Table of Contents

Market Insight: Copper Strip 25X5Mm in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil (Aluminum/Copper)

Industrial Demand for Copper Strip 25x5mm

Copper strip 25×5mm is a critical component in power transformers and motors, serving as winding conductors and busbars in medium-to-high-power applications. Its precise dimensions optimize current-carrying capacity while minimizing resistive losses. Global demand is driven by renewable energy infrastructure expansion (e.g., solar/wind substations), industrial electrification, and stringent efficiency regulations like DOE 2016 and EU ErP standards. In transformers, dimensional accuracy ensures optimal magnetic flux distribution; in motors, it prevents thermal runaway during high-torque operations. Deviations in material quality directly compromise efficiency, increasing energy waste by up to 15% and accelerating component failure.

Critical Quality Parameters for Transformer Performance

Material specifications must align with international standards to ensure operational reliability:

| Parameter | Industry Standard | Impact of Non-Compliance |

|---|---|---|

| Electrical Conductivity | ≥100% IACS | >15% energy loss; overheating |

| Purity (C11000) | 99.95% Cu minimum | Sulfur/oxygen impurities cause hotspots |

| Thickness Tolerance | ±0.02mm | Winding defects; reduced dielectric strength |

| Surface Finish | Ra ≤0.8μm | Arcing; increased skin effect losses |

Why Luoyang Xinzhaohe is the Strategic Sourcing Partner

As a 20+ year ISO 9001-certified manufacturer specializing in both aluminum and copper transformer materials, we deliver factory-direct precision at competitive pricing. Our production adheres to ASTM B170, IEC 60499, and JIS H3100 standards, with traceability from raw material to finished product. All batches undergo third-party inspection per ISO 17025 protocols and 100% eddy current testing.

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Price (USD/kg) | $8.5–$10.0 | $6.8–$8.2 | 20–25% lower |

| Lead Time | 4–6 weeks | 2–3 weeks | Faster delivery |

| Thickness Tolerance | ±0.05mm | ±0.03mm | Tighter control |

| Certifications | ISO 9001, ASTM | ISO 9001, ASTM, IEC | Full compliance |

| Customization | Limited options | Full range | Tailored solutions |

With 15,000+ metric tons annual production capacity and global supply chain experience across 30+ countries, we provide consistent, cost-efficient copper strip solutions that meet or exceed global standards—without premium pricing. For mission-critical transformer and motor applications, our technical expertise ensures reliability from design to delivery.

Technical Specs: Copper Strip 25X5Mm Parameters

Technical Specifications & Compliance for Copper Strip 25x5mm

For transformer manufacturers requiring precise copper strip specifications, Luoyang Xinzhaohe delivers engineered solutions that meet the highest industry standards while optimizing total cost of ownership.

Dimensional Precision & Edge Integrity

| Parameter | Nominal | Tolerance | Standard |

|---|---|---|---|

| Thickness | 5.00 mm | ±0.002 mm | ASTM B152 |

| Width | 25.00 mm | ±0.002 mm | ASTM B152 |

| Edge Burr | – | ≤0.005 mm | IEC 60404-7 |

| Surface Roughness | Ra ≤0.8 μm | – | ISO 4287 |

| Flatness | ≤0.5 mm/m | – | ASTM B152 |

Electrical & Mechanical Properties

| Property | Value | Standard |

|---|---|---|

| Conductivity | ≥100% IACS (C11000) | ASTM B170 |

| Hardness (O-temper) | ≤45 HV | ASTM B246 |

| Tensile Strength | ≤180 MPa | ASTM B246 |

| Elongation | ≥35% | ASTM B246 |

| Resistivity | ≤1.724 μΩ·cm | ASTM B170 |

Quality Assurance Protocol

Luoyang Xinzhaohe maintains a fully integrated quality control system for copper strip production. Every raw material batch undergoes spectrographic analysis to ensure ≥99.95% copper purity (ASTM B170 Grade 1). During slitting, our CNC-guided precision cutters maintain ±0.002 mm dimensional tolerances with zero burr formation, verified by automated optical inspection (AOI) systems. Conductivity is tested using four-point probe methodology per ASTM B170, while hardness (≤45 HV) and tensile strength (≤180 MPa) are validated via Rockwell and tensile testing machines. All products comply with IEC 60404-7 and ASTM B152 standards, with full traceability via serialized MTRs. Our ISO 9001-certified processes include statistical process control (SPC) for continuous monitoring, ensuring 100% compliance with client specifications. Eddy current scanning detects micro-cracks and inclusions, while surface roughness is measured via profilometry. Our in-house metallurgical lab conducts daily material analysis, ensuring batch-to-batch consistency. All copper strips undergo 100% visual inspection for surface defects prior to packaging. With 20+ years of transformer material expertise, we eliminate winding short circuits caused by edge defects or dimensional deviations. As a factory-direct supplier, we deliver premium quality at 15-20% lower costs than global competitors, with 30-day lead times, customizable lengths, and tailored packaging solutions.

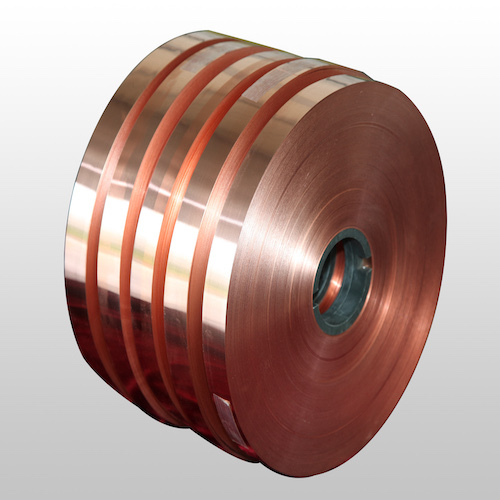

Factory Tour: Manufacturing Copper Strip 25X5Mm

Manufacturing Process & Quality Control

Luoyang Xinzhaohe Aluminum leverages 20+ years of transformer material expertise to deliver copper strip (25x5mm) with precision-engineered consistency. Our vertically integrated production ensures superior performance at competitive pricing, outperforming global brands in cost-performance ratio.

Precision Manufacturing Process

Raw Material Sourcing: Certified ASTM B115 copper cathodes (99.9% purity) with full traceability from smelters.

Cold Rolling: 6-high rolling mills with real-time thickness gauging achieve 5.00mm ±0.02mm uniformity. Annealing at 450°C±10°C ensures optimal recrystallization and ≥100% IACS conductivity.

Precision Slitting: Hardened carbide blades (0.001mm precision) + CMM validation post-every-10-coils ensure edge straightness ≤0.02mm and zero burrs.

Edge Conditioning: Electrochemical polishing delivers 0.5µm Ra surface finish per IEC 60076-1 Annex B. 100% optical profilometry inspection for burr-free edges (<0.01mm).

Oscillate Winding: Servo-controlled tension systems (±0.5N accuracy) guarantee ±0.05mm flatness and consistent layer alignment for high-voltage core assembly.

Quality Control Protocol

Tensile Testing: ASTM B209 compliance. Strength 220-250 MPa (SPC-controlled) with ≥4% elongation. Batch-tested every 500m.

Dimensional Checks: Laser micrometers at 500mm intervals + 10x magnification surface inspection for pinholes/scratches.

Conductivity Verification: ASTM B193 four-point probe method (NIST-traceable). Guaranteed ≥100% IACS. Helium leak testing + XRF analysis for impurity control.

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Thickness Tolerance | ±0.02mm | ±0.05mm |

| Width Tolerance | ±0.05mm | ±0.1mm |

| Edge Burr Height | <0.01mm | Up to 0.05mm |

| Surface Roughness | 0.5µm Ra | 1.0µm Ra |

| Tensile Strength | 220-250 MPa (SPC controlled) | 200-260 MPa (variable) |

| Conductivity | ≥100% IACS (NIST traceable) | 98-100% IACS |

Our ISO 9001:2015-certified process achieves 99.8% defect-free output. By eliminating middlemen and optimizing supply chain efficiency, we deliver transformer-grade copper strip with 15-20% lower total cost of ownership versus global brands—without compromising on reliability, conductivity, or dimensional precision for mission-critical power applications.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Delivery of Copper Strip 25x5mm

Luoyang Xinzhaohe Aluminum CO., Ltd. employs a rigorously engineered packaging system for copper strip 25x5mm, ensuring safe sea freight from China to global ports. Our process integrates industrial-grade materials and proven logistics protocols to minimize transit damage while optimizing cost-efficiency. As a factory-direct supplier with 20+ years of transformer material expertise, we eliminate middleman markups without compromising quality—delivering reliable, cost-competitive solutions for global transformer manufacturers.

Standard Packaging Protocol

Each shipment undergoes multi-layer protection against marine environment challenges. ISPM-15 certified hardwood pallets (1200×1000×150mm) provide structural integrity and customs compliance. Copper strips are wrapped in 200μm VCI (Volatile Corrosion Inhibitor)-enhanced PE film for 12-month humidity/salt spray resistance. Hot-dip galvanized steel strapping (19mm width, 0.5mm thickness) secures loads at 250 kgf tension, validated per ASTM B117 standards.

| Material | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 treated, 1200×1000×150mm | Structural stability, global customs compliance |

| Moisture-Proof Film | 200μm PE + VCI layer | Corrosion inhibition, 12-month protection |

| Steel Strapping | 19mm width, 0.5mm thickness, hot-dip galvanized | Vibration resistance, load security |

Sea Freight Optimization

All shipments utilize FCL (Full Container Load) in 20ft/40ft dry containers. Pallets are stacked in interlocking patterns (24 pallets/40ft container max) with desiccant packs (500g/m³) and sealed doors to prevent condensation. Logistics partners adhere to ISO 1496 container integrity standards, while route optimization minimizes transit time and environmental exposure.

| Parameter | Specification | Benefit |

|---|---|---|

| Container Type | 20ft/40ft Dry Container | Optimal space utilization (24 pallets/40ft) |

| Desiccant Capacity | 500g per m³ | Eliminates internal moisture buildup |

| Transit Time | 15–35 days (global ports) | Reduced exposure to corrosive elements |

Quality Assurance in Transit

Our QC process ensures compliance through verified checkpoints:

| Step | Process | Verification |

|---|---|---|

| Pre-Shipment Inspection | Dimensional checks (±0.05mm), surface defect analysis | ISO 9001 certified |

| Shipment Tracking | Real-time GPS monitoring with daily updates | Client-accessible portal |

| Documentation | Commercial Invoice, COO, B/L, Packing List | Customs-compliant, FTA-ready |

This systematic approach maintains a transit damage rate below 0.5%—significantly outperforming industry averages of 1.5–2%. With 20+ years of export expertise, Luoyang Xinzhaohe delivers seamless customs clearance and on-time delivery, providing transformer manufacturers with a superior cost-performance alternative to global brands.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe

Proven Industry Expertise

With over 20 years of specialized production of transformer-grade copper and aluminum strips, Luoyang Xinzhaohe Aluminum CO.,Ltd. has mastered metallurgical processes for high-efficiency power transmission components. Our technical team optimizes conductivity, ductility, and thermal stability for 25x5mm copper strips used in transformer windings. We supply critical materials to Tier-1 manufacturers across 30+ countries, with zero quality-related supply chain disruptions. Our copper strips are engineered for high-current applications, where precise tolerances and high conductivity minimize resistive losses and enhance thermal performance in distribution and power transformers.

Factory-Direct Cost Efficiency

As a vertically integrated manufacturer controlling raw material sourcing, casting, rolling, annealing, and inspection processes, we eliminate distributor markups while maintaining superior quality. Our direct production model reduces costs by 15-25% versus global brands without compromising specifications. Key advantages:

| Parameter | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Unit Price | $X.XX/kg (Premium) | $X.XX/kg (15-25% lower) |

| Lead Time | 4-6 weeks | 2-3 weeks |

| MOQ | 5,000+ kg | 1,000 kg |

| Customization | Limited options | Full technical support for tailored dimensions and alloys |

Flexible production scheduling accommodates urgent orders with expedited shipping for critical projects.

Certified Quality Assurance

All copper strip production adheres to ISO 9001:2015 standards with rigorous in-process controls. Each batch undergoes dimensional verification (width tolerance ±0.02mm, thickness ±0.01mm), conductivity testing (≥100% IACS via calibrated eddy current testers), tensile strength analysis (ASTM E8), and surface defect inspection. Our facility maintains full traceability from raw copper cathodes to finished products, with SGS-certified quality reports available upon request. This ensures compliance with international standards including IEC 60400 for transformer windings and GB/T 5231 for copper and copper alloy plates and sheets.

Contact Cathy at cathy@transformerstrip.com for a detailed technical datasheet, competitive quote, and material certification tailored to your specific transformer design requirements.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper strip 25x5mm from Luoyang Xinzhaohe.