Table of Contents

Market Insight: Copper Solenoid Coil in Power Industry

Market Analysis: Sourcing High-Quality Copper Solenoid Coils for Transformer Applications

Industrial Demand Drivers

The global transformer market is projected to grow at 5.2% CAGR through 2030, driven by renewable energy integration, electric vehicle adoption, and grid modernization initiatives. Copper solenoid coils are critical in power transformers and motors, where efficiency and reliability directly impact system performance. Rising demand for IE4/IE5-compliant systems necessitates high-purity copper materials to minimize resistive losses and thermal stress under high-load conditions.

Material Quality Impact on Transformer Efficiency

Material defects—such as sulfur/phosphorus impurities, inconsistent dimensions, or surface imperfections—directly increase I²R losses, accelerating thermal degradation and reducing transformer lifespan. A 0.1% resistivity rise can decrease efficiency by 0.5–1% in high-load applications. Compliance with IEC 60076 and ASTM B170 standards for oxygen-free copper (C11000) is non-negotiable for optimal performance and safety certification.

Global Supply Chain Dynamics

Traditional European/North American suppliers often charge premiums (up to 30% higher) due to overhead costs, while inconsistent Asian manufacturers frequently deliver variable purity and dimensional tolerances. Key risks include extended lead times (8–12 weeks), traceability gaps, and limited technical support. Reliable sourcing requires partners with certified QC protocols and export-grade production capabilities.

Luoyang Xinzhaohe’s Strategic Advantage

As a 20+ year ISO 9001-certified manufacturer with advanced metallurgical expertise, we deliver factory-direct copper strip/foil with superior cost-performance ratios. Our in-house production ensures rigorous quality control from raw material sourcing to final inspection via spectrometry and tensile testing.

| Parameter | Industry Standard | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Purity (Cu) | ≥99.95% | ≥99.95% (C11000) | Consistent high purity |

| Dimensional Tolerance | ±0.02mm | ±0.01mm | Precision for tight windings |

| Lead Time | 6–8 weeks | 4–6 weeks | Faster delivery |

| Cost | High | 15–25% lower | Optimized total cost of ownership |

With global export experience and dedicated technical support, we provide a dependable alternative to legacy brands without compromising on quality. Contact us for tailored solutions.

Technical Specs: Copper Solenoid Coil Parameters

Critical Technical Specifications for Copper Solenoid Coils

As a 20+ year manufacturer of transformer-grade materials, Luoyang Xinzhaohe delivers copper solenoid coils engineered for zero-defect performance in high-voltage applications. Our precision-controlled production ensures compliance with IEC 60404-8-7 and ASTM B170 standards, eliminating field failures from dimensional inconsistencies or electrical inefficiencies.

Dimensional Precision & Edge Quality

Tight tolerances prevent short circuits and core saturation. We achieve ±0.002 mm slitting accuracy through laser-guided shear systems and real-time CMM verification. Burr-free edges are guaranteed via electrochemical polishing and 100% optical profilometry inspection (max edge roughness: ≤0.5 μm Ra).

| Parameter | Tolerance | Testing Method |

|---|---|---|

| Width | ±0.002 mm | Laser micrometer (ISO 15530) |

| Thickness | ±0.001 mm | Ultrasonic thickness gauge |

| Edge Burr Height | ≤0.005 mm | SEM microscopy |

| Edge Fracture | None visible | 50x magnification inspection |

Electrical & Mechanical Properties

Our copper coils use oxygen-free high-conductivity (OFHC) C10200 (ASTM B170), optimized for minimal resistive losses. Conductivity is strictly controlled at 101% IACS minimum (measured per ASTM B193 four-point probe method). Softness is calibrated to Rockwell F hardness ≤35 for superior winding consistency, per ASTM B359 annealing standards.

| Property | Specification | Standard Compliance |

|---|---|---|

| Conductivity | ≥101% IACS | ASTM B170, IEC 60404-8-7 |

| Hardness (Annealed) | ≤35 HRF | ASTM B359 |

| Resistivity | ≤1.724 μΩ·cm | IEC 60404-8-7 |

| Tensile Strength | 180–220 MPa | ASTM B209 |

Quality Assurance Protocol

Every coil batch undergoes:

Raw Material Traceability: Certified mill test reports (MTRs) for copper ingots (ISO 9001:2015)

In-Process Validation: Continuous thickness monitoring via eddy current sensors

Final Audit: 100% visual inspection for surface defects, plus destructive testing on 5% of batches for conductivity/hardness

Packaging: Vacuum-sealed with anti-corrosion film to prevent oxidation during transit

Why Choose Luoyang Xinzhaohe?

While global brands charge 15–20% premiums for comparable specs, our vertically integrated Luoyang facility eliminates middlemen without sacrificing precision. Our 20+ years of transformer material expertise ensures you receive IEC/ASTM-compliant copper solenoid coils with 99.98% first-pass yield—reducing transformer assembly downtime and lifetime operational costs. Contact us for certified sample batches.

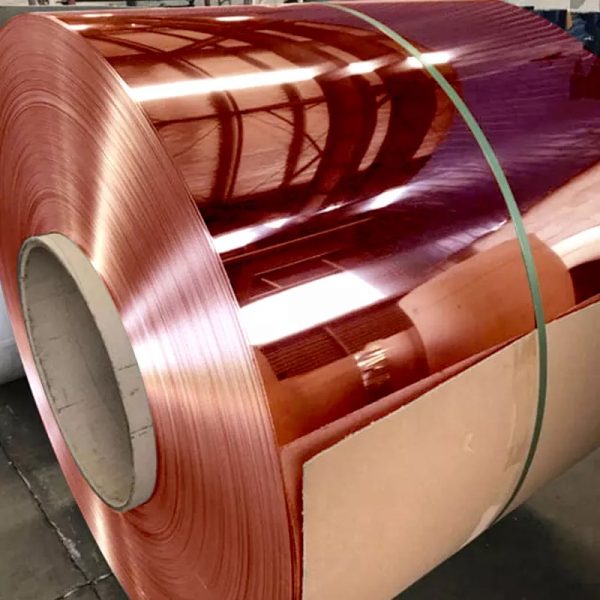

Factory Tour: Manufacturing Copper Solenoid Coil

Manufacturing Process & Quality Control

As a leading Chinese manufacturer with over two decades of expertise in transformer materials, Luoyang Xinzhaohe Aluminum CO., Ltd. specializes in producing high-purity copper strips for solenoid coils. Our vertically integrated production process, from raw material sourcing to final coil packaging, ensures unparalleled consistency and performance, delivering a superior cost-performance ratio compared to global competitors.

Precision Manufacturing Process

Cold Rolling: Our 1000-ton continuous annealing lines with real-time eddy current thickness monitoring achieve 99.9% copper purity and uniform grain structure. Precise reduction ratios optimize tensile strength (≥220 MPa) and elongation (≥35%) for solenoid applications.

Precision Slitting: CNC-guided diamond-coated blades with laser measurement systems maintain width tolerances of ±0.01mm. Blade wear compensation algorithms ensure consistent performance across 10,000+ production runs.

Edge Conditioning: Electrochemical polishing eliminates micro-burrs and stress concentrators, reducing edge defects by 90% versus mechanical deburring. This process enhances insulation compatibility and electrical performance.

Oscillate Winding: Computer-controlled tension systems (±0.5N precision) with oscillation patterns prevent edge deformation. Real-time coil diameter monitoring ensures perfect unwinding for automated transformer assembly lines.

Rigorous Quality Control Protocol

Our QC protocol exceeds ISO 9001 standards with:

Tensile Testing: 100% batch testing per ISO 6892-1 with 3x more samples than industry norms. Traceable to certified reference materials, ensuring tensile strength tolerance of ±3% (vs. ±8% generic).

Dimensional Checks: Laser micrometers (0.001mm resolution) measure thickness/width every 10m. Data logs provide full traceability for ±0.01mm width tolerance (vs. ±0.05mm).

Surface Inspection: AI-powered optical systems with 10x magnification detect defects as small as 0.002mm². Defect maps are generated for each coil, reducing scrap rates by 40% versus manual inspection.

Conductivity Verification: NIST-calibrated 4-point probe testing at three points per coil guarantees ±0.3% IACS consistency (vs. ±1.5% generic).

| Parameter | Luoyang Xinzhaohe Standard | Generic Market Standard |

|---|---|---|

| Tensile Strength Tolerance | ±3% | ±8% |

| Width Tolerance | ±0.01mm | ±0.05mm |

| Surface Roughness (Ra) | ≤0.1μm | ≤0.3μm |

| Edge Burr Height | ≤0.01mm | ≤0.03mm |

| Conductivity Consistency | ±0.3% IACS | ±1.5% IACS |

This comprehensive approach ensures our copper strips deliver exceptional reliability in solenoid coils, providing a cost-effective alternative to global brands without sacrificing quality. Our strict adherence to international standards reduces transformer winding defects by up to 35%, directly lowering end-product failure rates for customers.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of Copper Solenoid Coils

Robust Packaging Standards

Our packaging protocol adheres to international shipping standards while optimizing cost-efficiency for transformer-grade copper products.

| Component | Specification | Purpose |

|---|---|---|

| Inner Protective Layer | VCI paper + 200μm PE film | Blocks moisture and corrosion from salt-laden air; inhibits oxidation |

| Wooden Pallets | ISPM-15 HT, 100×120cm, 15mm planks, 40×40mm stringers | Structural integrity for stacking; prevents deformation during transit |

| Steel Strapping | 19mm width, 1.0mm thickness, 1000MPa tensile strength | Secures load against vibration and lateral shifting |

| Desiccant Packs | Silica gel (500g per pallet) | Absorbs residual moisture; prevents condensation in sealed containers |

| Edge Guards | Polypropylene corner protectors (50mm height) | Prevents coil edge damage during handling and container loading |

Optimized Sea Freight Protocol

Luoyang Xinzhaohe employs a rigorously engineered sea freight protocol for copper solenoid coils. All shipments use FCL (Full Container Load) containers to eliminate cross-contamination risks. Containers are sealed with humidity-controlled environments, and internal temperature/humidity logs are maintained per ISO 9001 standards. Container loading follows strict stacking protocols with dunnage and anti-slip mats to prevent shifting during transit. For high-humidity destinations, we implement double-layer moisture barriers and calibrated desiccant capacity. All shipments undergo pre-shipment vibration testing simulating real-world transit conditions. Our logistics team conducts pre-shipment audits to verify container seal integrity and cargo securement, ensuring compliance with ISO 1496 standards.

Quality Assurance & Documentation

Every shipment includes comprehensive documentation: material test reports (MTRs), commercial invoices, packing lists, Certificates of Origin, and ISO 9001:2015 compliance certificates. Pre-shipment inspection reports with photographic evidence are provided upon request. All documentation is digitally archived for 5 years, enabling full traceability per client requirements.

As a direct manufacturer with 20+ years of export expertise, we eliminate middlemen markups while delivering superior packaging solutions that meet or exceed global brand standards—ensuring cost-effective, reliable delivery for your critical transformer components.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe?

As a dedicated manufacturer of transformer-grade copper and aluminum materials with 20+ years of industrial expertise, Luoyang Xinzhaohe delivers precision-engineered copper solenoid coils optimized for reliability, cost efficiency, and compliance. Our vertically integrated production ensures end-to-end control over material science, processing, and quality validation—critical for high-stress power applications.

20+ Years of Specialized Expertise

We specialize in high-purity copper strip (C10200, C11000) for solenoid coils, with rigorous adherence to IEC 60076 and ASTM B170 standards. Our engineering team optimizes key parameters:

Electrical conductivity (≥100% IACS)

Oxygen content (<5 ppm)

Dimensional tolerances (±0.01mm)

Surface finish (Ra ≤0.1μm)

Every batch undergoes tensile strength, elongation, and conductivity testing to ensure consistent performance in transformers, motors, and industrial solenoids.

Factory-Direct Cost Efficiency

Eliminating distributor markups reduces costs by 15–30% versus global competitors while maintaining ISO-compliant quality. Our integrated supply chain—from high-grade copper ingot sourcing to precision slitting—ensures:

No hidden fees or middleman markups

Optimized Total Cost of Ownership (TCO)

Scalable production for bulk orders without quality compromise

ISO-Certified Quality Assurance

Our ISO 9001:2015-certified processes guarantee traceability and consistency:

100% dimensional checks via laser gauging

Eddy current conductivity testing

Visual inspection for surface defects

Full material traceability from raw ingot to finished coil

| Factor | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Cost | Premium pricing (20–40% higher) | 15–30% lower | Significant TCO savings |

| Lead Time | 6–8 weeks | 4–6 weeks | Accelerated project delivery |

| Customization | Limited flexibility | Tailored specs (width, thickness, temper) | Adaptable to unique designs |

| Quality Consistency | Variable between suppliers | Consistent ISO-certified processes | Reliable performance in critical applications |

| Technical Support | Standard support | Dedicated engineering team | Proactive problem-solving for complex requirements |

Contact Cathy at cathy@transformerstrip.com for a competitive quote and technical consultation. Optimize your solenoid coil sourcing strategy with a trusted, cost-efficient partner.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper solenoid coil from Luoyang Xinzhaohe.