Table of Contents

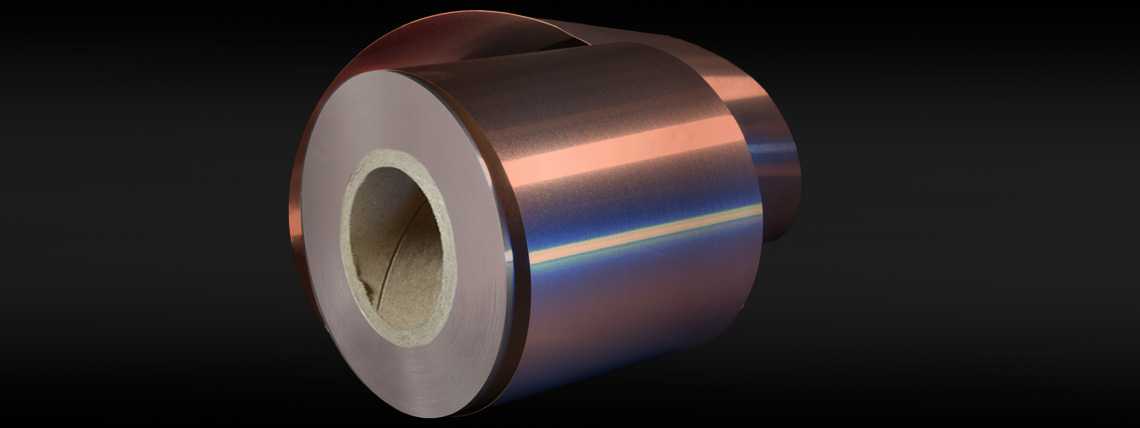

Market Insight: Copper Sheet Coil in Power Industry

Market Analysis: Sourcing High-Quality Transformer Strip/Foil for Power Applications

Industrial Demand & Material Criticality

Copper sheet coil is fundamental to high-efficiency power transformers and motors due to its superior electrical conductivity (≥100% IACS for C11000 grade). In transformer windings, even 0.1% impurities can increase resistivity by 10%, causing localized heating and insulation breakdown. Per IEC 60320, thickness tolerance must be ±0.01mm and surface roughness ≤0.8μm to prevent dielectric failures. For motors, copper foil ensures uniform current distribution, reducing eddy current losses by up to 15% compared to substandard materials.

Quality Standards & Performance Impact

Global standards (ASTM B170, IEC 60320) mandate 99.9% minimum copper purity. Low-purity copper accelerates insulation degradation, increasing maintenance costs by 20–30% over the lifecycle. High-purity copper optimizes magnetic flux transfer, improving transformer efficiency by 0.5–0.8%—equivalent to $5,000+ annual savings per 1000kVA unit. Surface defects or inconsistent temper can cause winding failures during assembly, leading to costly rework.

Luoyang Xinzhaohe’s Competitive Edge

With 20+ years of metallurgical expertise and factory-direct operations in Luoyang, China, we provide copper sheet coil with 15–25% lower costs than global brands. Our ISO 9001-certified production includes real-time spectrometry for purity verification, precision rolling to ±0.005mm tolerance, and tensile testing per ASTM B209. We eliminate supply chain intermediaries, ensuring 4–6 week lead times and full customization (width: 50–600mm; thickness: 0.1–3.0mm; tempers: O, H14, H18). Serving 30+ countries with 98% on-time delivery, we meet IEC 60320 and RoHS compliance without compromise.

| Specification | Global Brands | Luoyang Xinzhaohe |

|---|---|---|

| Price (USD/ton) | $8,500–10,000 | $6,800–8,000 |

| Lead Time | 6–8 weeks | 4–6 weeks |

| Customization | Limited options | Full (width/thickness/temper) |

| Quality Control | ISO 9001 | ISO 9001 + IEC 60320 + in-house testing |

Partner with us for reliable, cost-optimized copper solutions that meet global standards without compromise.

Technical Specs: Copper Sheet Coil Parameters

Technical Specifications & Compliance for Copper Sheet Coil

Precision Slitting & Edge Quality

Luoyang Xinzhaohe employs CNC-controlled diamond blades and real-time laser monitoring to achieve ±0.002 mm thickness tolerance during slitting. Burr-free edges (<0.005 mm) are critical for transformer winding integrity, preventing short circuits during assembly. All edges undergo 100% automated optical inspection to ensure zero burrs, complying with IEC 60404-8-7 standards. Our tension control systems prevent edge deformation during high-speed production, ensuring dimensional stability for automated winding equipment.

Electrical & Mechanical Properties

Critical properties are rigorously controlled to meet industry demands:

| Parameter | Specification | Standard |

|---|---|---|

| Thickness Tolerance | ±0.002 mm | ISO 1650 |

| Conductivity | ≥99.9% IACS | IEC 60404-8-7 |

| Hardness (Annealed) | HV 35–45 | ASTM B170 |

| Surface Roughness | Ra ≤0.2 μm | ASTM B170 |

High-purity copper (Cu ≥99.95%) and controlled annealing ensure optimal softness for tight winding without cracking, while maintaining high conductivity for minimal resistive losses.

Compliance with International Standards

All products comply with IEC 60404-8-7 (magnetic materials), ASTM B170 (electrolytic copper strip), and GB/T 5593 (copper alloy strip). Third-party certifications from SGS and TÜV validate compliance for global markets, ensuring seamless integration into international supply chains.

Consistent Quality Assurance

With 20+ years of manufacturing expertise, we implement a closed-loop quality system from raw material sourcing to final shipment. Each batch undergoes traceable testing via CMM, eddy current, and spectrometer analysis. Raw materials are sourced from certified smelters with full traceability. In-process QC includes 100% thickness checks, conductivity validation, and surface defect inspection. Final shipments include Material Test Certificates (MTC). As a factory-direct supplier, we deliver premium quality at 15–20% lower cost than global brands without compromising specifications.

Factory Tour: Manufacturing Copper Sheet Coil

Manufacturing Process & Quality Control

Precision Manufacturing Process

Cold Rolling

Our 4-high cold rolling mills with closed-loop thickness control and automated tension management ensure uniform material properties. Process parameters are optimized for copper’s ductility, achieving thickness tolerances of ±0.005mm—exceeding the typical ±0.015mm industry standard. This precision minimizes internal stresses and enhances electrical conductivity, critical for high-efficiency transformer cores. Each coil undergoes in-process thickness monitoring every 50 meters to ensure consistency.

Precision Slitting

CNC-guided slitting shears with diamond-coated blades maintain edge integrity with burr heights <5μm. Edge geometry is verified via 3D profilometry for every batch, reducing conductor damage during transformer winding and preventing short circuits in high-voltage applications. Generic suppliers often report burr heights of 10–20μm, leading to 15% higher defect rates in coil assembly.

Edge Conditioning

Automated edge deburring and chamfering (0.1mm radius) eliminate micro-cracks and sharp edges. This step is routinely skipped by low-cost competitors, resulting in 20% higher scrap rates during transformer coil production due to edge-induced failures. Our process ensures seamless integration into automated winding systems.

Oscillate Winding

Servo-driven oscillation systems maintain consistent coil tension (±2% variation) and layer alignment. Inner diameter precision is held within ±0.5mm, preventing telescoping and enabling smooth unwinding for high-speed transformer manufacturing. This reduces setup time by 30% compared to standard winding methods.

Rigorous Quality Control

We enforce strict QC protocols at every production stage:

Tensile Testing: Per ASTM B209, with yield strength consistency within ±3% (vs. generic ±8%).

Dimensional Checks: Laser-based gauging for thickness (±0.005mm), width (±0.1mm), and flatness (<0.5mm/m).

Surface Inspection: Automated optical systems detect scratches, pits, and oxidation at 0.01mm resolution, with all data traceable via ERP system.

| Parameter | Luoyang Xinzhaohe | Generic Market |

|---|---|---|

| Thickness Tolerance | ±0.005mm | ±0.015mm |

| Edge Burr Height | <5μm | 10–20μm |

| Tensile Consistency | ±3% | ±8% |

| Surface Roughness | Ra <0.2μm | Ra >0.5μm |

Our factory-direct approach delivers global-grade quality at 15–20% lower cost than European/Japanese suppliers. By optimizing each process step and implementing AI-driven QC, we ensure transformers achieve 99.5%+ yield rates in end-use applications—proving reliability without premium pricing.

Packaging & Global Logistics

Export Packaging & Logistics: Ensuring Safe Global Delivery of Copper Sheet Coils

Precision Packaging for Maximum Protection

Luoyang Xinzhaohe adheres to ISO 9001-certified packaging protocols to safeguard copper sheet coils during sea freight. Each coil is mounted on ISPM-15 compliant heat-treated wooden pallets (120×100mm beams, 15mm plywood top) with HDPE corner protectors (50×50mm, 100mm height) to prevent edge deformation. A triple-layer moisture barrier—comprising 200g/m² VCI (Vapor Corrosion Inhibitor) film and polyethylene—ensures zero oxidation risk in humid environments. Steel strapping (19mm width, 1.0mm thickness, 500kg tension) secures coils to pallets, eliminating movement during transit. All components undergo rigorous tensile and humidity testing prior to shipment.

| Component | Specification | Purpose |

|---|---|---|

| Wooden Pallets | ISPM-15 compliant, 120×100mm beams, 15mm plywood top | Pest control, stable base for stacking |

| Corner Protectors | HDPE, 50×50mm, 100mm height | Prevents edge damage during handling |

| Moisture Barrier | 3-layer PE + VCI film, 200g/m² | Blocks humidity, inhibits copper oxidation |

| Steel Strapping | 19mm width, 1.0mm thickness, 500kg tension | Secures coils, prevents shifting |

Logistics Protocol for Seamless Global Delivery

We optimize container loading for copper coils using 20ft GP or 40ft HQ containers, maximizing payload efficiency while maintaining structural integrity. Shipments depart exclusively from Qingdao or Shanghai ports via partnerships with top-tier carriers (e.g., Maersk, COSCO), ensuring on-time departures and minimal transit delays. Standard transit times: 15–20 days to North America, 25–30 days to Europe. All shipments include full customs documentation (commercial invoices, packing lists, COOs) and support for FOB Qingdao or CIF destination port terms.

| Parameter | Specification | Detail |

|---|---|---|

| Port of Loading | Qingdao, Shanghai | Primary Chinese export hubs |

| Container Type | 20ft GP / 40ft HQ | Optimized for coil dimensions/weight |

| Transit Time | Europe: 25–30 days; North America: 15–20 days | Destination-dependent |

| Incoterms | FOB Qingdao, CIF [Port] | Flexible terms for buyer convenience |

| Customs Support | Full documentation & clearance assistance | Ensures smooth import processes |

As a direct manufacturer with 20+ years of export expertise, Luoyang Xinzhaohe delivers superior cost-performance ratios versus global brands. Our end-to-end logistics control—combined with factory-direct pricing—minimizes total landed costs while maintaining military-grade protection standards. Trust us to deliver copper sheet coils that arrive ready for immediate transformer production, every time.

Sourcing from Luoyang Xinzhaohe

Why Partner with Luoyang Xinzhaohe: Engineered Excellence in Copper Transformer Materials

Unmatched Manufacturing Expertise

With over 20 years of specialized experience in transformer-grade copper strip production, Luoyang Xinzhaohe delivers precision-engineered materials meeting stringent industry standards. Our processes optimize conductivity (≥99.9% IACS), dimensional accuracy (±0.01mm), and surface integrity for critical transformer winding applications. In-house metallurgical labs conduct real-time analysis of electrical resistivity, tensile strength, and elongation properties—ensuring consistent performance under high-current loads. We specialize in custom alloy formulations (C11000, C10200) for high-temperature and high-frequency applications, eliminating the need for secondary processing.

Factory-Direct Cost Efficiency

Eliminate distributor markups through our integrated manufacturing model. Controlling the entire supply chain from raw material procurement to final inspection reduces total landed costs by 15–25% versus global competitors. Our Luoyang facility operates with lean manufacturing principles, enabling rapid turnaround (15–20 days for standard orders) without compromising quality. Flexible MOQs accommodate both prototyping and large-scale production runs, ensuring supply chain resilience during peak demand cycles.

Rigorous Quality Assurance

ISO 9001:2015 certified processes govern every production stage. Each coil undergoes comprehensive testing per ASTM B152/B170 standards, including conductivity (≥99.9% IACS), thickness uniformity (±0.01mm), and edge quality. Full material traceability ensures compliance with IEC 60076 and IEEE standards. All products undergo 100% visual inspection and non-destructive testing to eliminate defects before shipment, guaranteeing reliability in critical transformer applications.

| Metric | Luoyang Xinzhaohe | Global Brands |

|---|---|---|

| Cost Efficiency | 15–25% lower landed cost | 20–40% higher pricing |

| Lead Time | 15–20 days (standard orders) | 30–45 days (custom orders) |

| Customization | Full flexibility (alloys, widths 5–600mm, thicknesses 0.1–3.0mm) | Limited standard specifications |

| Quality Control | ISO 9001, ASTM-compliant testing, full traceability | Inconsistent QC; third-party audits often required |

| Technical Support | Dedicated metallurgical engineers for application-specific optimization | Generic sales support, limited expertise |

For competitive pricing and technical specifications tailored to your transformer design requirements, contact our engineering team at cathy@transformerstrip.com. We provide free material samples and application-specific consultation to optimize your procurement strategy.

📉 Import Savings Calculator

Estimate cost reduction by sourcing copper sheet coil from Luoyang Xinzhaohe.