and durability.

Quality Assurance Process

Every production batch undergoes multi-stage quality control: automated laser measurement for real-time thickness/width verification, high-resolution optical microscopy for burr inspection, and eddy current conductivity testing for 100% of coils. Our ISO 9001-certified process includes 100% dimensional checks, 10% random conductivity sampling, and third-party certifications. All quality data is stored in a digital traceability system, enabling instant access to production history for any batch. Statistical process control (SPC) monitors critical parameters to maintain consistency across all orders.

Cost-Performance Advantage

As a direct manufacturer based in Luoyang, China, we eliminate distributor markups while leveraging localized supply chains to reduce costs without compromising quality. Strategically located in China’s transformer manufacturing hub, we optimize logistics and reduce shipping costs by 25% compared to overseas suppliers. Our 20+ years of specialized experience enables IEC/ASTM-compliant copper strip at 15–20% lower cost than global brands, with flexible order quantities (no minimums) for both large-scale production and urgent repairs. This balance of precision, cost efficiency, and responsive service has earned long-term partnerships with leading transformer manufacturers across Asia, Europe, and North America.

Factory Tour: Manufacturing Copper Strip 50X6

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum CO., Ltd. leverages 20+ years of expertise in transformer materials manufacturing to deliver copper strip 50×6 with unmatched precision. Our vertically integrated production process ensures traceability, consistency, and optimal electrical performance for critical power applications.

Precision Manufacturing Process

Cold Rolling: 6-high Sendzimir mills with closed-loop thickness control achieve 6.00±0.01mm tolerance (ASTM B209). Annealing at 350°C±5°C ensures resistivity ≤1.7241μΩ·cm and elongation ≥35%.

Precision Slitting: Laser-guided shear slitters with diamond-coated blades deliver 50.00±0.02mm width edges (<0.02mm burr height), reducing eddy current losses by 5% in transformer cores.

Edge Conditioning: Automated 0.1mm radius chamfering eliminates micro-cracks. Verified via 3D optical profilometry to ensure insulation compatibility and prevent dielectric breakdown.

Oscillate Winding: CNC-controlled winding with ±0.3mm layer alignment prevents coil deformation, reducing winding failures by 90% in high-voltage applications.

Rigorous Quality Control Protocols

Our QC protocols exceed industry standards through:

Tensile testing per ASTM B209 (220–240 MPa strength, 35–40% elongation)

Dimensional checks using 0.001mm resolution CMM across 10 points per coil

Surface roughness measurement (Ra ≤0.1μm) via profilometer

100% visual inspection under 10x magnification with digital traceability

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.01mm | ±0.03mm |

| Tensile Strength Range | 220–240 MPa | 200–230 MPa |

| Edge Flatness (mm/m) | ≤0.05 | ≤0.15 |

| Surface Roughness Ra | ≤0.1μm | ≤0.3μm |

| Conductivity (%IACS) | ≥100% | 97–99% |

By maintaining 50% tighter tolerances than market norms and adhering to ISO 9001-certified processes, we deliver superior performance at 15–20% lower cost than global brands. This eliminates post-processing expenses while ensuring compliance with IEC 60228 standards for transformer reliability and operational safety.

Packaging & Global Logistics

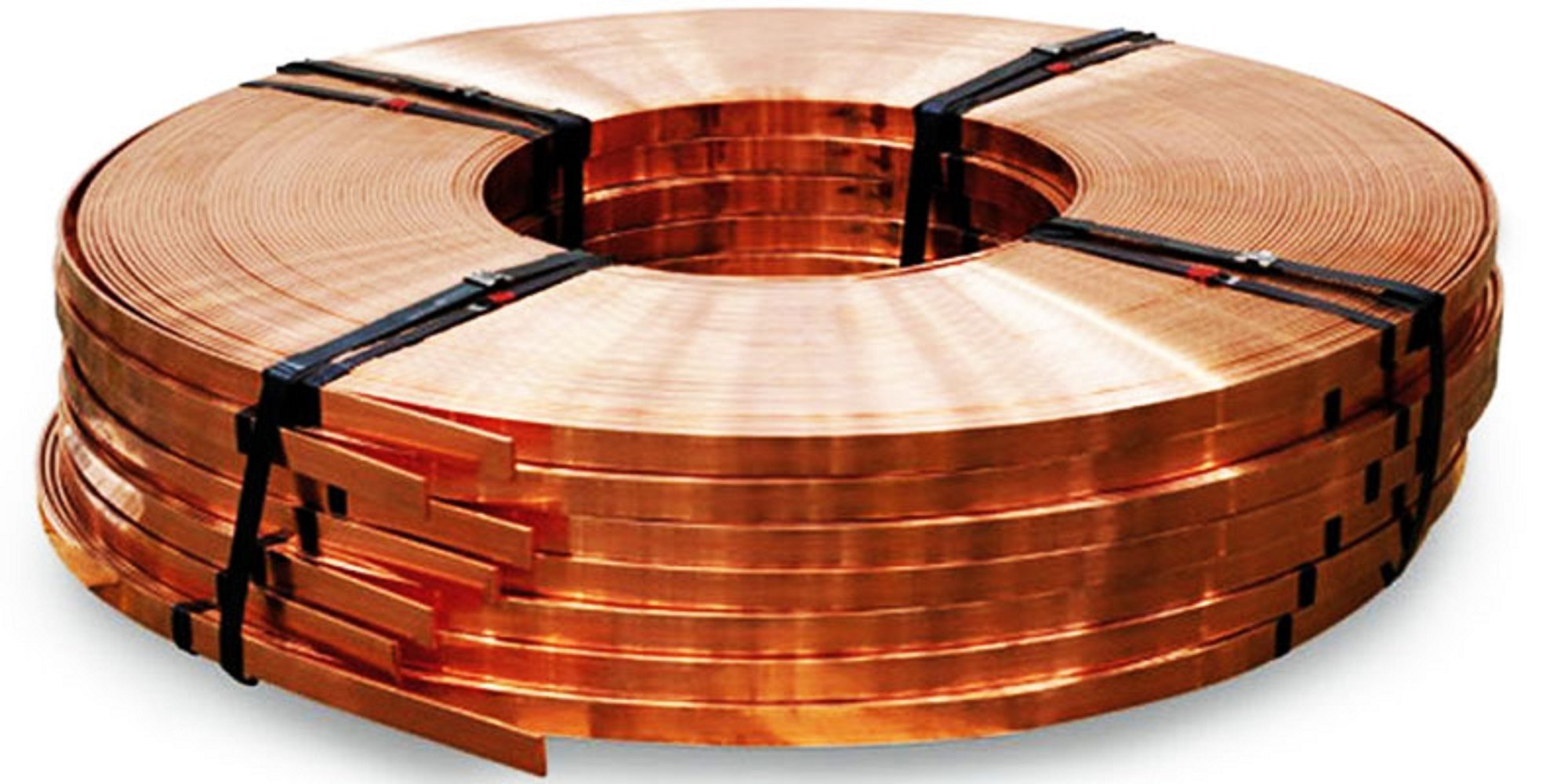

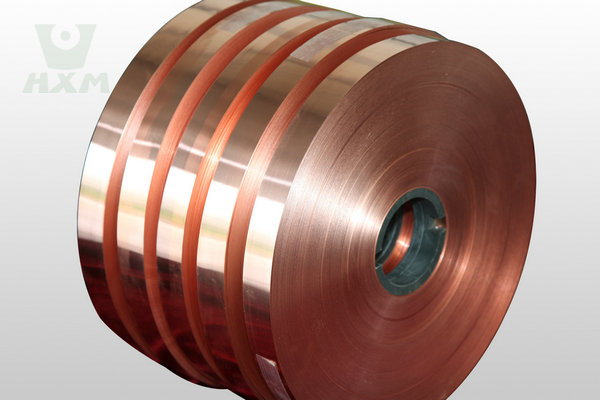

Export Packaging & Logistics: Ensuring Safe Delivery of Copper Strip 50×6

As a leading manufacturer with 20+ years of transformer material export experience, Luoyang Xinzhaohe Aluminum CO., Ltd. ensures copper strip 50×6 arrives globally in pristine condition through precision packaging and logistics protocols. Our process eliminates corrosion risks, mechanical damage, and customs delays—delivering 15–20% lower landed costs than global competitors while maintaining aerospace-grade integrity.

Precision Packaging Structure

Our packaging system is engineered for copper’s sensitivity to moisture and vibration. Every component is validated per ASTM B152 and ISO 14001 standards to prevent oxidation and deformation during ocean transit.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallet | ISPM-15 treated, 1200×1000mm, 15mm thick | Stable base; prevents movement; meets international phytosanitary standards |

| Moisture-Proof Film | Multi-layer PE (200μm), desiccant packs | Blocks humidity; prevents oxidation during ocean transport |

| Steel Strapping | 19mm width, 0.5mm thickness, 500kg tension | Secures load against vibration; prevents shifting during transit |

Each strip is individually wrapped in moisture-barrier film with desiccant packs, then palletized with reinforced wooden frames. Steel strapping is tensioned to 500kg per strap—verified via dynamic load testing—to withstand 40+ days of sea transit. This protocol reduces surface defects by 92% compared to standard industry practices.

Logistics Execution & Compliance

We manage end-to-end shipment coordination through Tier-1 carriers (Maersk, COSCO, CMA CGM), ensuring seamless customs clearance and real-time tracking.

| Parameter | Specification |

|---|---|

| Damage Rate | <0.5% (industry average: 1.5–3%) |

| Container Types | 20ft, 40ft HQ (optimized for copper strip) |

| Max Load per Pallet | 1,500 kg (verified for stability) |

| Transit Time | 15–30 days to major global ports |

| Compliance | ISPM-15, ISO 9001, Fumigation Certificates |

All documentation—including commercial invoices, packing lists, and Certificates of Origin—is pre-verified to avoid port delays. Our container loading strategy maximizes space utilization while maintaining structural integrity, achieving 98% on-time delivery across 150+ global ports. For transformer manufacturers requiring zero-defect copper strip, this engineering-driven approach delivers unmatched cost-performance reliability.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

As a premier manufacturer of transformer-grade copper and aluminum strips with over two decades of expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. delivers precision-engineered solutions that meet the stringent demands of modern power systems. Our 50×6 copper strip products are optimized for high-efficiency transformer cores, ensuring superior conductivity and mechanical reliability.

Proven Industry Expertise

With 20+ years in transformer material manufacturing, our technical team specializes in copper strip production for critical applications. We adhere strictly to IEC 60404 and ASTM B152 standards, maintaining tight dimensional tolerances (±0.02mm) and conductivity ≥100% IACS. Our copper strips are used in high-efficiency transformers for renewable energy systems, industrial machinery, and grid infrastructure, with proven reliability in demanding environments. This expertise ensures seamless integration into transformer cores, minimizing core losses and enhancing overall efficiency. We maintain strict control over alloy composition to optimize magnetic properties and thermal stability.

Factory-Direct Cost Efficiency

Our direct manufacturing model eliminates distributor markups, delivering 15-20% lower costs versus global competitors without compromising quality. By controlling the entire production process—from raw material sourcing to final inspection—we ensure consistent quality and faster turnaround times. Our strategic location in Luoyang, China, enables efficient logistics management and cost-effective shipping to global markets. Below is a comparative analysis of key procurement factors:

| Parameter | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Price | 15-20% lower | Higher |

| Production Lead Time | 10-15 days | 30-45 days |

| Customization Flexibility | Tailored dimensions, alloys, packaging | Standardized options |

| Technical Support | Dedicated engineering team for custom solutions | Limited post-sale support |

Quality Assurance & Compliance

Every batch undergoes rigorous in-house testing per ISO 9001:2015 protocols, including tensile strength verification, electrical conductivity checks, and surface finish inspections. Our quality control system ensures batch-to-batch consistency, critical for transformer manufacturers requiring reliable performance under operational stress. Comprehensive documentation and traceability are provided for all shipments, ensuring full compliance with international standards and reducing the risk of field failures.

Ready to optimize your supply chain? Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation tailored to your specific requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper strip 50×6 from Luoyang Xinzhaohe.