Table of Contents

Market Insight: Copper Sheet Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The industrial demand for copper sheet strip within the transformer sector remains significant despite aluminum’s prevalence in distribution transformers, primarily driven by specific performance requirements in critical applications. Copper strip, typically supplied in thicknesses ranging from 0.1 mm to 3.0 mm and widths up to 1,000 mm, is the material of choice for high-efficiency power transformers, large generator step-up units, and specialized applications where maximum electrical conductivity and mechanical robustness are non-negotiable. Its superior conductivity (minimum 100% IACS per ASTM B152) directly translates to lower resistive losses (I²R losses), a critical factor in meeting stringent global efficiency standards like DOE 2016 and IECEE Level I-IV. This is particularly vital in urban substations, data center infrastructure, and renewable energy integration points where space constraints and thermal management are paramount; copper’s higher current density allows for more compact core-and-coil designs compared to aluminum equivalents. While aluminum strip dominates the cost-sensitive distribution transformer market, copper maintains a resilient niche in segments demanding the absolute lowest no-load and load losses, justifying its higher material cost through lifecycle energy savings and enhanced reliability under high thermal and electromagnetic stress.

Quality parameters for copper transformer strip are exceptionally stringent, directly impacting transformer performance, longevity, and safety. Material purity is foundational, requiring electrolytic tough pitch (ETP) copper with a minimum Cu+Ag content of 99.95% and strict limits on impurities like oxygen (200-400 ppm), sulfur (<10 ppm), and harmful elements such as bismuth or lead which can cause hot shortness during processing or degrade conductivity. Surface integrity is equally critical; the strip must be free from scratches, pits, rolls marks, and oxide inclusions exceeding 5 µm in depth, as these act as stress concentrators during winding and can initiate partial discharges under high voltage stress. Dimensional precision is non-negotiable, with thickness tolerances often held to ±0.005 mm and width tolerances to ±0.1 mm to ensure uniform winding tension, prevent inter-turn insulation damage, and maintain consistent magnetic flux distribution. Deviations in flatness or camber exceeding 1 mm per meter can cause winding misalignment, increasing eddy current losses and localized heating. Adherence to international standards such as IEC 60137, ASTM B152, and EN 13605 is mandatory, but leading manufacturers implement tighter internal controls on grain structure homogeneity and residual stress to prevent dimensional instability during coil processing and transformer operation.

Substandard copper strip introduces severe operational risks that far outweigh initial material cost savings. Inadequate purity or surface defects accelerate insulation aging due to localized overheating, significantly reducing transformer lifespan and increasing the risk of catastrophic failure. Poor dimensional control leads to uneven magnetic flux, elevating core losses and audible noise levels beyond acceptable limits. Most critically, microscopic surface imperfections or embedded contaminants can puncture solid insulation during winding, creating latent weak points that develop into turn-to-turn or layer-to-layer faults under operational stress, resulting in unplanned outages and costly repairs. For mission-critical infrastructure, the procurement of copper strip demands rigorous supplier qualification, comprehensive mill test reports verifying chemical composition and mechanical properties, and in-process quality validation. Luoyang Xinzhaohe Aluminum Co., Ltd., leveraging two decades of precision foil and strip production expertise across both aluminum and copper systems, emphasizes that material quality is not a cost center but a fundamental investment in transformer reliability, grid stability, and total cost of ownership. Understanding these metallurgical and dimensional imperatives is essential for strategic sourcing decisions in the transformer supply chain.

Technical Specs: Copper Sheet Strip

Technical Specifications for Copper Sheet Strip

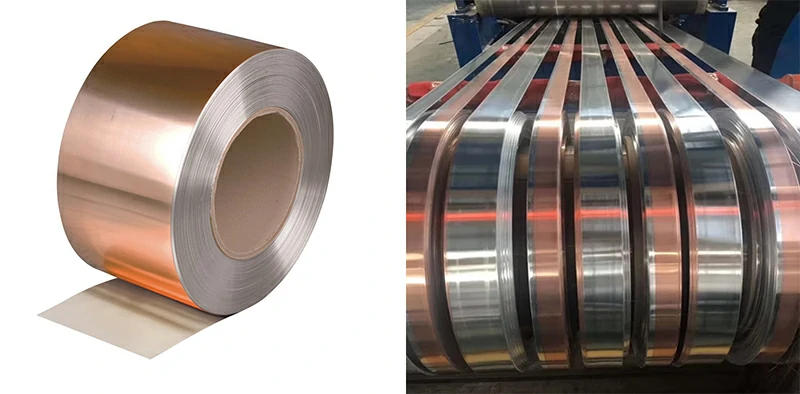

Luoyang Xinzhaoanghe Aluminum Co., Ltd. provides high-precision copper sheet strip products engineered for critical applications in power transmission, electronics, and transformer systems. With over two decades of metallurgical expertise, our manufacturing processes are optimized to meet stringent industry tolerances and performance benchmarks. The copper sheet strip is produced under controlled conditions to ensure dimensional stability, superior electrical conductivity, and edge quality suitable for automated assembly and high-frequency operation.

Precision slitting is a core capability in our strip processing line, enabling tight width tolerances of ±0.002 mm. This level of accuracy ensures consistent fit and performance in coil winding, busbar fabrication, and laminated core assemblies. The slitting process is monitored in real-time using laser micrometry and servo-controlled tension systems to maintain uniformity across production runs. Each coil undergoes post-slitting inspection to verify edge alignment and dimensional conformance.

Edge quality is critical in preventing dielectric breakdown and mechanical damage during downstream processing. Our copper strips are processed to deliver burr-free edges through optimized shear slitting tooling and precision roll polishing. Burr height is maintained below 2 µm, minimizing the risk of particle generation and insulation puncture in sensitive electromagnetic components. Edge profiling is verified using optical microscopy and profilometry at defined sampling intervals.

Electrical conductivity is measured at a minimum of 98% IACS (International Annealed Copper Standard) for oxygen-free electronic grade copper (C10100/C10200). This ensures minimal resistive losses and efficient thermal management in high-current applications. Conductivity is verified through four-point probe resistivity testing in accordance with ASTM B3 and ISO 13380 standards. Material is annealed in oxygen-free nitrogen atmospheres to prevent oxide formation and maintain lattice purity.

All copper sheet strips are supplied in temper conditions ranging from soft (O) to half-hard (H02), depending on application requirements for formability and mechanical strength. Surface finish is controlled to Ra ≤ 0.4 µm to support uniform coating adhesion and reduce skin effect losses at high frequencies.

Below are the key technical parameters for our copper sheet strip product line:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material Grade | C10100, C10200, C11000 | ASTM B152 |

| Thickness Range | 0.05 mm – 3.0 mm | ASTM E29 |

| Width Range | 5.0 mm – 300.0 mm | ASTM E29 |

| Width Tolerance | ±0.002 mm | ISO 9001 In-Process QC |

| Thickness Tolerance | ±2% of nominal or tighter upon request | ASTM B45 |

| Edge Burr Height | ≤ 2 µm | ISO 8501-1 (Modified) |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 |

| Electrical Conductivity | ≥ 98% IACS | ASTM B3, IEC 60317-0-1 |

| Temper Options | O (Annealed), H02 (1/2 Hard), H04 (Hard) | ASTM B974 |

| Coil Inner Diameter | 200 mm, 300 mm, 508 mm | Customizable |

| Maximum Coil Outer Diameter | 1200 mm | Customer Specification |

| Packaging | Anti-corrosion paper, sealed in wooden case with desiccant | MIL-STD-2073-5C |

All copper sheet strip products are traceable by heat lot and supported by full material certification, including chemical composition analysis and mechanical property reports. Luoyang Xinzhaohe Aluminum Co., Ltd. adheres to ISO 9001:2015 quality management protocols to ensure consistency and reliability in every shipment.

Factory Tour: Manufacturing

Manufacturing Process for High-Purity Copper Sheet Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise in non-ferrous processing to deliver precision copper sheet strip for critical transformer applications. While our core heritage is aluminum foil, our advanced facilities and quality systems extend to high-conductivity copper strip production, adhering to ASTM B152 and IEC 60137 standards. The process begins with Cold Rolling of electrolytic tough pitch (ETP) copper ingots. Primary hot-rolled coils undergo multi-stand cold rolling at controlled temperatures below the recrystallization threshold. This achieves precise thickness reduction (typically 0.05–0.50 mm) while enhancing mechanical strength and electrical conductivity. Critical parameters include interstand tension control, work roll grinding frequency, and emulsion coolant purity to prevent surface defects. Thickness variance is maintained within ±0.005 mm across the strip width, verified via在线 X-ray gauges.

Following cold rolling, Precision Slitting segments master coils into customer-specified widths. Our tension-controlled decoiling and recoiling systems ensure minimal strip distortion during high-speed slitting. Laser-guided rotary shear blades, calibrated to 0.002 mm concentricity, achieve width tolerances of ±0.05 mm. This stage is critical for transformer winding compatibility, where inconsistent width causes layer misalignment and thermal hotspots. Slitting occurs in a controlled environment to prevent oxidation, with immediate inert gas purging for oxygen-sensitive grades.

Edge Conditioning is the final mechanical step, eliminating micro-burrs and stress concentrations from slitting. Strips pass through precision edge rollers or abrasive brushing systems, removing protrusions down to 1–2 µm Ra surface roughness. This prevents insulation damage during coil winding and ensures uniform electrical field distribution. Edge radius is validated via optical profilometry to confirm ≤0.02 mm chamfer consistency.

Rigorous Quality Control is embedded at each phase. Cold-rolled coils undergo 100% surface inspection via automated vision systems detecting pits, scratches, or roll marks exceeding 5 µm depth. Slit strip samples are tested for width uniformity, edge squareness (±0.1°), and dimensional stability under thermal cycling. Final QC includes destructive testing: tensile strength (220–250 MPa), elongation (≥4%), and conductivity (≥100% IACS per ASTM E8). All batches receive traceable Certificates of Conformance with chemical composition (Cu ≥99.90%, O₂ 200–400 ppm) and mechanical data.

This integrated process ensures copper strip meets the stringent demands of transformer manufacturers, where dimensional precision directly impacts core loss efficiency and operational reliability. Our supply chain integration guarantees material traceability from cathode to shipment, minimizing lead times without compromising metallurgical integrity.

| Key QC Parameter | Tolerance/Range | Test Standard |

|---|---|---|

| Thickness | ±0.005 mm | ASTM E29 |

| Width | ±0.05 mm | ISO 7438 |

| Edge Roughness (Ra) | ≤2 µm | ISO 4287 |

| Conductivity | ≥100% IACS | ASTM E8 |

| Tensile Strength | 220–250 MPa | ASTM E8 |

| Elongation | ≥4% | ASTM E8 |

Packaging & Logistics

Export Packaging for Copper Sheet Strip: Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global distribution of transformer-grade aluminum and copper strip materials, we maintain rigorous standards for export packaging to ensure product integrity throughout the logistics chain. Given the sensitivity of copper sheet strip to environmental exposure and mechanical stress during maritime transport, our packaging protocols are engineered to mitigate risks associated with humidity, corrosion, vibration, and handling damage—common challenges in international sea freight.

All copper sheet strip shipments are secured on high-strength wooden pallets constructed from kiln-dried, ISPM-15 compliant timber. This certification ensures the wood has undergone thermal treatment to eliminate pests and pathogens, meeting international phytosanitary requirements for cross-border shipments. The pallets are designed with structural reinforcement to support the coil or strip weight, typically ranging from 500 kg to 5,000 kg, while maintaining compatibility with standard containerization and material handling equipment at ports and warehouses.

Each coil or stack of copper sheet strip is first wrapped in multi-layer moisture-proof film, specifically engineered with a metallized polyethylene barrier that provides a high level of water vapor transmission resistance. This film prevents condensation and atmospheric moisture ingress, which is critical during prolonged sea voyages where temperature fluctuations can lead to container rain. The sealing process involves heat-welded seams and overlapping wraps to create a fully enclosed, hermetic environment around the product.

Additional protective measures include the integration of desiccant packs within the wrapped layers to absorb any residual humidity and the use of edge protectors made from corrugated fiberboard or plastic to shield the strip edges from mechanical abrasion. For enhanced traceability and handling safety, each packaged unit is labeled with durable, weather-resistant tags indicating product specifications, batch number, weight, and handling instructions in compliance with IMDG and IATA maritime guidelines.

Our packaging design aligns with the operational realities of global container shipping, including 20-foot and 40-foot dry van or flat-rack containers. The configuration ensures optimal space utilization while maintaining load stability during transit, including roll, pitch, and heave motions experienced at sea. Palletized units are further secured within containers using steel strapping or dunnage bags to prevent lateral movement.

By integrating robust materials, moisture control, and structural engineering into our export packaging system, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that copper sheet strip arrives at its destination with preserved surface quality, dimensional accuracy, and electrical performance—critical factors for downstream applications in transformers, busbars, and power distribution systems. This commitment to packaging excellence supports our mission of delivering reliable, high-performance materials to global partners in the electrical and energy sectors.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Sheet Strip

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical engineering and precision rolling expertise to deliver mission-critical copper sheet strip for demanding transformer and electrical applications. Our core strength lies in the stringent integration of material science with advanced manufacturing processes, specifically tailored for the high-conductivity, dimensional stability, and surface integrity requirements inherent in transformer foil and strip production. We operate beyond standard trade, functioning as a technical extension of your engineering and procurement teams, ensuring the copper alloy substrate meets the exacting electrical and mechanical performance criteria essential for efficient power conversion and reliability.

Our dedicated copper processing facility employs state-of-the-art cold rolling mills, precision tension levelers, and controlled atmosphere annealing lines, all calibrated to maintain micron-level tolerances throughout production. This capability is fundamental for producing copper sheet strip where deviations directly impact transformer core losses, thermal management, and winding integrity. Key metallurgical and dimensional parameters we consistently achieve for standard C11000 ETP copper strip are summarized below:

| Parameter | Standard Tolerance | Precision Grade Tolerance | Test Method |

|---|---|---|---|

| Thickness Range | 0.05 mm – 3.0 mm | 0.05 mm – 1.5 mm | ASTM E29 |

| Thickness Tolerance | ±0.005 mm | ±0.002 mm | ASTM B9 |

| Width Tolerance | ±0.10 mm | ±0.05 mm | ASTM B9 |

| Surface Roughness | ≤ 0.4 µm Ra | ≤ 0.2 µm Ra | ISO 4287 |

| Conductivity | ≥ 100% IACS | ≥ 101% IACS | ASTM E1004 |

| Tensile Strength | 200-240 MPa | 210-230 MPa | ASTM E8 |

Material traceability is non-negotiable; every coil undergoes comprehensive chemical composition verification via OES spectrometry and mechanical property validation per ASTM standards. Our quality management system, certified to ISO 9001, implements rigorous in-process controls at critical stages—melting, casting, hot rolling, cold rolling, and slitting—to prevent defects such as edge cracks, surface scratches, or residual stress variations that compromise downstream processing or final component performance. This systematic approach minimizes scrap rates for our clients and ensures batch-to-batch consistency critical for automated transformer winding operations.

Supply chain resilience is engineered into our operational model. We maintain strategic raw material inventory buffers of high-purity cathode copper and operate a fully integrated production flow from casting ingot to slit coil, eliminating third-party dependencies that introduce latency and quality risk. Our 10,000-ton annual capacity for precision copper strip, coupled with flexible lot-sizing capabilities, supports both high-volume OEM contracts and specialized low-volume, high-mix requirements common in advanced transformer design. Logistics are optimized through partnerships with certified freight forwarders experienced in handling sensitive coil shipments, with real-time tracking and documented climate-controlled transport where specified.

For transformer manufacturers demanding copper sheet strip that meets the most stringent performance and reliability benchmarks, Luoyang Xinzhaohe provides the technical partnership and manufacturing excellence required. Submit your specific technical specifications, including alloy grade, dimensional requirements, surface finish, and testing protocols, to initiate a detailed capability review. Contact our technical sales team directly at cathy@transformerstrip.com to discuss how our precision copper strip solutions can enhance your transformer core efficiency and production yield. Partner with proven metallurgical expertise—reach out today.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper sheet strip directly from China.