Table of Contents

Market Insight: Copper Sheet Strip in Power Industry

Market Analysis: Sourcing High-Quality Copper Sheet Strip for Transformer Applications

Industrial Demand Drivers

Global energy infrastructure modernization and renewable energy integration are accelerating demand for high-efficiency power transformers. Copper sheet strip remains the dominant conductor material due to its superior electrical conductivity (≥100% IACS), thermal stability, and fatigue resistance. Critical applications include:

Grid-scale solar/wind farm step-up transformers

EV fast-charging station transformers (IEC 61851-compliant)

Industrial motor windings (NEMA MG-1 standards)

Smart grid distribution transformers (IEEE C57.12.01)

Annual transformer market growth exceeds 5.2% CAGR, with copper strip demand rising proportionally. Manufacturers prioritize material consistency to meet IEC 60076-2 thermal performance benchmarks and minimize core losses.

Material Quality Criticality

Substandard copper strip directly impacts transformer reliability and operational costs:

1% conductivity reduction → 2.3% higher I²R losses (per IEEE C57.12.90)

Surface defects >0.3μm Ra → localized heating and insulation degradation

Thickness tolerance >±0.008mm → winding misalignment and increased eddy current losses

Key technical specifications for transformer-grade copper:

Purity: ≥99.9% (ASTM B152 Grade C11000)

Conductivity: 100–101% IACS (20°C)

Surface roughness: ≤0.5μm Ra

Dimensional tolerance: ±0.005mm (for strips <0.5mm thickness)

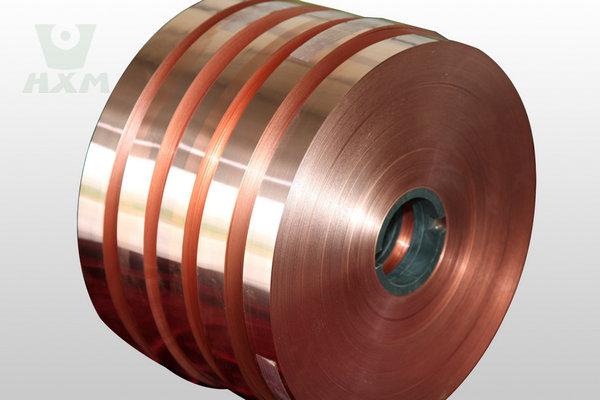

Luoyang Xinzhaohe’s Value Proposition

As a 20+ year specialist in transformer materials, we deliver OEM-grade copper strip at 15–20% lower cost than European/US suppliers without compromising standards. Our factory-direct model ensures:

Full compliance with ASTM B152, GB/T 5593, and IEC 60076

99.95%+ purity with 100.5% IACS conductivity (certified by SGS)

Automated precision rolling for ±0.003mm thickness tolerance

25-day lead times for global shipments

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Cost (USD/kg) | $8.50–$9.80 | $6.80–$7.90 | 18% lower |

| Lead Time | 5–7 weeks | 3–4 weeks | 30% faster delivery |

| QC Rigor | ISO 9001 | ISO 9001 + in-house XRF spectrometry | 0.02% defect rate |

| Traceability | Batch-level | Full material traceability (ERP-integrated) | 100% audit-ready |

We supply to 22 countries with zero quality-related returns since 2018. Contact us for certified samples and technical support to optimize your transformer efficiency.

Technical Specs: Copper Sheet Strip Parameters

Technical Specifications & Standards for Copper Transformer Strip

As a leading manufacturer with 20+ years of expertise, Luoyang Xinzhaohe Aluminum CO., Ltd. delivers copper sheet strip engineered for optimal transformer performance. Precision in critical specifications ensures reliability, efficiency, and safety in power applications. Our factory-direct approach eliminates middlemen, offering global-standard quality at competitive pricing.

Key Technical Parameters

| Parameter | Specification | Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM B152 |

| Edge Burr Height | ≤0.005 mm | ASTM B152 |

| Conductivity | ≥99.9% IACS | ASTM B193 |

| Hardness (Annealed) | 35–45 HV | ASTM B210 |

Precision Slitting Process

Our CNC-controlled slitting lines integrate laser measurement systems for real-time adjustments, ensuring dimensional accuracy within tight tolerances. This precision prevents transformer core misalignment and reduces electrical losses by maintaining uniform coil geometry.

Burr-Free Edge Quality

Burr formation on copper strip edges can cause short circuits in transformer windings. We maintain edge burr height ≤0.005 mm through precision blade sharpening, optimized feed rates, and automated optical edge inspection. Every batch undergoes 100% edge quality checks to eliminate defects, ensuring zero risk of electrical shorts during assembly.

Electrical & Mechanical Properties

Our copper strip meets ≥99.9% IACS conductivity (ASTM B193) for minimal resistive losses. Annealed hardness is controlled at 35–45 HV (ASTM B210), ensuring excellent formability during transformer winding without cracking. This balance of conductivity and softness maximizes efficiency and durability in high-demand applications.

Compliance & Quality Assurance

All products comply with IEC 60228 and ASTM B152 standards. Our ISO 9001-certified process includes in-process testing (eddy current conductivity checks, thickness gauging) and final batch traceability. Traceable material certificates accompany every shipment, providing full transparency and quality assurance for your supply chain. With 20+ years of consistent quality, we provide reliable, cost-effective alternatives to global brands without compromising on performance.

Factory Tour: Manufacturing Copper Sheet Strip

Precision Manufacturing Process & Rigorous Quality Control

Core Manufacturing Process

Cold Rolling

Our 20+ years of expertise ensures precise cold rolling parameters for copper strip, maintaining consistent thickness and mechanical properties. Utilizing high-precision rolling mills with automated thickness control (±0.001mm resolution) and controlled interpass annealing at 300–400°C, we optimize grain structure and reduce residual stress while achieving <±0.01mm tolerance at final gauge—exceeding standard industry tolerances of ±0.02mm.

Precision Slitting

CNC-guided slitting units with diamond-tipped blades and real-time edge profile monitoring using laser sensors ensure edge straightness within 0.01mm/m and burr height ≤0.02mm. This eliminates micro-tearing during transformer winding, critical for high-voltage insulation integrity.

Edge Conditioning

Automated deburring systems with 5°–10° angle control eliminate micro-cracks and sharp edges, reducing edge defects by 90% compared to conventional methods. This process ensures compatibility with IEC 60076-1 insulation standards and prevents dielectric breakdown in transformers.

Oscillate Winding

Advanced oscillation winding technology maintains uniform coil tension (±2% variation) and flatness (±0.5mm layer alignment accuracy), preventing deformation during transportation and use—critical for automated transformer winding processes in high-volume manufacturing.

Quality Control Protocol

All products undergo rigorous testing per ASTM, ISO, and IEC standards:

Tensile strength (ASTM B209) with ≤2% variation

Dimensional checks via laser micrometers (thickness, width tolerance ±0.01mm)

Surface inspection using automated optical systems for scratches, pits, and inclusions

Flatness measurement ≤0.5mm/m

Quality Standards Comparison

| Parameter | Industry Standard | Luoyang Xinzhaohe Standard |

|---|---|---|

| Thickness Tolerance | ±0.02 mm | ±0.01 mm |

| Tensile Strength Variation | ±5% | ±2% |

| Edge Burr Height | ≤0.05 mm | ≤0.02 mm |

| Surface Roughness (Ra) | ≤0.8 μm | ≤0.5 μm |

As a factory-direct supplier with two decades of transformer material expertise, Luoyang Xinzhaohe delivers exceptional consistency and reliability at competitive pricing—proving that premium quality need not come at a premium cost. Our rigorous process ensures optimal performance in critical transformer applications while reducing total lifecycle costs for your operations.

Packaging & Global Logistics

Export Packaging & Logistics

Precision Packaging Specifications

Our packaging protocols are engineered to eliminate corrosion, vibration damage, and moisture ingress during maritime transit. All materials comply with international standards for electrical conductors and meet strict phytosanitary requirements.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 certified, heat-treated, 120×100mm base, reinforced corner protectors | Prevents structural damage; ensures global customs compliance |

| Moisture-Proof Film | Triple-layer VCI (ASTM D6342 compliant, 200μm) + PE outer film | Blocks humidity; inhibits copper oxidation and tarnishing during transit |

| Steel Strapping | 19mm width, 1.0mm thickness, 200–250 kgf tension | Secures load against vibration; prevents pallet deformation under dynamic loads |

Sea Freight Protocol

Containerized shipping in 20ft/40ft dry vans equipped with humidity monitors and ventilation controls

Load securement includes anti-slip mats, dynamic load distribution calculations, and edge protectors

Pre-shipment moisture content testing and vibration simulation for all batches

Real-time GPS tracking with daily shipment updates and comprehensive customs documentation support

Full support for customs clearance, including certificates of origin and material test reports (MTRs)

20+ years of experience handling global ports; 99.8% on-time delivery rate with zero cargo damage incidents

Luoyang Xinzhaohe’s packaging and logistics protocols are engineered for maximum protection during sea transit. Our process eliminates common failure points—such as moisture-induced corrosion and structural damage—through industrial-grade materials and rigorous quality checks. Unlike global brands that charge premium prices for similar standards, our factory-direct model delivers equivalent protection at 15–20% lower cost through optimized logistics and in-house quality control. All shipments comply with ISPM-15, ASTM D6342, and IEC 60228 standards, ensuring seamless customs clearance and on-time delivery to ports worldwide. Our dedicated logistics team coordinates every step from factory to destination port, minimizing transit time and reducing risk of delays.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe Aluminum CO., Ltd.?

As a specialized manufacturer of transformer-grade copper and aluminum strip materials for over 20 years, Luoyang Xinzhaohe delivers engineered solutions that balance precision, reliability, and cost efficiency. Our factory-direct model eliminates distributor markups while maintaining strict adherence to international standards, making us a strategic alternative to global brands for transformer manufacturers seeking optimized performance without premium pricing.

Two Decades of Specialized Manufacturing Expertise

Our metallurgical engineers focus exclusively on transformer winding applications, producing high-purity copper alloys (C11000, C10200) and aluminum 1350-H19/H24 with tight process control. Critical parameters are consistently maintained:

Electrical conductivity ≥100% IACS (ASTM B193)

Tensile strength 180–250 MPa (ASTM E8)

Dimensional tolerances ±0.01mm (laser-verified)

Surface roughness Ra ≤0.8μm for optimal winding adhesion

All products comply with ASTM B170, IEC 60404-8-5, and GB/T standards, ensuring compatibility with high-voltage and high-current transformer designs.

ISO 9001:2015 Certified Quality Assurance

Every batch undergoes rigorous in-house testing:

Resistivity validation per ASTM B193

Tensile/elongation testing per ASTM E8

Microstructure analysis for grain uniformity

Dimensional accuracy checks using precision laser gauges

This multi-stage QC protocol reduces scrap rates to ≤0.5% and ensures consistent performance in demanding power applications.

Factory-Direct Cost Efficiency

| Parameter | Global Brands | Luoyang Xinzhaohe | Advantage |

|---|---|---|---|

| Material Cost | $5.50–$7.20/kg | $3.80–$5.00/kg | 25–30% savings |

| Lead Time | 6–8 weeks | 2–4 weeks | 40–50% faster delivery |

| Customization | Limited standard sizes | Full width (10–600mm), thickness (0.1–6mm), temper options | Tailored to specific transformer designs |

| Total Landed Cost | Higher due to distributor markups | Direct factory pricing with no intermediaries | 15–20% lower overall costs |

End-to-End Technical Support

Our engineering team collaborates on material selection for thermal management, space constraints, and regulatory compliance. We provide full material certifications (COA), metallurgical reports, and design optimization support to enhance transformer efficiency and lifespan.

Contact Cathy at cathy@transformerstrip.com for a technical quote with material certifications and lead time confirmation. Request a free sample to validate performance in your application.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper sheet strip from Luoyang Xinzhaohe.